Semi-direct drive megawatt-level permanent-magnet windmill generator

A wind power generator, megawatt-level technology, applied in the field of semi-direct-drive megawatt-level permanent magnet wind power generators, can solve the problem of not being able to effectively ensure that the temperature rise of the motor meets the requirements, high processing, process installation requirements, and difficult tightness of the iron core Adjustment and other issues to achieve the effect of prolonging the regular maintenance cycle, improving bearing insulation, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

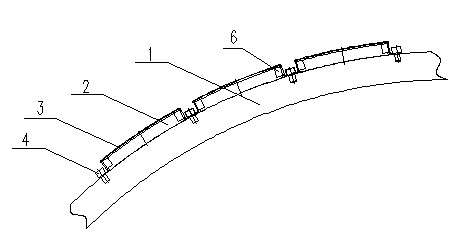

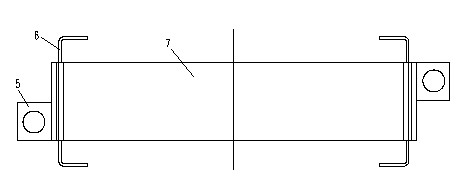

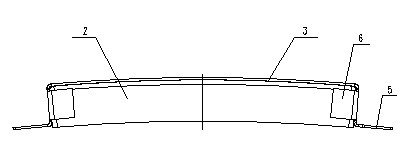

[0056] The invention discloses a semi-direct drive megawatt-level permanent magnet wind power generator, which includes a permanent magnet fixing structure, a cooling and ventilation structure, a bearing insulation structure and a stator core compression structure, such as Figure 1~3 As shown, the permanent magnet fixing structure includes a magnetic steel fixing frame 3 and stainless steel bolts 4 for installing the permanent magnet 2, the bottom 7 of the magnetic steel fixing frame 3 is closely attached to the permanent magnet 2, and the magnetic steel fixing frame 3 The connecting ears 5 at both ends of the bottom 7 are provided with through holes for matching with the stainless steel bolts 4, the magnetic steel fixing frame 3 is connected with the rotor cylinder 1 through the stainless steel bolts 4, and the material of the magnetic steel fixing frame 3 is stainless steel .

[0057] The permanent magnet 2 is installed in the magnetic steel fixing frame 3, and the bottom 7...

Embodiment 2

[0061] On the basis of Example 1, another preferred embodiment of the present invention is as follows: as Figure 4~9 As shown, the cooling ventilation structure includes a cooler 1, a cover plate 2, a partition 3, a frame arc plate 4, a rib plate 5 and a stator core 6; wherein, the cooler 1 is placed on the top of the motor, and the cylindrical frame arc The plate 4 is placed outside the stator core 6, the cover plate 2 is placed outside the frame arc plate 4, the partition plate 3 is located between the frame arc plate 4 and the cover plate 2, and the partition plate 3 connects the frame arc plate 4 and The area between the cover plates 2 is separated into two wind areas that are not ventilated in the axial direction. In the wind area, multiple groups of radial ventilation holes are evenly distributed along the circumferential direction on the frame arc plate 4 , and multiple axial ribs 5 are installed between the frame arc plate 4 and the stator core 6 . A plurality of rib...

Embodiment 3

[0064] On the basis of Examples 1 and 2, a preferred embodiment of the present invention is: as Figure 10~11 As shown, the bearing insulation structure includes a bearing 1 installed on the bearing sleeve of the main shaft of the generator, two insulating rings installed on both axial ends of the bearing 1, an insulating steel ring arranged on the outer ring of the bearing 1, and a bearing used to fix the bearing 1. The bolts 8 of the inner cover and the outer cover, the bolts 8 penetrate into the insulating sleeve 6 through the insulating washer 5, and the insulating sleeve 6 runs through the two insulating rings.

[0065] The present invention consists of a bearing 1 installed on the bearing sleeve of the main shaft of the generator, insulating rings on both ends of the axial direction of the bearing 1, a steel ring 3 of the outer ring of the bearing 1 and an outer insulating layer 4 of the steel ring 3, and fixing bolts 8 of the inner and outer covers. Between the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com