Flexible outlet-inlet guide and guard unit as well as guiding and guarding method

A guide device, entrance and exit technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of easily bumping and scratching the surface of straightened and rolled materials, and achieve the effect of improving the smoothness and avoiding bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

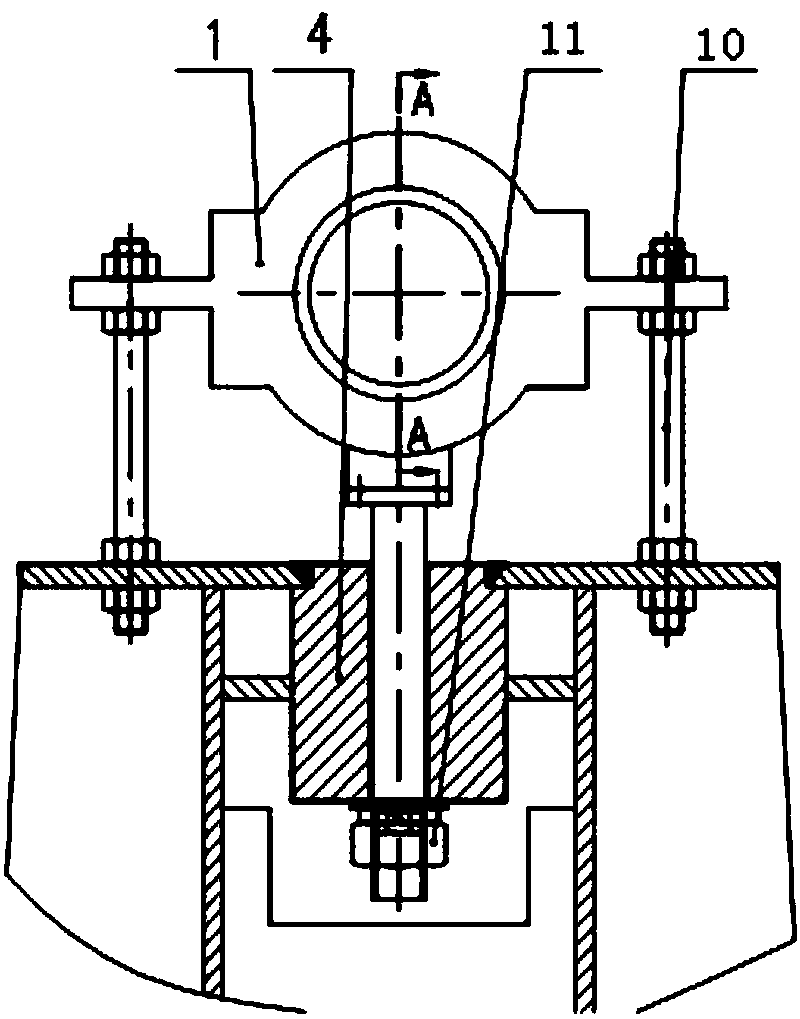

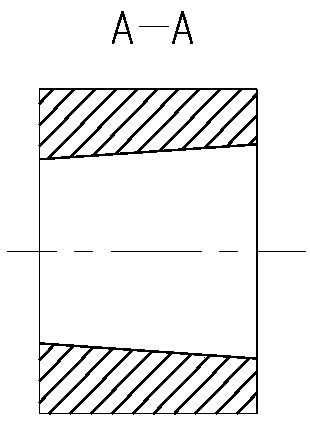

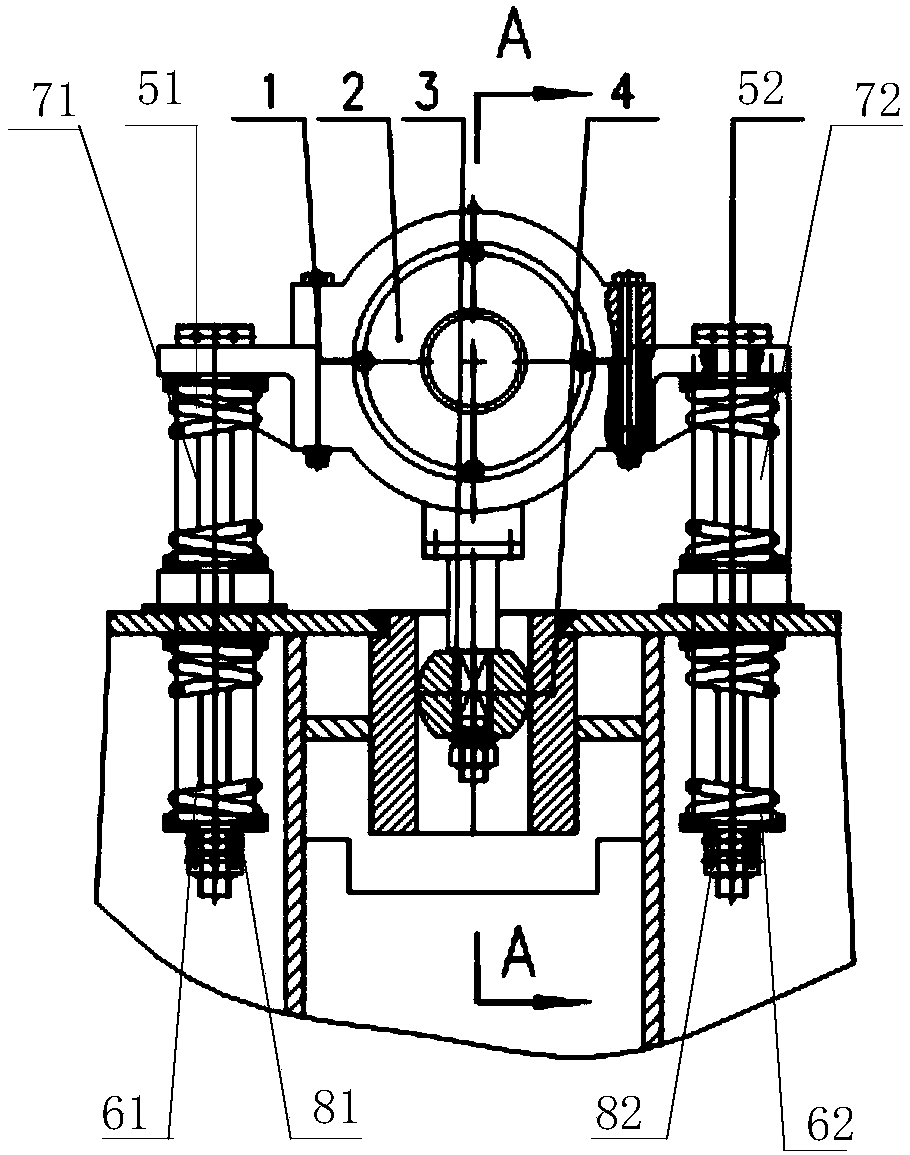

[0029] see image 3 and Figure 4 , is the flexible entrance and exit guide device of the present invention, including a guide mechanism 1, a guide bracket 4, a spherical swing device 3, a first floating support and a second floating support; the two sides of the guide mechanism 1 respectively pass through the first The floating support and the second floating support are floatingly supported on the guide bracket 4, and the bottom of the guide mechanism 1 is fixedly connected to the spherical swing device 3 through a connecting piece; the guide bracket 4 is provided with a cylinder that cooperates with the spherical swing device 3 The hole, the spherical swinging device 3 is located in the cylindrical hole; the spherical swinging device 3 allows the guide mechanism 1 to swing in the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com