Patents

Literature

33results about How to "Convenient printing work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile printing device

InactiveCN107415504AConvenient printing workAvoid damageStampingTextile printerMechanical engineering

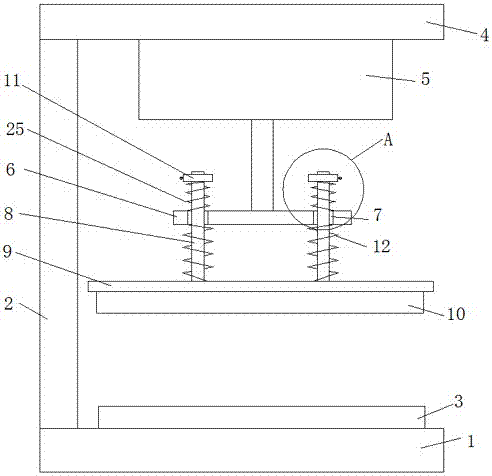

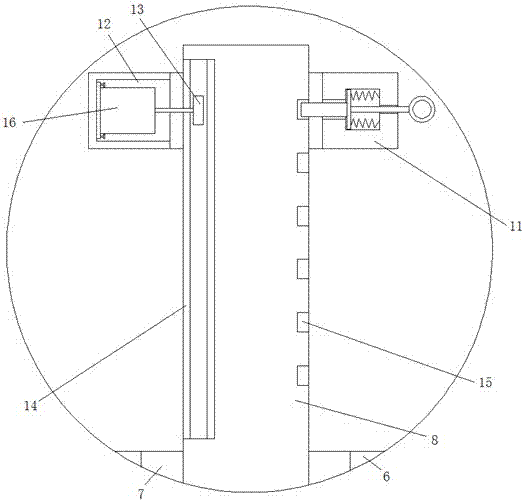

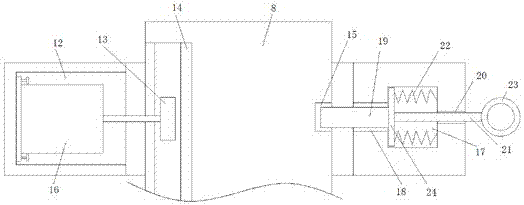

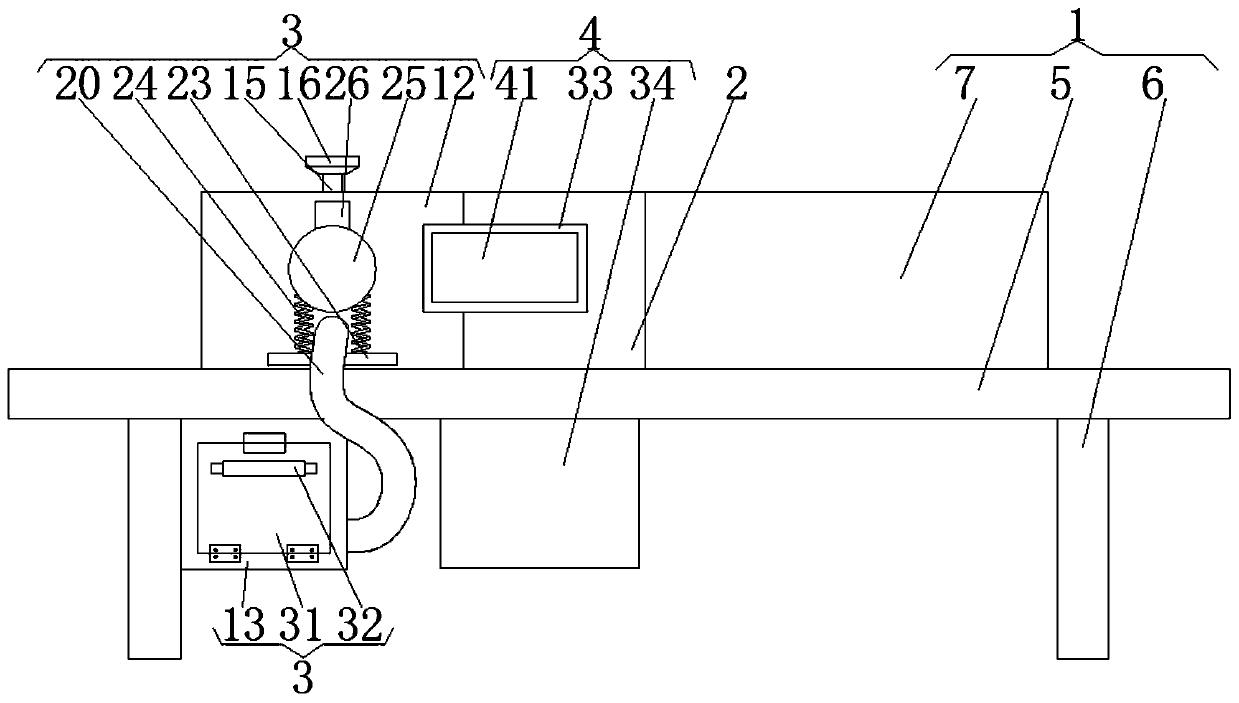

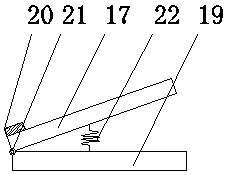

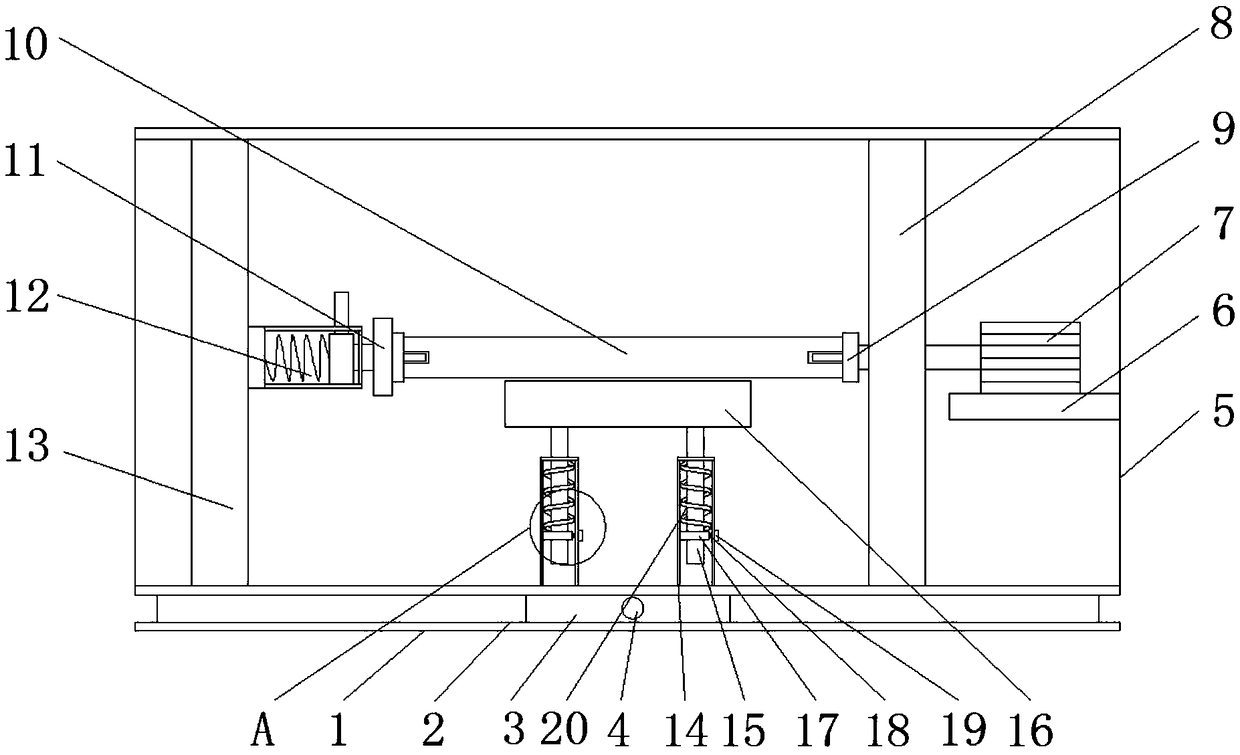

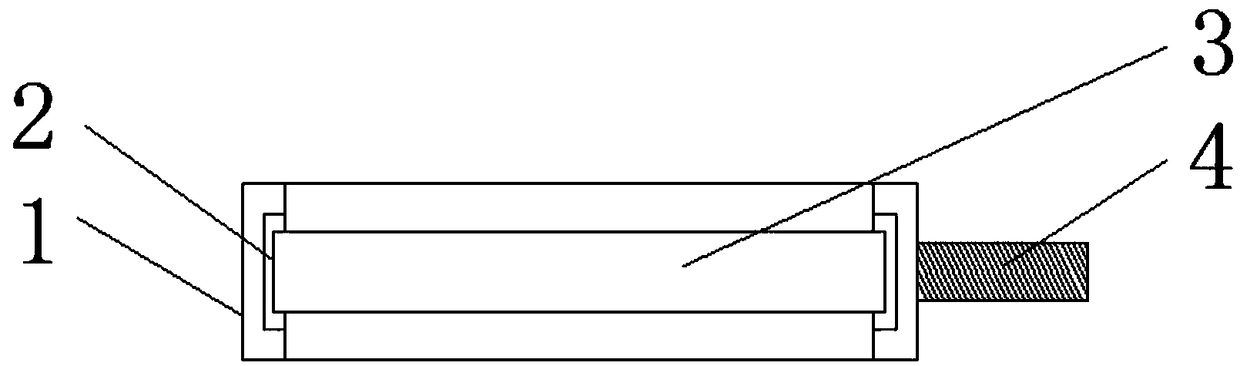

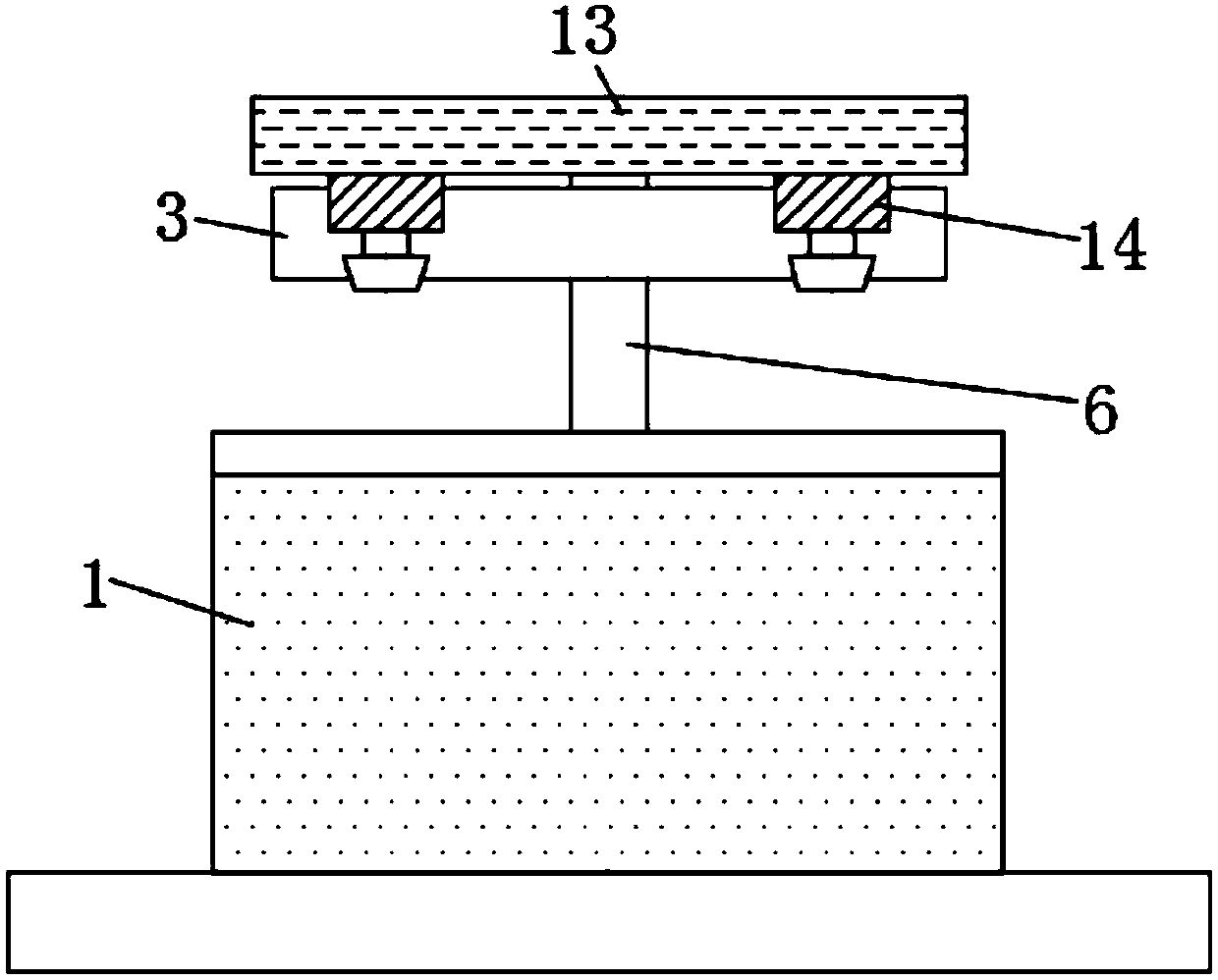

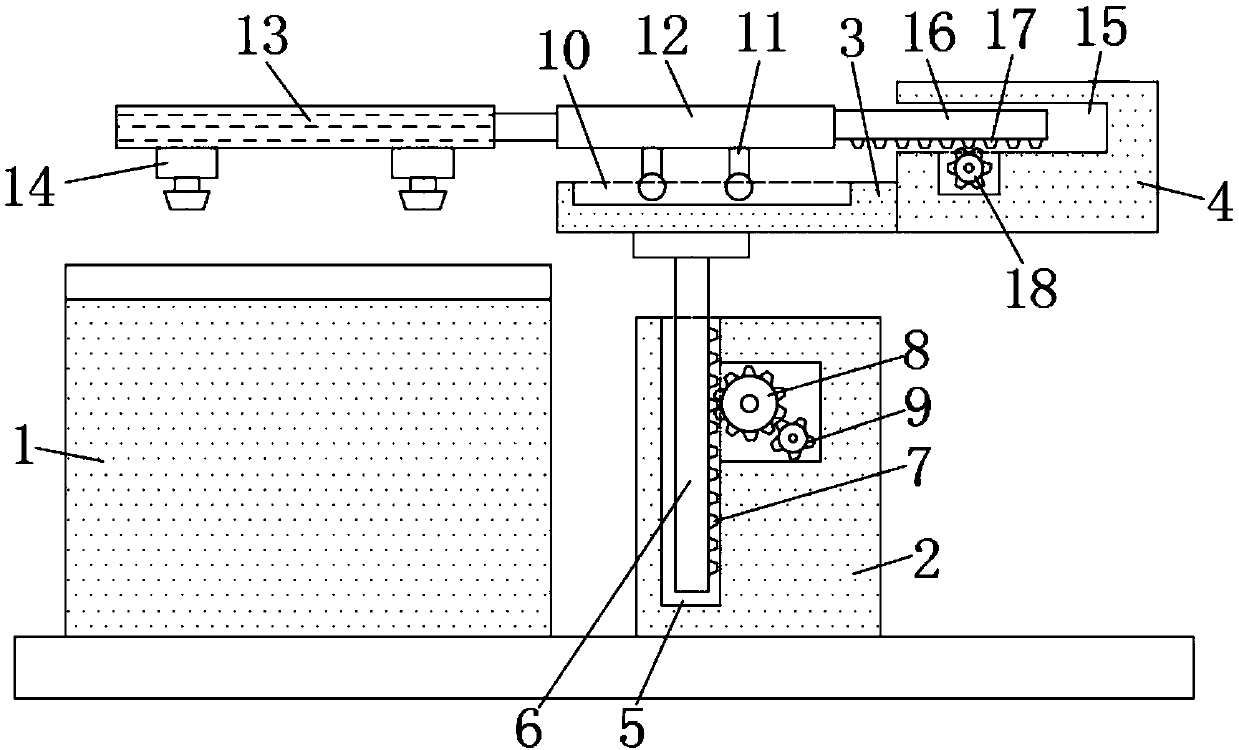

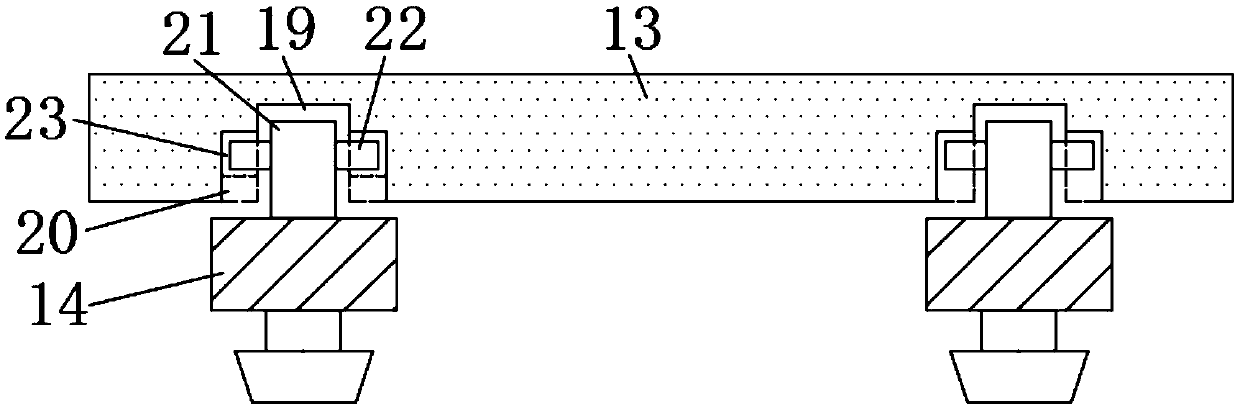

The invention discloses a printing device for fabric weaving, which comprises a base, a vertical bar is welded on one side of the top of the base, a horizontal bar is welded on the top of the vertical bar, and a printing table is also welded on the top of the base. A push rod motor is fixedly installed at the bottom of the cross bar, and a push plate is welded on the output shaft of the push rod motor, and two symmetrically arranged sliding holes are opened on the push plate, and a slide rod is slidably installed in the slide hole, The bottom ends of the two slide bars are welded with the same fixed plate, the fixed plate is located below the push plate, and the bottom of the fixed plate is fixedly equipped with a printing mold, and the printed mold is located above the printing table. The invention is simple in structure, easy to operate, easy to buffer the pressure between the printing mold and the fabric, prevents the printing mold and fabric from being damaged by excessive pressure, and is convenient to adjust the compression degree of the spring and the auxiliary spring, which is convenient for the printing mold. usage of.

Owner:浙江德清华丝纺织有限公司

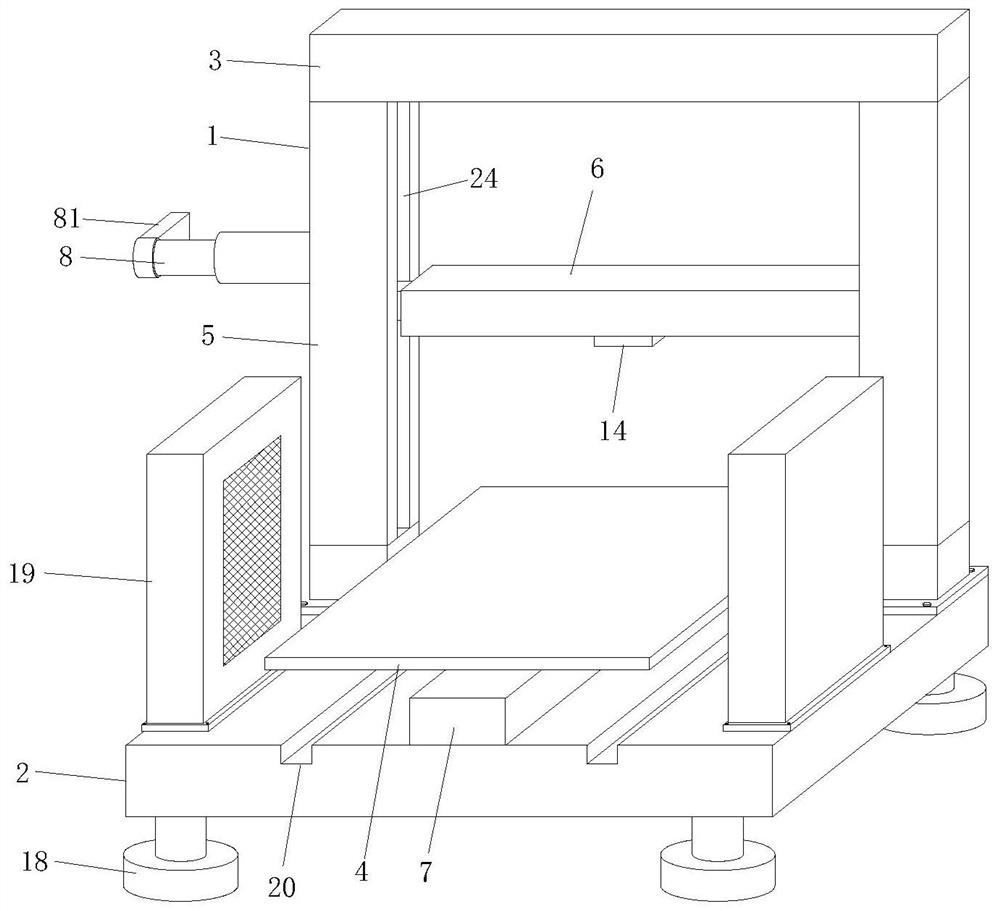

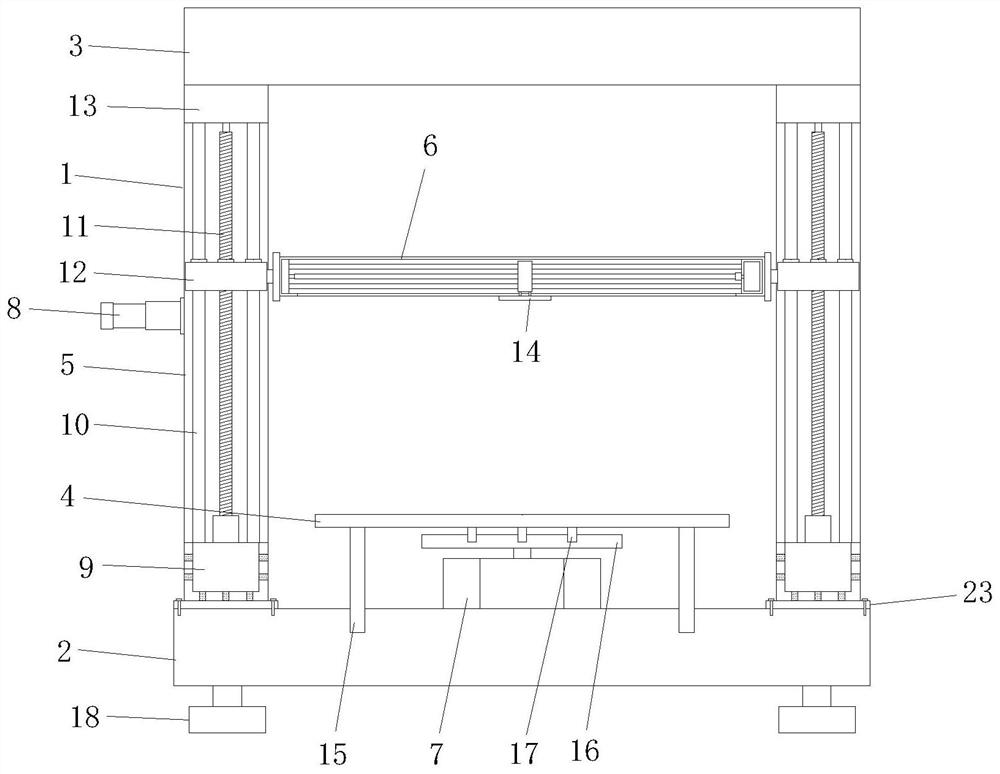

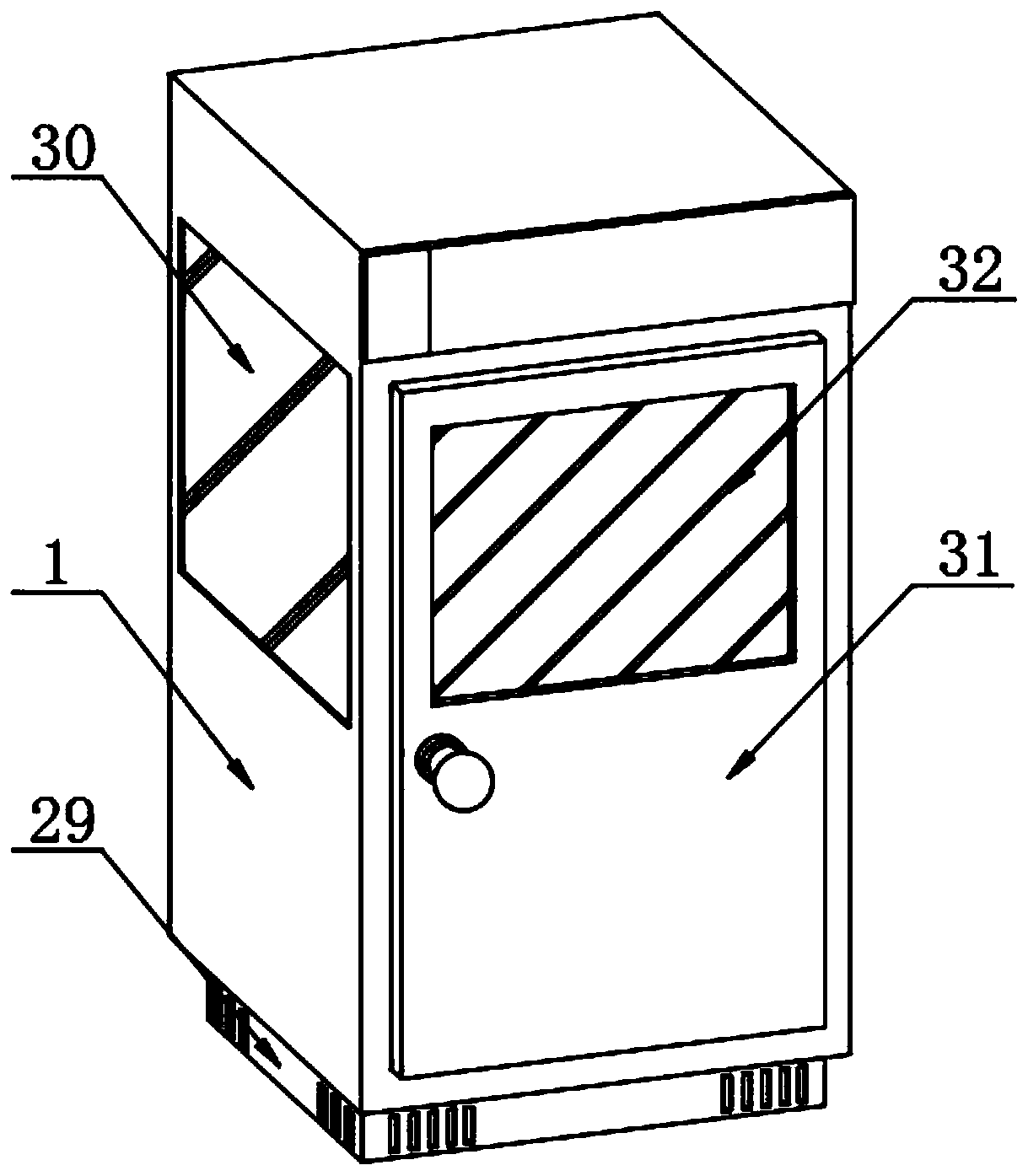

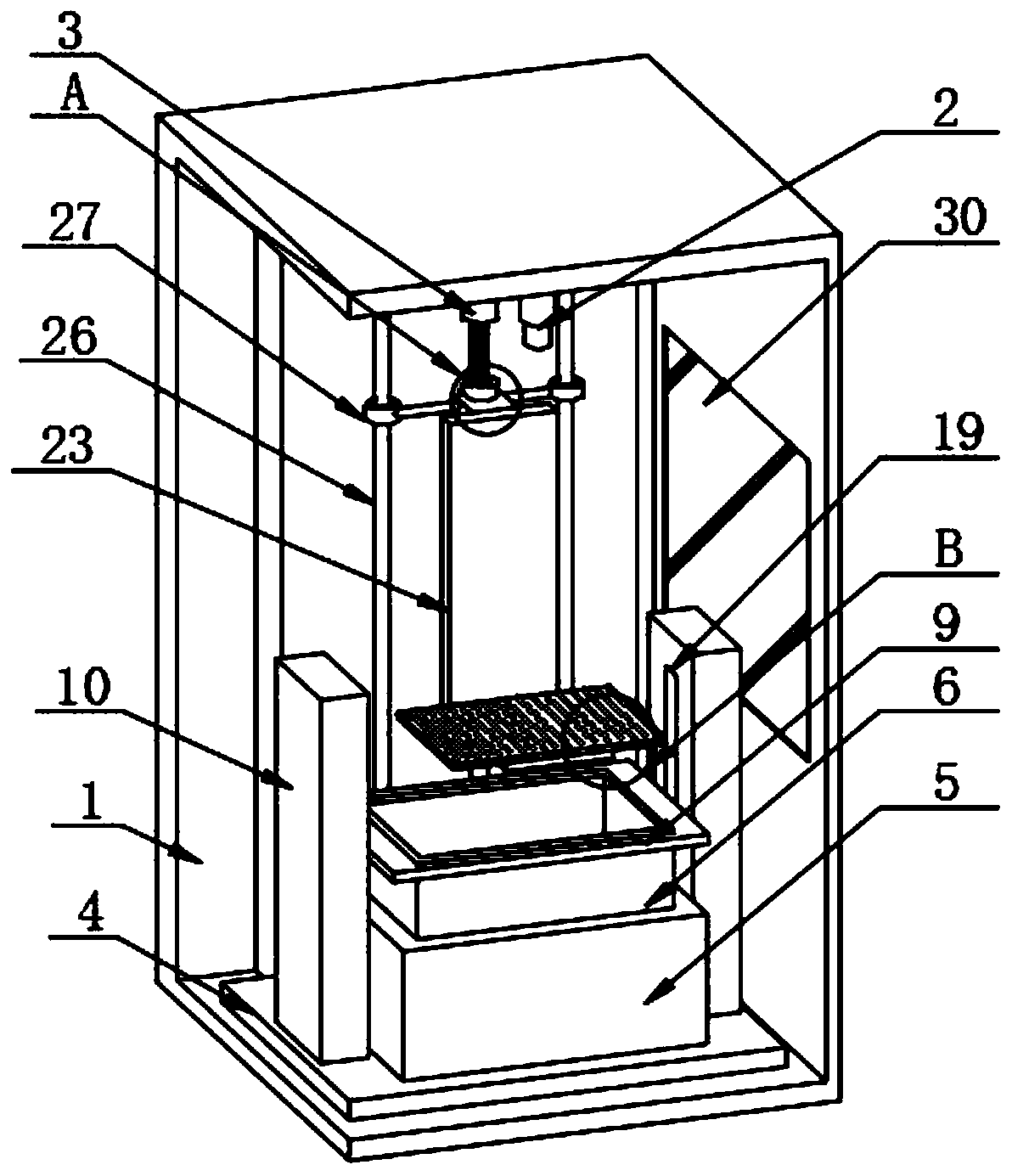

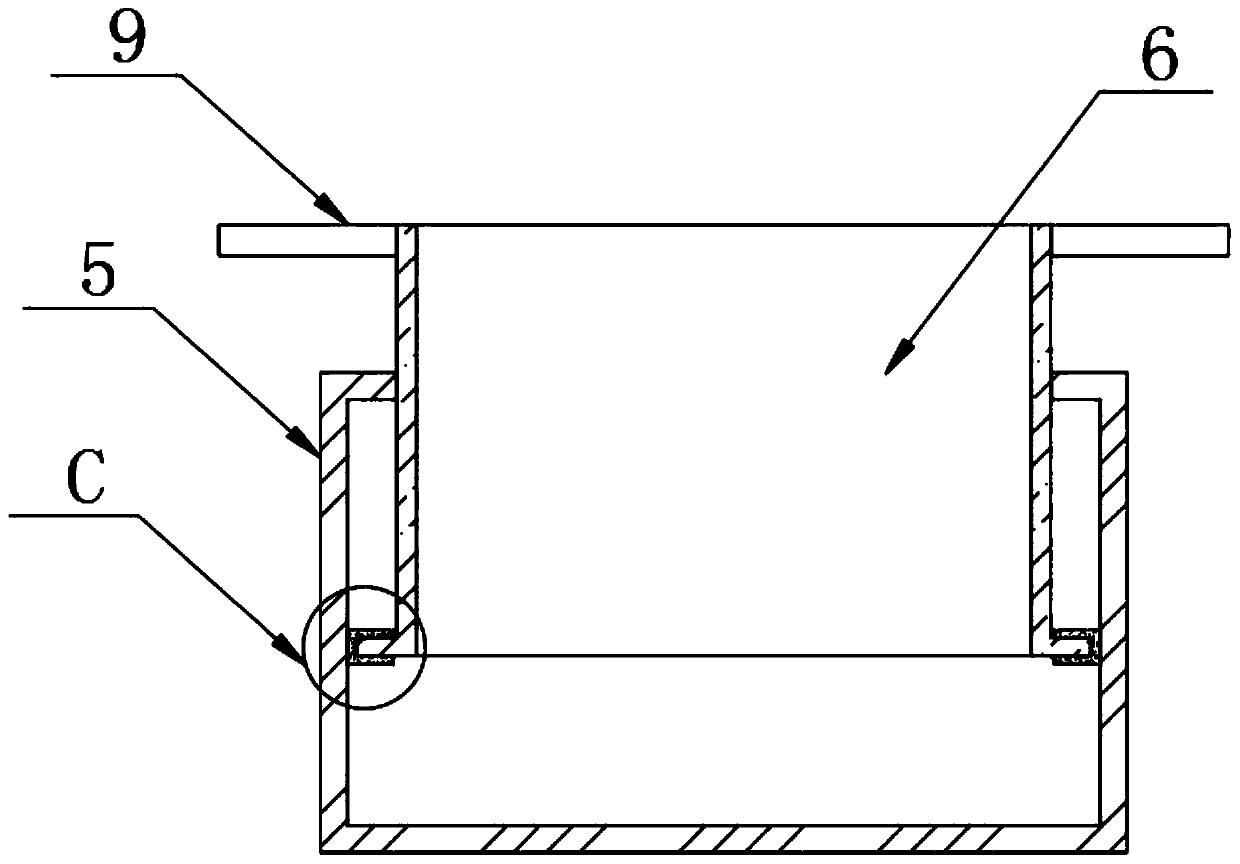

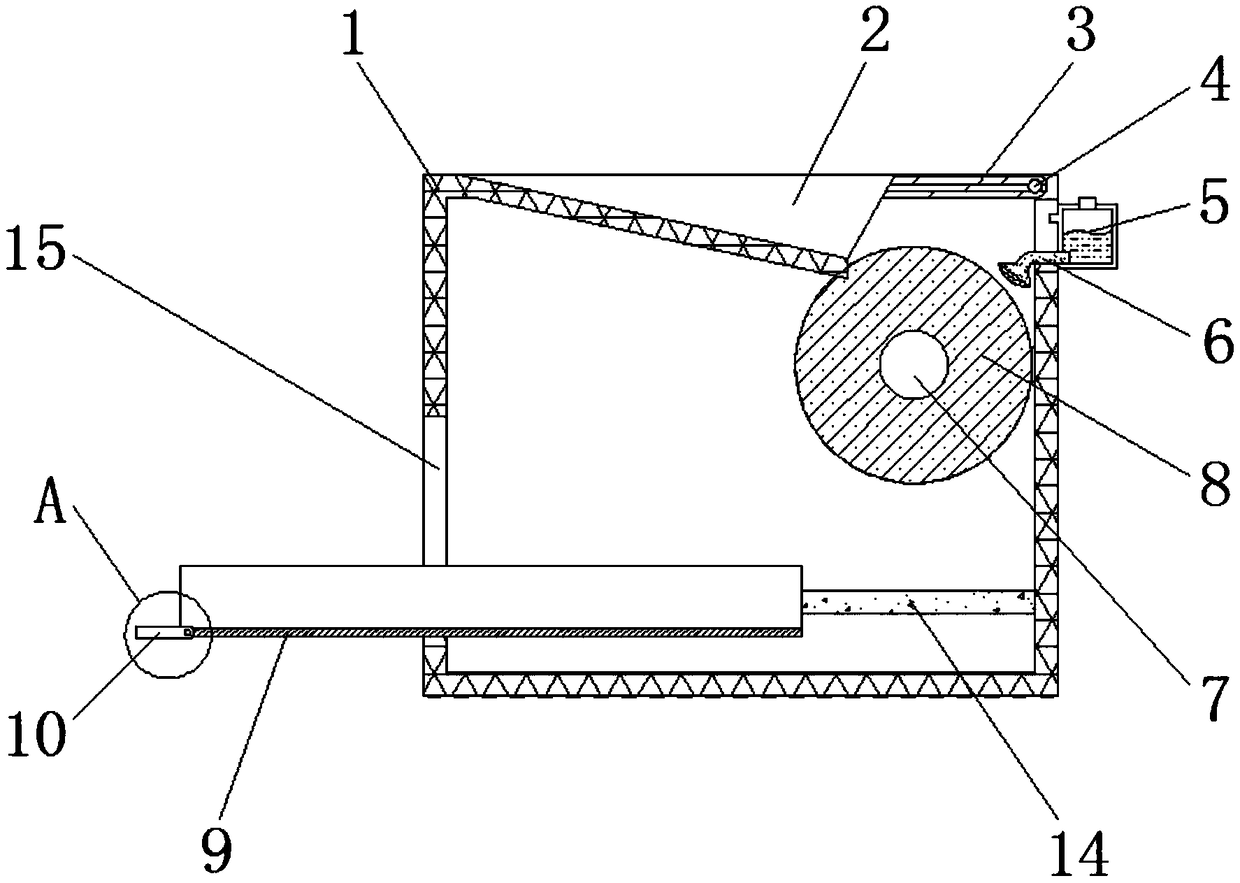

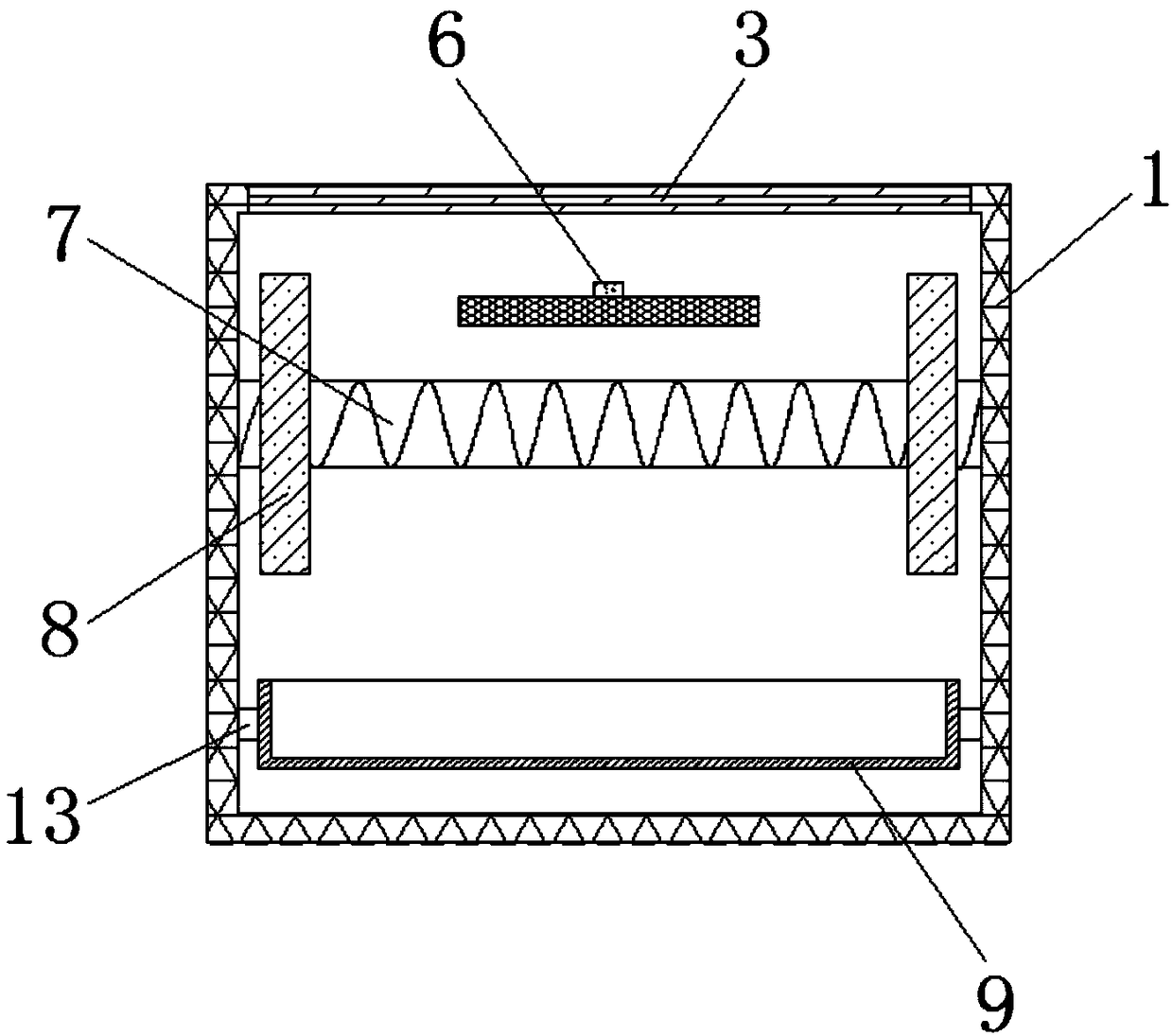

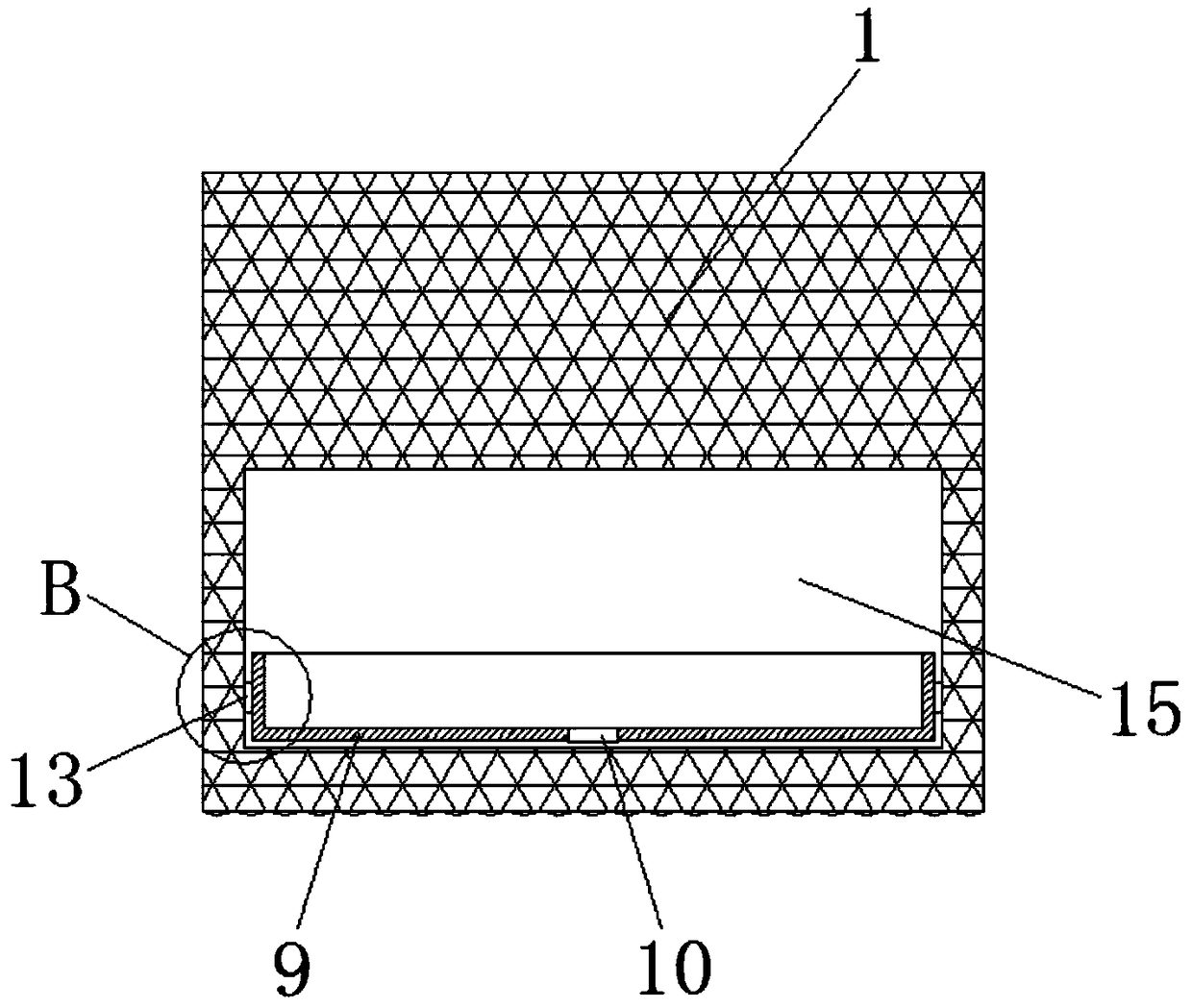

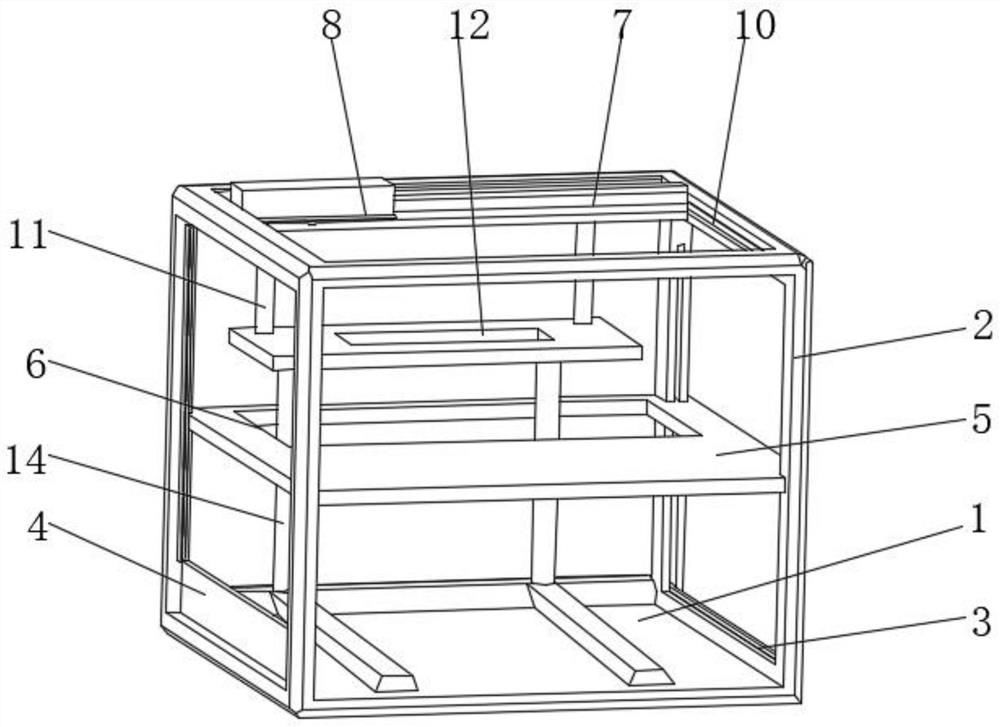

3D-printed Microwave heating mechanism

ActiveCN107901403AImprove plasticityAvoid heatingManufacturing heating elements3D object support structures3d printEngineering

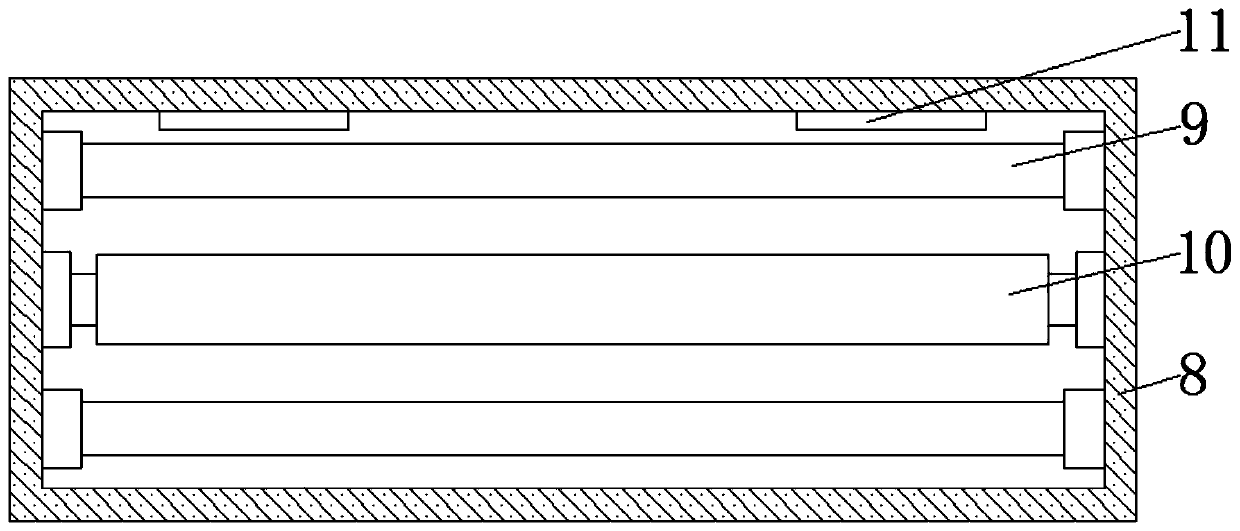

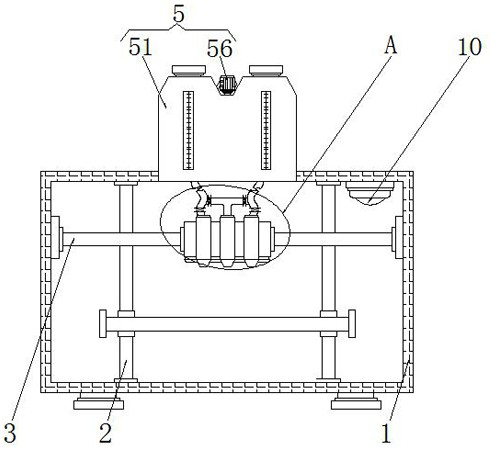

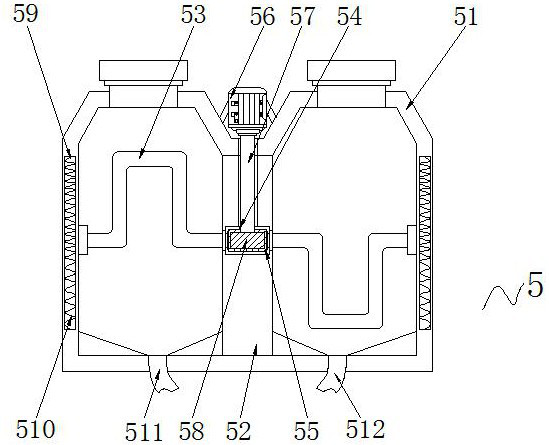

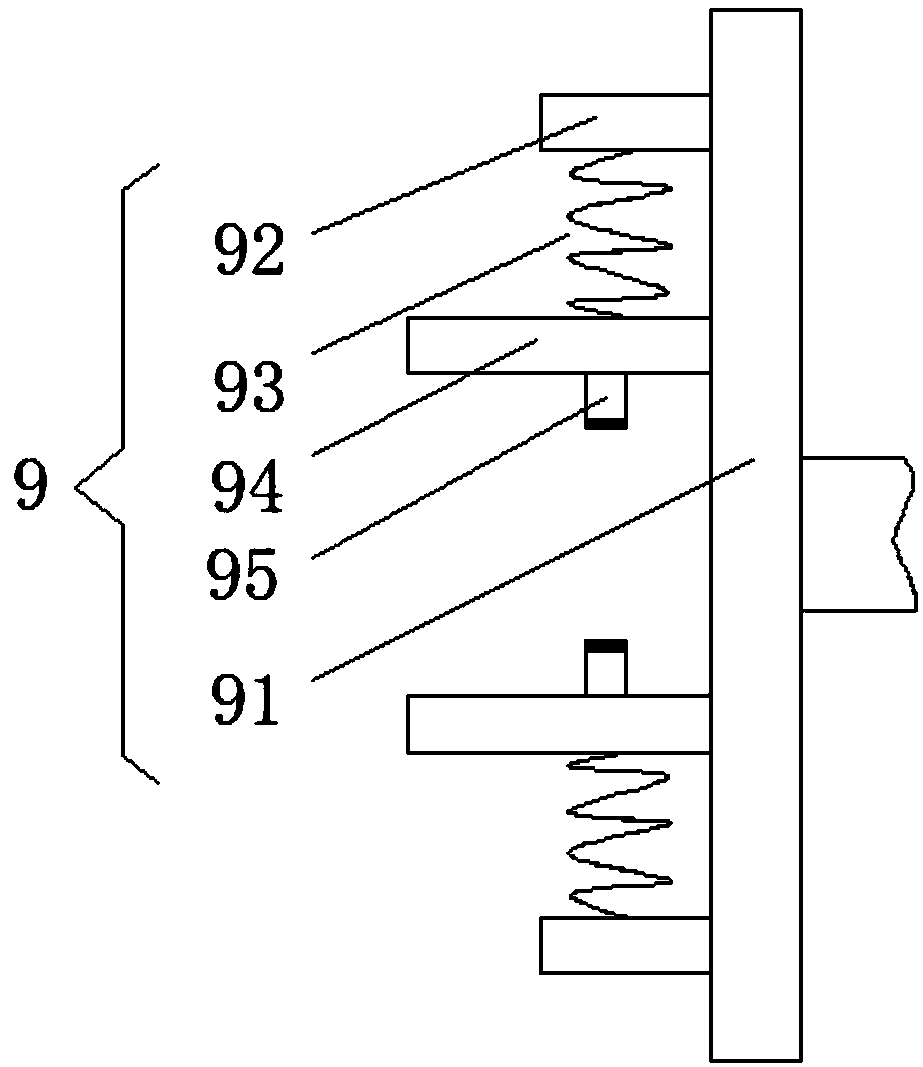

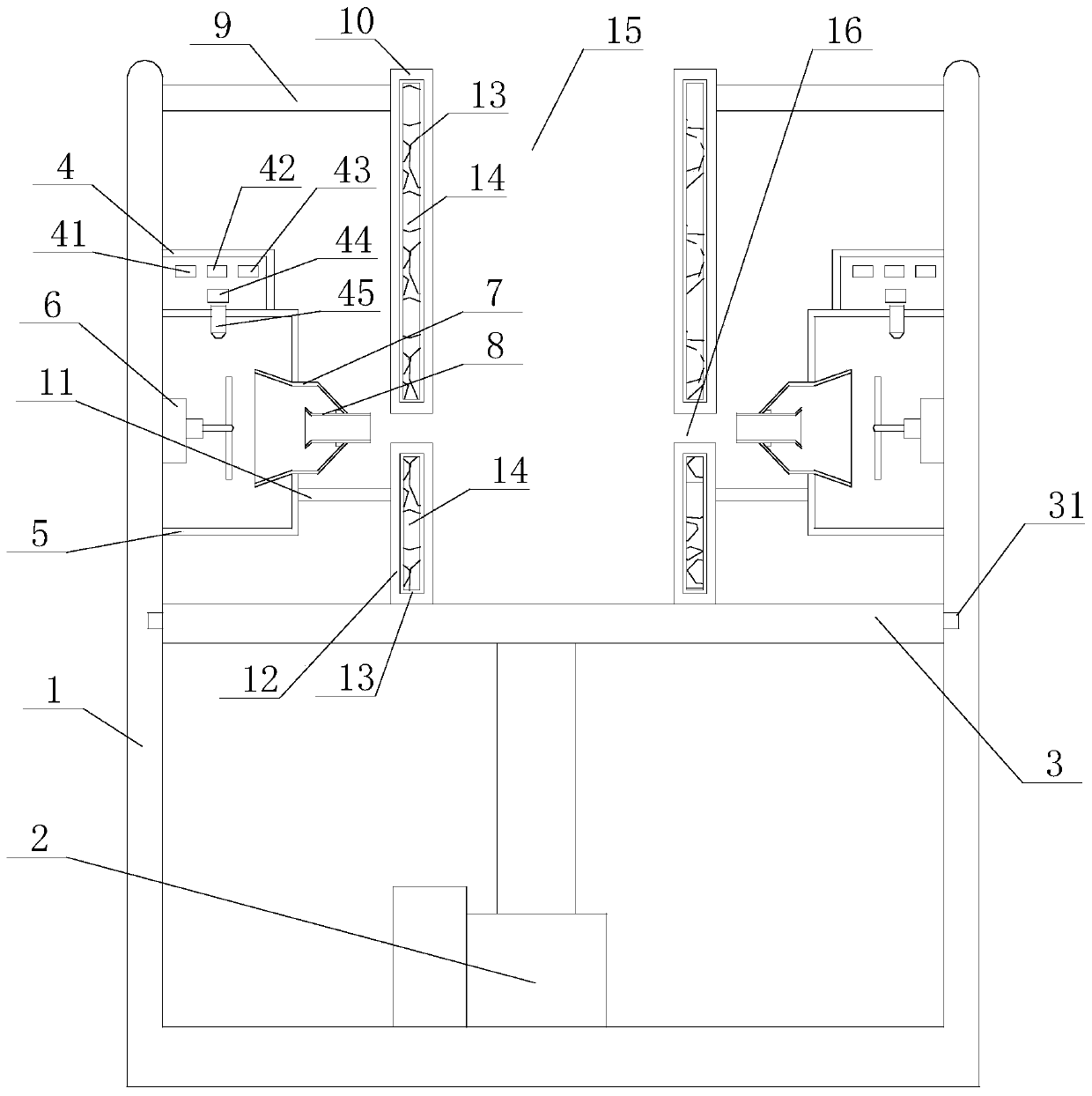

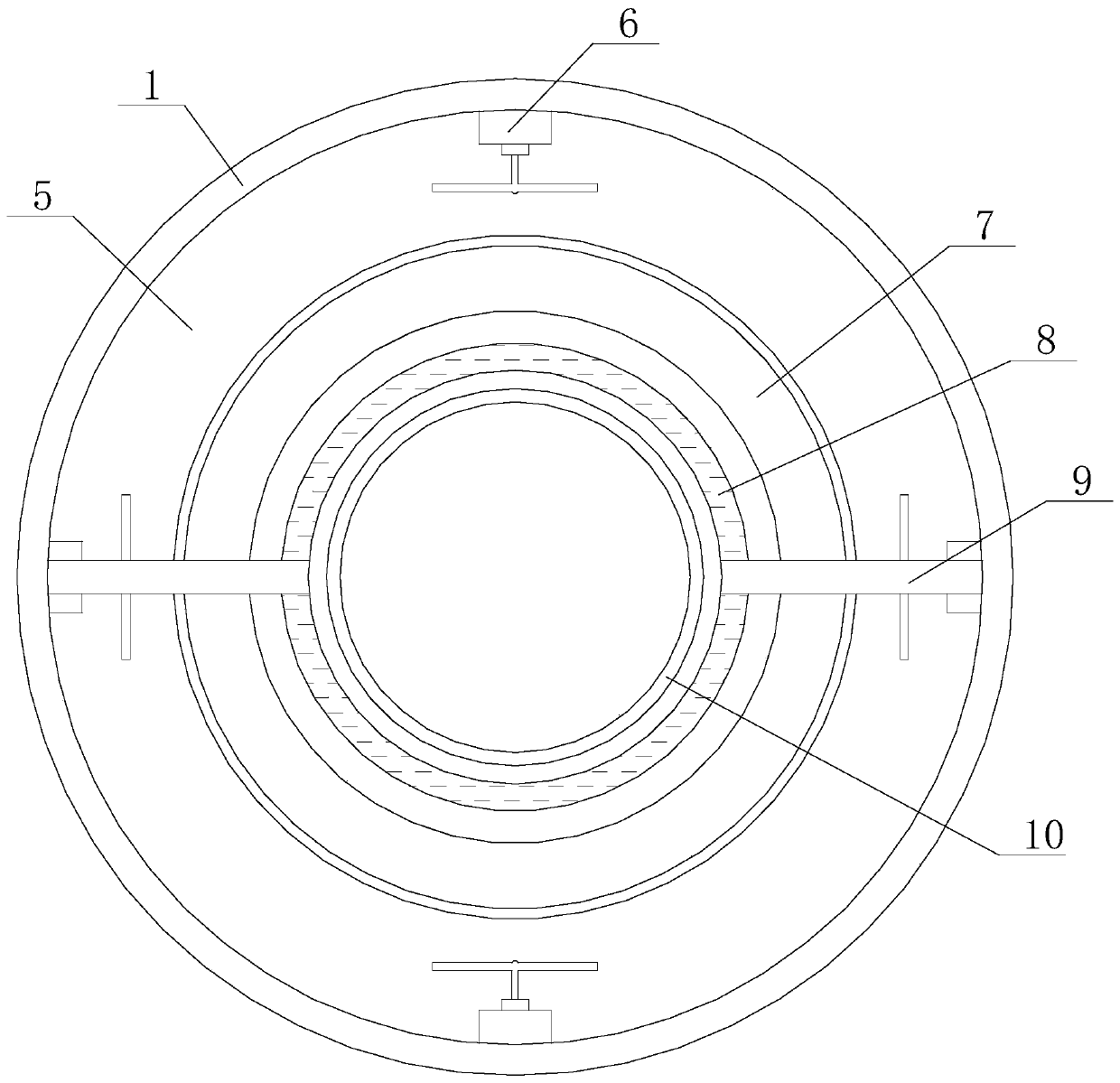

The invention discloses a 3D-printed microwave heating mechanism. The microwave heating mechanism comprises a 3D-printed rack and a lifting mechanism arranged at the bottom part of an inner cavity ofthe 3D-printed rack; the lifting mechanism is composed of an electric push rod vertically arranged at the bottom end of the 3D-printed rack and a printing platform horizontally installed at the top end of the electric push rod, and two ends of the printing platform are connected to the inner side wall of the 3D-printed rack through clamping blocks in a sliding mode; the inner side wall of the 3D-printed rack is provided with microwave flow guide covers positioned at the top part of the printing platform, and two ends of the microwave flow guide covers are provided with microwave generators with consistent structures; the sides, close to the inner cavity of the 3D-printed rack, of the microwave flow guide covers are embedded with flow guide covers; and tail ends of the flow guide covers areconnected with microwave outlet rings, wherein upper microwave shielding frames are arranged at the top ends of the microwave outlet rings, lower microwave shielding frames are arranged at the bottomends of the microwave outlet rings, and the upper microwave shielding frames and the lower microwave shielding frames are consistent in internal structures. The 3D-printed microwave heating mechanismhas the advantages of being reasonable in structural design and worthy of popularization and application.

Owner:DONGGUAN EONTEC CO LTD +1

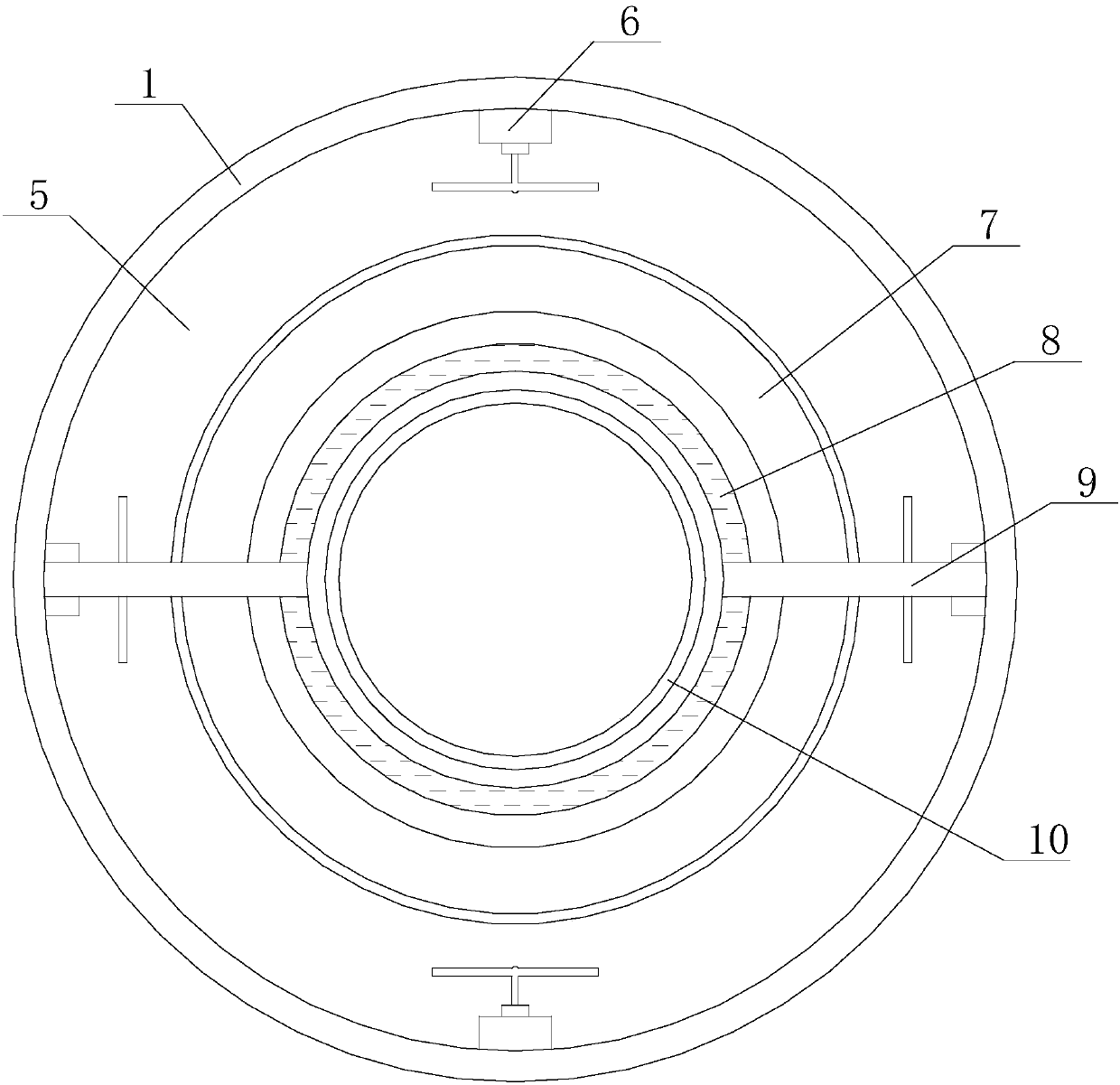

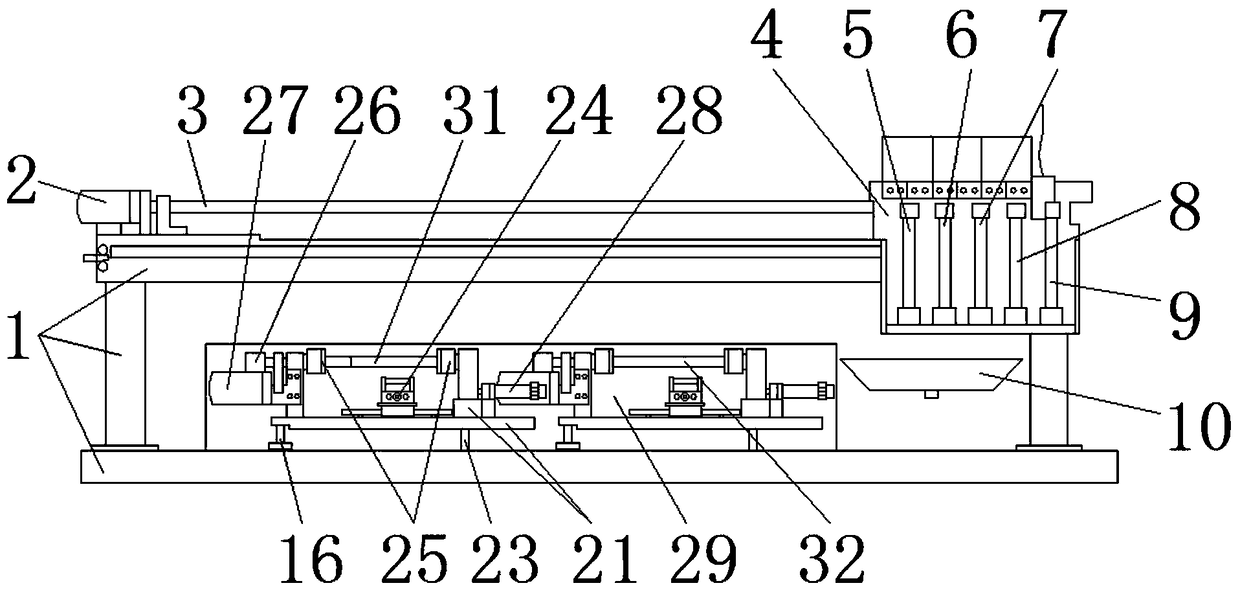

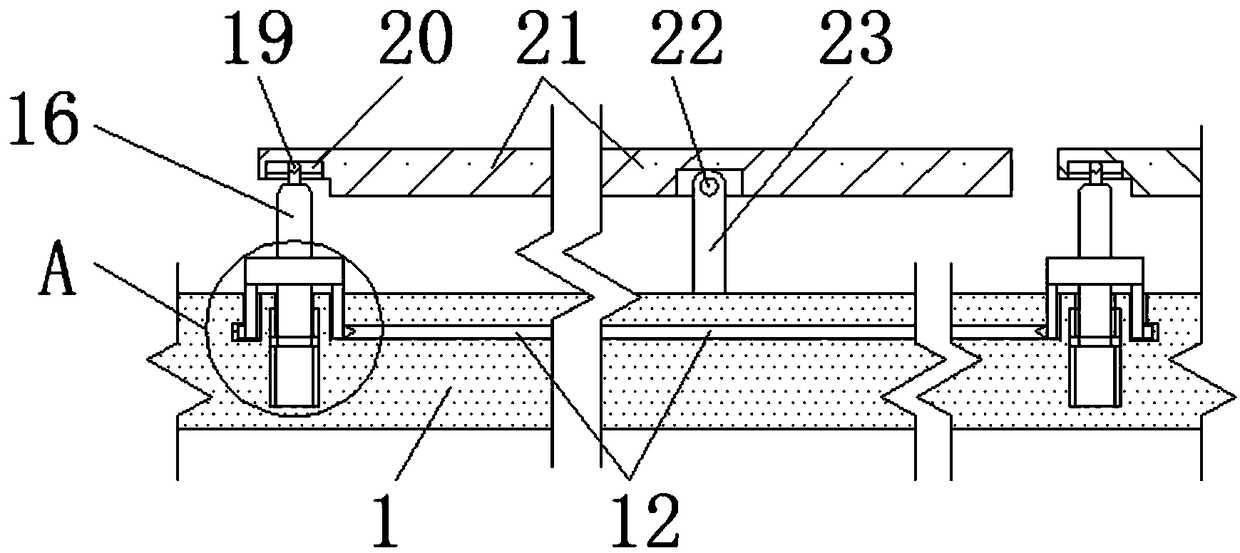

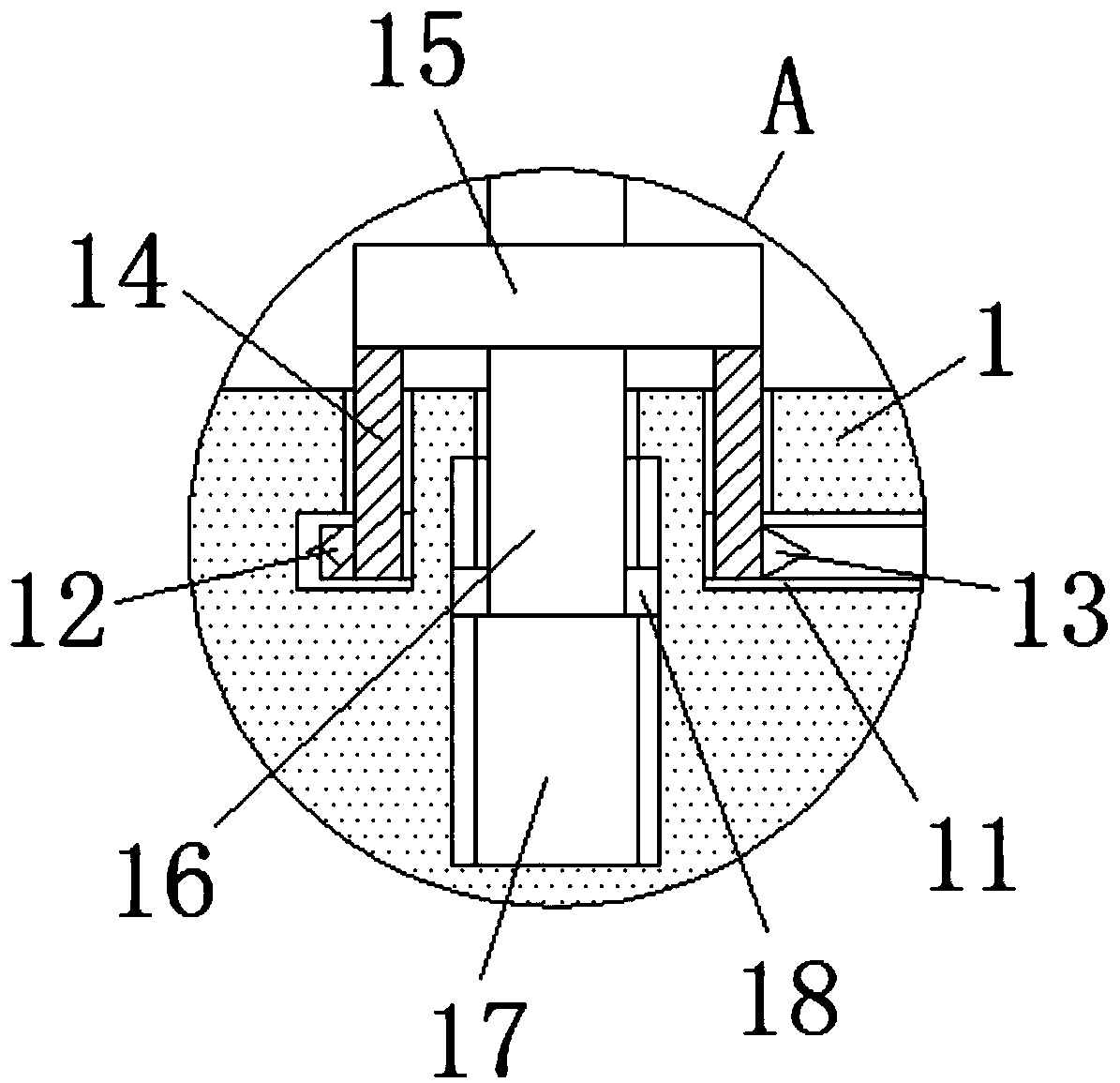

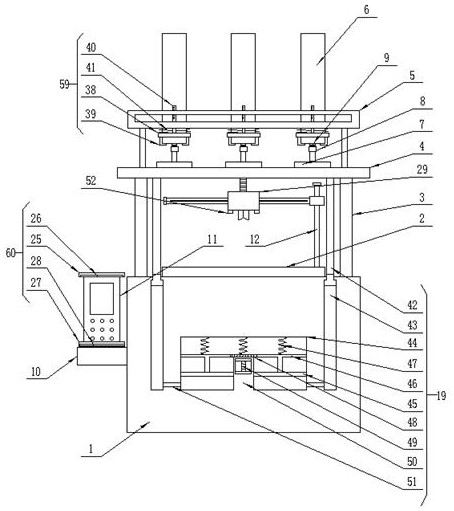

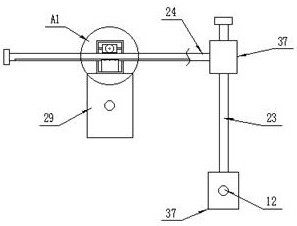

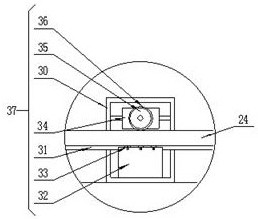

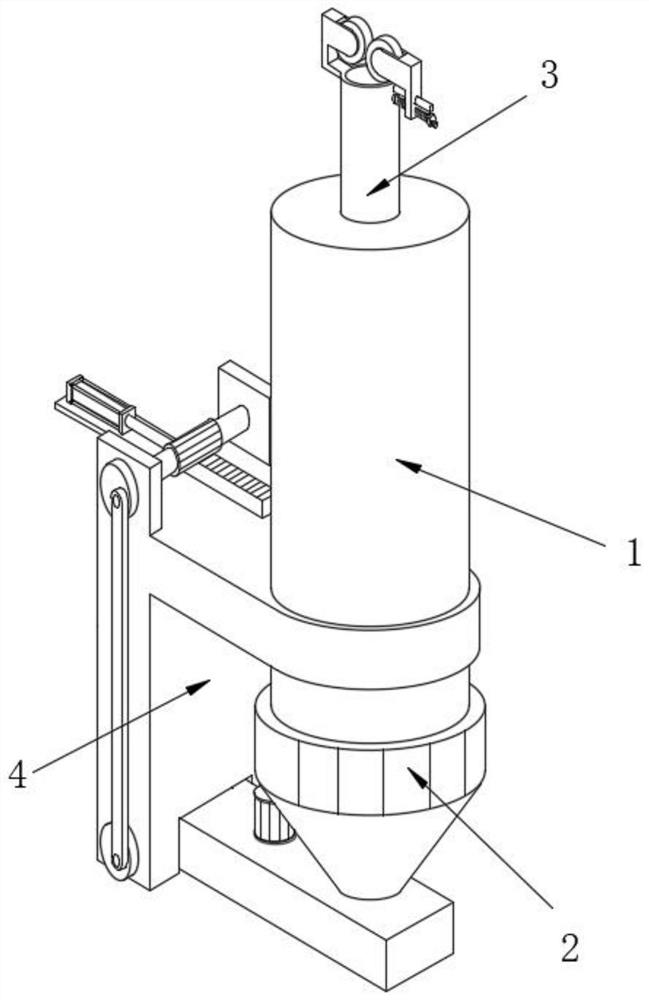

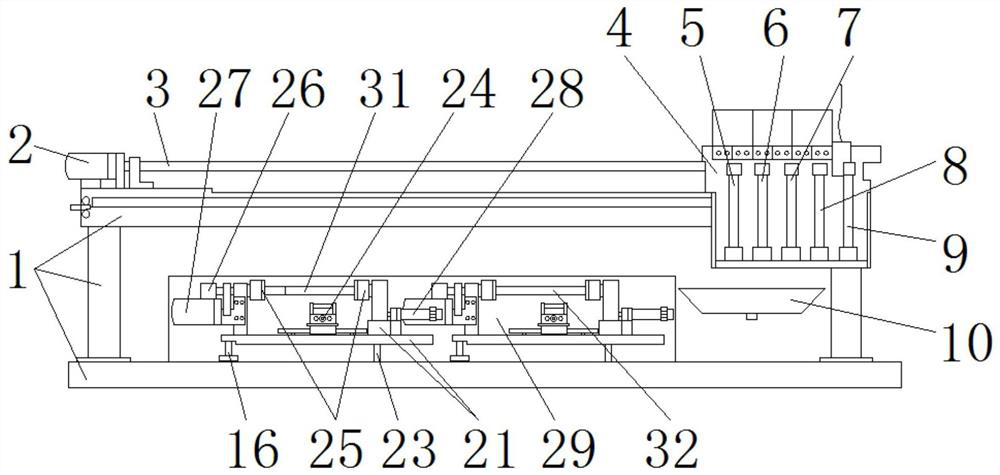

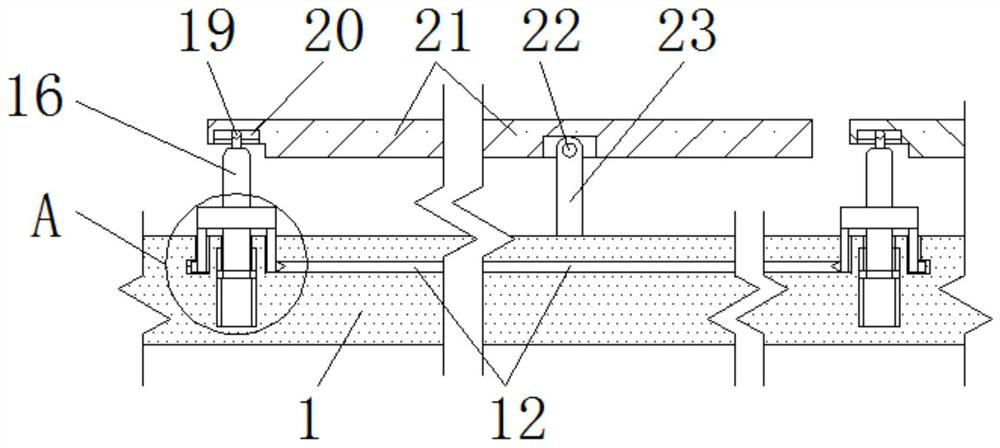

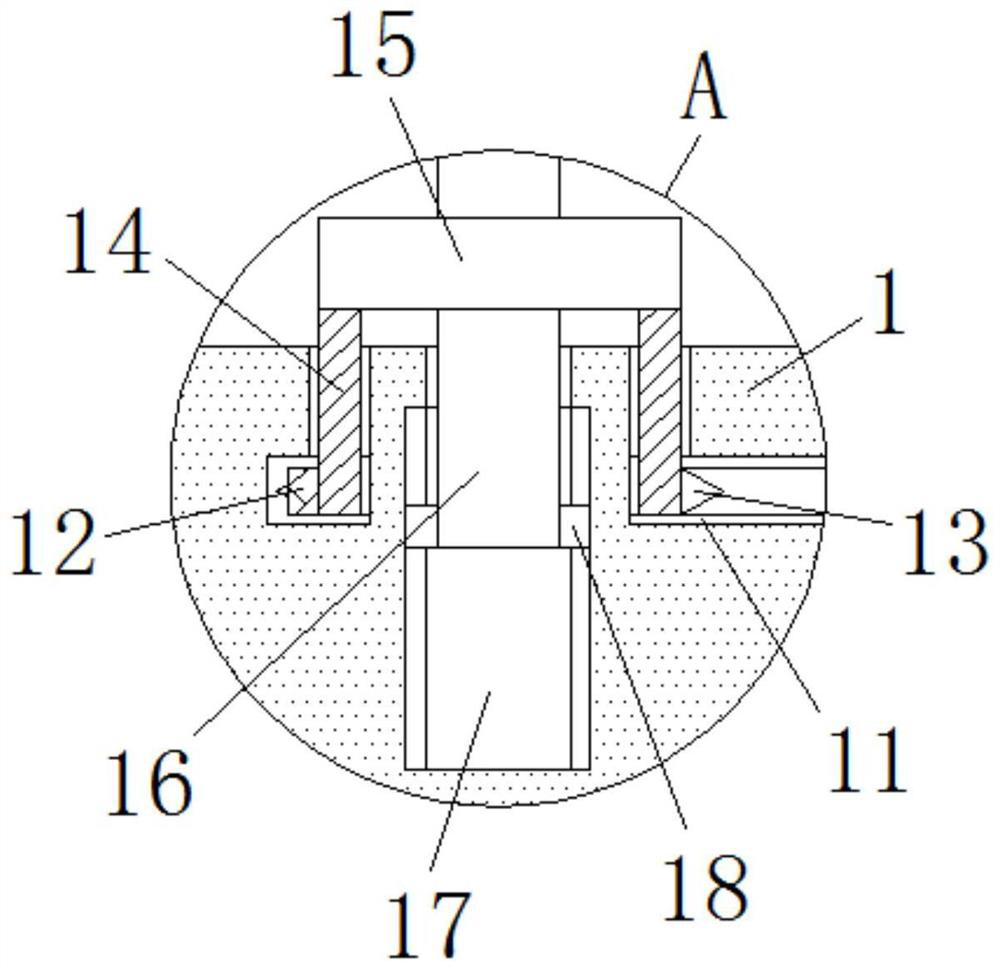

Novel high-speed regular and tapered cylinder printing equipment and method

ActiveCN109334273AConvenient printing workImprove work efficiencyTypewritersOther printing apparatusAgricultural engineeringNozzle

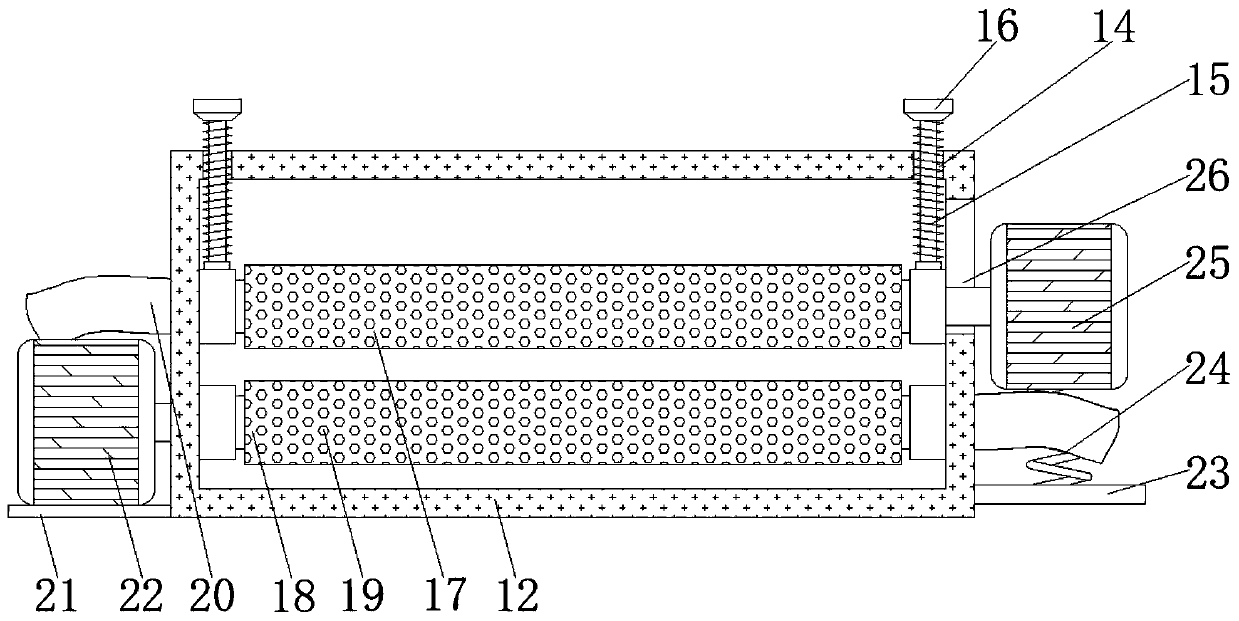

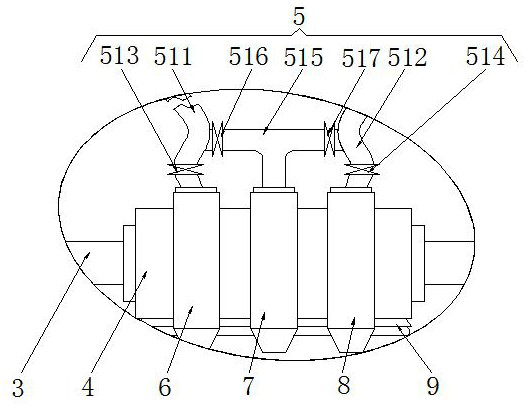

The invention discloses novel high-speed regular and tapered cylinder printing equipment and a method. The novel high-speed regular and tapered cylinder printing equipment comprises a frame, a first servo motor, a headstock, a first UV lamp and a second UV lamp, wherein the first servo motor is arranged above the left end of the frame, a cross beam shaft is arranged on the right end of the first servo motor, the cross beam shaft is connected with the frame, the headstock is arranged on the right end of the cross beam shaft, the headstock is connected with the frame, a first nozzle, a second nozzle, a third nozzle, a fourth nozzle and a fifth nozzle are arranged on the headstock, a waste ink box is arranged below the headstock, and a mounting groove is formed in the bottom end of the frame.According to the novel high-speed regular and tapered cylinder printing equipment and the method, the inclination of tapered workpieces can be adjusted by virtue of stations and auxiliary fixtures, and the surfaces of the workpieces and the nozzles can be effectively kept horizontal, so that irregular cylinders can be conveniently printed by the printing equipment.

Owner:浙江普崎数码科技有限公司

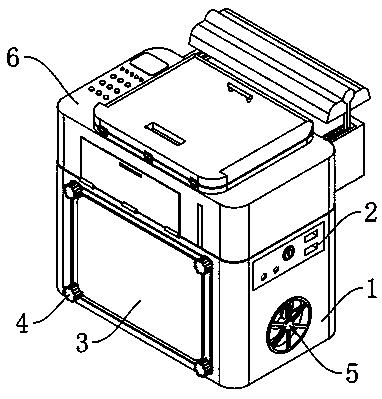

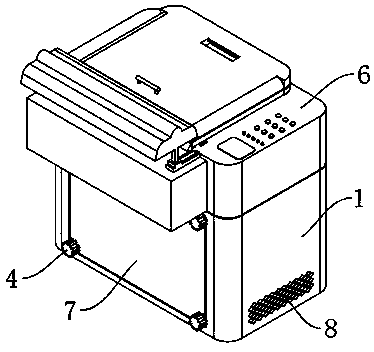

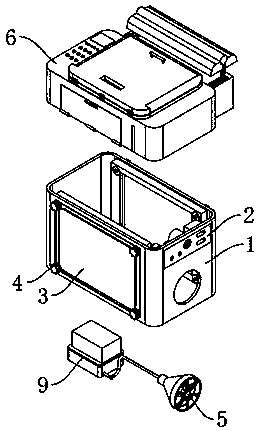

Printing integrated computer host

InactiveCN111038117AFlexible structureAvoid damageTypewritersOther printing apparatusComputer printingPush-button

The invention discloses a printing integrated computer host, and belongs to the technical field of multifunctional computers. The printing integrated computer host comprises a machine case and an airinlet fan. A front face plate of the machine case is fixedly connected with a button interface face plate. The left side wall and the right side wall of the machine case are provided with a transparent side plate and a protection side plate correspondingly. Fixing bolts are screwed at the four corners of the transparent side plate and the four corners of the protection side plate. The transparentside plate and the protection side plate are fixedly connected with the machine case through the fixing bolts. The air inlet fan is fixedly installed on the front face plate of the machine case and isfurther connected with a power supply cooling device. The end, away from the air inlet fan, of the cooling device is connected with an exhaust hole. The printing integrated computer host aims to solve the problems that a printer of existing design is only simply fixedly connected to a computer host, the structure is fixed, the function is monotonous, a power supply is high in load when driving the computer host and the printer to work at the same time, heating is severe and potential safety hazards exist.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

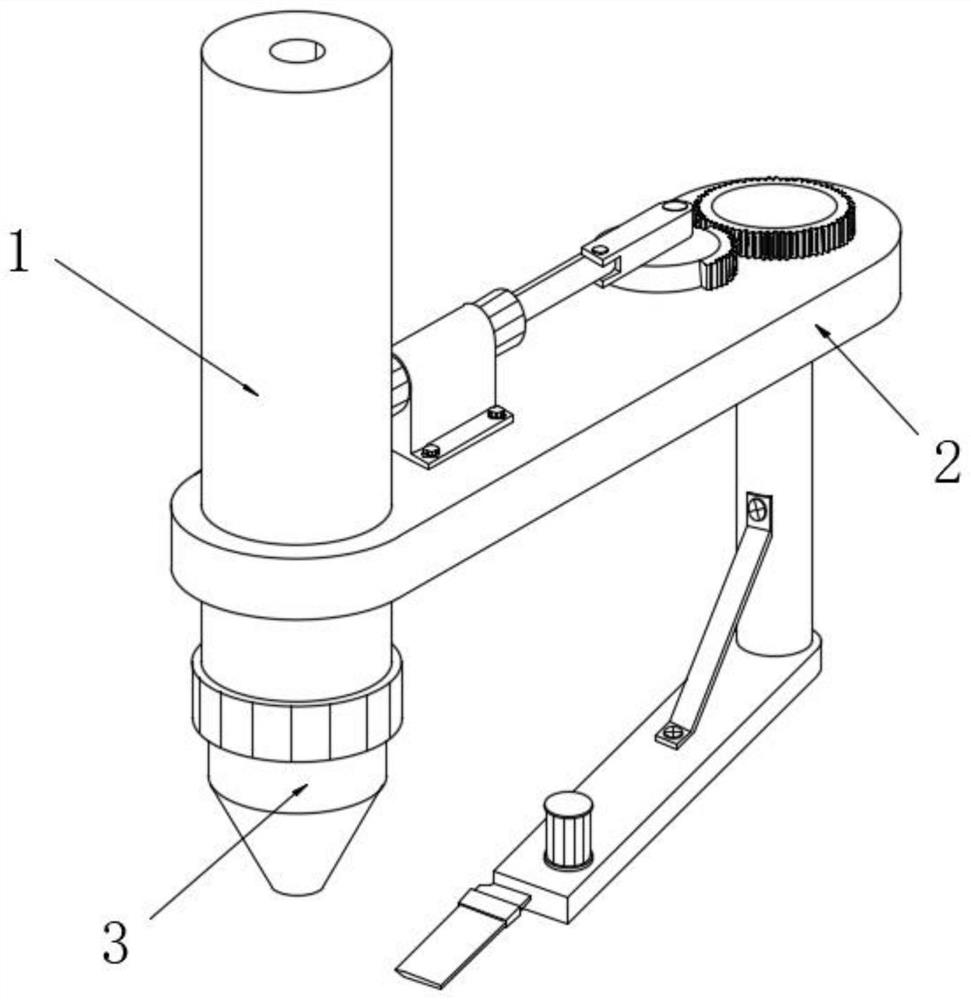

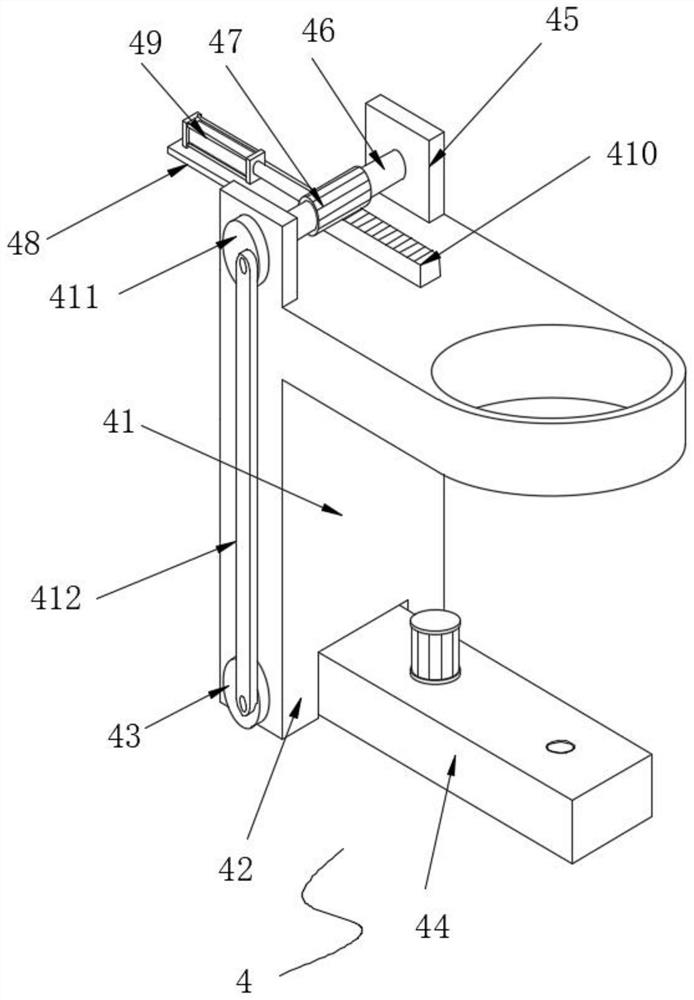

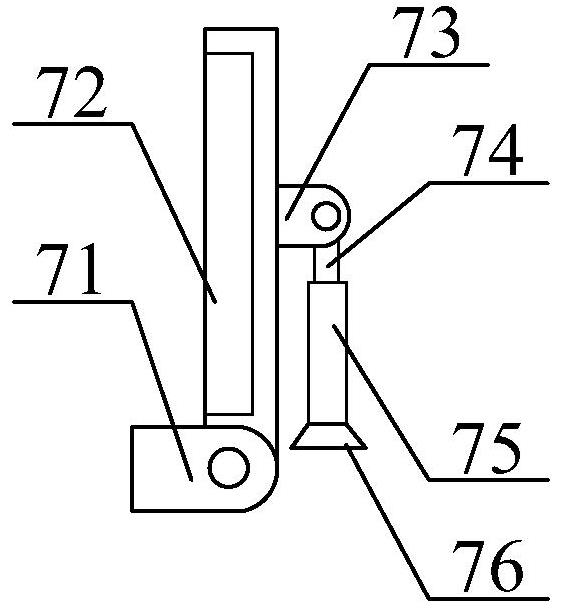

Filament cutoff device of continuous fiber reinforced composite 3D printer

PendingCN113752557AImprove safety performanceGuaranteed cleanlinessAdditive manufacturing apparatusMetal working apparatusEngineeringFiber-reinforced composite

The invention discloses a filament cutoff device of a continuous fiber reinforced composite 3D printer. The filament cutoff device comprises a filament conveying cylinder, the lower end of the filament conveying cylinder is fixedly connected with a nozzle, the outer surface of the filament conveying cylinder is connected with a cutting assembly in a sleeved manner, the cutting assembly comprises a fixed shaft, the lower end of the fixed shaft is fixedly connected with a base plate, a cutter is fixedly connected to the front side of the base plate, and a cleaning driving piece is arranged on the lower surface of the base plate. The invention relates to the technical field of 3D printers. According to the filament cutoff device of the continuous fiber reinforced composite 3D printer, the cutting assembly is arranged, after printing of the 3D printer is completed, the cutter can automatically cut off filaments on the nozzle under the work of an electric push rod, and therefore subsequent printing work of the 3D printer is facilitated, manual cutting is not needed, the safety performance is improved, under the elasticity of a second spring, after the filaments are cut off, the cutter can automatically return to the original position, and normal printing work of the nozzle of the 3D printer is not hindered.

Owner:江苏铭亚科技有限公司

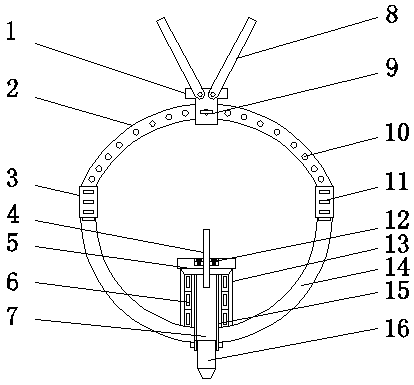

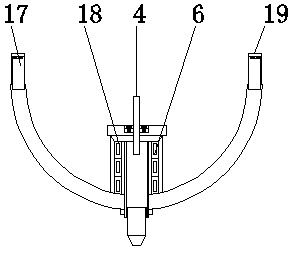

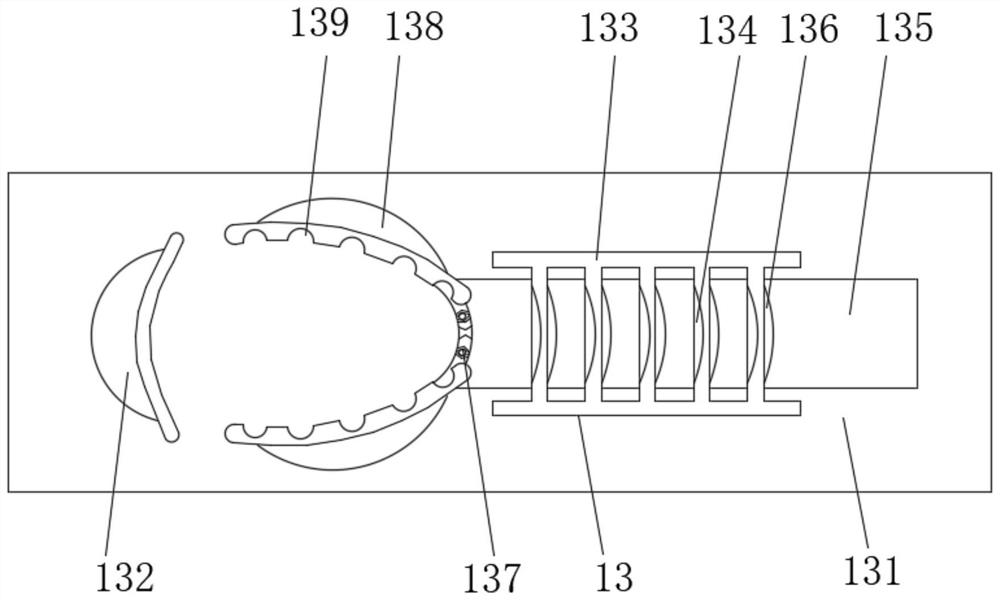

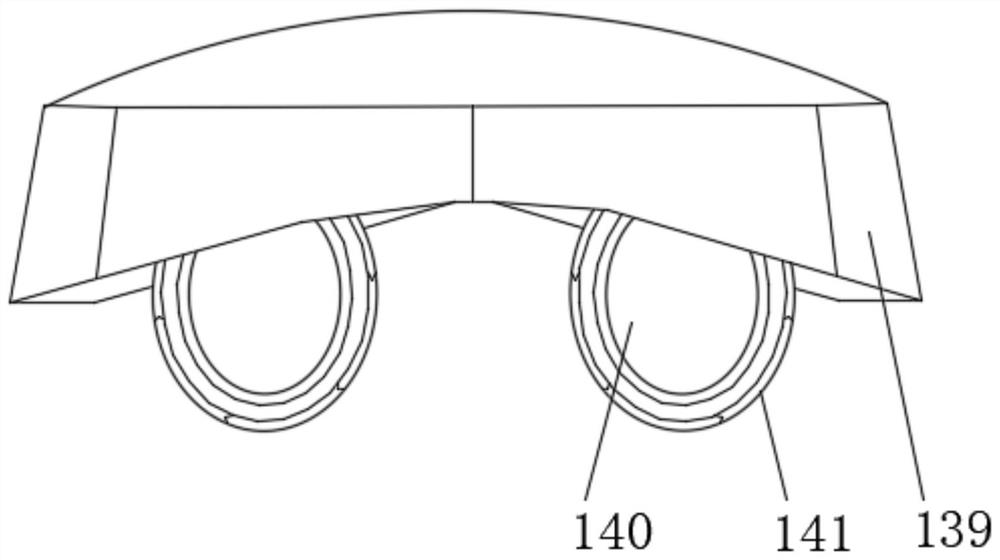

Detection device based on blood coagulation and platelet function analyzer

PendingCN113238035AGuaranteed stabilityConvenient detection workTypewritersBiological testingTest agentComputer printing

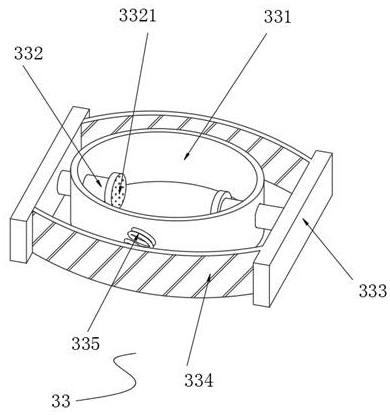

The invention discloses a detection device based on a blood coagulation and platelet function analyzer. The device comprises a machine body; to-be-tested agent cup slots are uniformly formed in the middle position of the upper surface of the machine body; a detection piece and a printer are respectively arranged on the upper surfaces of the two sides of the machine body; interfaces are uniformly formed in the rear surface of the machine body; and one side surface of the machine body is fixedly connected with a paper storage mechanism. The relates to the technical field of blood coagulation and platelet detection. According to the detection device based on the blood coagulation and platelet function analyzer, the elasticity of a first spring and arc-shaped sheets is utilized, when blood coagulation and platelets in a reagent bottle need to be detected, the two arc-shaped sheets are pinched so that clamping blocks on two sliding rods are opened, the reagent bottle is placed in an annular cylinder, then the arc-shaped sheets are loosened, and the clamping blocks on the two sliding rods can firmly clamp the two sides of the reagent bottle, so that a worker can better detect blood coagulation and blood platelets in the reagent bottle.

Owner:世纪亿康(天津)医疗科技发展有限公司

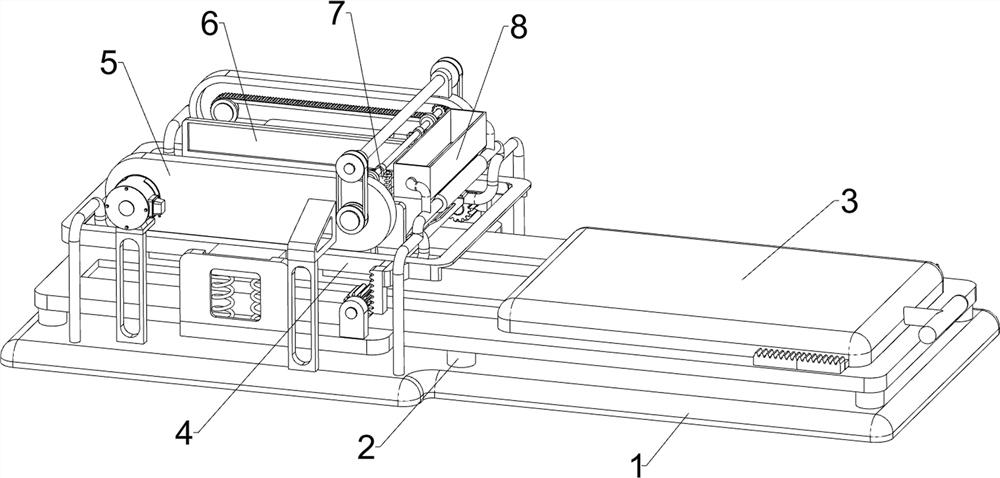

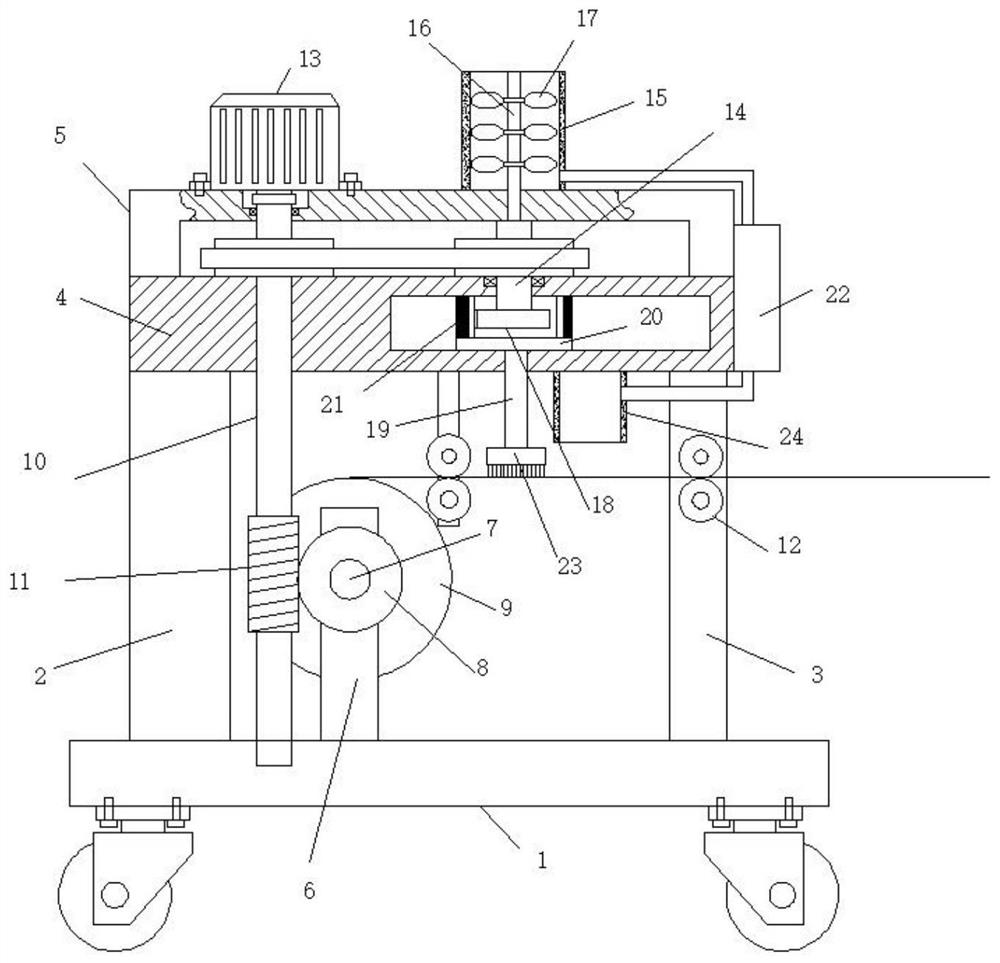

A printing machine for textile fabrics

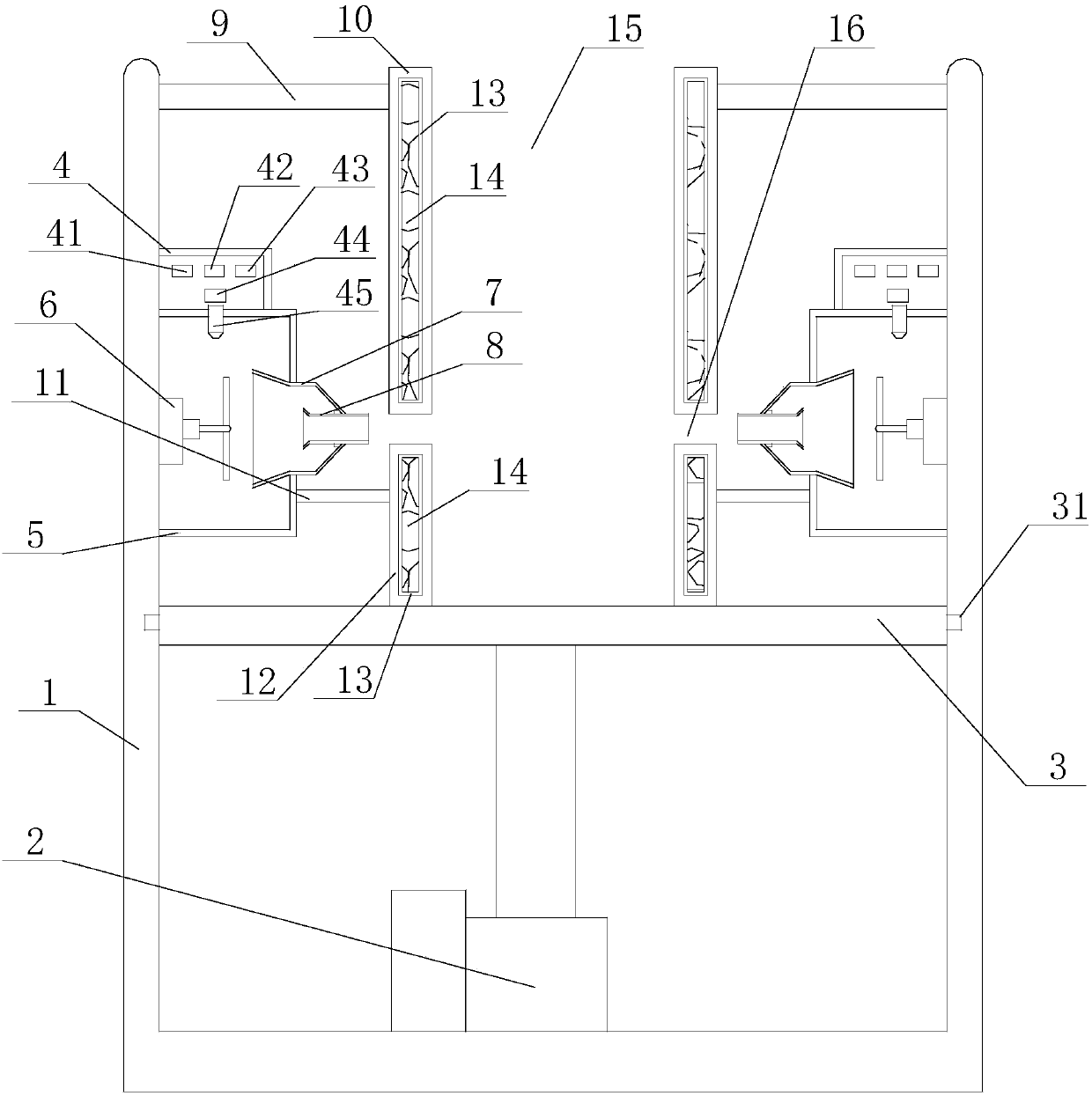

ActiveCN109664623BQuality assuranceConvenient printing workTypewritersOther printing apparatusTextile printerDust control

The invention discloses a printing machine for a textile fabric, which comprises a printing machine body, wherein a heating device is fixedly connected with the left side of the top of the printing machine body; a dust collection device is fixedly connected with the top of the printing machine body and located on the left side of the heating device; and a controller is fixedly connected with the top of the printing machine body and located at the front ends of the heating device and the dust collection device. According to the printing machine, a heating box, heating lamps, a first roll shaftand temperature sensors are matched for use, so that cloth can be subjected to preheating treatment; printing quality is better ensured; a second roll shaft, a third roll shaft, dust collection holes,a hose, a first motor, a second motor, a suction machine and an isolation net are matched for use, so that impurities on the surface of the cloth can be cleared; the printing quality is better ensured; great convenience is brought to printing work; with the adoption of the temperature sensors, a temperature of an inner cavity of the heating box can be monitored; and the temperature can be monitored according to the different cloth.

Owner:FUJIAN JINYIFENG IND & TRADE CO LTD

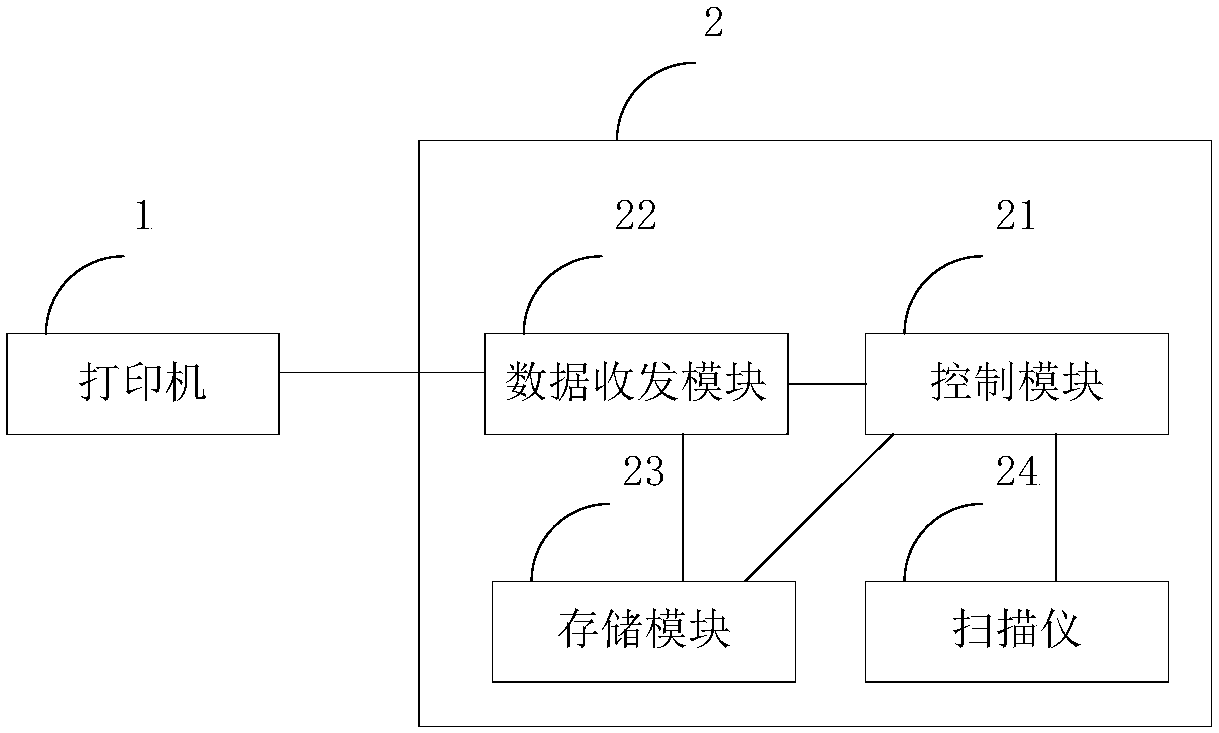

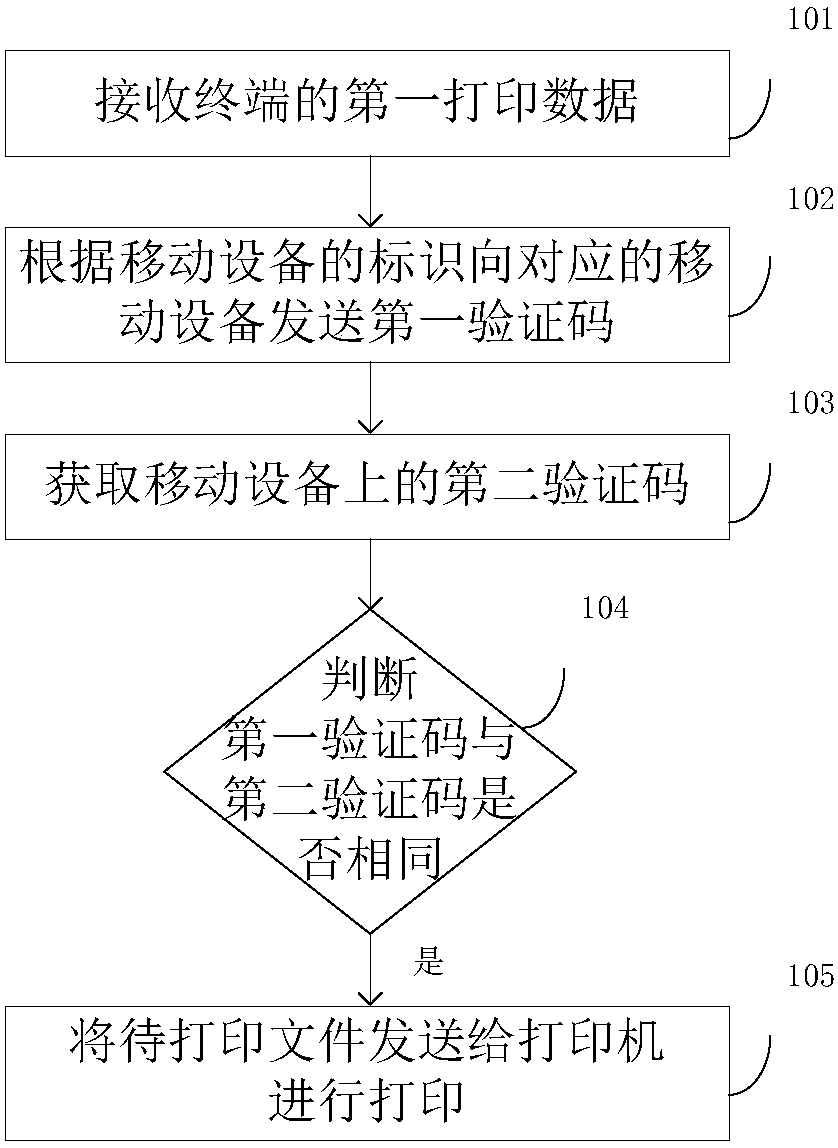

Printing method and device

InactiveCN108595129AConvenient printing workTake it away in timeDigital output to print unitsMobile deviceInformation leakage

The invention provides a printing method and device. The device comprises a printer and a printing auxiliary component, wherein the printing auxiliary component comprises a control module, a data transceiving module, a storage module and a scanner; the data transceiving module, the storage module and the scanner are connected with the control module; the data transceiving module is used for receiving the first printing data of a terminal and sending a first verification code to mobile equipment; the storage module is used for storing second printing data; the scanner is used for scanning a second verification code displayed on the mobile equipment; and the control module is used for sending a file to be printed to the printer according to the second verification code. Through the above printing device, after the second verification code on the mobile equipment is scanned through the scanner, the printing auxiliary component can control the printer to begin to print, the file to be printed can be guaranteed to be taken away in time, information leakage is avoided, the user can more conveniently print the file to be printed, user experience is improved, and the printing work of the terminal which can not be conveniently moved is convenient.

Owner:长沙明尧测控科技有限公司

3D printer head structure

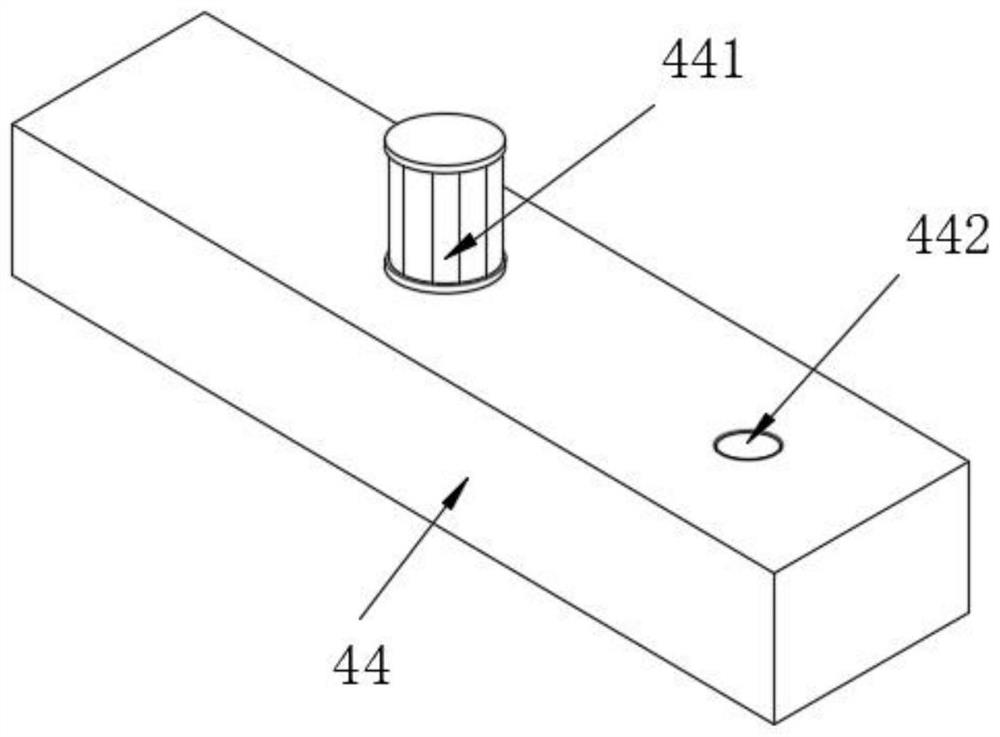

InactiveCN107696489AConvenient printing workEasy to fix and removeApplying layer meansSpray nozzlePiston

The invention discloses a 3D printer head structure. The 3D printer head structure comprises a turning rack, a casing and a fixed bracket, wherein a base is mounted on the turning rack; pull rods arefixed at two ends of the top of the base; screw holes are uniformly formed in the turning rack; an adjusting bolt is fixed on one side of the base and connected with the screw holes; fastening blocksare fixed at two ends of the turning rack; clamp slots are uniformly formed in the fastening blocks; the fixed bracket is fixed at the bottom end of the turning rack; connecting blocks are fixed at two ends of the fixed bracket; a heat conducting layer is arranged between a heating cavity and a cylinder; a feeding pipe is mounted at the top end of a piston, and the bottom end of the feeding pipe vertically penetrates through the piston to extend into the cylinder. The turning rack is mounted, and the screw holes are uniformly formed in the turning rack, so that the screw holes and adjusting bolt are connected, the base is fixed on the turning rack, change of the spraying direction of a spray nozzle is realized, and printing of the printer is convenient.

Owner:刘庆芳

High-precision continuous 3D printer and printing method thereof

InactiveCN112092371APrevent impurities from settlingQuality assuranceManufacturing heating elementsManufacturing material handlingPhysicsColor printing

The invention discloses a high-precision continuous 3D printer, and relates to the technical field of 3D printing. The high-precision continuous 3D printer comprises a machine body, a vertical rod anda transverse rod fixedly connected between the two sides of the inner wall of the machine body. A sliding block is slidably connected to the surface of the transverse rod; a multi-color printing assembly is arranged on the top of the machine body, and the multi-color printing assembly comprises a material box; a vertical plate is fixedly connected between the top and the bottom of the inner wallof the material box; a fixed groove is formed in the vertical plate; a curved bar is rotatably connected between the two sides of the inner wall of the material box through a bearing; and a worm sleeve is fixedly connected to the position, located in the fixed groove, of the surface of the curved bar. According to the high-precision continuous 3D printer and the printing method thereof, multi-color or mixed-color printing of products can be achieved, meanwhile, the problem that colored photosensitive resin liquid is prone to solidification and impurity precipitation in the storage process canbe solved, a foundation is laid for irradiation curing work of a UV lamp, and meanwhile the quality of the printed products is guaranteed.

Owner:黄利华

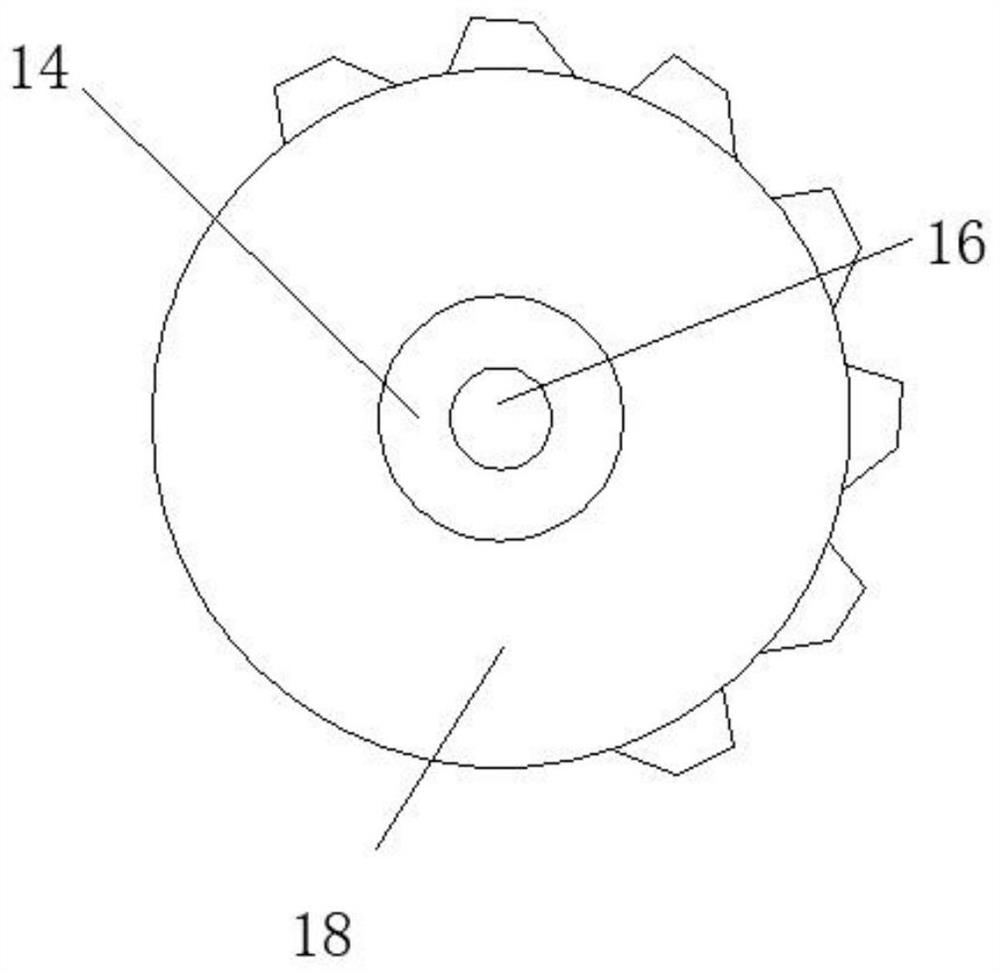

Photosensitive drum device capable of realizing thorough cleaning

InactiveCN109201546AWash thoroughlyPlay a protective effectFlexible article cleaningCleaning using toolsElectric machineryEngineering

The invention relates to a technical field of a selenium drum and discloses a photosensitive drum device capable of realizing thorough cleaning. The device includes a base, wherein the middle of the base is provided with a slot, the slot is internally movably sleeved with a sliding block, the middle of a front surface of the sliding block is fixedly connected with a control rod, the control rod penetrates through and extends to the external portion of the base, a top portion of the base is fixedly equipped with a cabinet, an inner wall of the cabinet is fixedly connected with a side surface ofa fixing station, a top portion of the fixing station is fixedly connected with a motor, an outer shaft of the motor extends outside a fixed plate and is further fixedly connected with a side surfaceof a grasping device, and the fixed plate is fixedly mounted in the cabinet. The photosensitive drum device is advantaged in that a telescopic rod is fixed through tightening a nut to match with a passive plate, the height of the telescopic rod is adjusted, so the positional relationship between a cleaning brush and the photosensitive drum can be easily adjusted, reasonable control of the cleaning effect is achieved, the photosensitive drum is protected, and the printing work is facilitated.

Owner:江门市新会区国源电镀有限公司

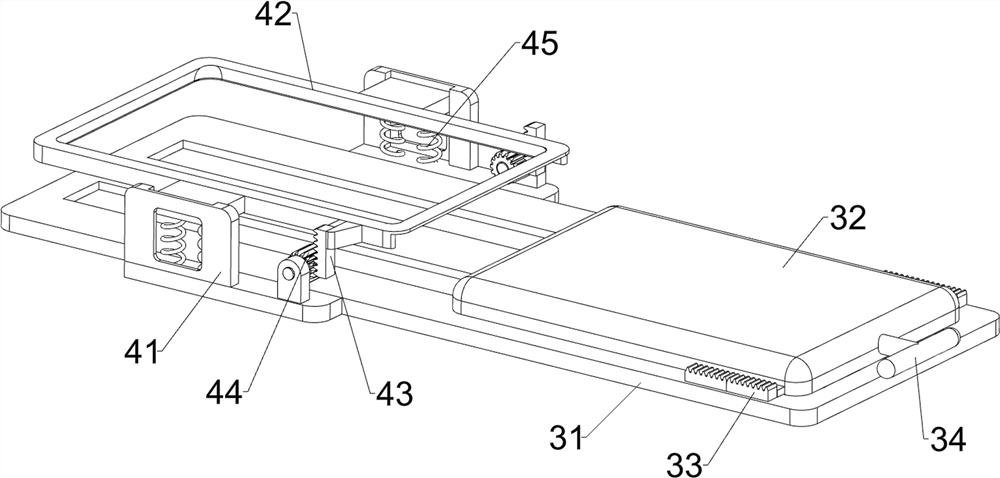

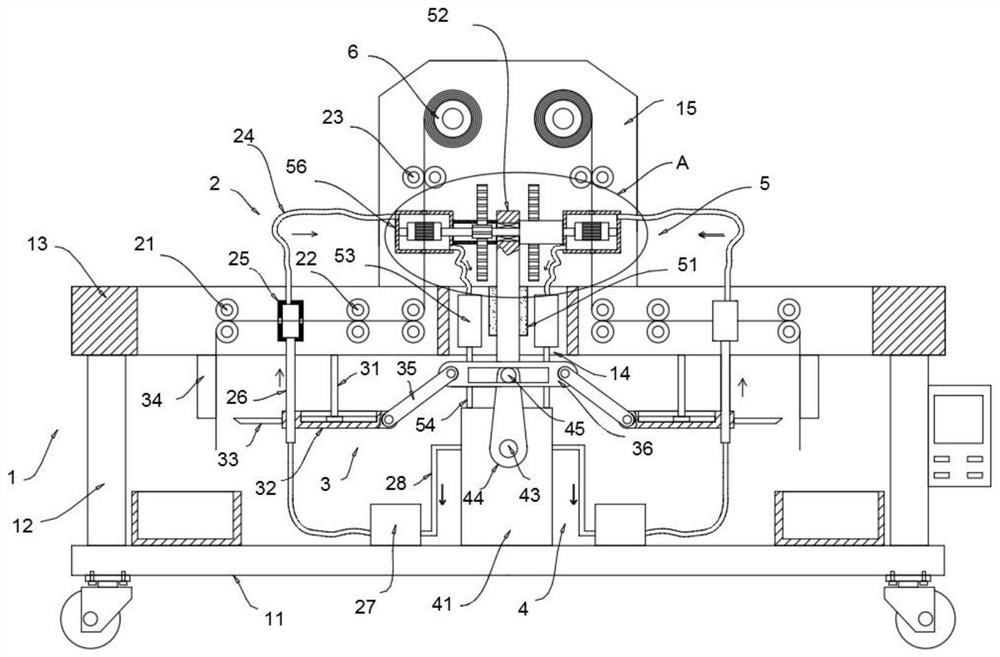

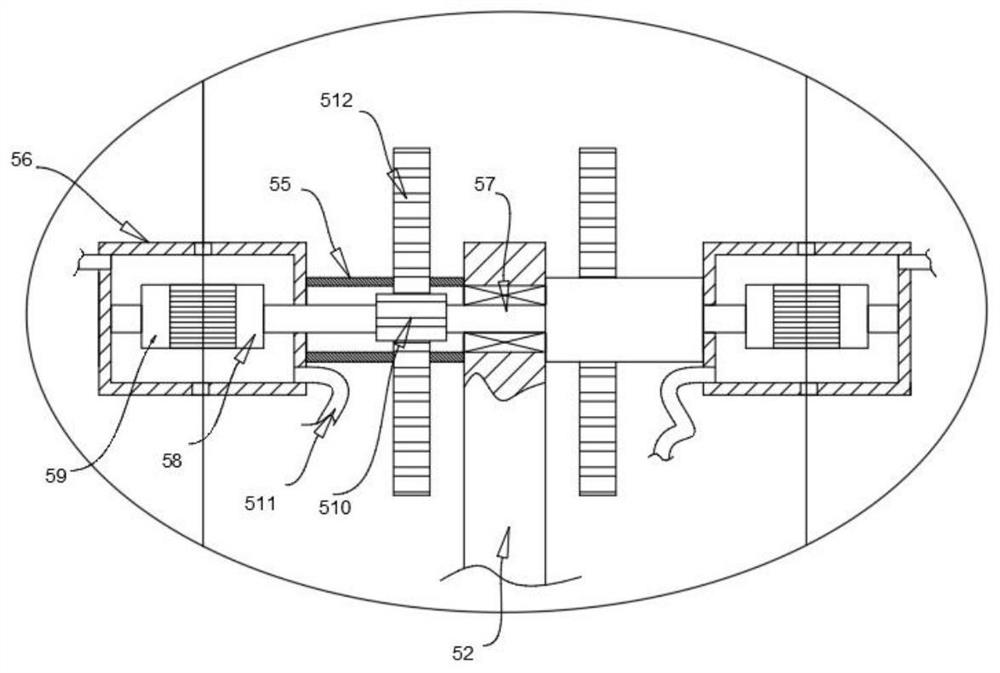

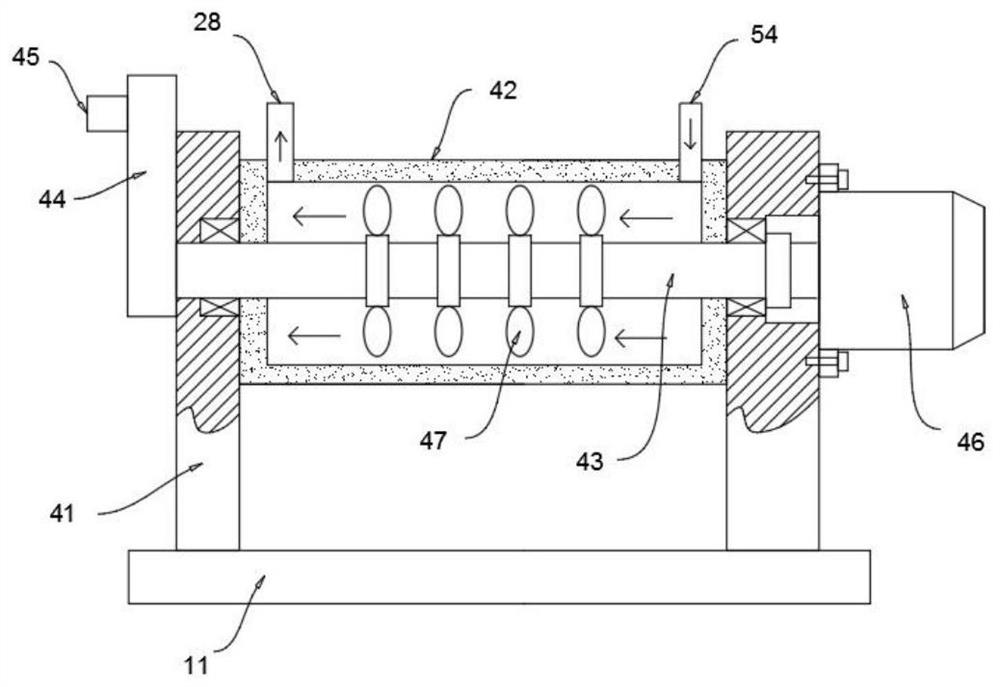

A precision printing error proofing equipment for garment production

ActiveCN112406280BTransfer preventionAvoid offsetRotary pressesOther printing apparatusTextile printerMechanical engineering

Owner:ZHEJIANG SCI TECH UNIV SHAOXING KEQIAO RES INST CO LTD

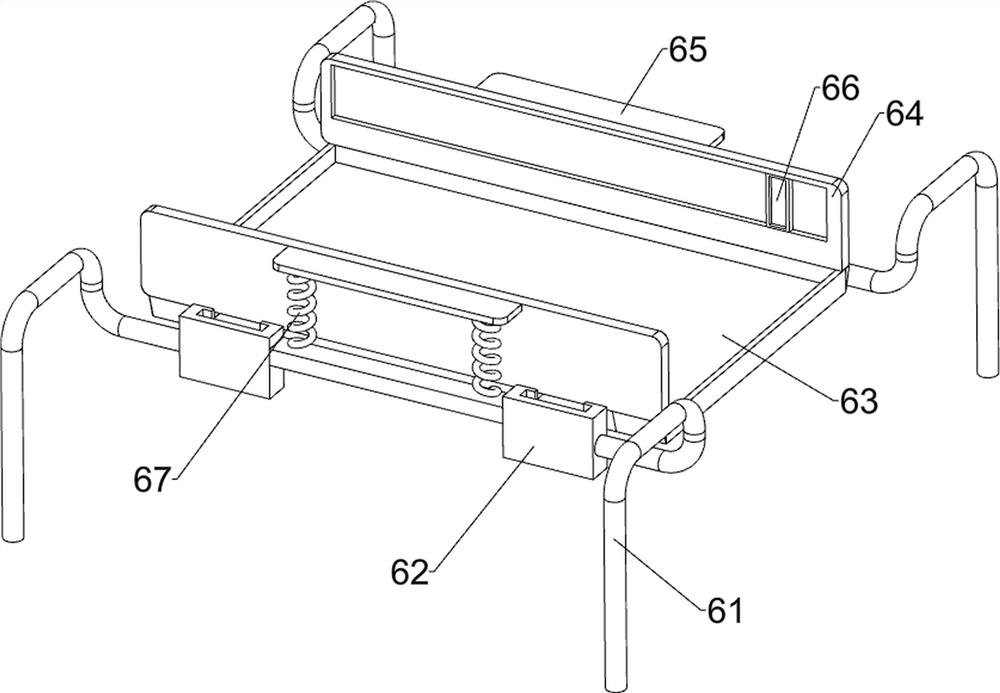

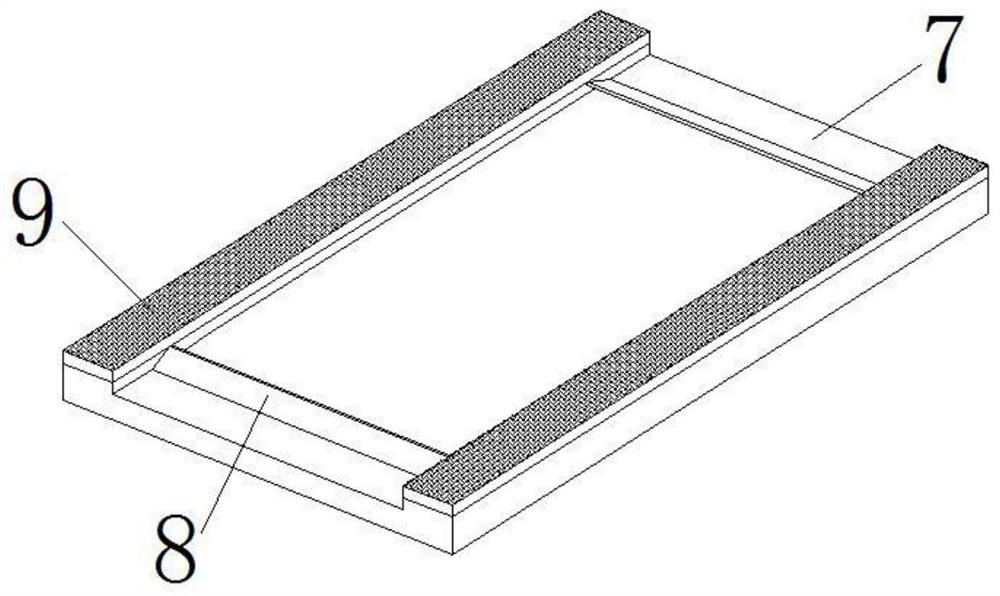

3D printing technology printing frame and application thereof

InactiveCN111890682AEasy to assemble and disassemblePrevent movementManufacturing platforms/substratesEngineeringSupport plane

Owner:安徽金博略文化产业有限责任公司

Three-dimensional (3D) printing system based on cloud data and printing method thereof

ActiveCN113103583AConvenient printing workEasy to processAdditive manufacturing apparatus3D object support structuresComputer hardwareData transport

The invention discloses a three-dimensional (3D) printing system based on cloud data and a printing method thereof. The system comprises a machine body, a control box, a storage tank and a spray head, wherein a forming table is fixedly mounted in the center of the upper end of the machine body; a partition mechanism is arranged in the machine body; and a supporting plate is horizontally and fixedly mounted at the left side end of the machine body. According to the 3D printing system based on the cloud data and the printing method thereof provided by the invention, after a computer draws a picture, picture information is numbered and then stored in a cloud database; and when printing is needed, a picture information number is input through an input module, numbered information is transmitted and emitted through a first wireless receiving and transmitting module through the control box, the numbered information is received through a second wireless receiving and transmitting module, the data is transmitted to the interior of a terminal controller, the terminal controller retrieves the interior of the cloud database through a first retrieval module, image data matched with retrieval is sent out through the second wireless receiving and transmitting module, and the image data is received by the first wireless receiving and transmitting module and transmitted to the interior of the control box, so that subsequent printing work is facilitated.

Owner:SIMPLE MEDICAL SHENZHEN LTD

Photocuring 3D printing equipment

InactiveCN110667107AReduce occupancyEasy to operateManufacturing enclosures3D object support structuresStructural engineeringIndustrial engineering

The invention discloses photocuring 3D printing equipment which comprises a box body, a photocuring head and a first motor, wherein the top of the photocuring head is movably connected with the top ofthe inner wall of the box body; the top of the first motor is fixedly connected with the top of the inner wall of the box body; a bottom plate is fixedly connected with the bottom of the inner wall of the box body; a resin groove is movably connected with the top of the bottom plate; an outer frame is movably connected with the top of the resin groove; a dual rectangular shaped plate is fixedly connected with the bottom of the outer frame; and a seal ring is fixedly connected with the surface of the dual rectangular shaped plate. The invention relates to the technical field of 3D printing. According to the photocuring 3D printing equipment, the top of the photocuring head is movably connected with the top of the inner wall of the box body to avoid frequent change of the resin groove, savethe changing time and provide convenience for printing operation; sliding rods are fixedly connected with the two sides between the top and the bottom of the interior of an inner box, the operation is simple and fast, and time and labor are saved; and the photocuring 3D printing equipment is precisely suitable for component height, and the material occupancy rate is reduced to the minimum.

Owner:东莞市神说科技有限公司

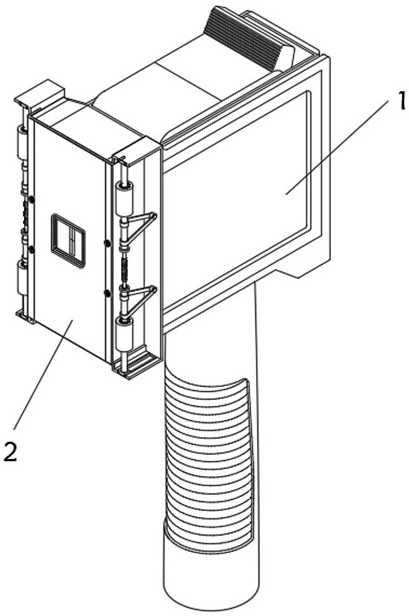

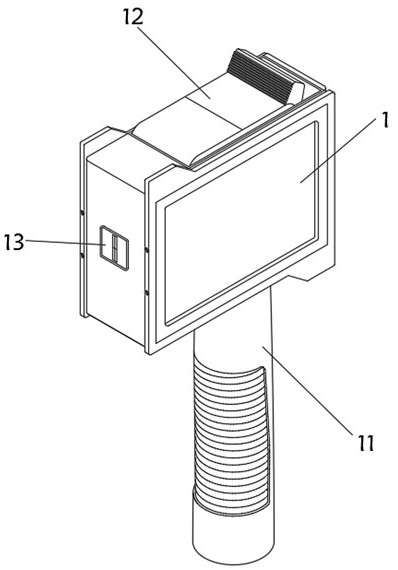

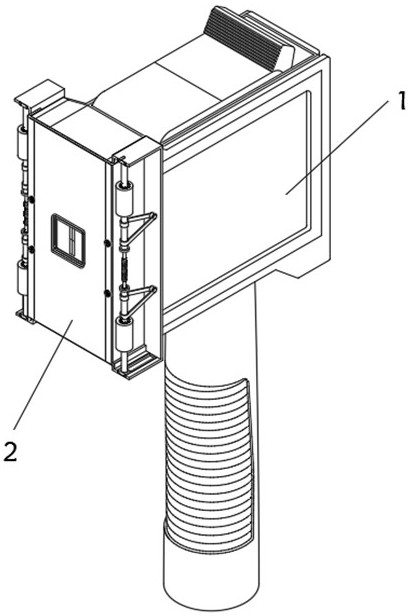

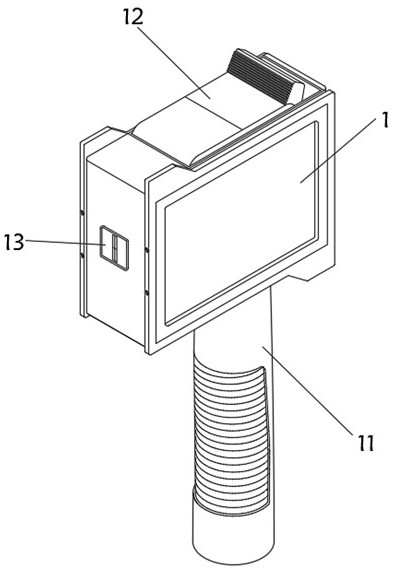

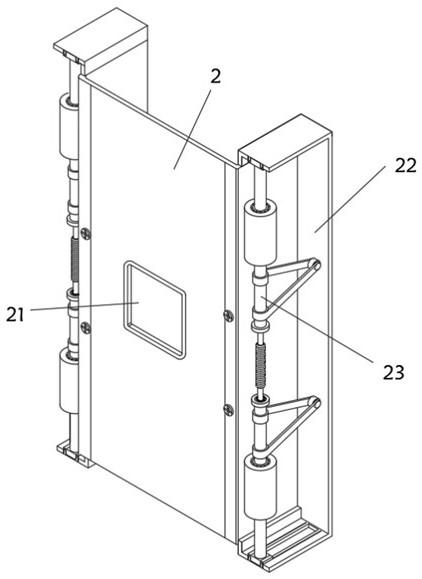

A kind of hand-held green printing equipment and printing method

Owner:广东宝丰数字印刷科技有限公司

3D sculpture printer structure of continuous fiber reinforced composite material

PendingCN113977944AConvenient printing workPlay a role in dustAdditive manufacturing apparatus3D object support structuresComputer printingEngineering

The invention discloses a 3D sculpture printer structure made of continuous fiber reinforced composites. The 3D sculpture printer structure comprises a barrel, a spray head is fixedly connected to the lower end of the barrel, a wire conveying pipe is arranged at the upper end of the barrel, a dustproof part is arranged on the outer surface of the barrel in a sleeving mode, and the dustproof part comprises an L-shaped plate installed on the outer surface of the barrel in a sleeving mode; protruding blocks are arranged on the lower surfaces of the front side and the rear side of the L-shaped plate correspondingly, and the faces, opposite to each other, of the two protruding blocks are rotationally connected with first rotating discs correspondingly. The invention relates to the technical field of 3D sculpture printers, according to the 3D sculpture printer structure of the continuous fiber reinforced composite material, a dustproof part is arranged, after the printer works, under the action of an electric push rod, a hollow batten can abut against the lower end of a spray head, and then the dustproof effect on the spray head is achieved; external dust is prevented from entering the inside of the spray head to pollute the spray head, and when the spray head needs to be used, a hollow batten can be automatically opened, and the printer can conveniently conduct printing work.

Owner:JIANGSU UNIV OF TECH

A 3D printed microwave heating mechanism

ActiveCN107901403BImprove plasticityAvoid heatingManufacturing heating elements3D object support structuresEngineeringMicrowave shielding

The invention discloses a 3D-printed microwave heating mechanism. The microwave heating mechanism comprises a 3D-printed rack and a lifting mechanism arranged at the bottom part of an inner cavity ofthe 3D-printed rack; the lifting mechanism is composed of an electric push rod vertically arranged at the bottom end of the 3D-printed rack and a printing platform horizontally installed at the top end of the electric push rod, and two ends of the printing platform are connected to the inner side wall of the 3D-printed rack through clamping blocks in a sliding mode; the inner side wall of the 3D-printed rack is provided with microwave flow guide covers positioned at the top part of the printing platform, and two ends of the microwave flow guide covers are provided with microwave generators with consistent structures; the sides, close to the inner cavity of the 3D-printed rack, of the microwave flow guide covers are embedded with flow guide covers; and tail ends of the flow guide covers areconnected with microwave outlet rings, wherein upper microwave shielding frames are arranged at the top ends of the microwave outlet rings, lower microwave shielding frames are arranged at the bottomends of the microwave outlet rings, and the upper microwave shielding frames and the lower microwave shielding frames are consistent in internal structures. The 3D-printed microwave heating mechanismhas the advantages of being reasonable in structural design and worthy of popularization and application.

Owner:DONGGUAN EONTEC CO LTD +1

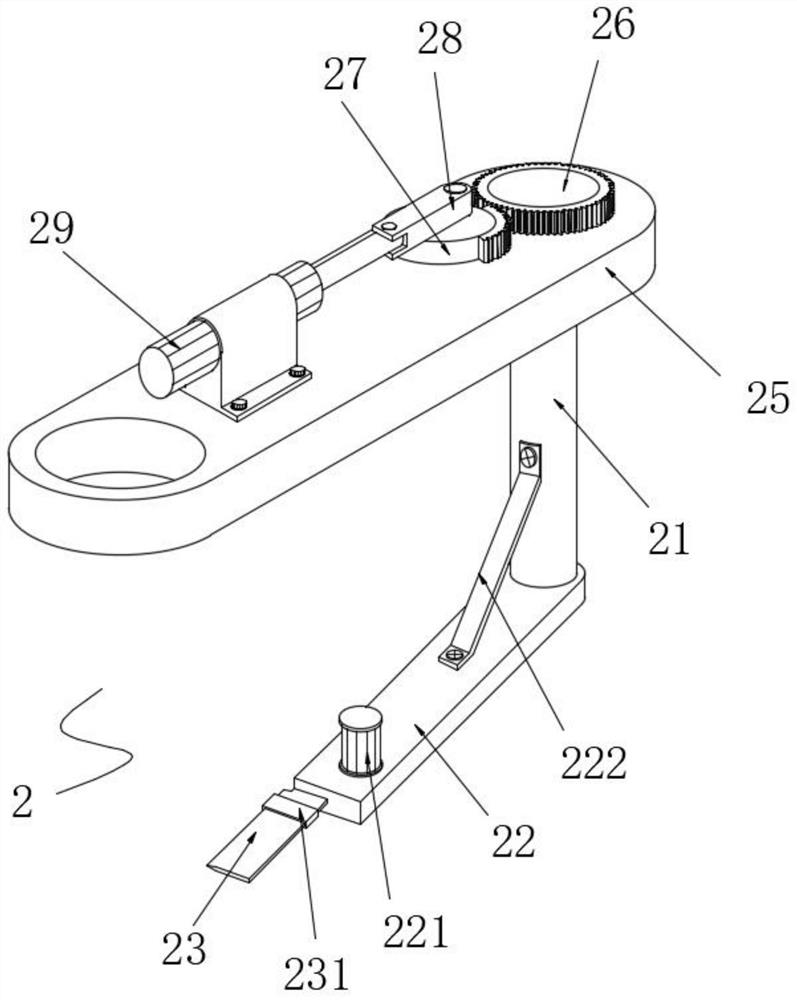

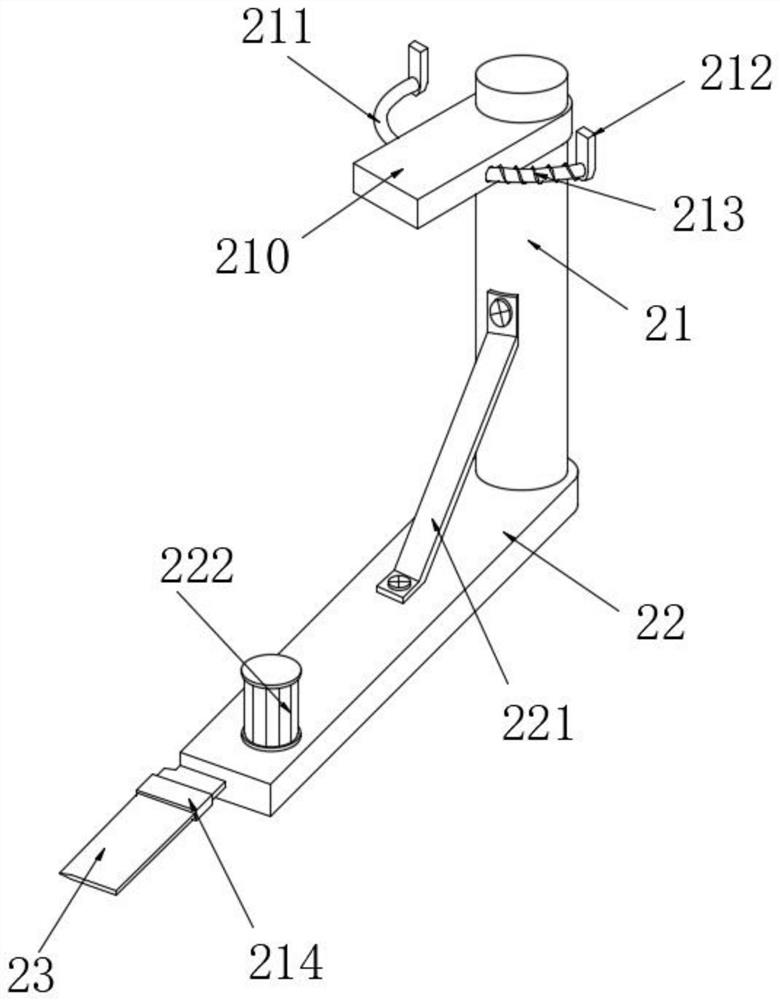

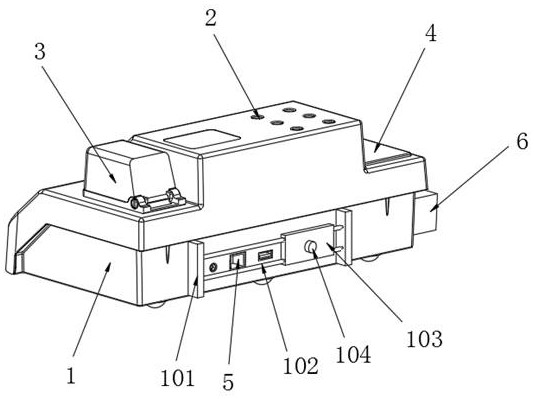

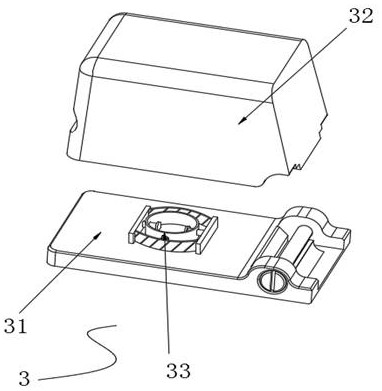

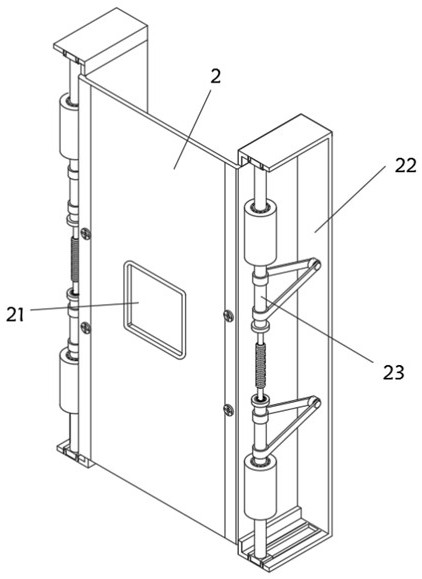

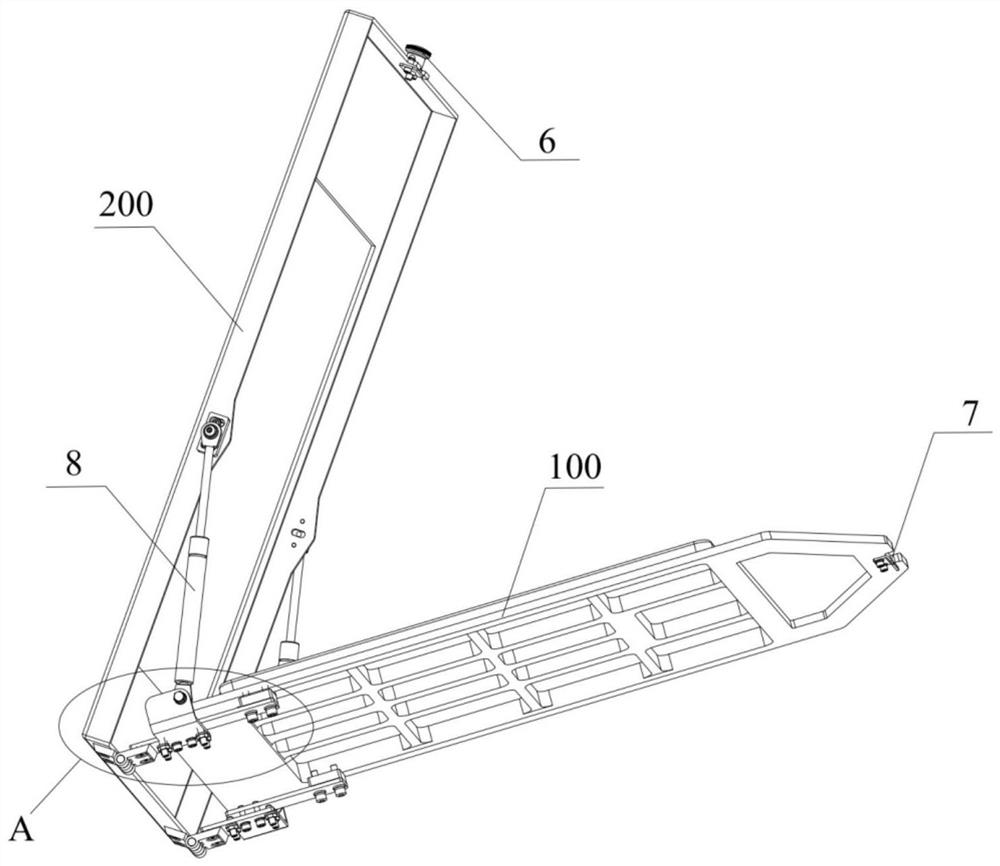

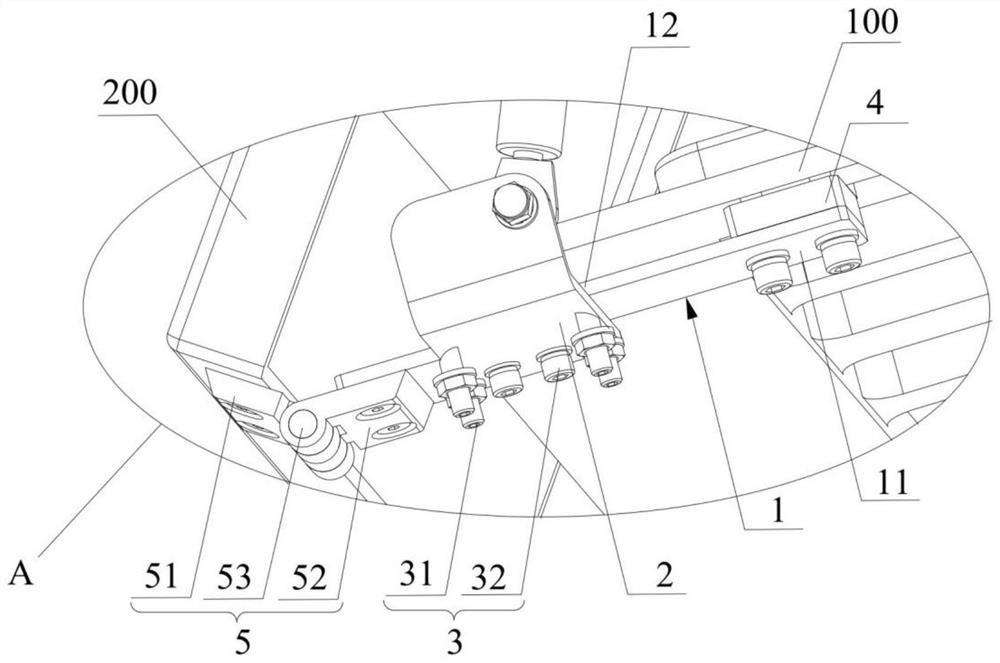

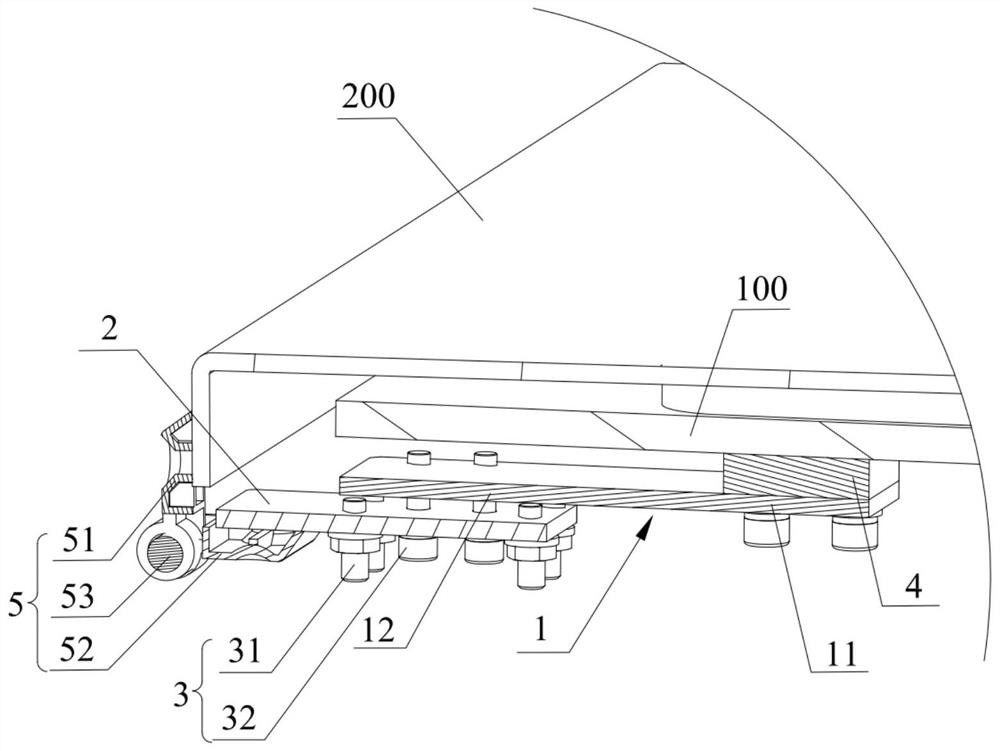

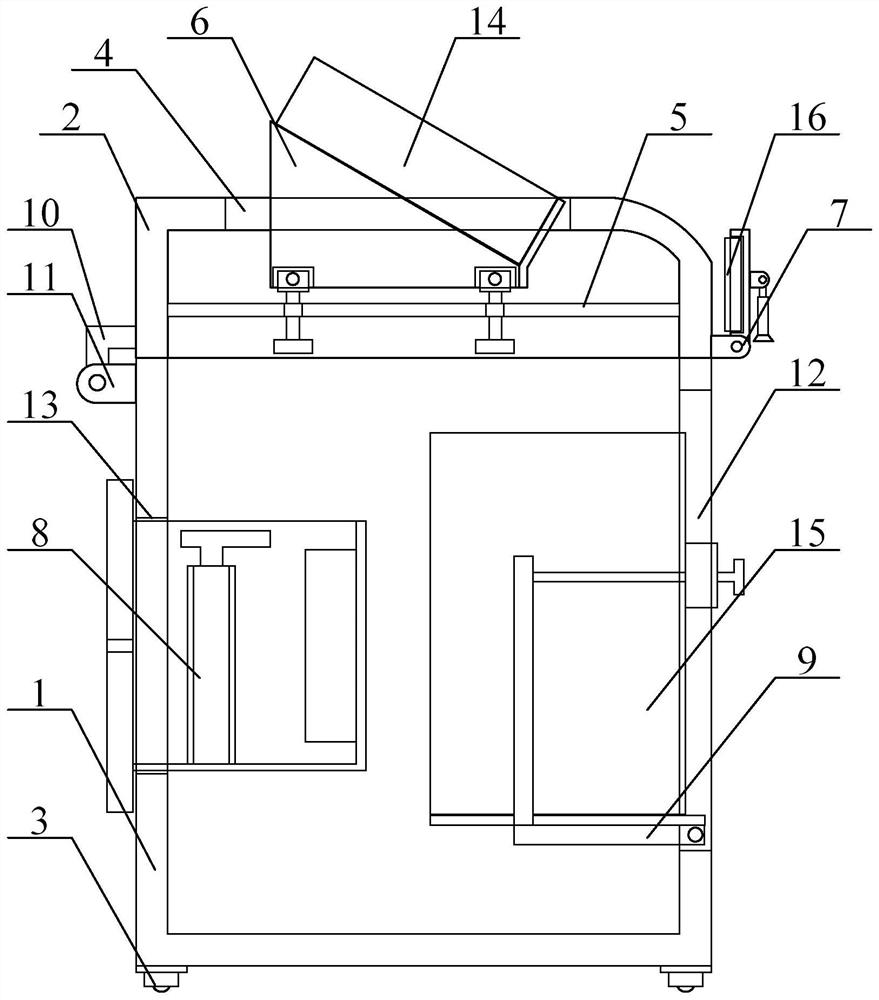

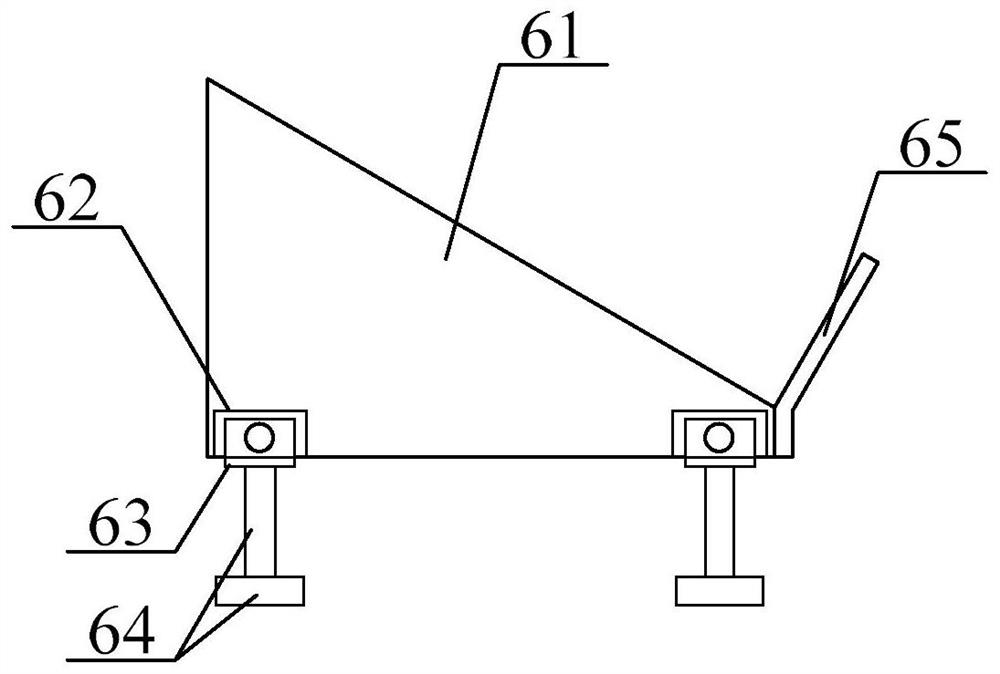

Platen spacing adjusting mechanism and printing machine

PendingCN113858785AImprove work efficiencyImprove consistencyRotary pressesOther printing apparatusBackplaneCantilever

The invention belongs to the technical field of printing machines, and discloses a platen spacing adjusting mechanism and a printing machine which are used for adjusting the spacing between a bottom plate and a cover plate of the printing machine.The distance adjusting mechanism of the bedplate comprises a connecting plate, a connecting seat and an adjusting piece, the connecting plate comprises a connecting end and a cantilever end, the connecting end is connected to the bottom plate, and the cantilever end is arranged below the bottom plate in a suspended mode;the connecting base is connected to the cantilever end of the connecting plate and rotationally connected to the cover plate.The adjusting piece is used for adjusting the distance between the bottom plate and the cover plate by adjusting the distance between the connecting plate and the connecting base.According to the distance adjusting mechanism of the bedplate, one end of the connecting base is connected to the cover plate, the other end of the connecting base is connected to the cantilever end of the connecting plate, when the cantilever end of the connecting plate is subjected to force in the vertical direction and then is bent and deformed, the cover plate is indirectly installed at the cantilever end of the connecting plate, and the distance between the cover plate and the bottom plate is changed;and the effect of automatically adjusting the distance is achieved.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

All-in-one computer image transmission processing equipment

ActiveCN114055969AAdjustable angleEasy to adjustEnergy efficient computingOther printing apparatusWireless transmissionComputer printing

The invention provides all-in-one computer image transmission processing equipment which comprises a machine shell, a machine cover, universal balls, a display hole, a supporting frame, a rotatable adjusting supporting base structure, a rotatable supporting operation table structure, a pluggable transmission frame structure, a rotatable supporting fixing frame structure, a rotating rod, a U-shaped base, a printing hole, a pluggable hole, an all-in-one machine mechanism, a printing machine body structure, and a treatment operation equipment mechanism; the machine cover is arranged at the upper end of the machine shell; the universal balls are arranged at the four corners of the lower end of the machine shell respectively. The display hole is formed in the middle of the upper end of the machine cover. Through the arrangement of the shielding cover, the fixing frame, the network card mechanism, the wireless transmission module mechanism and the all-in-one machine mechanism, wired and wireless transmission work can be conveniently carried out through the network card mechanism and the wireless transmission module mechanism in the use process, and image transmission work can be conveniently carried out in the use process.

Owner:SHENZHEN WEIGUANTONG IND CO LTD

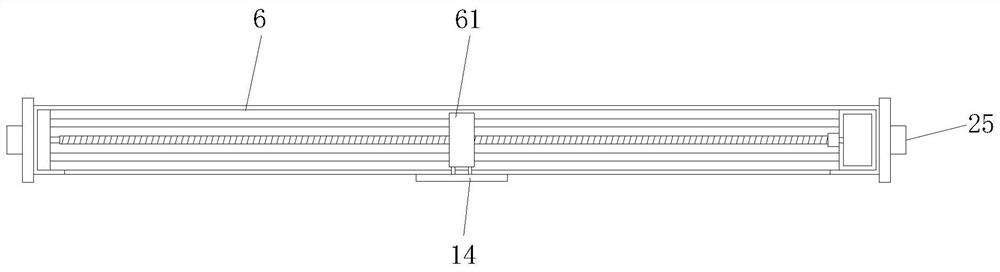

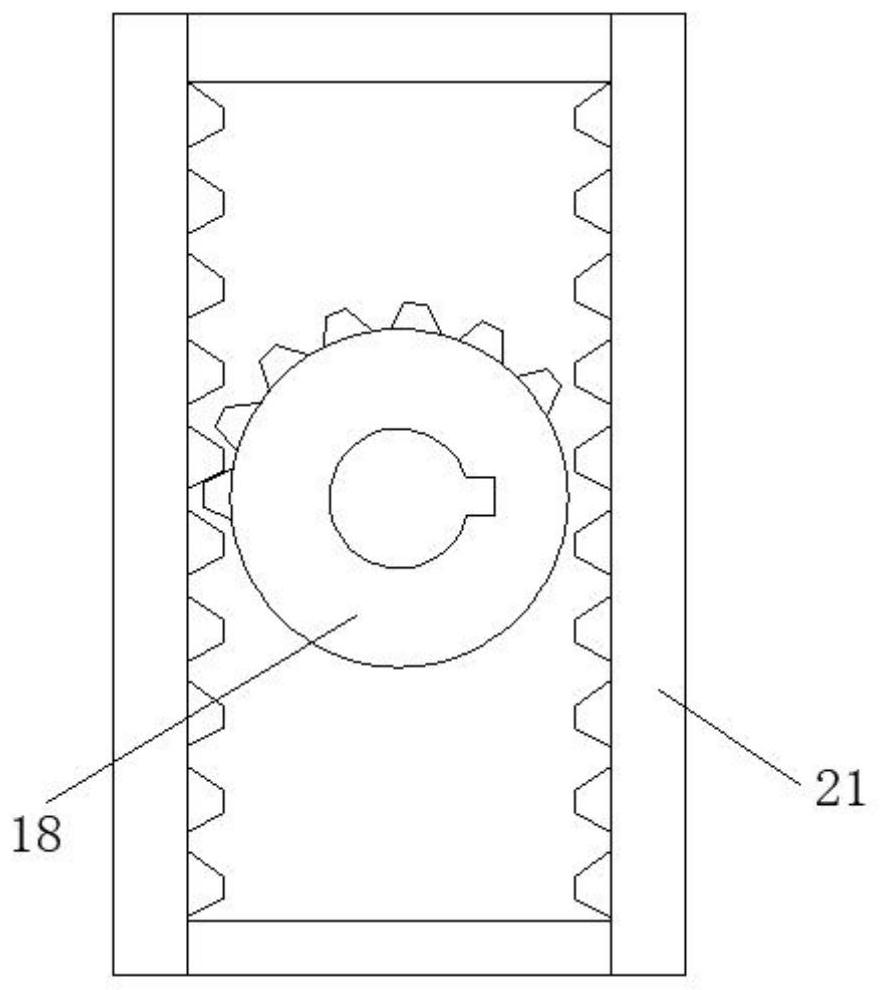

Paper winding device capable of avoiding paper core shifting and used for printer

InactiveCN108975035AAvoid offsetHas a fixed effectPile receiversOther printing apparatusPulp and paper industryConductor Coil

The invention discloses a paper winding device capable of avoiding paper core shifting and used for a printer. The paper winding device comprises a box and is characterized in that an inlet is formedin the upper portion inside the box, a first fixing shaft penetrates a box door, a rectangular sprayer penetrates the box, a fixing rod is arranged on the upper portion inside the box, a water tank isfixed at the right end of the box, the lower portion inside the box is provided with a second hole, a clamp block is arranged inside the second hole, a storage plate is located on the inner side of the clamp block, the left end inside the storage plate is provided with a first hole, a second fixing shaft is arranged inside the first hole, an a fixing plate is fixed to the inner side of the secondfixing shaft. The paper winding device has the advantages that paper core shifting during winding can be avoided, paper can be slightly wetted, the paper can be conveyed out to facilitate collecting,and the space occupation of the whole device can be freely adjusted.

Owner:湖州天骊正隆电子科技有限公司

A printing method for high-speed regular and tapered cylinder printing equipment

ActiveCN109334273BConvenient printing workImprove work efficiencyTypewritersOther printing apparatusStructural engineeringMechanical engineering

The invention discloses novel high-speed regular and tapered cylinder printing equipment and a method. The novel high-speed regular and tapered cylinder printing equipment comprises a frame, a first servo motor, a headstock, a first UV lamp and a second UV lamp, wherein the first servo motor is arranged above the left end of the frame, a cross beam shaft is arranged on the right end of the first servo motor, the cross beam shaft is connected with the frame, the headstock is arranged on the right end of the cross beam shaft, the headstock is connected with the frame, a first nozzle, a second nozzle, a third nozzle, a fourth nozzle and a fifth nozzle are arranged on the headstock, a waste ink box is arranged below the headstock, and a mounting groove is formed in the bottom end of the frame.According to the novel high-speed regular and tapered cylinder printing equipment and the method, the inclination of tapered workpieces can be adjusted by virtue of stations and auxiliary fixtures, and the surfaces of the workpieces and the nozzles can be effectively kept horizontal, so that irregular cylinders can be conveniently printed by the printing equipment.

Owner:浙江普崎数码科技有限公司

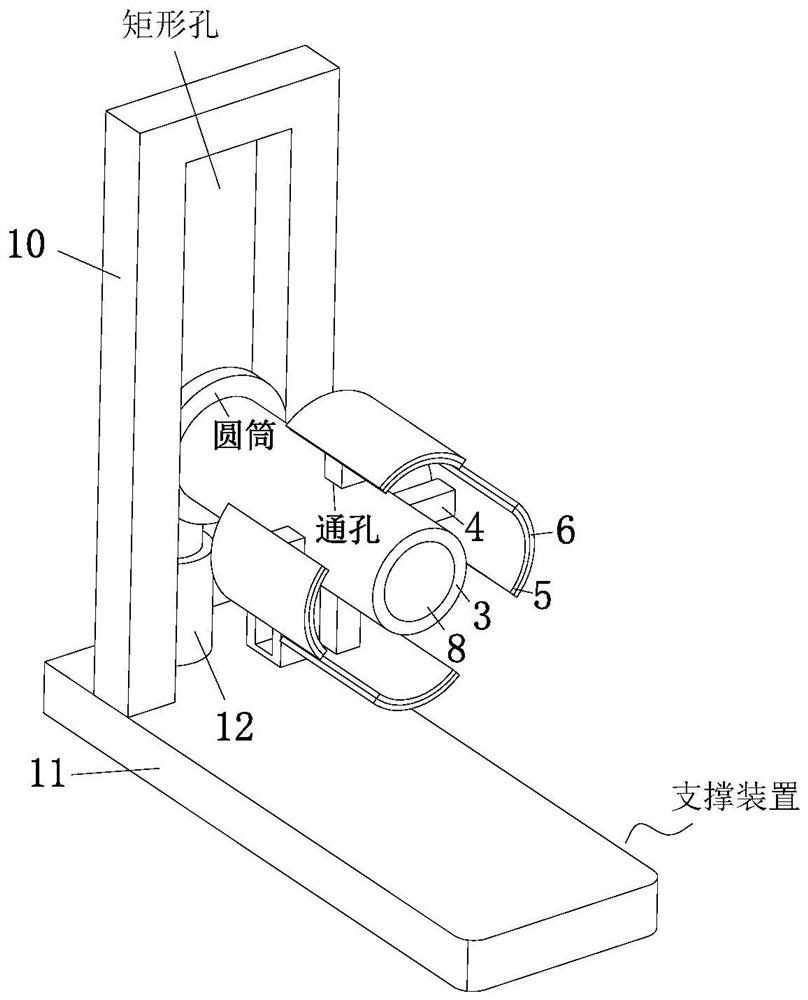

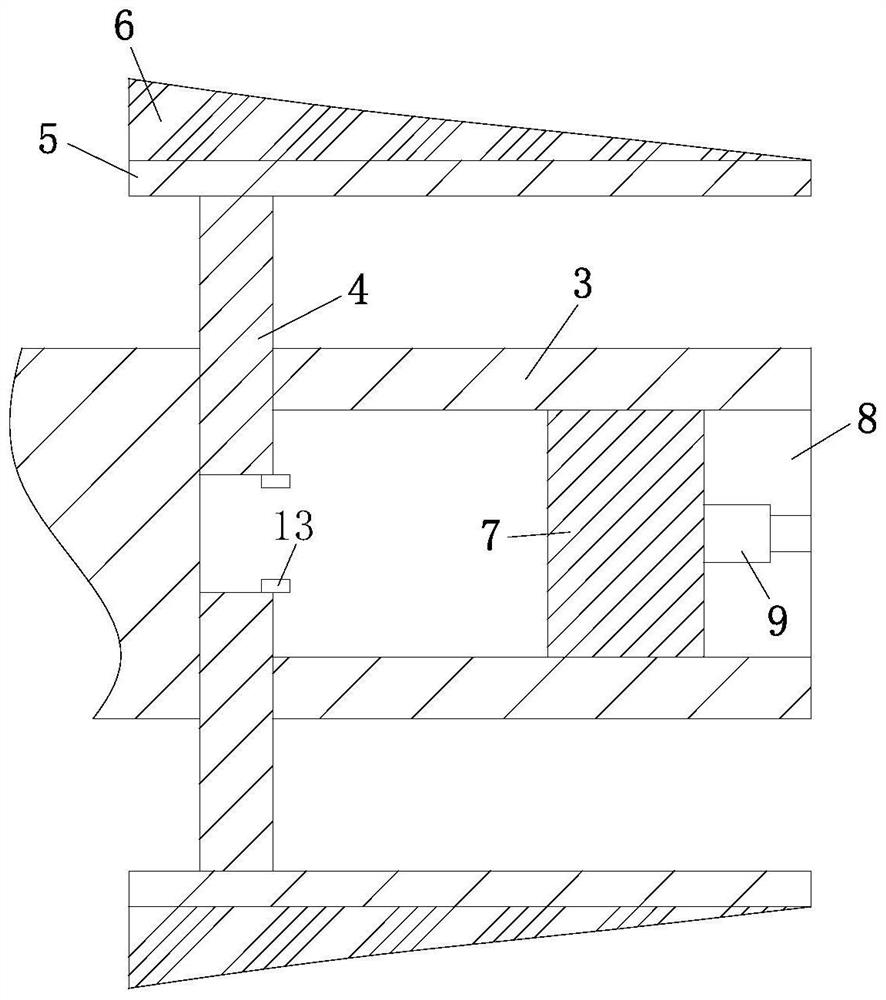

Precise electronic ceramic film screen printing machine

PendingCN114013175AImprove work efficiencyIncrease the scope of applicationScreen printersScreen printingRotational axisTextile printer

The invention belongs to the technical field of ceramic production equipment, and particularly relates to a precise electronic ceramic film screen printing machine which comprises a main frame, a supporting device, a printing device and a controller. The supporting device comprises a vertical plate and a transverse plate; a rectangular hole is formed between the two faces, facing the main frame, of the vertical plate; a cylinder is connected in the rectangular hole in a sliding manner; a rotating shaft is rotationally connected into the cylinder; a groove is formed in the end, away from the main frame, of the rotating shaft; a pressing plate is connected into the groove in a threaded transmission sealing mode; and a positioning block is connected to the rotating shaft in a sliding and sealing manner. According to the machine, hydraulic oil in the groove is extruded through the pressing plate to be matched with the positioning block, so that ceramic of different sizes and different shapes can be printed, the supporting device does not need to be replaced, the printing working process of the ceramic of different sizes is facilitated, and then the ceramic printing working efficiency of the screen printing machine is improved; and the application range of the screen printing machine is widened.

Owner:朱尹颖

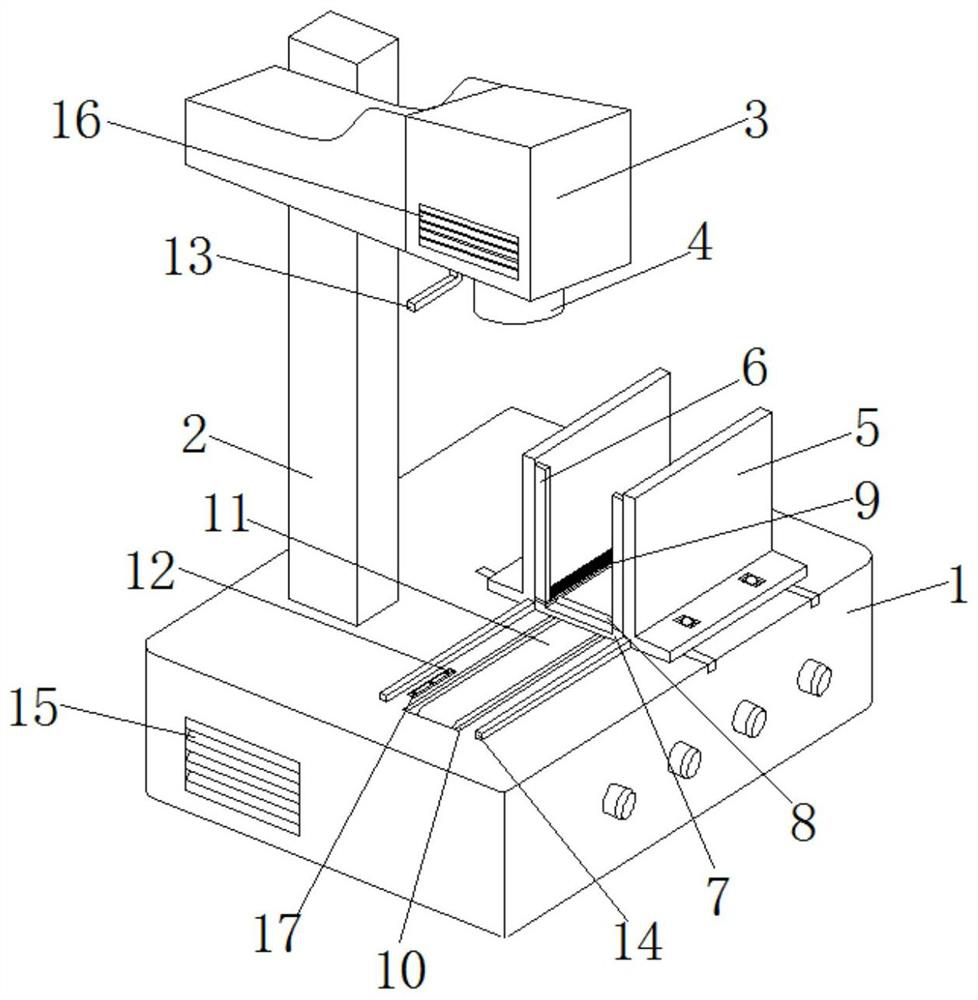

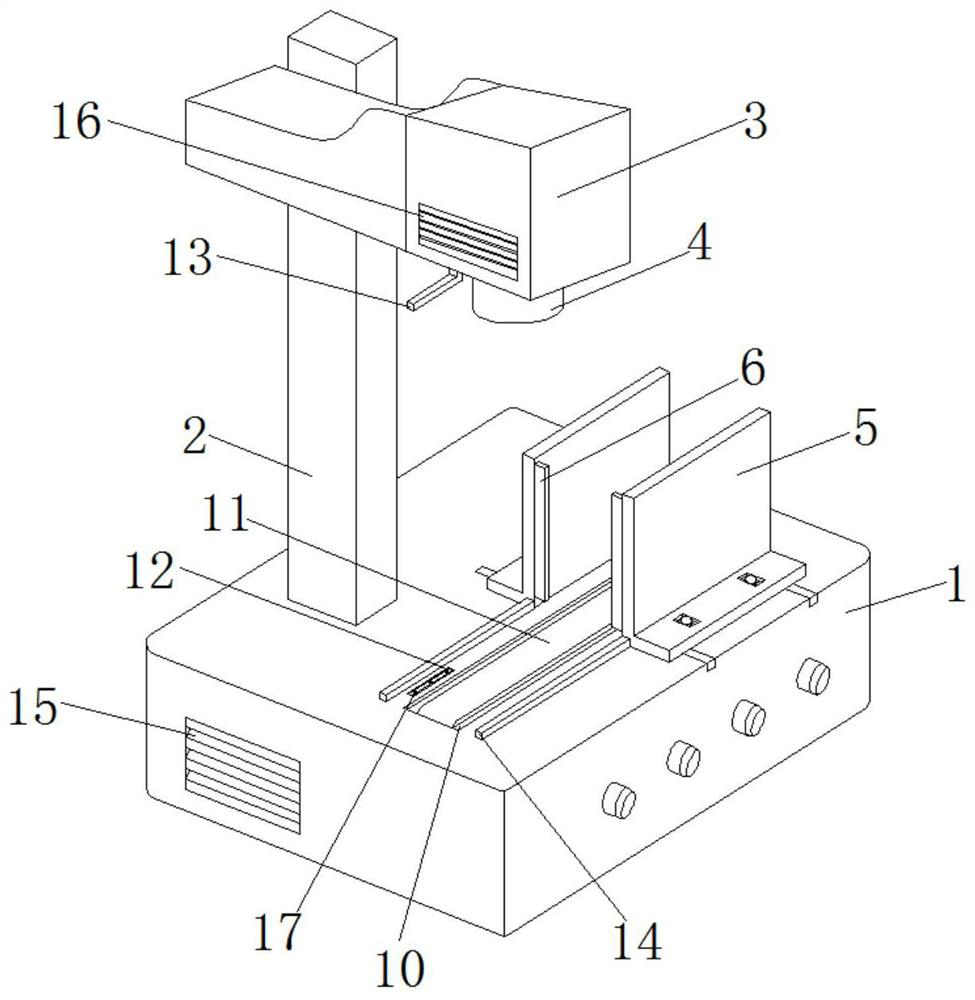

Adjustable full-automatic laser printer and printing method thereof

PendingCN112477442AEasy to adjustEasy to useTypewritersOther printing apparatusEngineeringMechanical engineering

The invention discloses an adjustable full-automatic laser printer and a printing method thereof. The adjustable full-automatic laser printer comprises a control box, wherein a supporting block is fixedly installed at the upper end of the control box, a main machine box is fixedly installed at the front end of the supporting block, and a laser head is fixedly installed at the lower end of the mainmachine box; and symmetrical first limiting blocks are movably installed at the upper end of the control box, second limiting blocks are fixedly installed on the inner walls of the left ends and theright ends of the first limiting blocks, a movable plate is movably arranged at the upper end of the control box, and symmetrical inclined plates are fixedly installed at the upper end of the movableplate. According to the adjustable full-automatic laser printer and the printing method thereof, by arranging the movable plate and the inclined plates, the movable plate and the inclined plates of specific specifications are used for limiting and fixing to-be-printed objects, and the to-be-printed objects of different specifications can be rapidly fixed; and by arranging a first infrared gratingand a second infrared grating, the effect of automatically turning on and turning off the laser head is achieved, printing work of the laser head is facilitated, and use is convenient.

Owner:广州安联电气有限公司

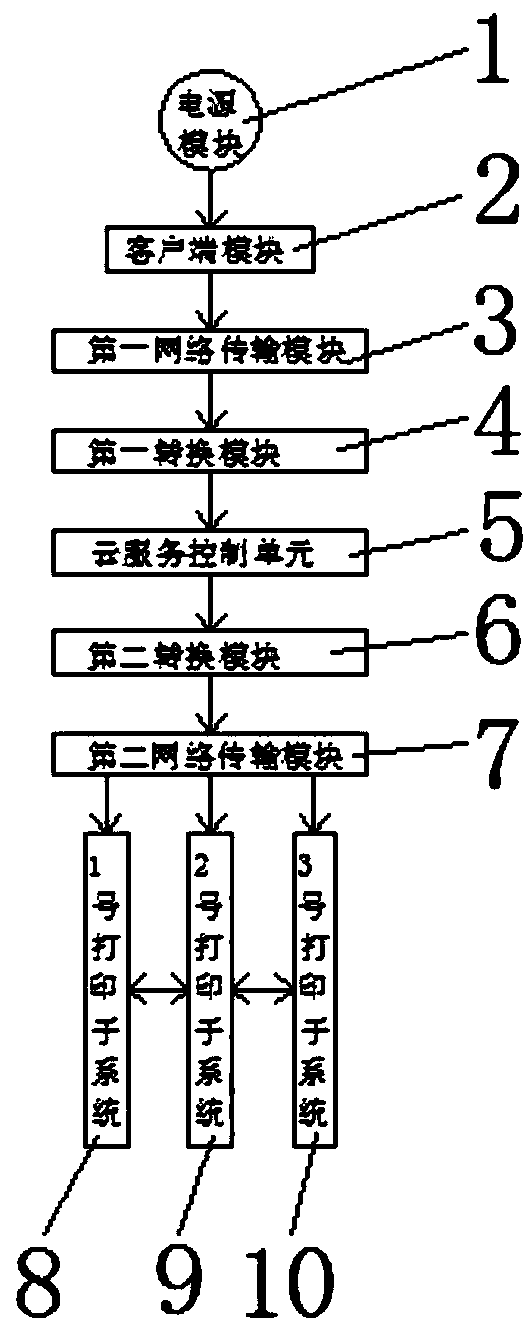

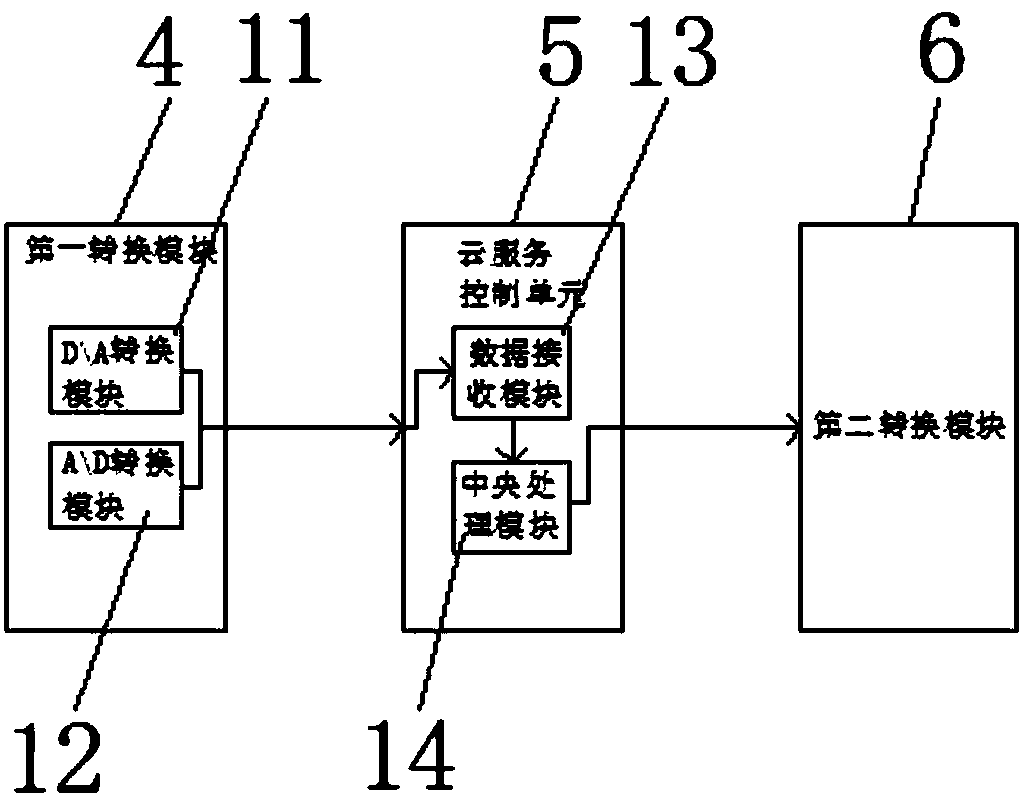

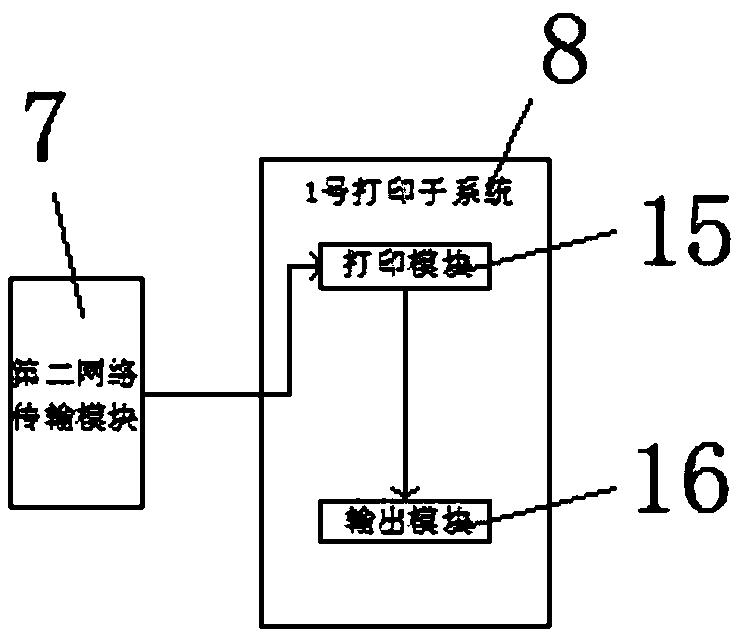

Cloud printing management system based on Internet

InactiveCN108897503AImprove confidentialityConvenient printing workTransmissionDigital output to print unitsService controlThe Internet

The invention discloses a cloud printing management system based on the Internet. The cloud printing management system comprises a power supply module, a first conversion module and a number printingsubsystem. The output end of the power supply module is electrically connected with a client side module, and the output end of the client side module is electrically connected with a first network transmission module. The first conversion module is electrically connected with the output end of the first network transmission module, and the output end of the first conversion module is electricallyconnected with a cloud service control unit. The output end of the cloud service control unit is electrically connected with a second conversion module. According to the cloud printing management system based on the Internet, the cloud service control unit is arranged and the cloud service control unit comprises a data receiving module and a central processing module. The data uploaded by the client side module can be received by the data receiving module in the cloud service control unit and the data can be analyzed and processed under the effect of the central processing module.

Owner:ANHUI TIANSINU INFORMATION TECH

Multi-station printing device for mask production

PendingCN113601972AEasy to processConvenient printing workRotary pressesPrinting press partsTextile printerEngineering

The invention discloses a multi-station printing device for mask production, and relates to the field of dental treatment instruments. The multi-station printing device comprises a mounting frame, the mounting frame comprises a moving seat, a supporting rod fixed to the moving seat, rectangular frames fixed to the upper end of the supporting rod, a connecting plate fixed between the two rectangular frames and a mounting vertical plate fixed to the top of the connecting plate, and two cloth winding rollers which are symmetrically arranged are mounted on the mounting vertical plate; and a conveying and drying mechanism which is mounted on the mounting frame and is used for conveying mask cloth on the cloth winding rollers. According to the whole device of the invention, the cloth can be automatically cleaned before being printed, follow-up printing work is facilitated, the cloth can be dried after printing, automatic fixed-length cutting is carried out after drying, cleaning, drying and cutting work of the cloth are mutually linked and supplement each other, and then processing of the cloth is convenient.

Owner:鲁艳芳

Unwinding device for digital printing machine

InactiveCN112406331AEasy to cleanAvoid dustMechanical cleaningPressure cleaningTextile printerStructural engineering

The invention discloses an unwinding device for a digital printing machine. The unwinding device comprises a moving base, wherein a left fixed plate, a right vertical plate and a fixed vertical plateare fixed to the top of the moving base in the vertical direction; a hollow mounting plate is fixed between the upper end of the left fixed plate and the upper end of the right vertical plate; a U-shaped plate is fixed to the top of the hollow mounting plate; the fixed vertical plate is positioned between the left fixed plate and the right vertical plate; a longitudinal rotary shaft rod is rotatably mounted at the upper end of the fixed vertical plate; a longitudinal material roll is detachably fixed to the rear end of the rotary shaft rod; a worm gear which is positioned on the front side ofthe fixed vertical plate is fixed to the front end of the rotary shaft rod; and a vertical rotating vertical rod is rotatably mounted on the hollow mounting plate. The whole device is simple in structure and is low in manufacturing cost, can be used for unwinding and also can perform clearing and dust removal of the fabrics, and can conveniently do subsequent printing operations; and the whole device is simple in structure, low in manufacturing cost, is good in using effect, and is flexible and convenient to use.

Owner:上海御契纺织科技有限公司

3D printer

InactiveCN112873833AAvoid wastingAchieve fixationManufacturing platforms/substratesGrinding carriagesComputer printing3d printer

Owner:徐同强

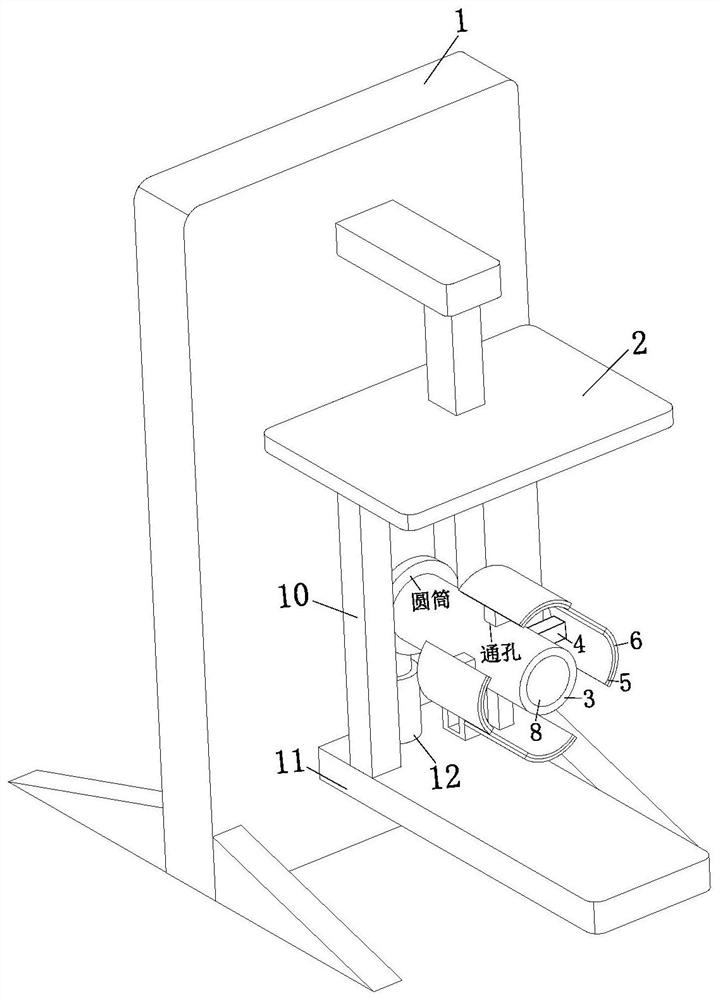

Handheld green printing device and printing method

The invention relates to the technical field of printing, in particular to a handheld green printing device and a printing method. The handheld green printing device comprises a printing head, wherein a handheld grip used for holding is installed at the bottom of the printing head, an ink box used for supplying ink is installed on the inner wall of the printing head, a printing hole used for discharging ink is formed in one side of the printing head, a baffle is arranged on the side, close to the printing hole, of the printing head, a through hole matching the printing hole in size is formed in the center of the baffle, side frames are symmetrically installed on the two sides of the baffle, and a pair of positioning devices are symmetrically installed on the inner walls of the side frames. According to the device, the design reduces gaps between the printing hole and a packaging box are reduced, printing ink accumulation is avoided, printing ink waste is reduced, energy is saved, environment friendliness is achieved, and green printing is achieved.

Owner:广东宝丰数字印刷科技有限公司

High-efficiency multi-head 3D printer

InactiveCN109664501AImprove work efficiencyFlexible adjustment3D object support structuresApplying layer means3d printerIndustrial engineering

The invention discloses a high-efficiency multi-head 3D printer and relates to the technical field of 3D printers. The 3D printer comprises a worktable, a lifting box, a supporting table and a adjusting box, wherein the top of the lifting box is opened with a lifting channel; a lifting plate is movably arranged in the lifting channel; a first rack is fixedly connected to one side of the lifting plate; a first gear and a second gear are movably arranged on one side of the lifting channel; the top of the lifting plate penetrates through the top of the lifting channel and fixedly connected with the supporting table. According to the high-efficiency multi-head 3D printer, through the arrangement of a fixture block and a rotating groove, an inserting block is driven by the clockwise rotation ofa printing head when passing through a socket and inserted into a mounting plate to move the fixture block to rotate from one end of the rotating groove to the other end of the fixture block, so thatthe printing head is installed; through coordinating arrangement of four sockets and four inserting blocks, four printing heads can be simultaneously installed, so that the overall work efficiency ofthe 3D printer is higher.

Owner:JIMEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com