Handheld green printing device and printing method

A printing equipment and hand-held technology, applied in the field of hand-held green printing equipment and printing, can solve the problems of affecting the printing effect, ink pushing, and printing ghosting, etc., to achieve smooth sliding, reduce ink waste, and reduce gaps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

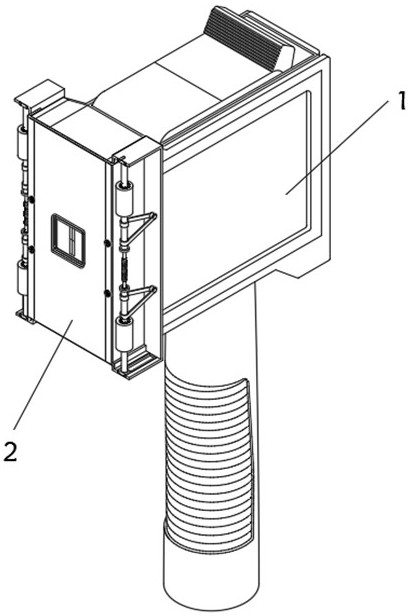

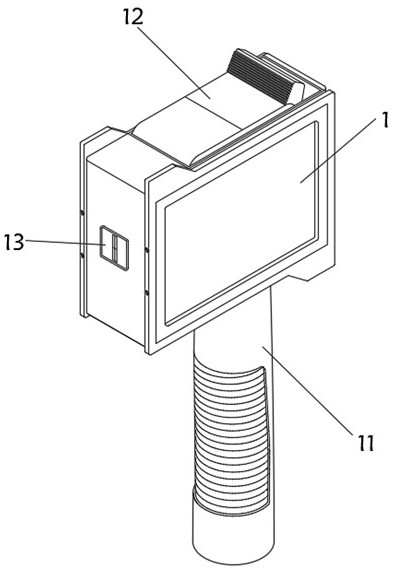

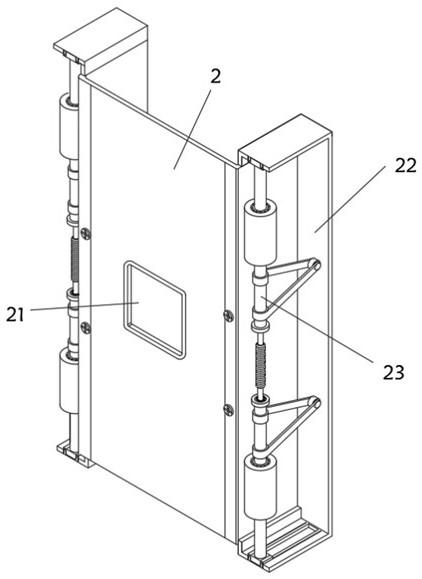

[0040]The present invention provides a hand-held green printing apparatus and a printing method, such asFigure 1 - Figure 8 As shown, including the printhead 1, the bottom of the printhead 1 is mounted with a hand-held grip 11 for grip, and the inner wall of the printhead 1 is mounted for the ink cartridge 12 for ink, and the printhead 1 is opened for ink. The printing hole 13 is provided with a baffle 2 on the side of the print hole 13, and the center position of the baffle 2 is opened with a through hole 21 having a size of the print hole 13, and the baffle 2 is installed, and the through hole 21 and The print hole 13 is located in the same position, facilitating the ink from the print hole 13, and prints the package, the two sides of the baffle 2, and the side frame 22, the inner wall of the side frame 22 has a pair of positioning devices 23, The positioning device 23 includes a slider 231, a connecting plate 221 in which the upper and lower ends of the side frame 22 is integrall...

Embodiment 2

[0047]As a second embodiment of the present invention, in order to enhance the toughness between the two positioning devices 23, the present invention also provided a connecting rod 3, such asFigure 9 As shown, a connecting rod 3 is mounted between the two restricted plates 236, and the connecting rod 3 is made of a tough plastic material.

[0048]In this embodiment, the connection rod 3 feedstock comprises a PVC resin, a methyl tin heat stabilizer, a stearic acid, an MBS resin, and a rubber particle, which is prepared as follows:

[0049](1) Mixing PVC resin, methyl tin heat stabilizer, stearic acid, MBS resin, and rubber particles were added to the high-speed mixer for 5 minutes;

[0050](2) will be mixed

Embodiment 3

[0052]As a third embodiment of the present invention, in order to prevent the slider 231 from slipping in the chute 222, the present invention also improves the slider 231 as a preferred embodiment, such asFigure 10 - Figure 12As shown, both ends of the slider 231 are configured with "L" plate 2311, "L" plate 2311, and the slider 231 are integrated structures, so that "L"-shaped plate 2311 and slider 231 integrally integrity, not easy After the break, the "L" plate 2311 and the slider 231 have a gap groove 2312, and the connecting plate 221 is adjacent to both ends of the slide 222, and the "L"-shaped plate 2311 and the limit slot 223 slide connection. The "L"-shaped plate 2311 slides in the limit slot 223, and the sliding slider 231 slides smoothly in the chute 222, and the slider 231 is positioned in the slide 222.

[0053]Among them, a plurality of rollers 2314 having a strip groove 2313 in the "L"-shaped plate 2311, and the strip groove 2313 is mounted, and both ends of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com