3D printer

A 3D printer and printing box technology, applied in the direction of 3D object support structure, grinding frame, grinding machine parts, etc., can solve the problems of affecting the printing effect, inconsistent upper and lower shapes of objects, lack of stable devices for machines, etc. To achieve the effect of optimizing the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

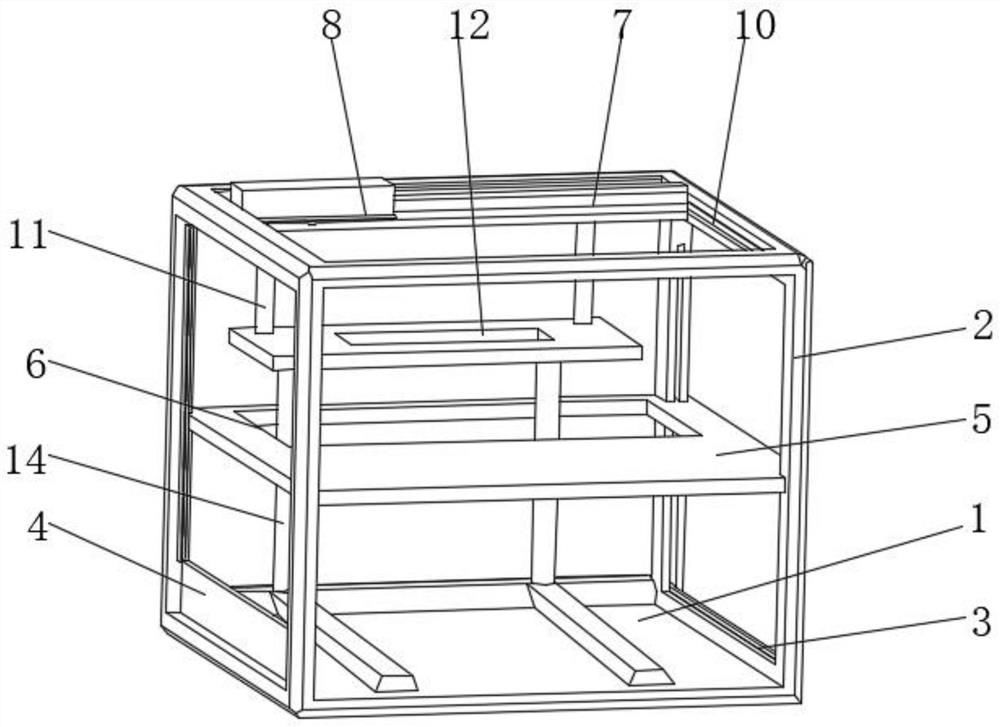

[0029] see Figure 1-2 , the invention provides a technical solution: a 3D printer. Including the printing box 1, the outer surface of the printing box 1 is evenly opened with windows 2, the inner surfaces of the windows 2 on the left and right sides are fixedly connected with the first chute 3, and the inner surface of the first chute 3 is slidably connected with the winding window 4 , the inner surface of the printing box 1 is fixedly connected with a horizontal plate 5, the outer surface of the horizontal plate 5 is provided with a through groove 6, the top and bottom of the printing box 1 are fixedly connected with a sliding track 7, and the outer surface of the top sliding track 7 is slidingly connected There is a print head 8, the bottom of the print head 8 is fixedly connected with a grinding mechanism 9, and the inner surface of the top window 2 is uniformly provided with a second chute 10, and the inner surface of the second chute 10 slides with the left and right end...

Embodiment 2

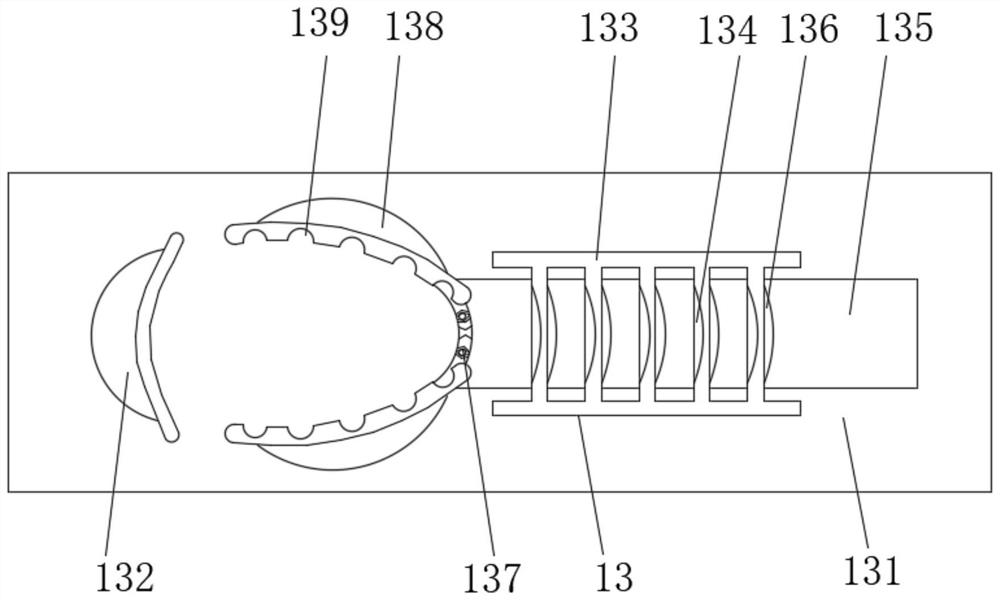

[0031] see figure 2 The present invention provides a technical solution: the fixing mechanism 13 includes a fixing frame 131, the bottom of the fixing frame 131 is fixedly connected with the top of the console 12, the left side of the fixing frame 131 is fixedly connected with an arc pad 132, and the right side of the fixing frame 131 The side is fixedly connected with a layer frame 133, and the outer surface of the layer frame 133 is uniformly provided with an arc-shaped curved surface 134, and the inner surface of the fixed frame 131 is slidably connected with a sliding rod 135 at the bottom of the layer frame 133, and the outer surface of the sliding rod 135 is fixedly connected. There is an arc-shaped card 136 , and the outer surface of the arc-shaped card 136 is engaged with the outer surface of the arc-shaped curved surface 134 .

[0032]The left side of the sliding rod 135 is fixedly connected with a magnetic rod 137, and the top and bottom of the magnetic rod 137 are ...

Embodiment 3

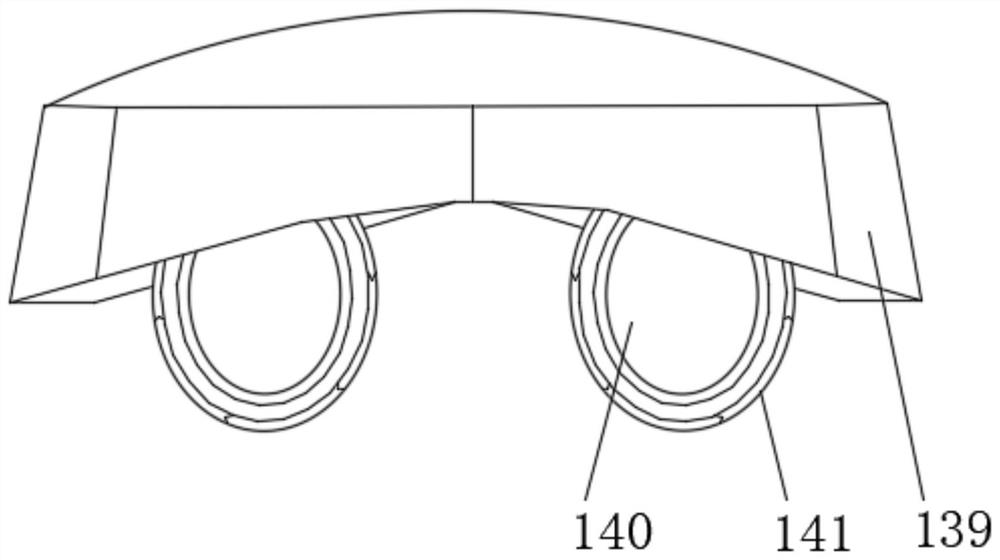

[0034] see Figure 3-5 The present invention provides a technical solution: the destab mechanism 142 includes a connecting rod a1, the outer surface of the connecting rod a1 is rotatably connected to the inner surface of the receiving groove 141, and the bottoms of the two connecting rods a1 are respectively fixedly connected with the first destab assembly (a2 and the second deburring component a3. The thorn edge outside the object is removed to optimize the appearance of the object.

[0035] The first thorn removing assembly (a2) includes a conical column a21, the outer surface of which is fixedly connected to the bottom of the connecting rod a1, and the outer surface of the conical column a21 is evenly distributed with toothed spurs a22.

[0036] The second destab assembly a3 includes an arc-shaped column a31, the top of which is fixedly connected to the bottom of the connecting rod a1, and the bottom of the arc-shaped column a31 is evenly and fixedly connected with a foot-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com