A precision printing error proofing equipment for garment production

A precise printing and error-proofing technology, applied in printing, printing machines, printing devices, etc., can solve the problems of easy movement of clothing, inability to fix clothing, offset printing position, etc., to facilitate printing work and prevent printing position offset. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

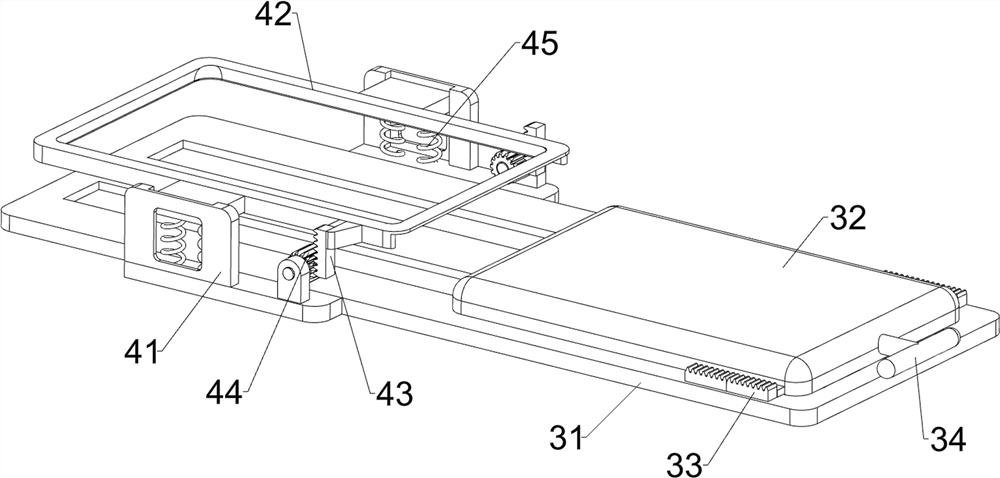

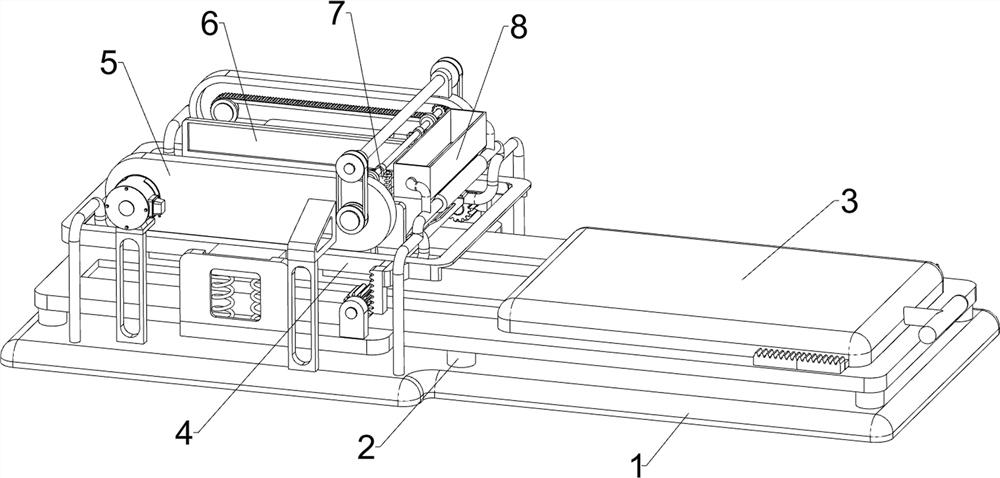

[0027] A precision printing error proofing equipment for garment production, such as figure 1 , figure 2 and Figure 4 As shown, it includes a bottom plate 1, a support column 2, a sliding feed plate mechanism 3, a clamping mechanism 4 and a printing frame mechanism 6. The front and rear sides of the top of the bottom plate 1 are symmetrically connected with a plurality of support columns 2, and a plurality of support columns. A sliding feeding plate mechanism 3 is installed between 2 , a clamping mechanism 4 is installed on the sliding feeding plate mechanism 3 , and a printing frame mechanism 6 is installed on the top of the bottom plate 1 .

[0028] The sliding feeding plate mechanism 3 includes a slotted slide rail plate 31, a placement plate 32, a first gear block 33 and a push rod 34, and a slotted slide rail plate 31 is connected between the top ends of the plurality of support columns 2. The slotted slide rail A placing plate 32 is slidably connected to the plate 31...

Embodiment 2

[0033] On the basis of Example 1, as figure 1 and image 3As shown, a drive mechanism 5 is also included, and the drive mechanism 5 includes a first support frame 51, a guide plate 52, a servo motor 53, a first transmission belt group 54, a rack belt 55, a second transmission belt group 56 and a transmission shaft 57. Two first support frames 51 are connected to the front and rear sides of the left side of the top of the bottom plate 1, a guide plate 52 is connected between the first support frames 51 on the left and right sides, and the top of the first support frame 51 on the left front side is installed with Servo motor 53, a first transmission belt group 54 is rotatably connected to the guide plate 52, the first transmission belt group 54 on the front side is drivingly connected to the servo motor 53, and a rack belt 55 is connected to the belt of the first transmission belt group 54. A transmission shaft 57 is rotatably connected between the top right sides of the two gu...

Embodiment 3

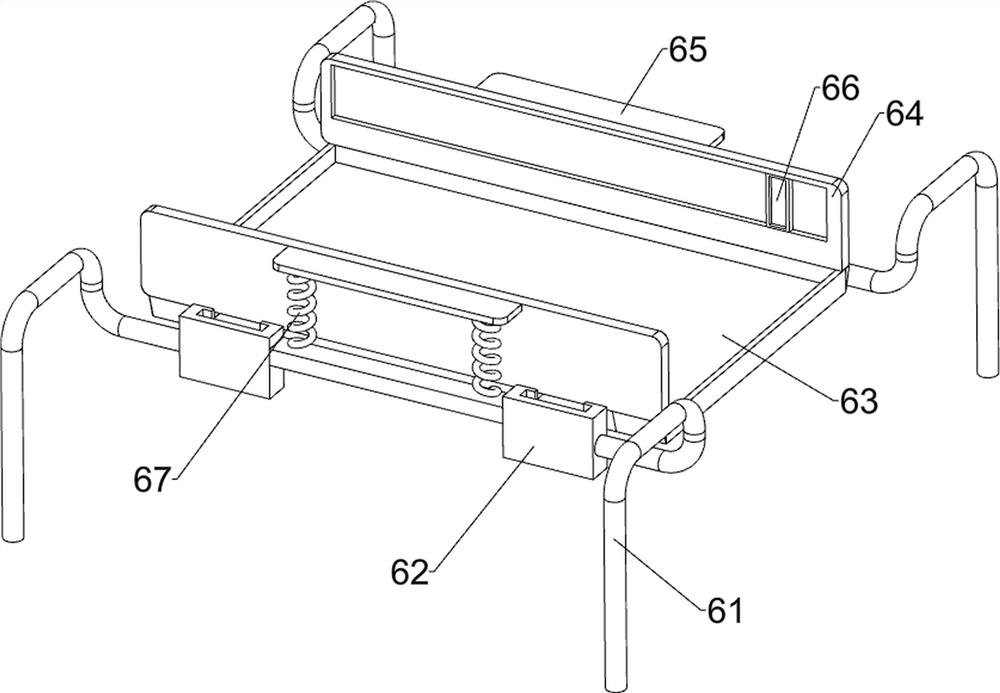

[0037] On the basis of Example 2, as figure 1 and Figure 5 As shown, it also includes a dye replenishing mechanism 8, and the dye replenishing mechanism 8 includes a mounting frame 81, a storage box 82, a guide block 83 and an insert frame 84, and the top right side of the two second support frames 61 is connected with a Mounting frame 81, a storage box 82 is connected to the mounting frame 81, guide blocks 83 are connected to both the front and rear sides of the lower part of the right side of the storage box 82, and a plug-in frame 84 is slidably connected between the two guide blocks 83. The board rack 84 is slidably connected to the storage box 82 .

[0038] The dye can be poured into the storage box 82, and the insert frame 84 can be pulled to the right so that the insert frame 84 does not block the storage box 82, and the dye in the storage box 82 falls on the printing plate 63. After an appropriate amount of dye is dropped on the printing plate 63, the inserting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com