Transportation apparatus for wire retaining poles and a method for producing wire coils

A wire holding and handling device technology, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of complicated operations, easy entanglement of wires, etc., and achieve the effect of simple manufacturing, simple equipment, and suppression of swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

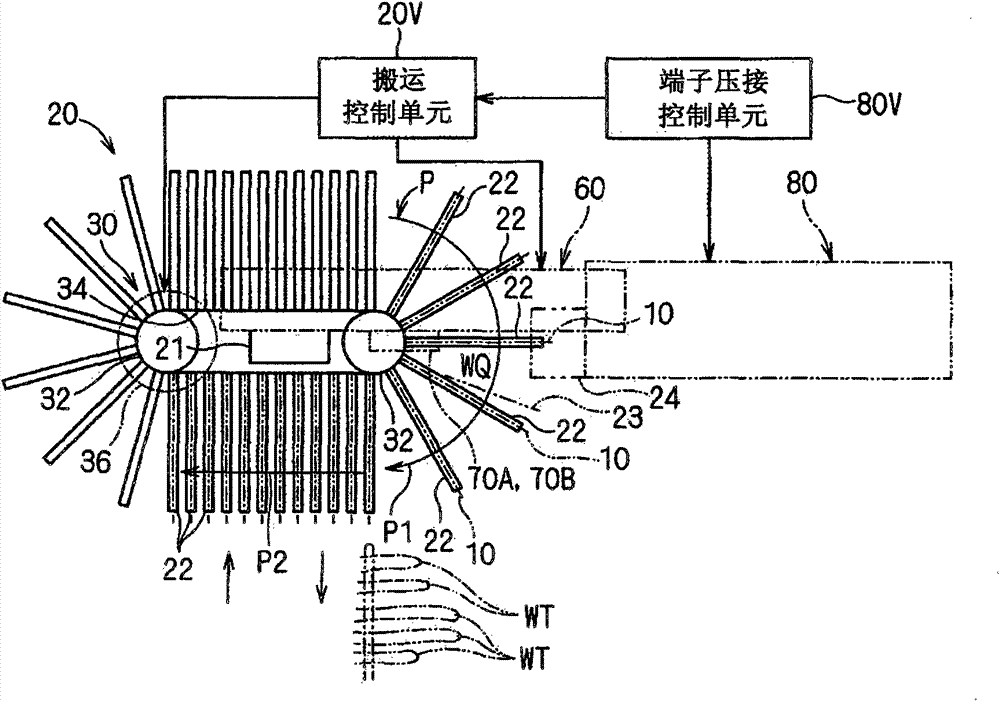

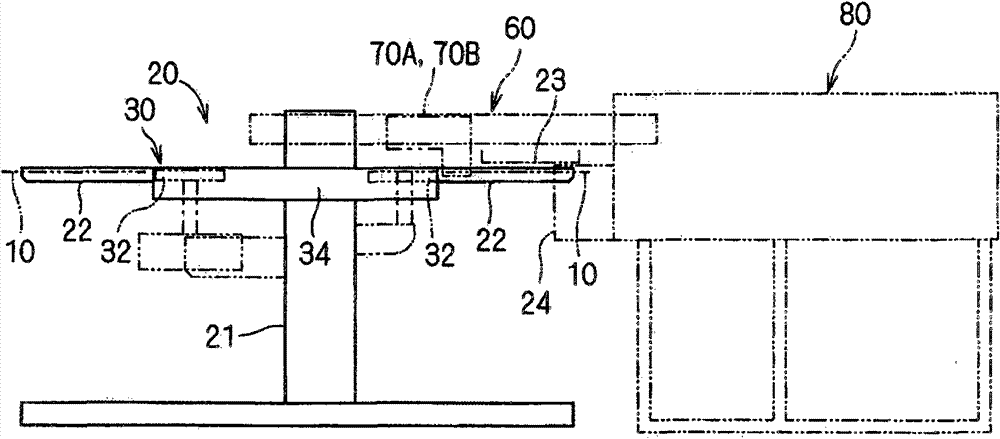

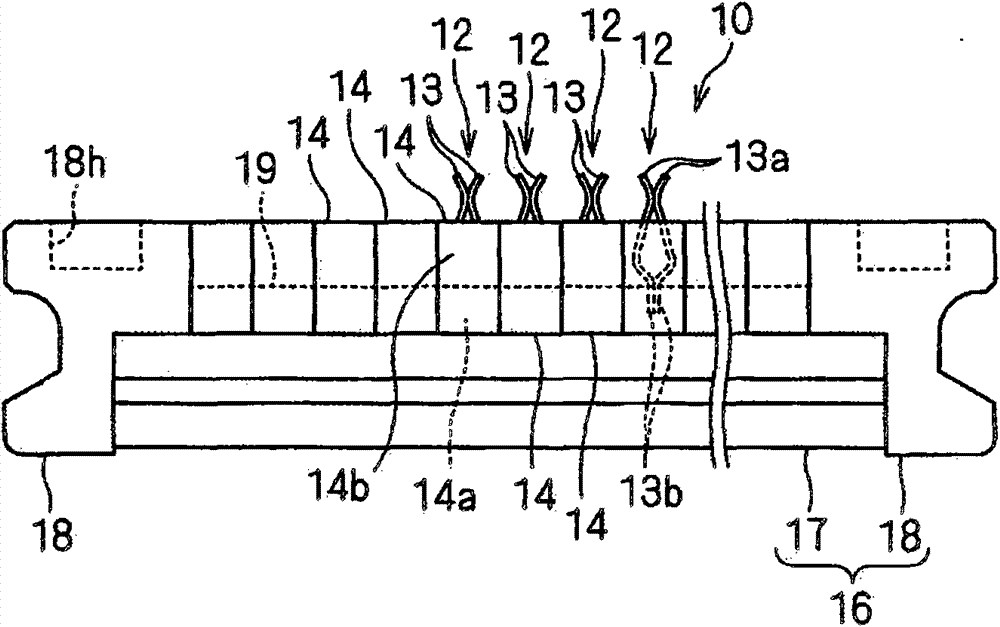

[0043] Hereinafter, an electric wire holding rod conveying device according to the embodiment and an electric wire group manufacturing method using the electric wire holding rod conveying device will be described.

[0044]

[0045] First, a manufacturing example of a wiring harness used in automobiles, various electric equipment, and the like will be described.

[0046] That is, the wire harness is manufactured by bundling a plurality of electric wires in a predetermined wiring form in conformity with the wiring form of a vehicle or various electrical equipment as a wiring destination.

[0047] The manufacturing process of the wire harness is manufactured through, for example, a cutting and pressing process, a subassembly manufacturing process, and a wire harness assembling process.

[0048] The cutting and crimping process is a process of manufacturing an electric wire with a terminal obtained by subjecting the electric wire to a cutting process and a terminal crimping proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com