Multi-station printing device for mask production

A multi-station, mask technology, used in printing, printing machines, rotary printing machines, etc., can solve the problems of long time consumption, low plant space utilization, insufficient processing convenience, etc., to achieve small occupation of plant area and improve space utilization. The effect of high efficiency and convenient printing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

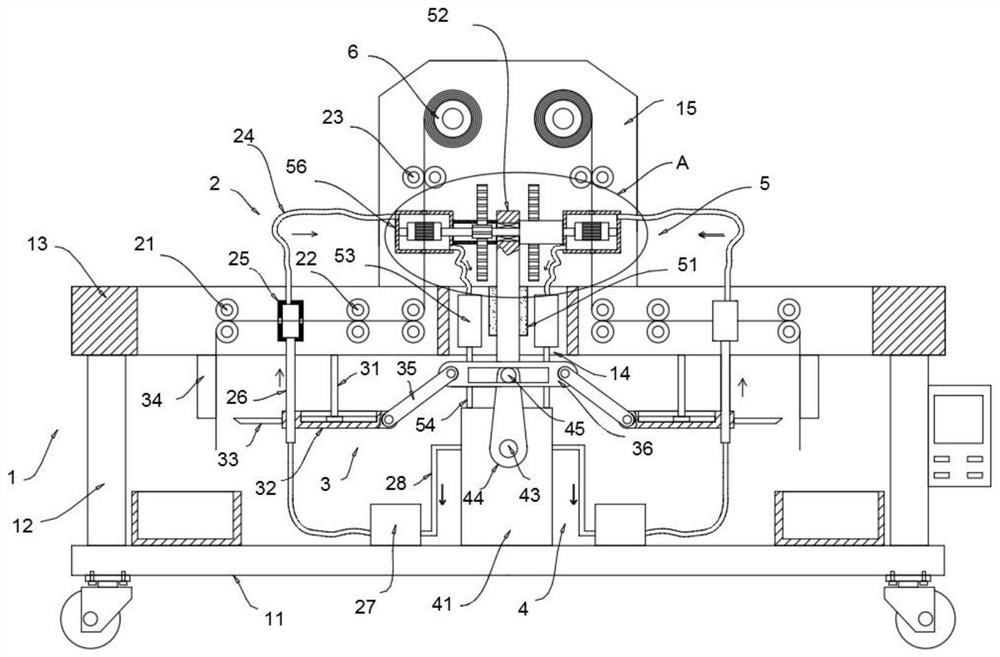

[0044] A kind of multi-station printing device for mask production, comprising:

[0045] Mounting frame 1, mounting frame 1 comprises mobile seat 11, the support bar 12 that is fixed on the mobile seat 11, the rectangular frame 13 that is fixed on support bar 12 upper ends, the connecting plate 14 that is fixed between two rectangular frames 13, is fixed on The installation riser 15 at the top of the connecting plate 14 is installed with two cloth reel rollers 6 which are symmetrically arranged on the installation riser 15 .

[0046] Conveying and drying mechanism 2, conveying and drying mechanism 2 is installed on the mounting frame 1, and it is used for conveying the mask cloth on the cloth roll 6, and carries out printing and drying to mask cloth in the process of conveying.

[0047]Cutting mechanism 3, cutting mechanism 3 is installed on the mounting frame 1 and is used for cutting the dried cloth, it is connected with conveying drying mechanism 2, when cutting mechanism 3...

Embodiment 2

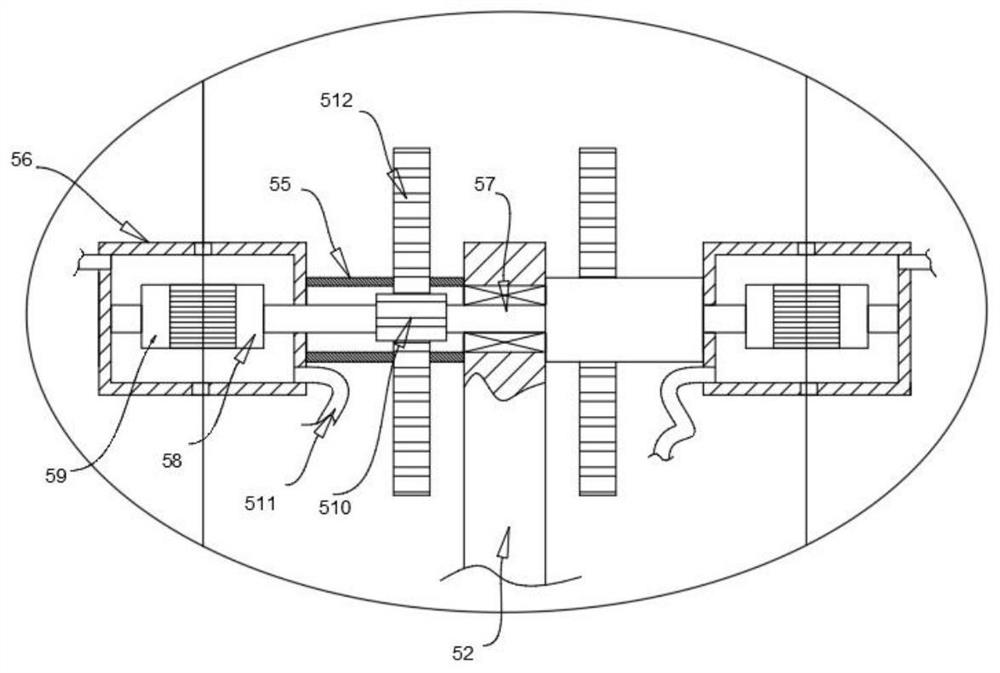

[0054] A multi-station printing device for mask production. On the basis of Embodiment 1, the conveying and drying mechanism 2 includes two groups of lower conveying rollers 21 arranged horizontally in the rectangular frame 13, and two groups of lower conveying rollers. The embossing roller 22 between 21 and the upper transmission roller 23 that the rotation is installed on the vertical plate 15 are installed, and the lower transmission roller 21, the embossing roller 22, the upper transmission roller 23 are all transmitted with cloth.

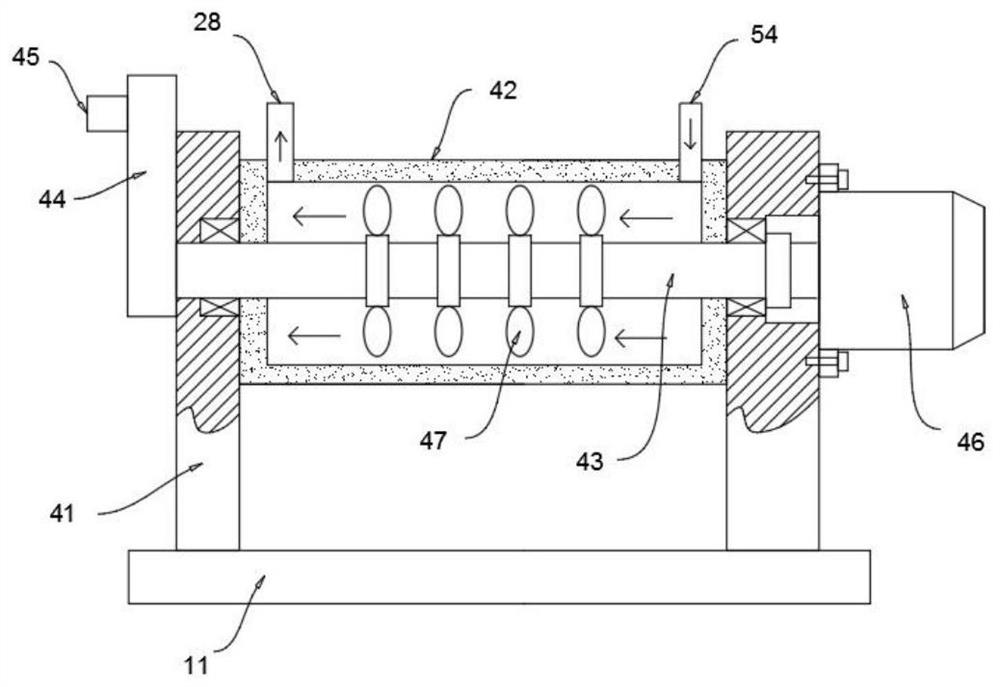

[0055] Between the discharge end of the embossing roller 22 and the corresponding lower transmission roller 21, there is a drying shell 25 that is covered on the cloth and can move laterally. The bottom of the drying shell 25 is fixed and communicated with a vertical first fixed pipe 26. , the lower end of the first fixed pipe 26 communicates with the gas outlet of the electric heating box 27 fixed on the mobile seat 11 through a pipeline.

[...

Embodiment 3

[0059] A multi-station printing device for mask production, on the basis of Embodiment 2, the cutting mechanism 3 includes a knife seat 34 fixed on the bottom of the rectangular frame 13 and a T-shaped guide block 31, and the lower end of the T-shaped guide block 31 is slidably fitted There is a laterally movable connecting plate 32;

[0060] The connecting plate 32 is fixed with a cutting knife 33 for cutting the cloth near the side of the corresponding knife seat 34, and the drive pin 45 is slidingly fitted with a horizontal lifting frame 36; An inclined driving rod 35 is rotatably connected between the corresponding ends, and the first fixing pipe 26 is embedded and fixed on the corresponding connecting plate 32 .

[0061] In this embodiment, the connecting plate 32 is provided with a chute with a convex cross-section, and the lower end of the T-shaped guide block 31 has a limit slider slidably fitted in the chute. The four corners of the bottom of the mobile seat 11 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com