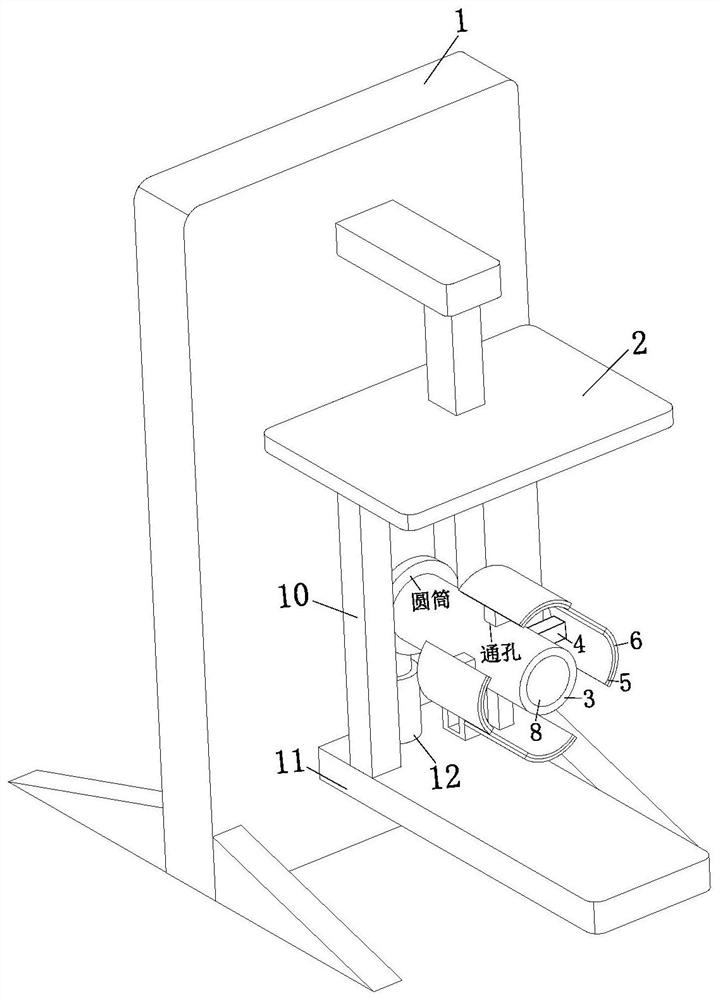

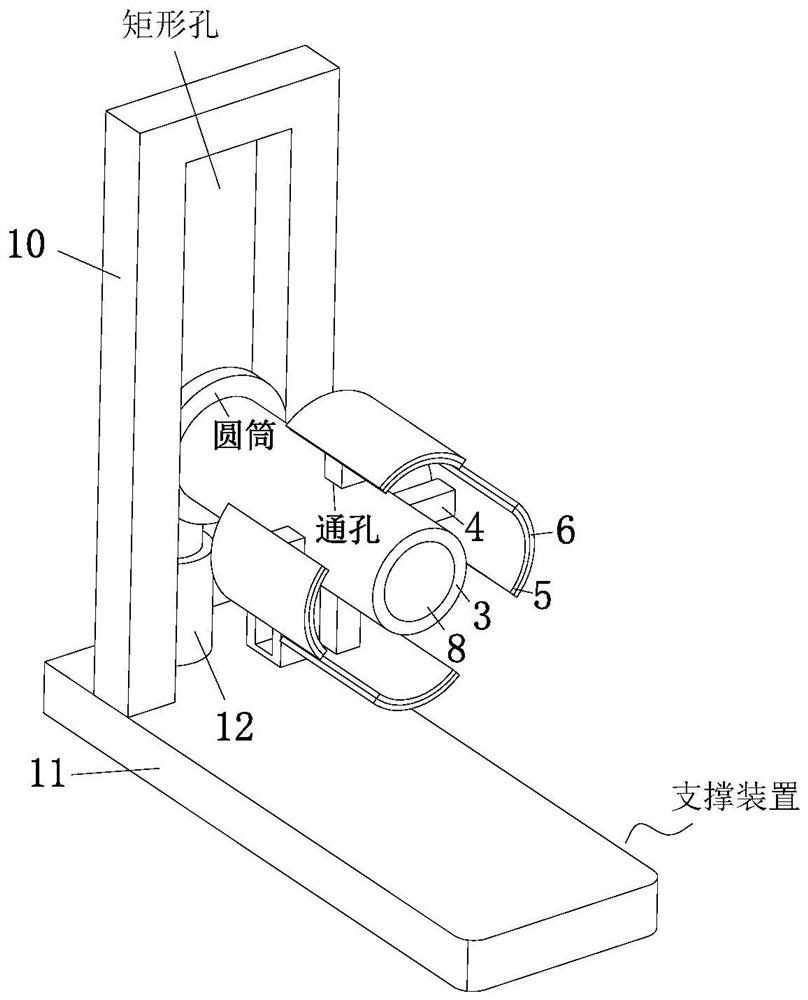

Precise electronic ceramic film screen printing machine

A technology of ceramic film and precision electronics, which is applied in screen printing machines, printing machines, screen printing, etc., can solve the problems of cumbersome ceramic printing, affect the work efficiency of silk screen printing ceramics, cumbersome printing, etc., and achieve positioning and protection effects Enhanced, improved practicability, good limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

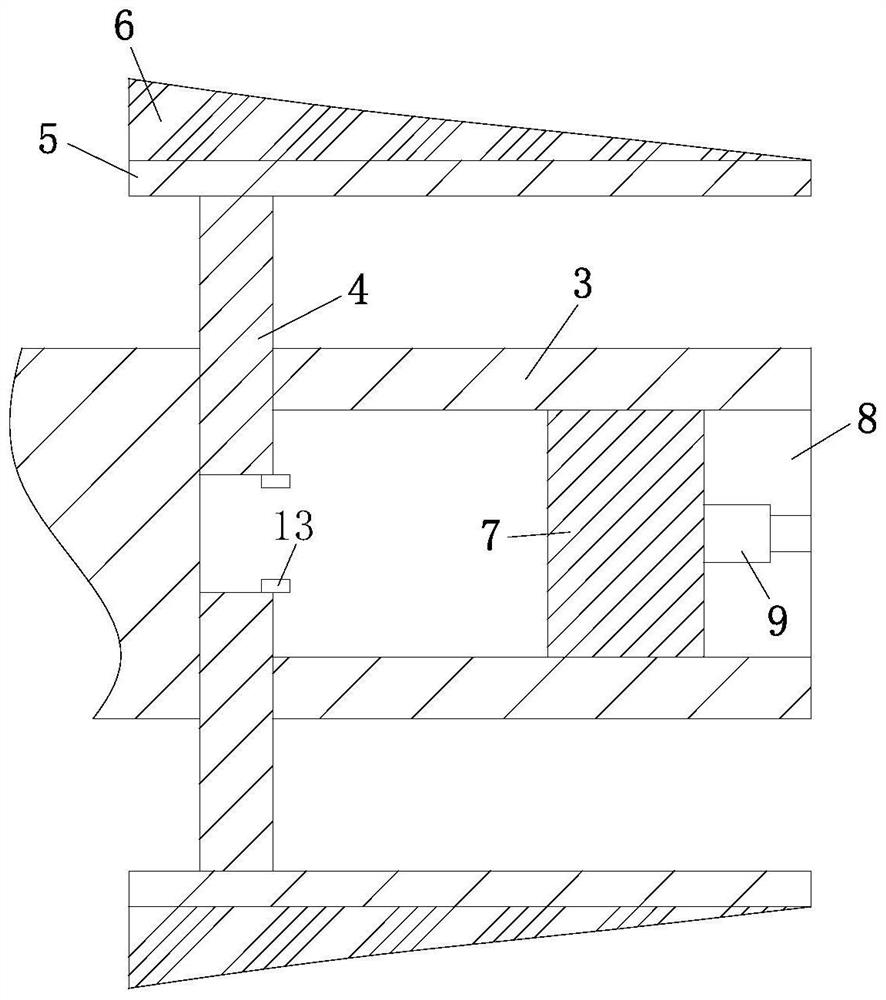

[0030] As an embodiment of the present invention, an arc-shaped plate 5 is fixedly connected to the end of the positioning block 4 away from the groove 8; a soft plate 6 is fixedly connected to the arc-shaped plate 5; The end of the positioning block 4 away from the groove 8 is fixedly connected with an arc-shaped plate 5, so that when the positioning block 4 contacts the inner wall of the ceramic, the contact area is increased, and simultaneously the arc-shaped plate 5 is fixedly connected with a soft plate 6, thereby enabling Better limit the ceramics, and then protect the inner wall of the ceramics during the printing process, so that the positioning and protection effect of the positioning block 4 on the ceramics is enhanced, preventing the ceramics from shaking during the printing process of the ceramics, which reduces the printing effect , while ensuring that the ceramics will not fall off and cause ceramic damage.

[0031] As an embodiment of the present invention, grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com