High precision fiber filter

A fiber filter, high-precision technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

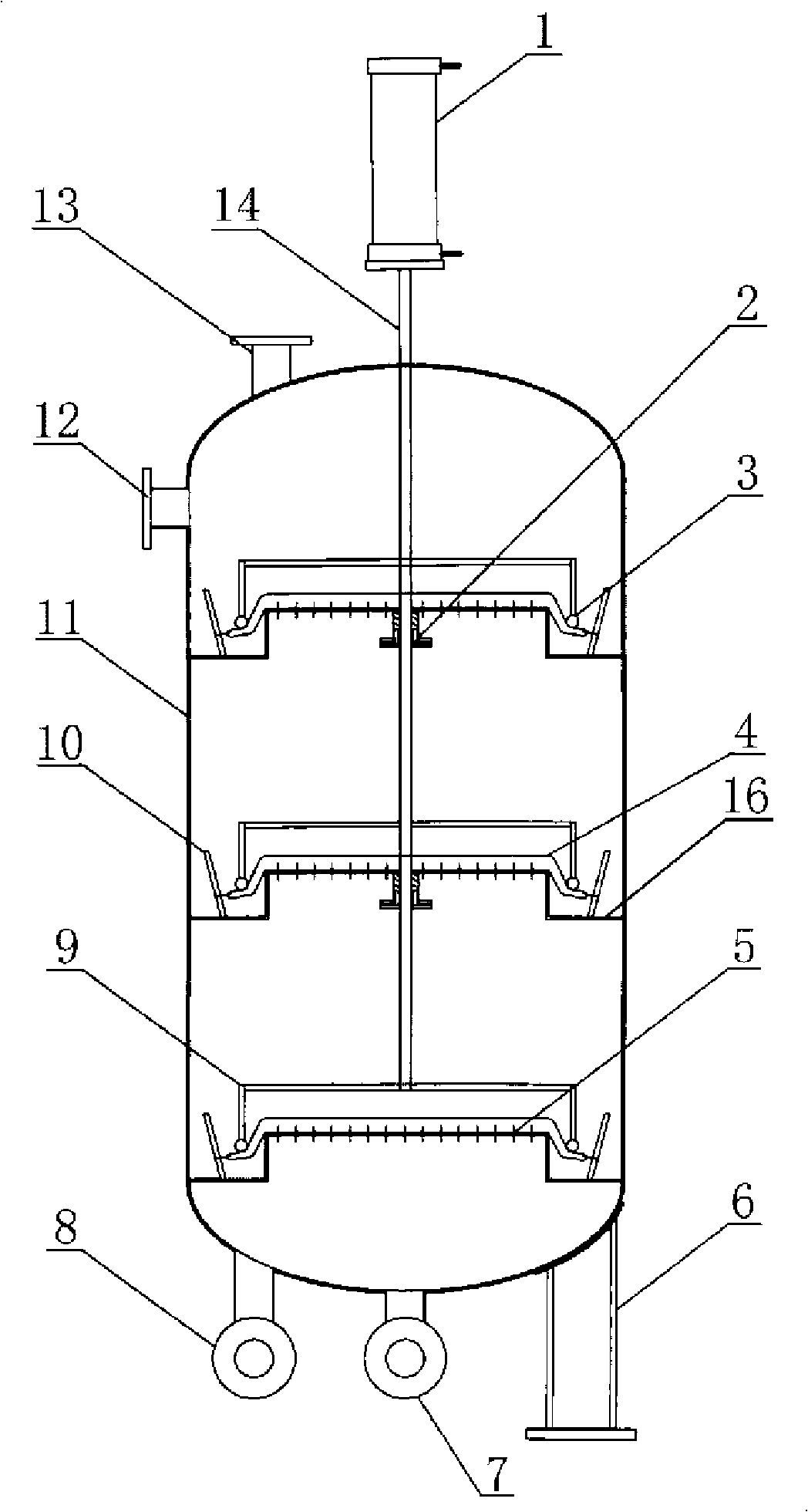

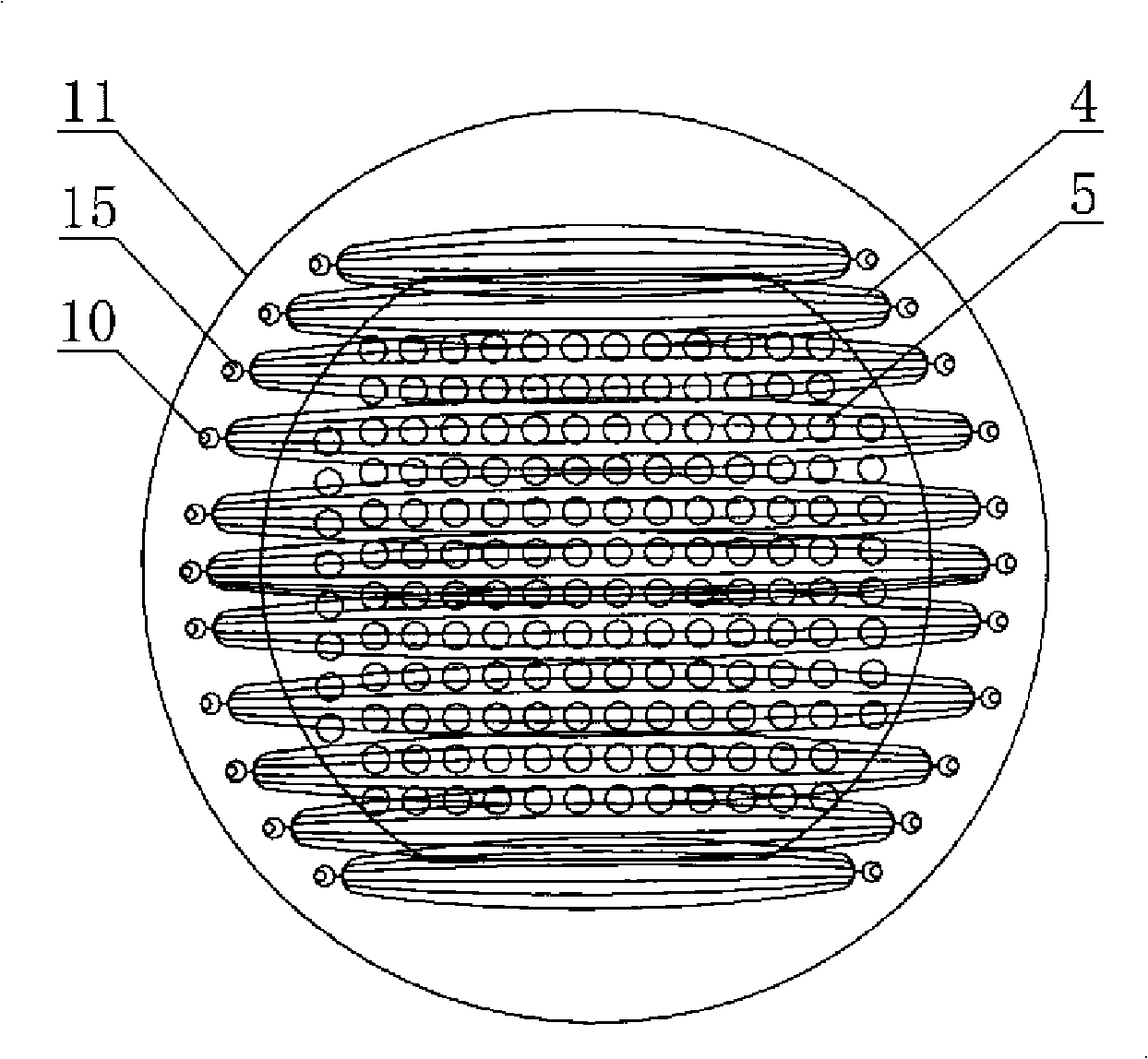

[0031] Embodiment one sees Figure 1-Figure 4 , this pot-shaped high-precision fiber filter includes a cylindrical housing 11, fiber bundles 4 inside the housing, and a hanging thread rod 10. There are water inlet pipes 12 and outlet pipes 7 on the housing. One end of the water outlet pipe is provided with a backwash air intake pipe 8, and one end of the water inlet pipe is provided with a backwash drain pipe 13. The inner wall of the housing is provided with at least one layer of L-shaped shelf ring 16 with an L-shaped cross-section. The horizontal plate of the L-shaped shelf ring is connected with the side wall of the housing. The vertical plate of the L-shaped shelf ring is covered with a perforated plate 5. The body or tank body is divided into one or more filter chambers, each filter chamber has one or more layers of fiber filaments, the fiber filaments are arranged in parallel to the porous plate, and hung on the hanging wire rod, and the fiber bundles are made of fiber ...

Embodiment 2

[0036] Embodiment two see Figure 5-Figure 8 , The difference from Embodiment 1 is that the casing of Embodiment 2 is a square tank with an open top, and the backwash drain pipe is located on the side of the casing. see Image 6 , the shape of the perforated plate is square, if it is used in open equipment, it does not need to be sealed.

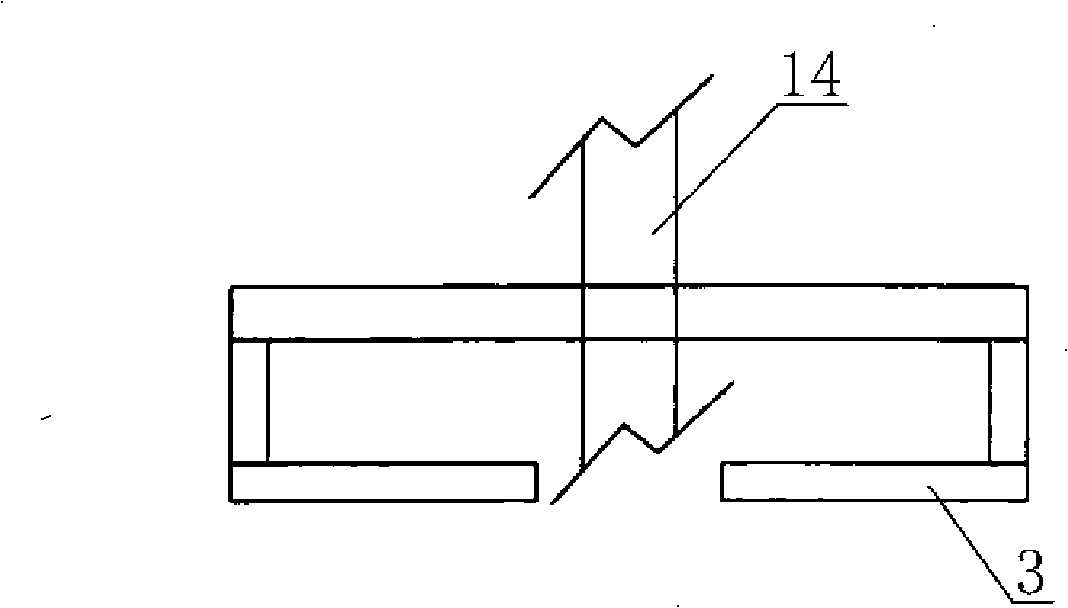

[0037] see Figure 7 , Figure 8 The above-mentioned fiber tensioning press frame 9 includes a frame connected to the drive shaft at the center and a depression bar under the frame, and the compression bar 3 is straight.

[0038] Working principle: When filtering, the driving device drives the fiber tensioning frame through the transmission shaft to press down the fiber bundle. The raw water passes through the multi-stage filter layer in the shell, and is filtered through the fiber layer step by step from top to bottom to become purified water. Discharged through the outlet.

[0039] During backwashing, the driving device drives the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com