Ribbed steel bar short-circuit heat treatment equipment and heating power supply thereof

A heat treatment equipment and ribbed steel bar technology, applied in the field of steel bar manufacturing, can solve the problems of uneven heating, high cost, large consumption of spare parts, etc., improve electric heating efficiency and thermal efficiency, ensure close contact and heating, and reduce electromagnetic conversion links. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

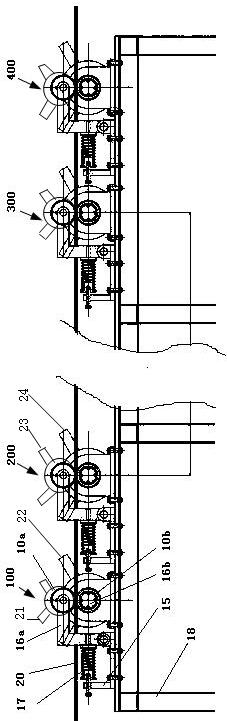

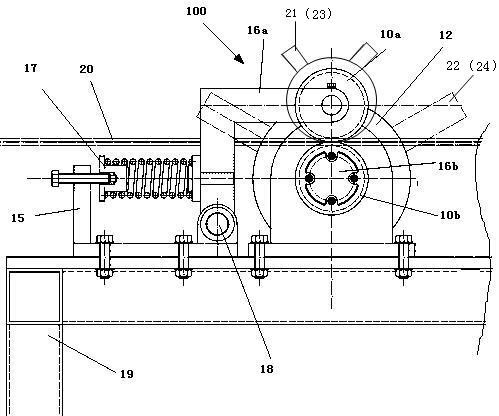

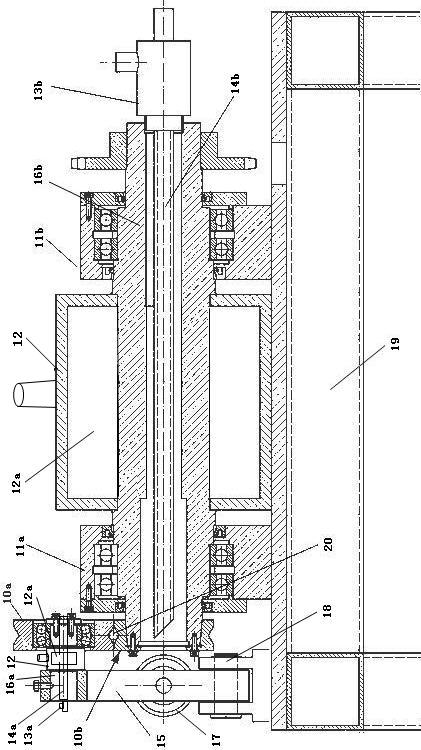

[0032] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] A short-circuit heat treatment equipment for ribbed steel bars, figure 1 It is the present invention that sets the structure in the ribbed steel bar production line, figure 2 It is a schematic diagram of the side structure of a single heating module on the production line, image 3 It is a schematic diagram of the transverse cross-sectional structure of a single heating module on the production line. The short-circuit heat treatment equipment for the ribbed steel bar 20 includes a steel bar guide roller, and the steel bar short-circuit heat treatment device includes a plurality of modules, and the plurality of modules are arranged on the frame 19. Each module includes two sets of steel bar guide rollers, one of which is The positive pole of the heating power supply is connected to the rebar guide rollers, and the negative pole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com