Method for producing nickel-based high-temperature alloy difficult to deform through compensation heating assisted free forging

A technology of nickel-based superalloy and compensatory heating, which is applied in the field of superalloy manufacturing, can solve the problems of narrow thermal processing temperature range, etc., and achieve the effects of increasing the opening forging/final forging temperature, rationalizing the amount of forging deformation, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Specifications of finished bar: Φ250mm

[0048] 2. Mechanical properties: The heat treatment parameters of all mechanical properties test samples are as follows:

[0049] Solution treatment: 995℃~1035℃, heat preservation for 4 hours, water cooling;

[0050] Stabilization heat treatment: 845°C±10°C, heat preservation for 4±0.5 hours, air cooling;

[0051] Aging heat treatment: 760°C±10°C, heat preservation for 16±1 hours, air cooling.

[0052] The mechanical property of bar head / tail in the embodiment 1 of table 1

[0053]

[0054] 3. Ultrasonic inspection

[0055] The bars are subjected to 100% ultrasonic inspection one by one, which meets the requirements of Φ1.5mm flat-bottomed holes in GB / T4162-2008.

[0056] 4. High-magnification tissue

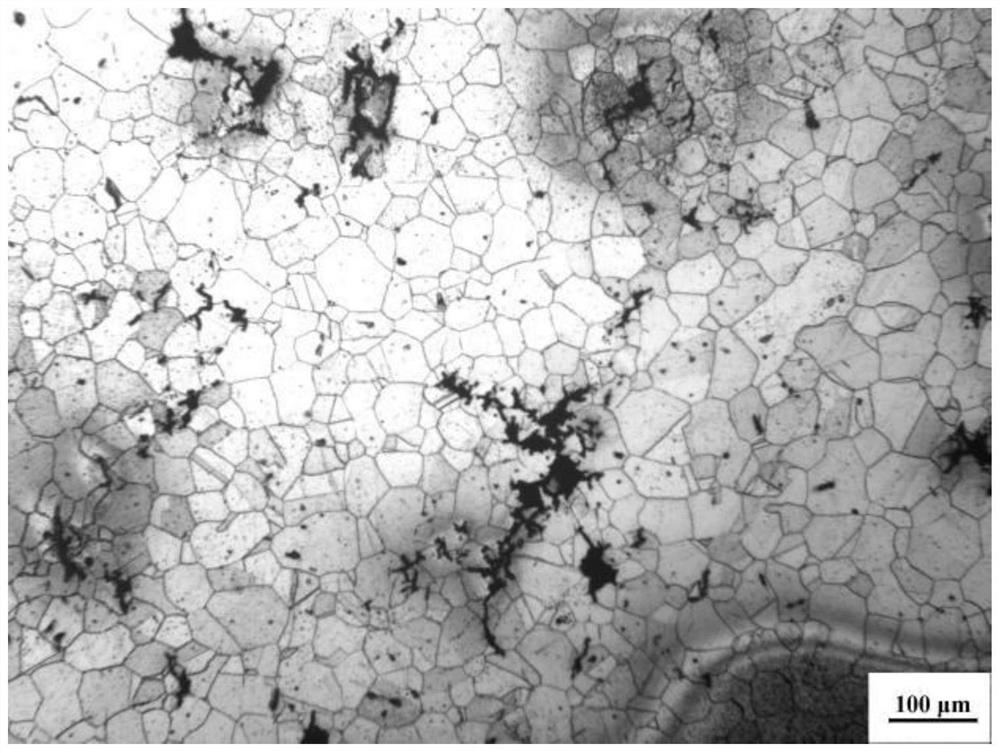

[0057] See grain size Figure 5 . The overall grain size is 6 grades, and the difference is less than or equal to 2 grades.

Embodiment 2

[0059] 1. Specifications of finished bar: Φ250mm

[0060] 2. Mechanical properties:

[0061] Heat treatment system for all mechanical properties testing samples:

[0062] Solution treatment: 995℃~1035℃, heat preservation for 4 hours, water cooling;

[0063] Stabilization heat treatment: 845°C±10°C, heat preservation for 4±0.5 hours, air cooling;

[0064] Aging heat treatment: 760°C±10°C, heat preservation for 16±1 hours, air cooling.

[0065] The mechanical property of bar head / tail in the embodiment 2 of table 2

[0066]

[0067]

[0068] 3. Ultrasonic inspection

[0069] The bars are subjected to 100% ultrasonic inspection one by one, which meets the requirements of Φ1.5mm flat-bottomed holes in GB / T4162-2008.

[0070] 4. High-magnification tissue

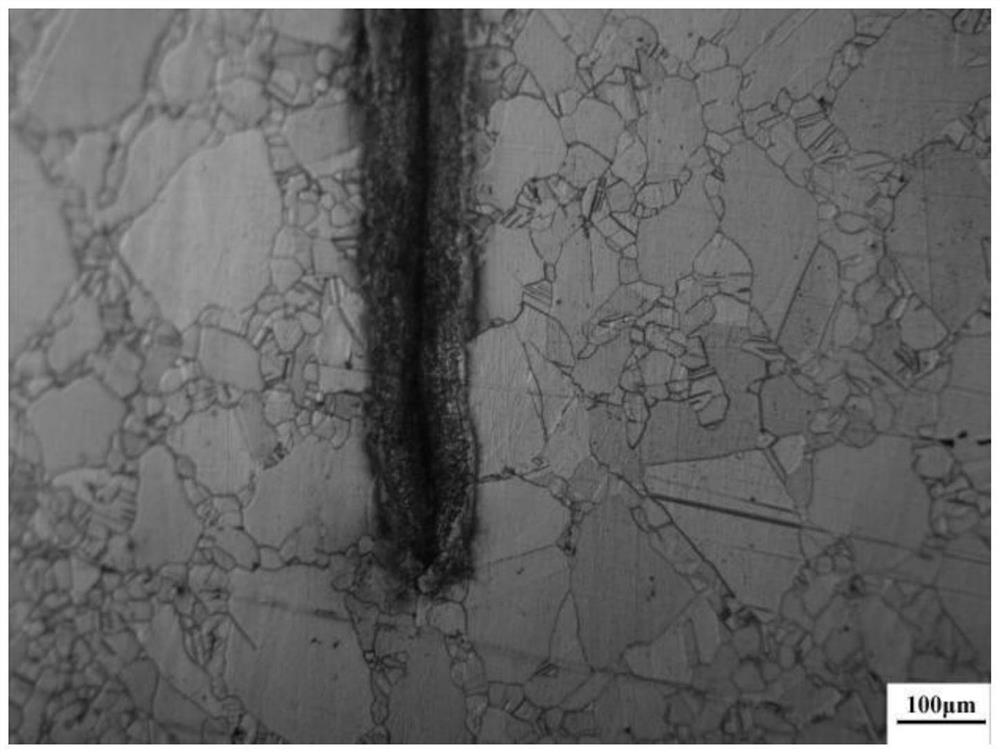

[0071] See grain size Image 6 . The overall grain size is 6.5 grades, and the grade difference is less than or equal to 2 grades.

Embodiment 3

[0073] 1. Specifications of finished bar: Φ250mm

[0074] 2. Mechanical properties:

[0075] Heat treatment system for all mechanical properties testing samples:

[0076] Solution treatment: 995℃~1035℃, heat preservation for 4 hours, water cooling;

[0077] Stabilization heat treatment: 845°C±10°C, heat preservation for 4±0.5 hours, air cooling;

[0078] Aging heat treatment: 760°C±10°C, heat preservation for 16±1 hours, air cooling.

[0079] The mechanical property of bar head / tail in the embodiment 3 of table 3

[0080]

[0081] 3. Ultrasonic inspection

[0082] The bars are subjected to 100% ultrasonic inspection one by one, which meets the requirements of Φ1.5mm flat-bottomed holes in GB / T4162-2008.

[0083] 4. High-magnification tissue

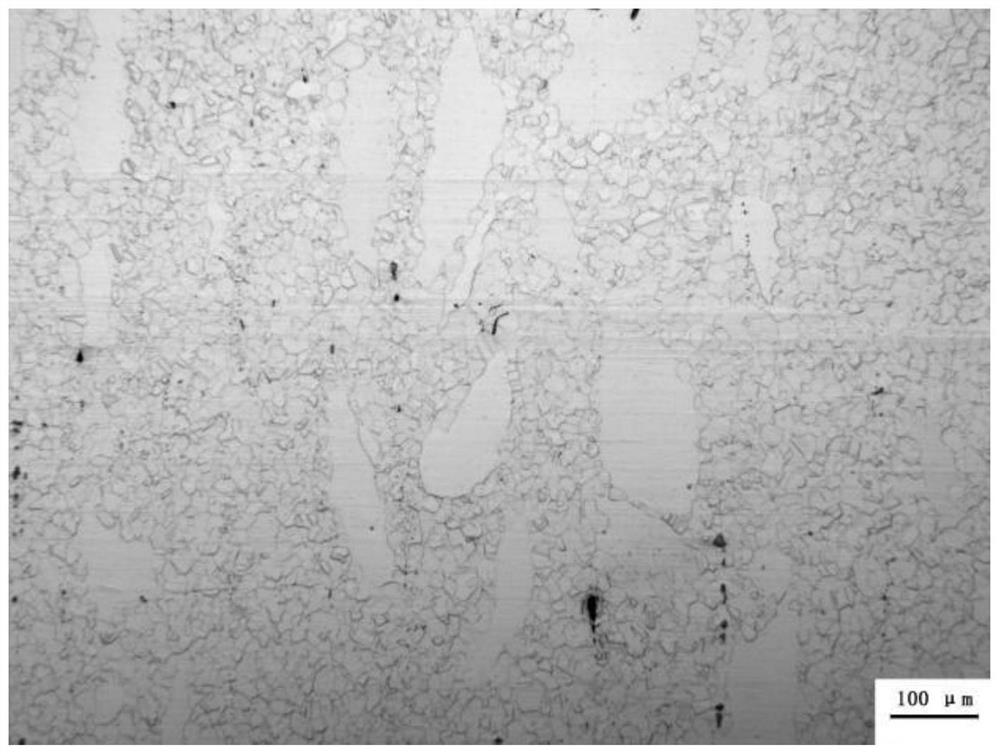

[0084] See grain size Figure 7 . The overall grain size is 6 grades, and the difference is less than or equal to 2 grades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com