Forging method for improving axial structure uniformity of large titanium alloy bar

A technology with uniform structure and large size, applied in the field of titanium alloy forging, can solve the problems of aggravated non-uniformity, excessive free end of the head and bottom of the bar, fluctuation of the structure and properties of the bar, etc., to reduce the cumulative deformation and improve the β The effect of grain size uniformity, improvement of microstructure and property anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

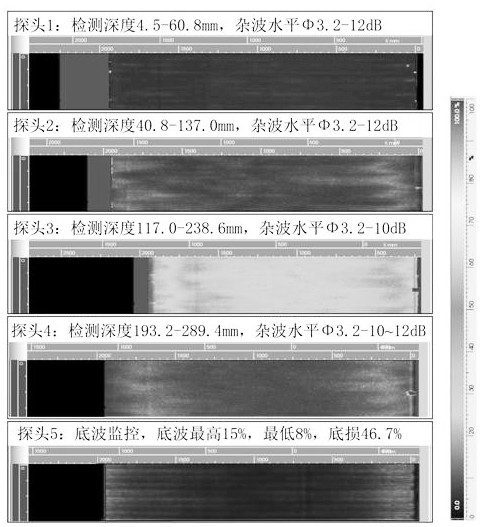

Embodiment 1

[0027] In this example, the raw material is a TC18Φ680mm ingot, the phase transition temperature of the ingot measured by metallographic method is 865°C, and the finished product is a Φ500mm large-sized bar. The ingot is heated to 1150°C, and after the heat preservation, a 45MN fast forging machine is used to spheronize the ingot to Φ610×~1780mm (indicating that the shaped blank is a cylinder with a diameter of 610mm and a length of about 1780mm, because the spheronization forging process controls the size of the blank. Diameter, so 610mm is an accurate control value, and the length is an estimated value, not a forging control value, the "~" in front of the number means "approximately equal to"), air cooling after forging; ②Single-phase area forging: Reshape the billet The obtained billet was forged in single-phase zone for 4 times. The heating temperature of each heat was 1080°C, 1050°C, 1000°C, and 950°C. After each heat, a 45MN fast forging machine was used for 2 upsetting a...

Embodiment 2

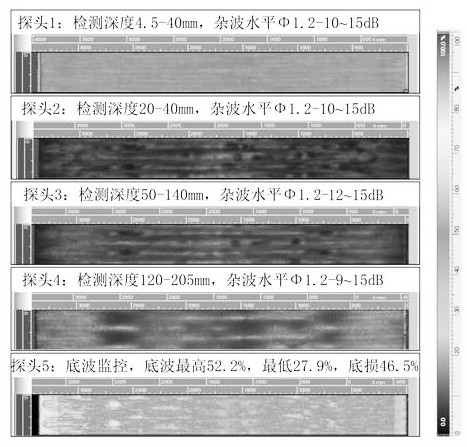

[0029]In this example, the raw material is a TC11Φ680mm ingot, the phase transition temperature of the ingot is 1000°C measured by metallographic method, and the finished product is a Φ350mm large-sized bar. The ingot is heated to 1170°C. After the heat preservation is completed, the ingot is spheronized to Φ590×~1530mm using a 45MN fast forging machine (same as above, 590mm is an accurate control value, while the length of 1530mm is an estimated value, not a forging control value. The preceding "~" means "approximately equal to"), air cooling after forging; ②Single-phase zone forging: The billet obtained after blanking and shaping is forged in single-phase zone for 4 times, and the heating temperature for each fire is 1100℃, 1080℃. ℃, 1050℃, 1050℃, 45MN fast forging machine is used for 2 upsetting and 2 pulling after each heating, the upsetting deformation is controlled between 40~45%, and the drawing deformation is controlled at 38~43 Between %, the upsetting deformation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com