A high-performance superhard high-speed steel

A high-speed steel, high-performance technology, applied in the field of metal materials, can solve the problems that hinder the application and development of high-speed steel W2Mo9Cr4VCo8, affect the thermal processing performance of high-speed steel, and affect the service life of tools, so as to reduce decarburization sensitivity and precious metal consumption , Improve the effect of hot and cold processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

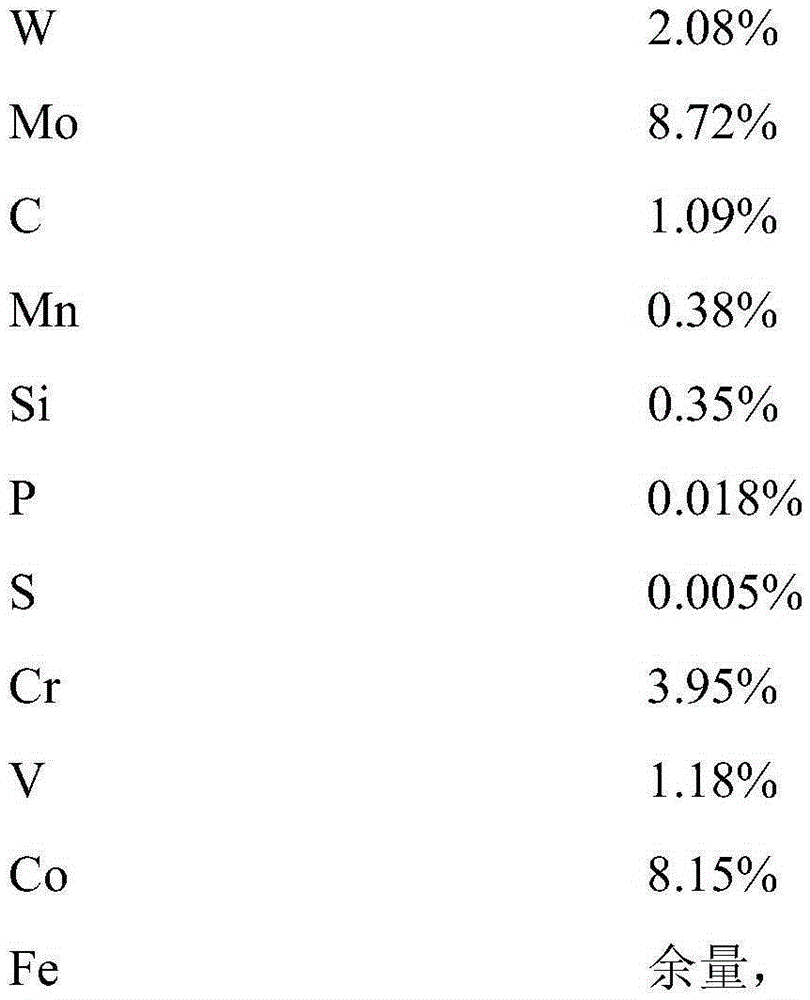

Embodiment 1

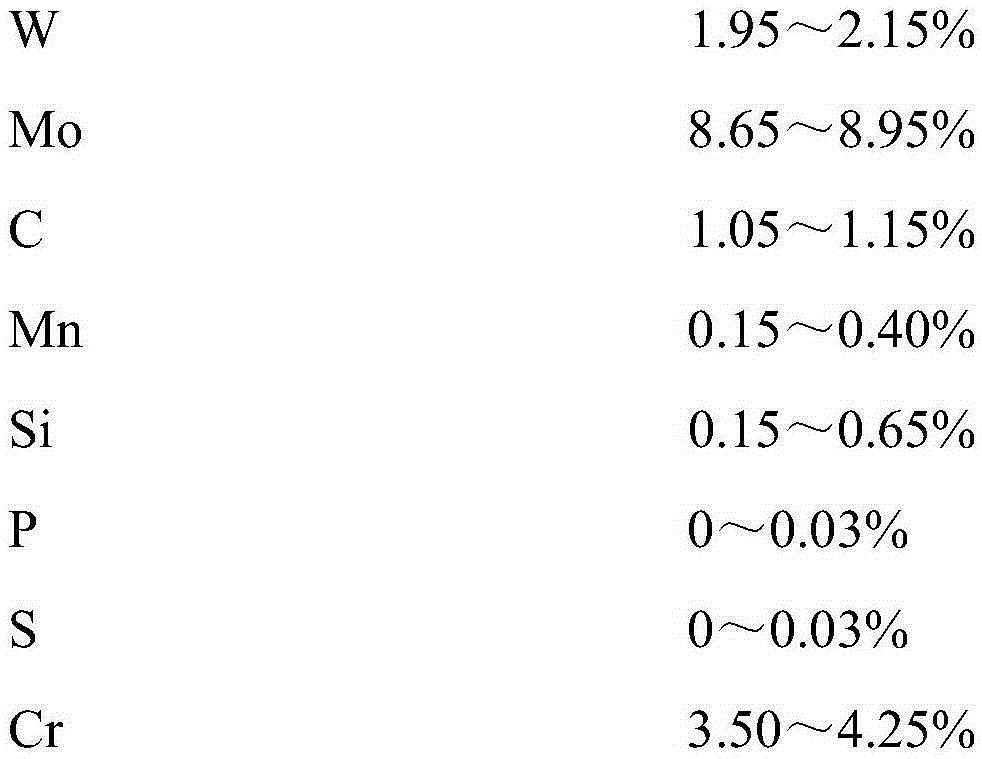

[0017] A high-speed steel, said high-speed steel comprises the following components by mass percentage:

[0018]

[0019] The sum of the above chemical components is 100%.

[0020] The above-mentioned high-speed steel is prepared by smelting-diffusion annealing-hot processing-cold drawing.

[0021] The thermal processing includes precision forging machine forging process and rolling process. The forging process of the precision forging machine is as follows: the furnace temperature is 600°C; the temperature is raised from 600°C to 900°C for preheating, and the heating rate is 2°C / min; the temperature is raised from 900°C to 1040°C, and the heating rate is 1°C / min; Heat preservation at 1090°C, the heating rate is 1°C / min; the final forging temperature is 900°C, and annealed after forging. The rolling process is as follows: the furnace temperature is 700°C; the temperature is raised from 700°C to 900°C for preheating, and the heating rate is 7°C / min; the temperature is rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com