Freeze-drying technology of bortezomib for injection

A technology for bortezomib and injection, applied in the field of freeze-drying technology, can solve the problems of poor quality of freeze-dried finished products, low freeze-drying efficiency, low resolubility, etc., and avoid uneven crystallization, long reconstitution time, ester The effect of low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

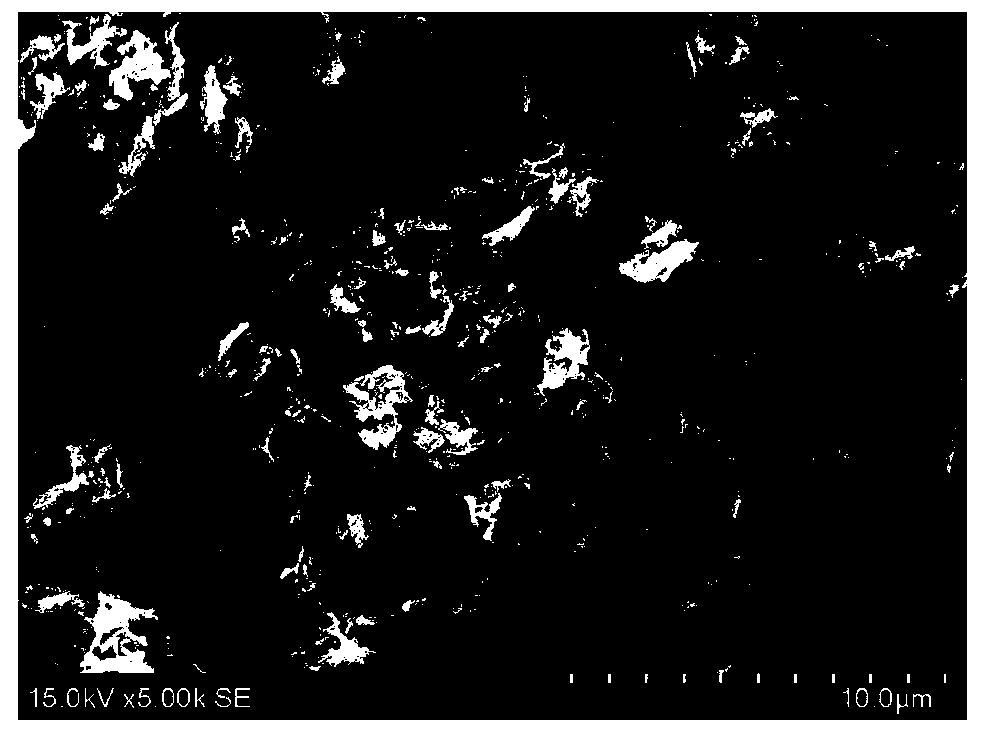

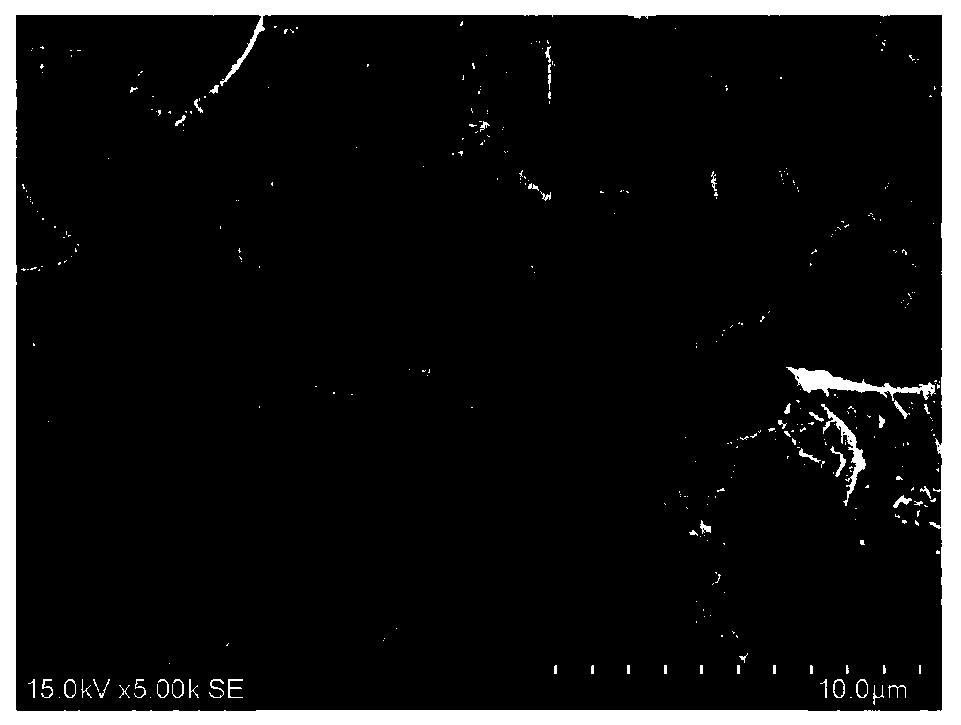

Image

Examples

Embodiment 1

[0066] The lyophilization process of the bortezomib for injection of embodiment 1 comprises the following steps:

[0067] (1) Pre-freezing:

[0068] (1a) Lower the liquid medicine from room temperature to -15°C at a cooling rate of 4.6-5.6°C / min, and keep at -15°C for 2 hours;

[0069] (1b) Cool the sample obtained in step (1a) to -35°C at a cooling rate of 2.3-2.7°C / min, and keep it at -35°C for 2.5h;

[0070] (1c) heating the sample obtained in step (1b) to -21°C at a heating rate of 0.5-0.7°C / min, and keeping it at -21°C for 2 hours;

[0071] (1d) Cool the sample obtained in step (1c) to -38°C at a cooling rate of 2.3-2.7°C / min, and keep it at -38°C for 3 hours;

[0072] (2) Once dry:

[0073] (2a) Under the condition of vacuum degree of 0.2mbar, the temperature of the sample obtained in step (1d) is raised to -31°C at a heating rate of 1-2.5°C / h, and kept at -31°C for 19h;

[0074] (2b) Under the condition of a vacuum degree of 0.2mbar, the temperature of the sampl...

Embodiment 2

[0080] The freeze-drying process of the bortezomib for injection of embodiment 2 comprises the following steps:

[0081] (1) Pre-freezing:

[0082] (1a) Lower the liquid medicine from room temperature to -14°C at a cooling rate of 4.6-5.6°C / min, and keep at -14°C for 3 hours;

[0083] (1b) Cool the sample obtained in step (1a) to -45°C at a cooling rate of 1.8-3.1°C / min, and keep at -45°C for 3h.

[0084] (1c) Heat the sample obtained in step (1b) to -22°C at a heating rate of 0.4-0.8°C / min, and keep at -22°C for 3h.

[0085] (1d) Cool the sample obtained in step (1c) to -35°C at a cooling rate of 2.3-2.7°C / min, and keep at -35°C for 4h.

[0086] (2) Once dry:

[0087] (2a) Under the condition of vacuum degree of 0.15mbar, the temperature of the sample obtained in step (1b) is raised to -33°C at a heating rate of 1-7.5°C / h, and kept at -33°C for 20h;

[0088] (2b) Under the condition of vacuum degree of 0.15mbar, the temperature of the sample obtained in step (2a) is r...

Embodiment 3

[0094] The lyophilization process of the bortezomib for injection of embodiment 3 comprises the following steps:

[0095] (1) Pre-freezing:

[0096] (1a) Lower the liquid medicine from room temperature to -18°C at a cooling rate of 4.6-5.6°C / min, and keep at -18°C for 1 hour;

[0097] (1b) Cool the sample obtained in step (1a) to -40°C at a cooling rate of 1.8-3.1°C / min, and keep at -40°C for 2h.

[0098] (1c) Heat the sample obtained in step (1b) to -20°C at a heating rate of 0.4-0.8°C / min, and keep it at -20°C for 1 hour.

[0099] (1d) Cool the sample obtained in step (1c) to -45°C at a cooling rate of 1.8-3.1°C / min, and keep at -45°C for 2h.

[0100] (2) Once dry:

[0101] (2a) Under the condition of a vacuum degree of 0.25mbar, the temperature of the sample obtained in step (1b) is raised to -30°C at a heating rate of 1-7.5°C / h, and kept at -30°C for 18h;

[0102] (2b) Under the condition of a vacuum degree of 0.25mbar, the temperature of the sample obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com