Camellia oil squeezing preparation system and preparation method

A preparation system, camellia oil technology, applied in presses, manufacturing tools, grain processing, etc., can solve the problems of tea cake tea oil residue, insufficient pressing, waste of manpower and material resources, etc., to improve oil yield, save manpower, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

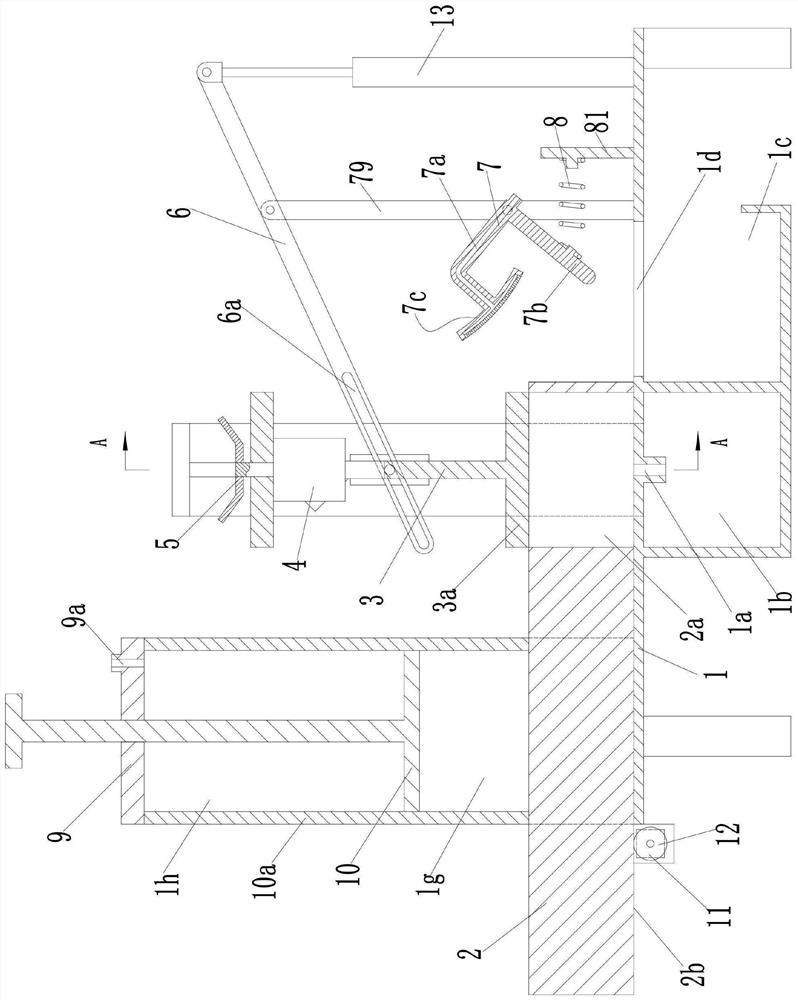

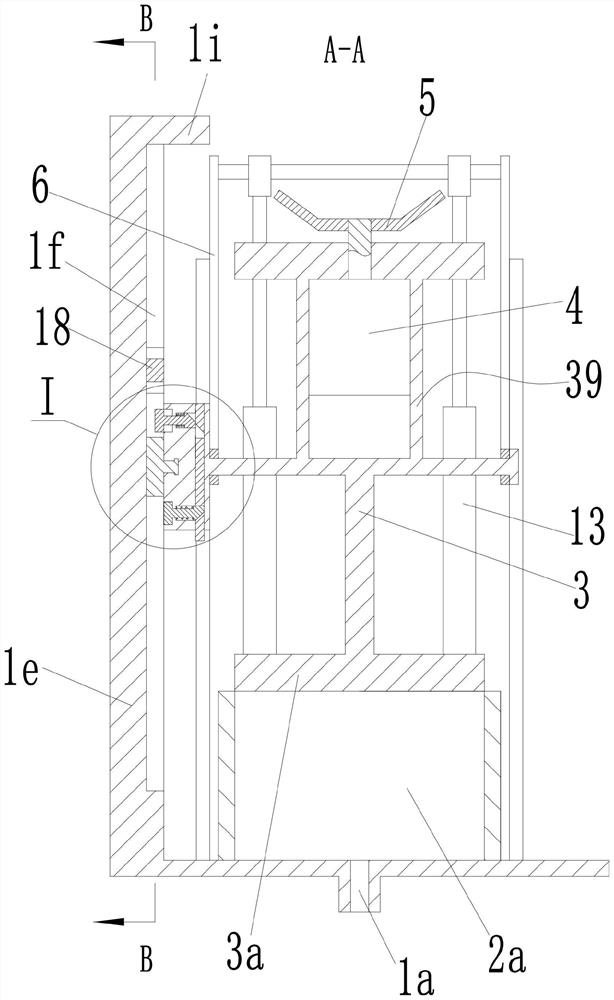

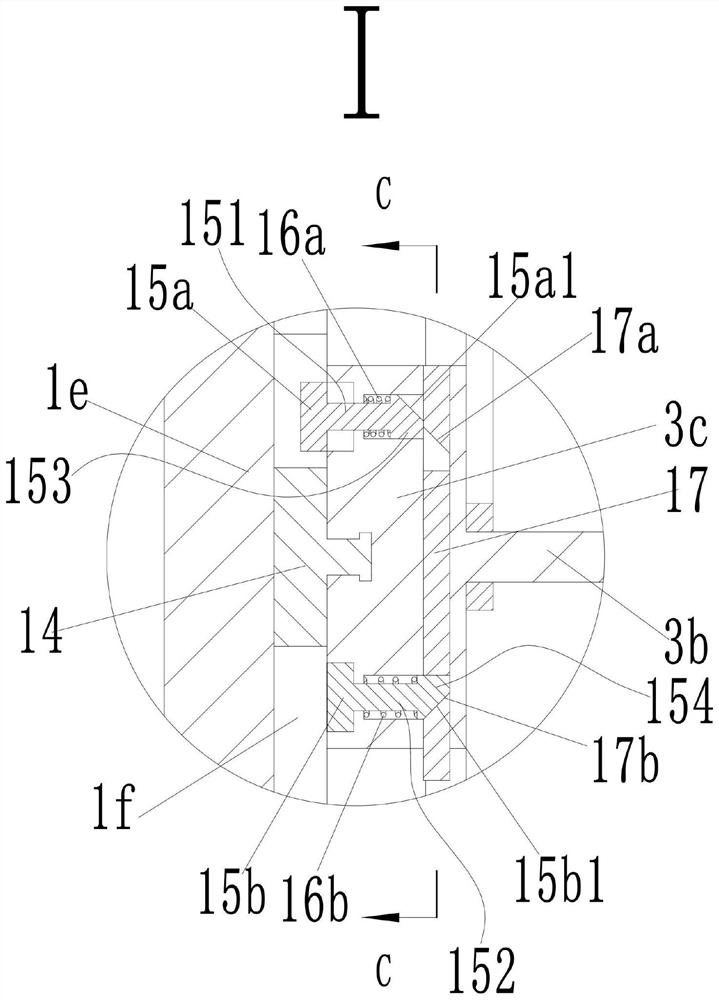

[0030] see Figure 1-5 Shown, a kind of camellia oil pressing preparation system comprises body 1, and described body 1 is provided with pressing assembly, and described body 1 is provided with feeding assembly on the left side of pressing assembly, and is provided with cleaning assembly on the right side of pressing assembly , the feeding assembly is used to sequentially send the tea seed powder to the pressing assembly and the cleaning assembly, and the cleaning assembly is used to clean the pressing chamber 2a in the feeding assembly; the pressing assembly includes a conversion block 3c, and the body The rear side of 1 is provided with a vertical plate 1e along the vertical direction, and a track groove 1f is arranged inside the vertical plate 1e; the rear end of the conversion block 3c is rotatably connected with a slider 14, and the slider 14 The front end of the conversion block 3c is provided with a shaft 3b extending forward, and the outer side of the shaft 3b is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com