Patents

Literature

63results about How to "Easy to filter jobs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

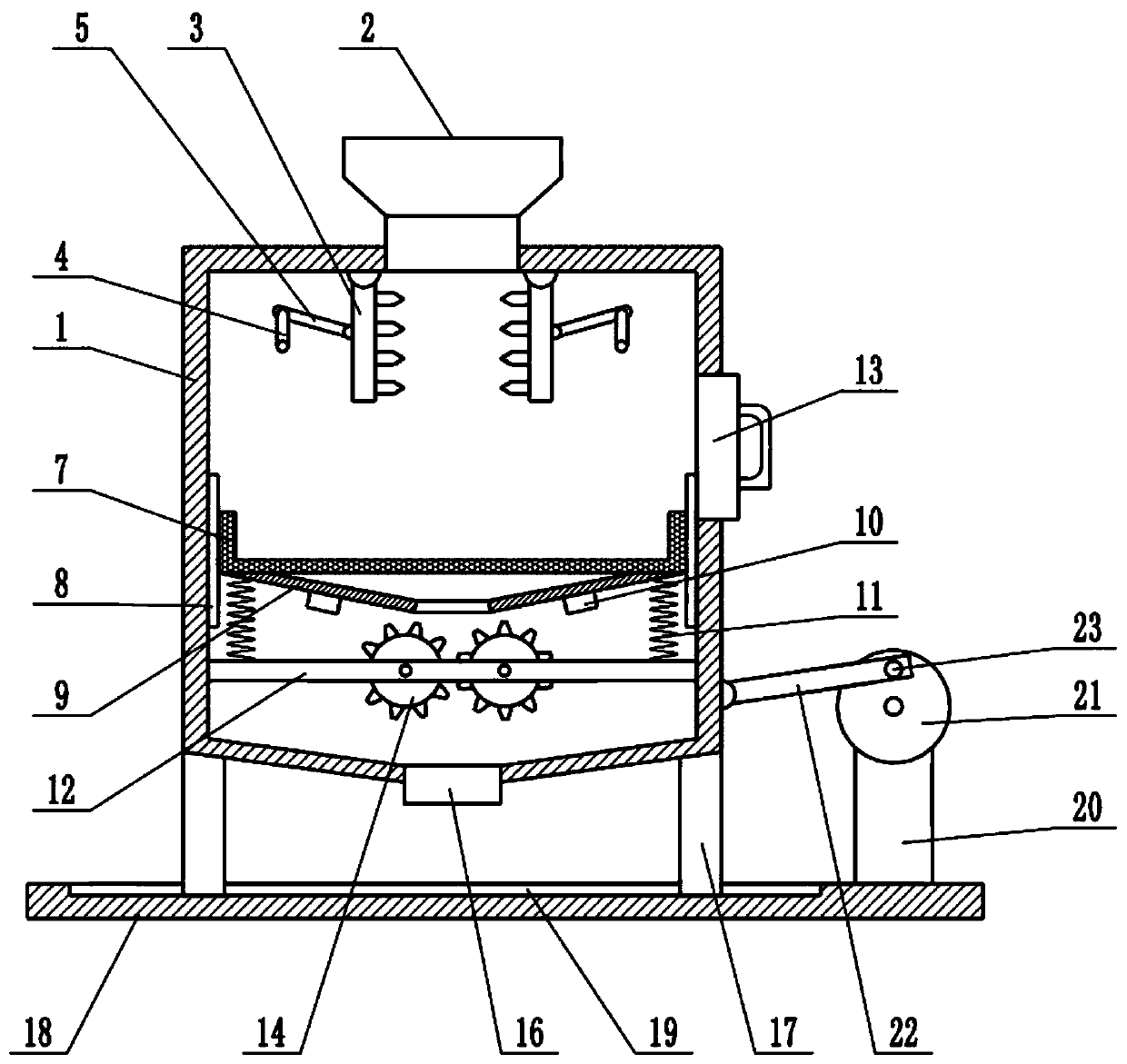

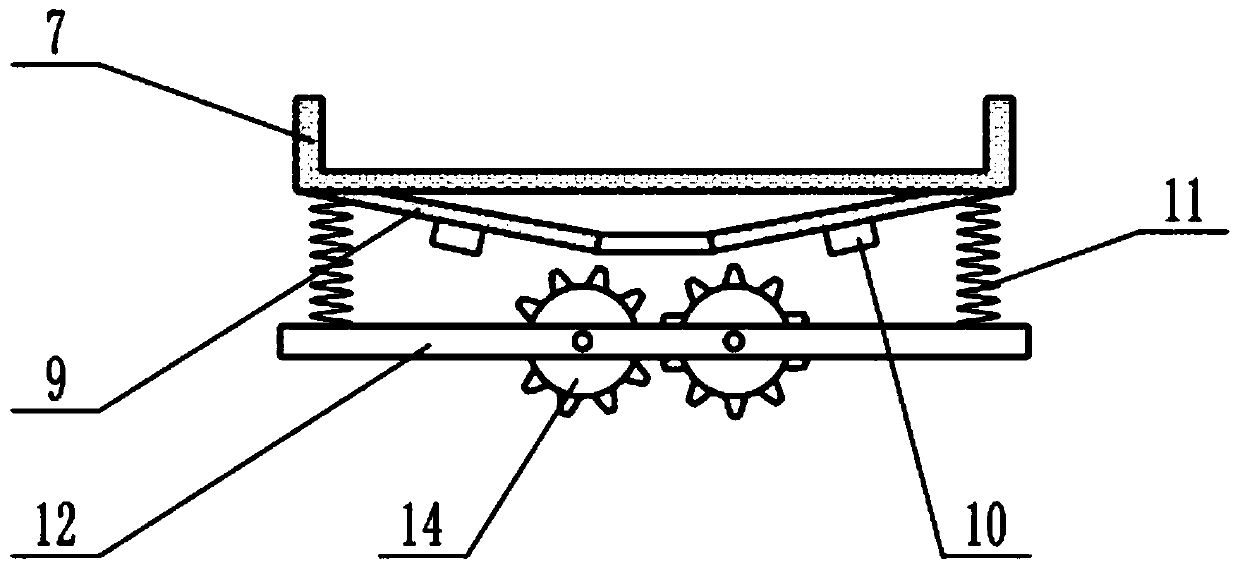

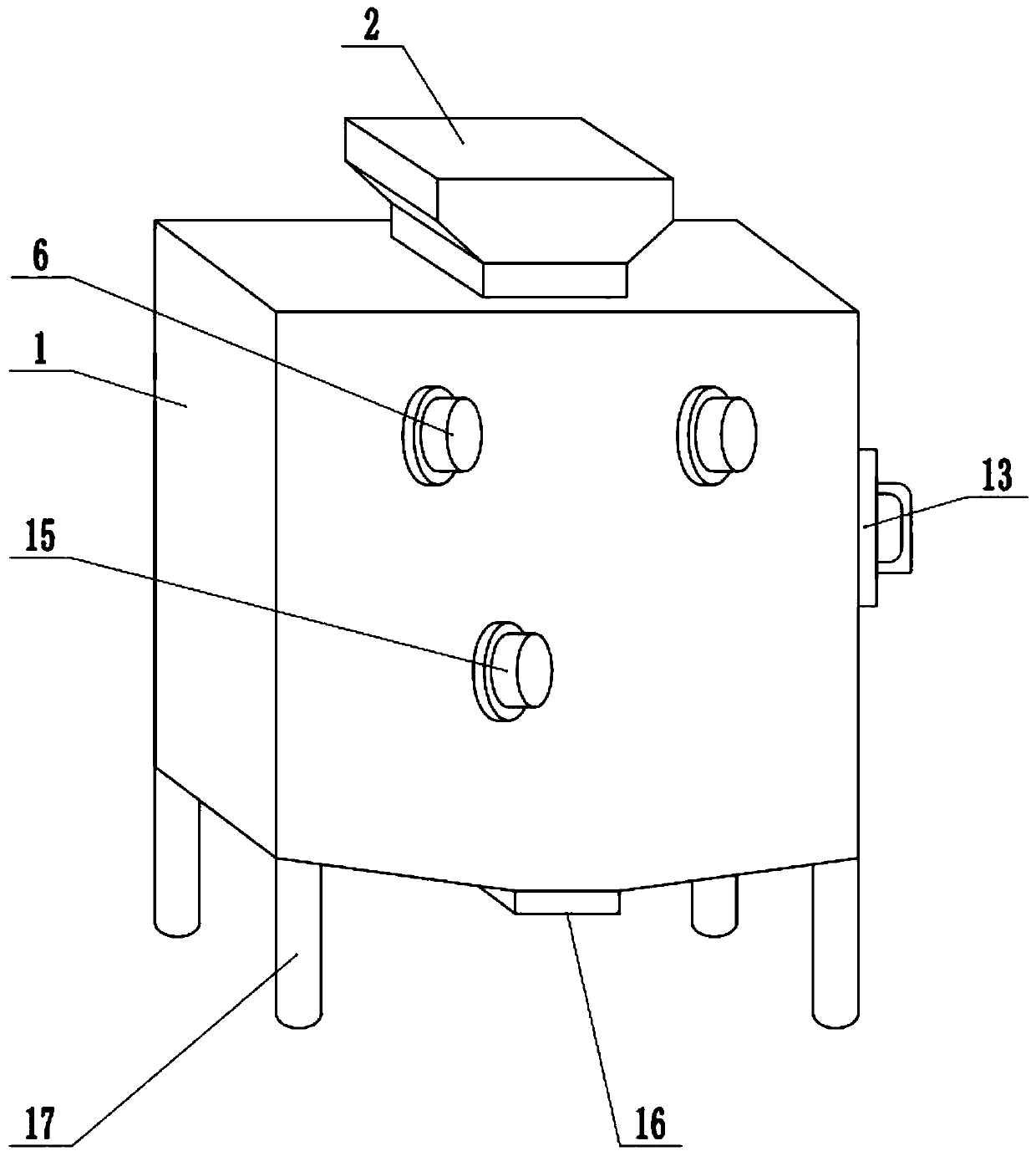

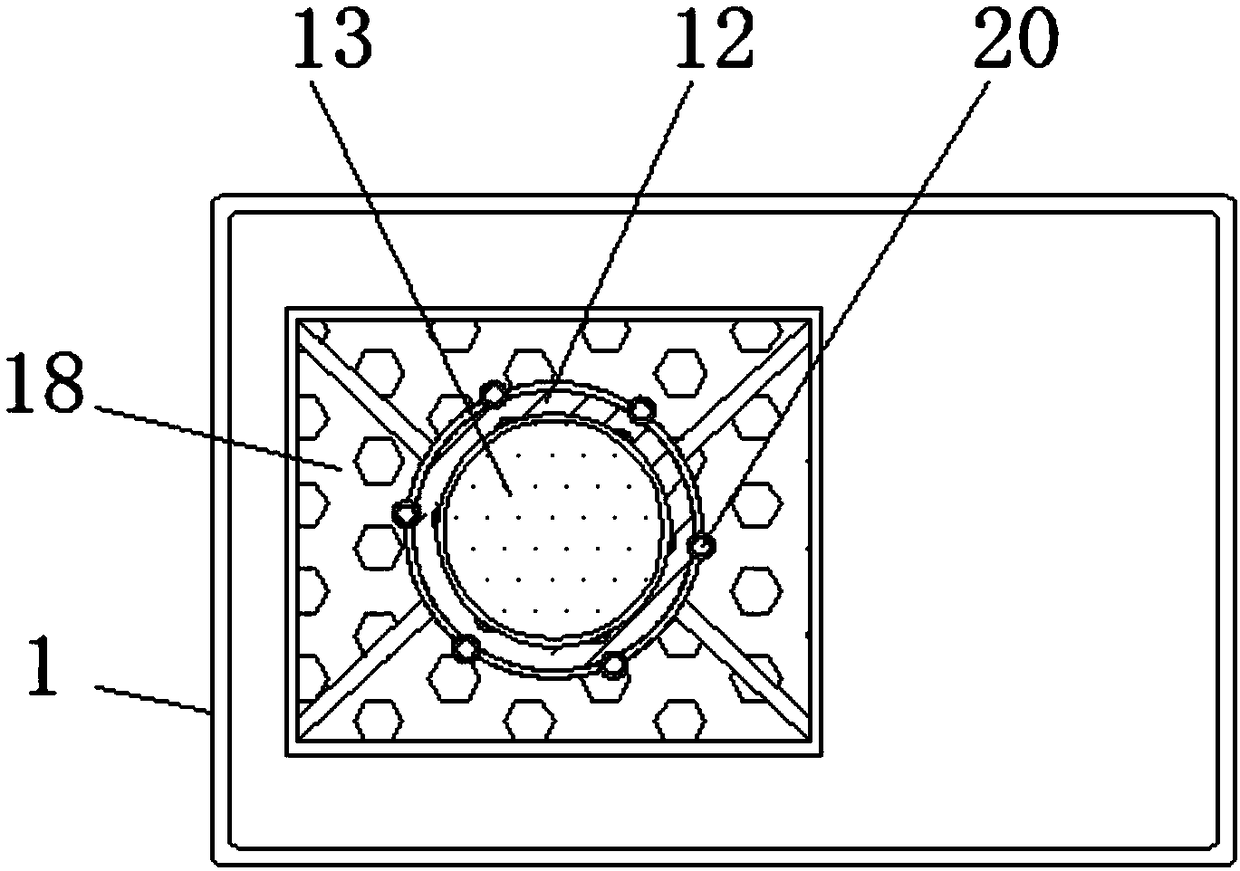

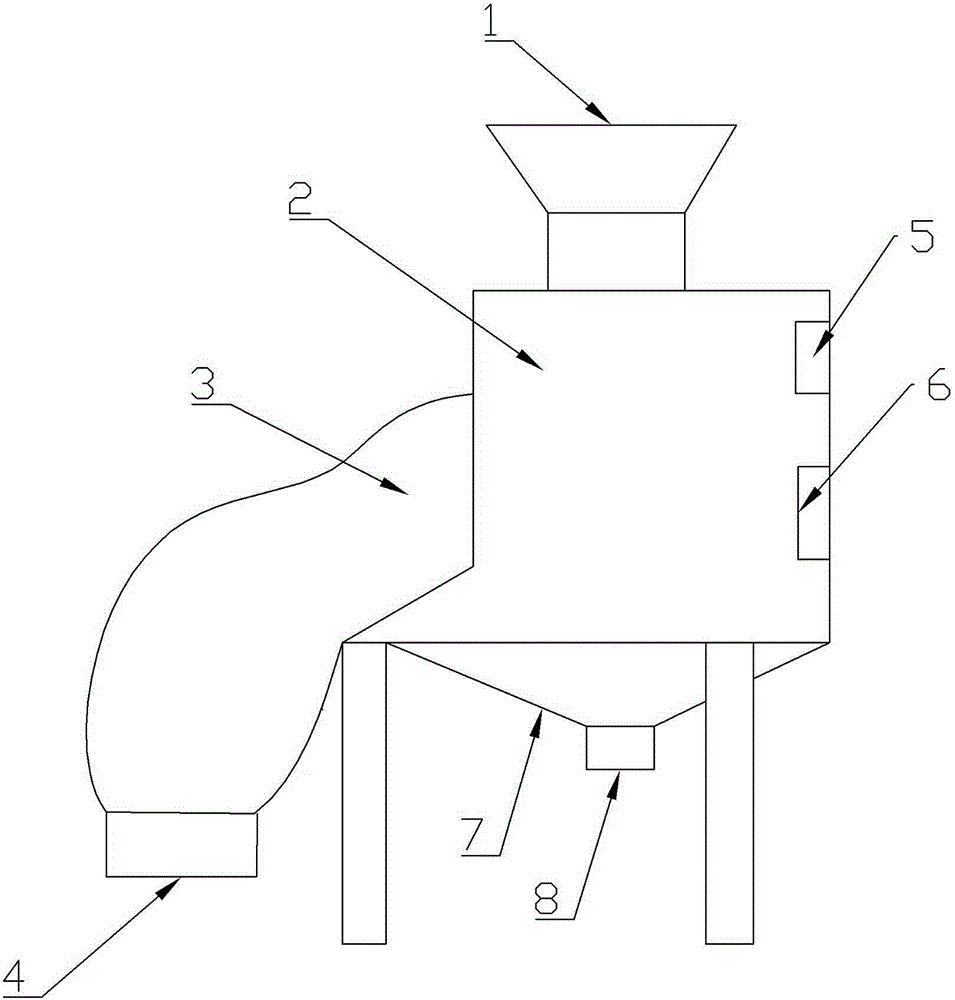

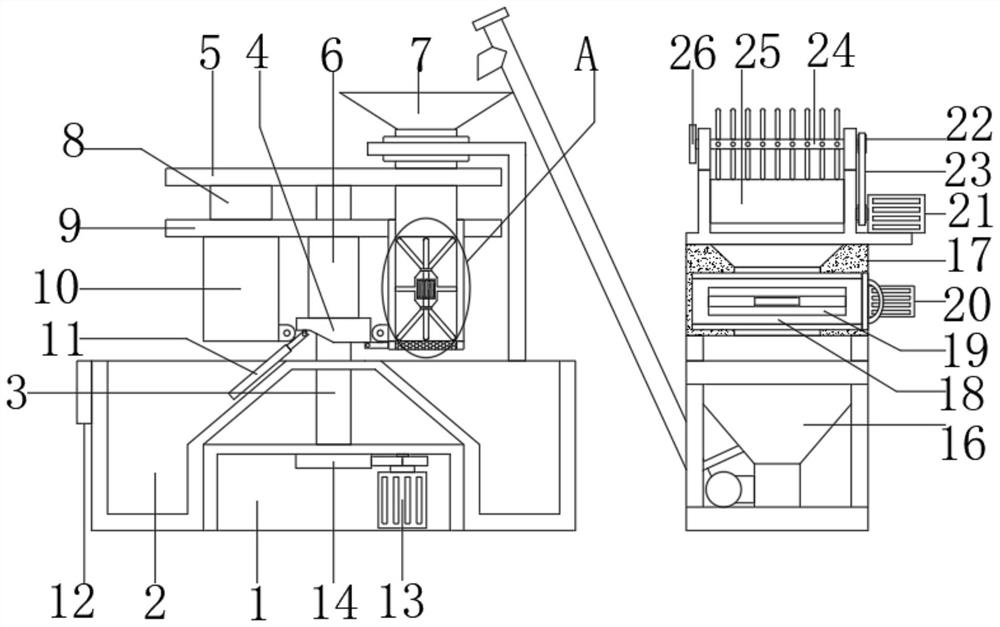

Efficient and energy-saving bio-organic fertilizer screening equipment

InactiveCN108816458AReasonable designRealize automatic feeding processSievingScreeningAgricultural engineeringOrganic fertilizer

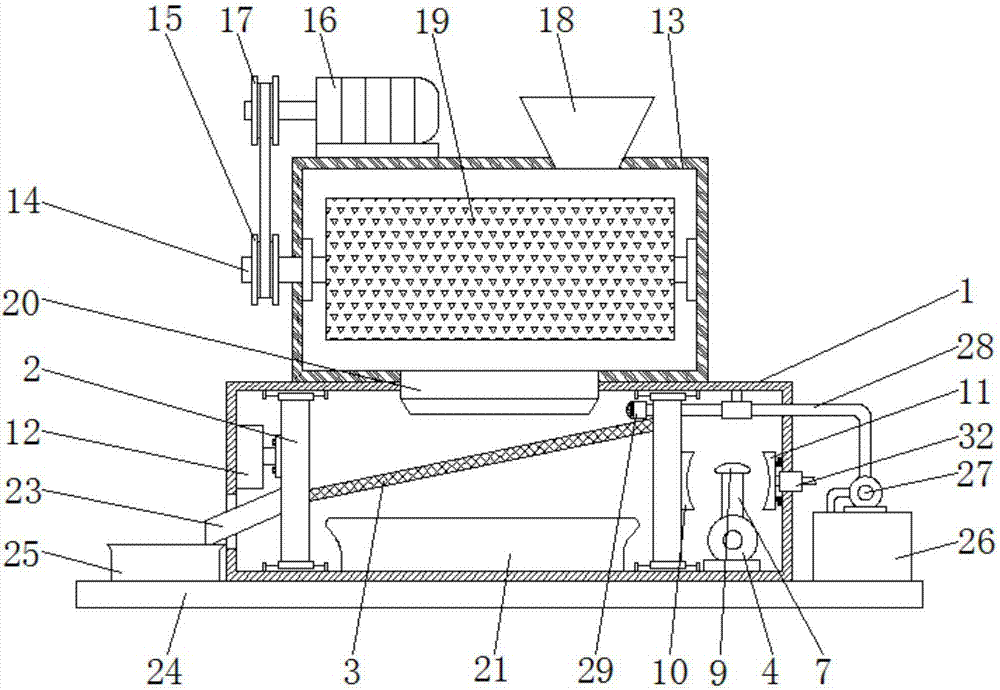

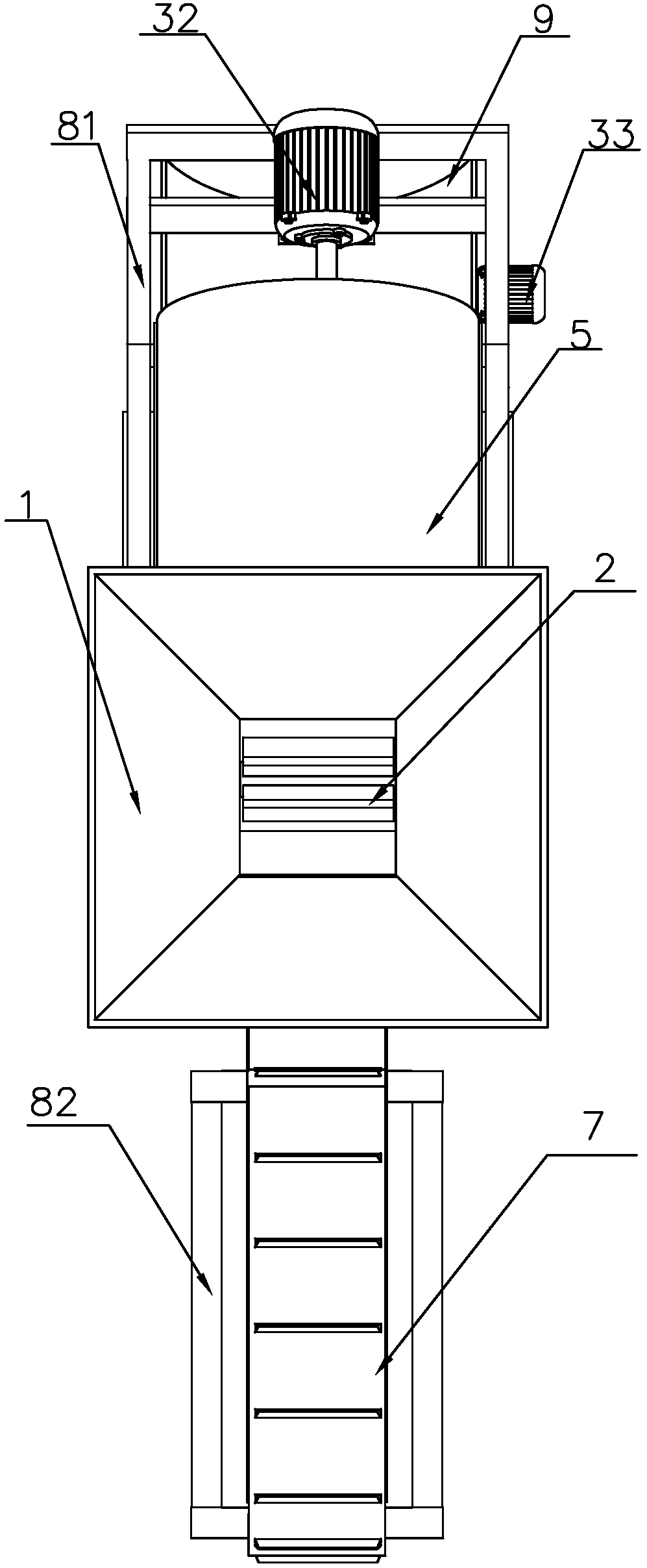

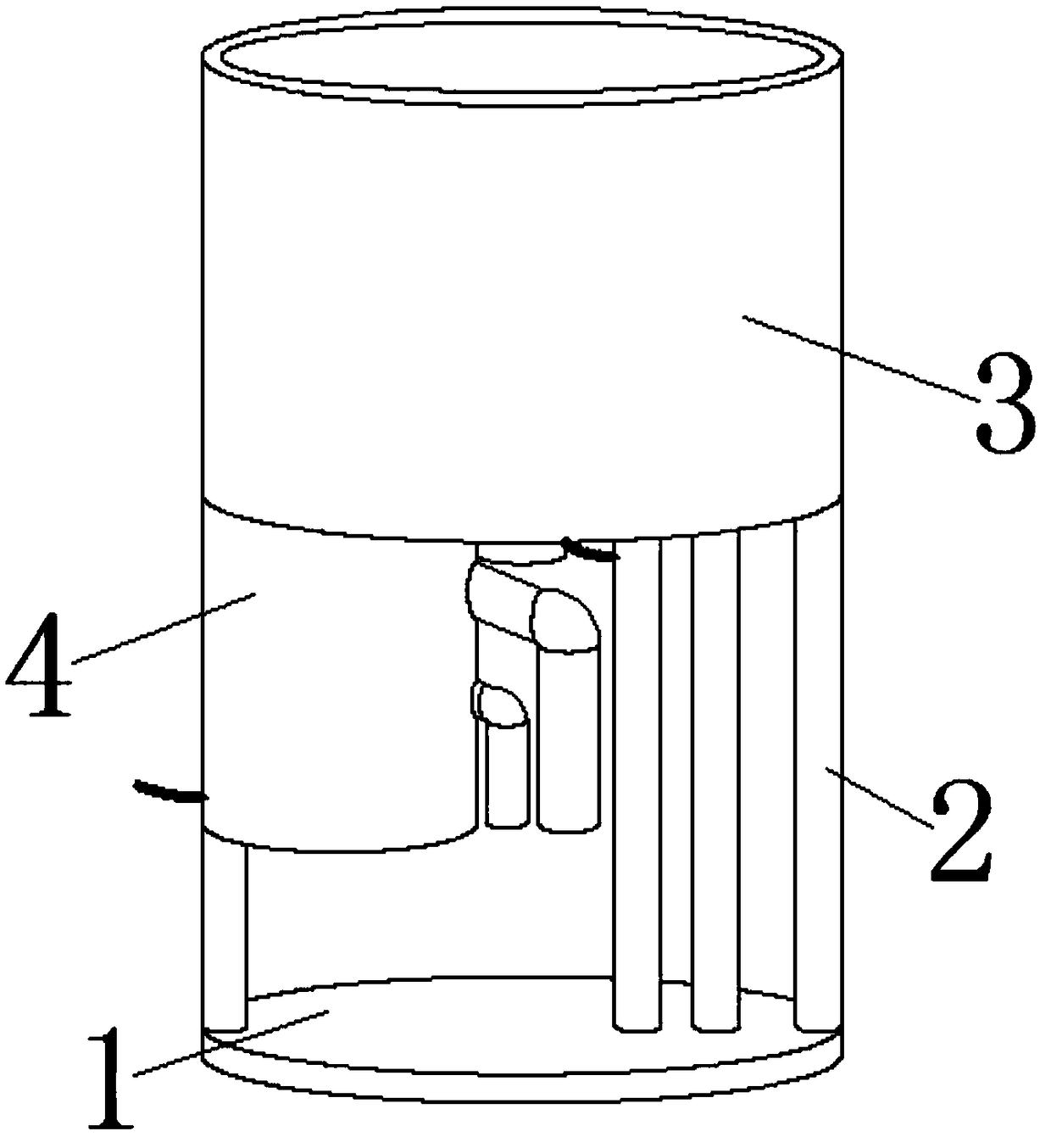

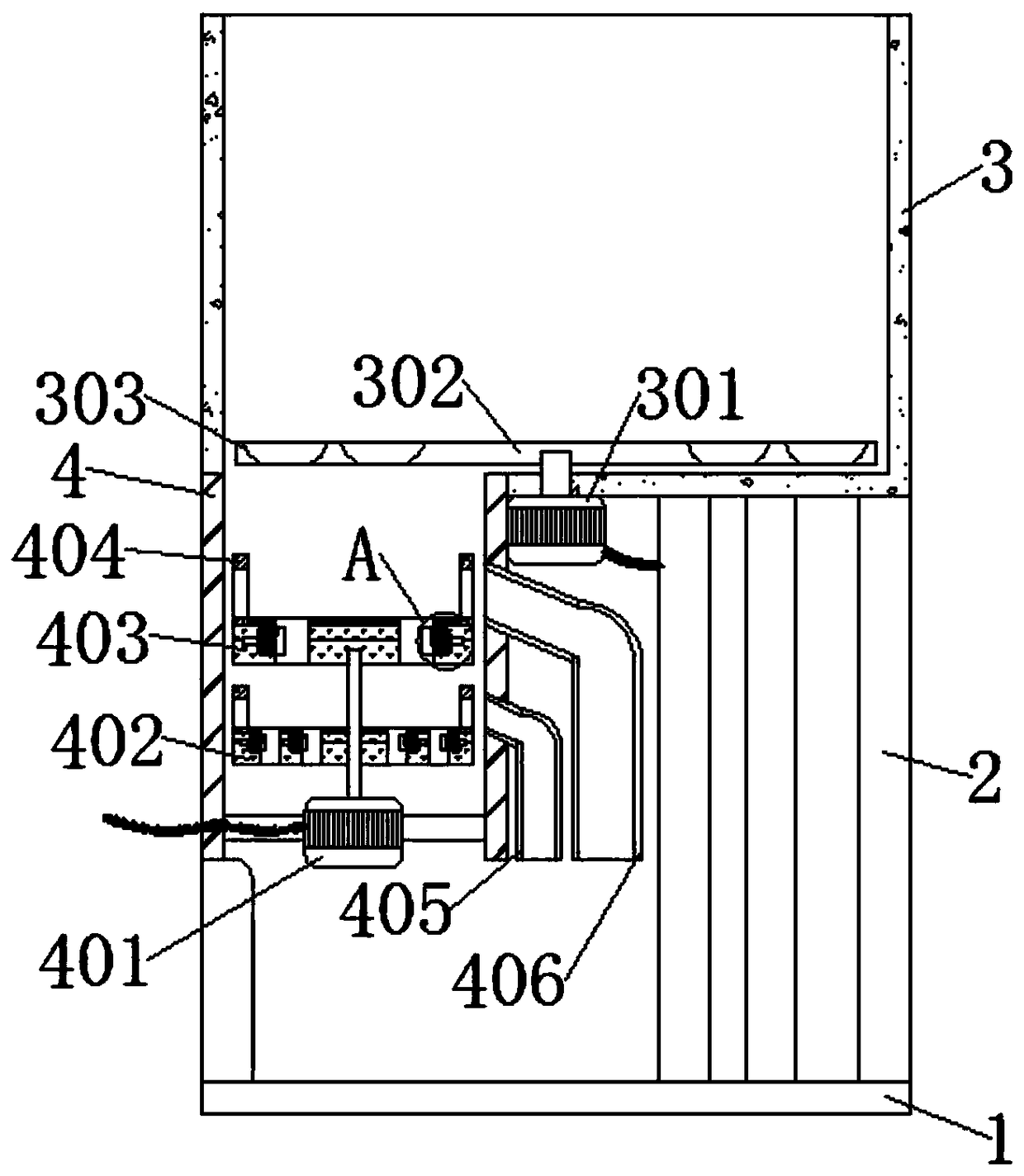

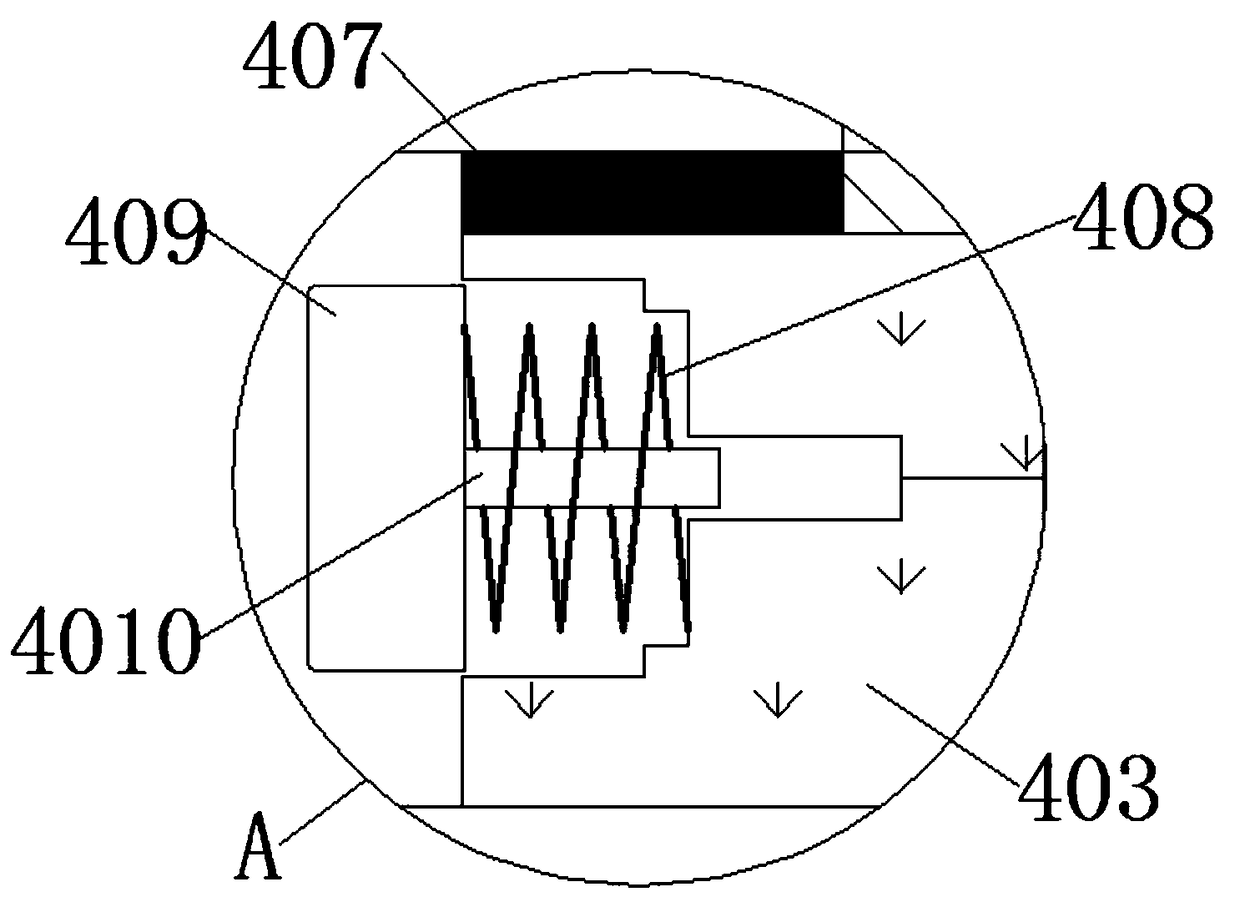

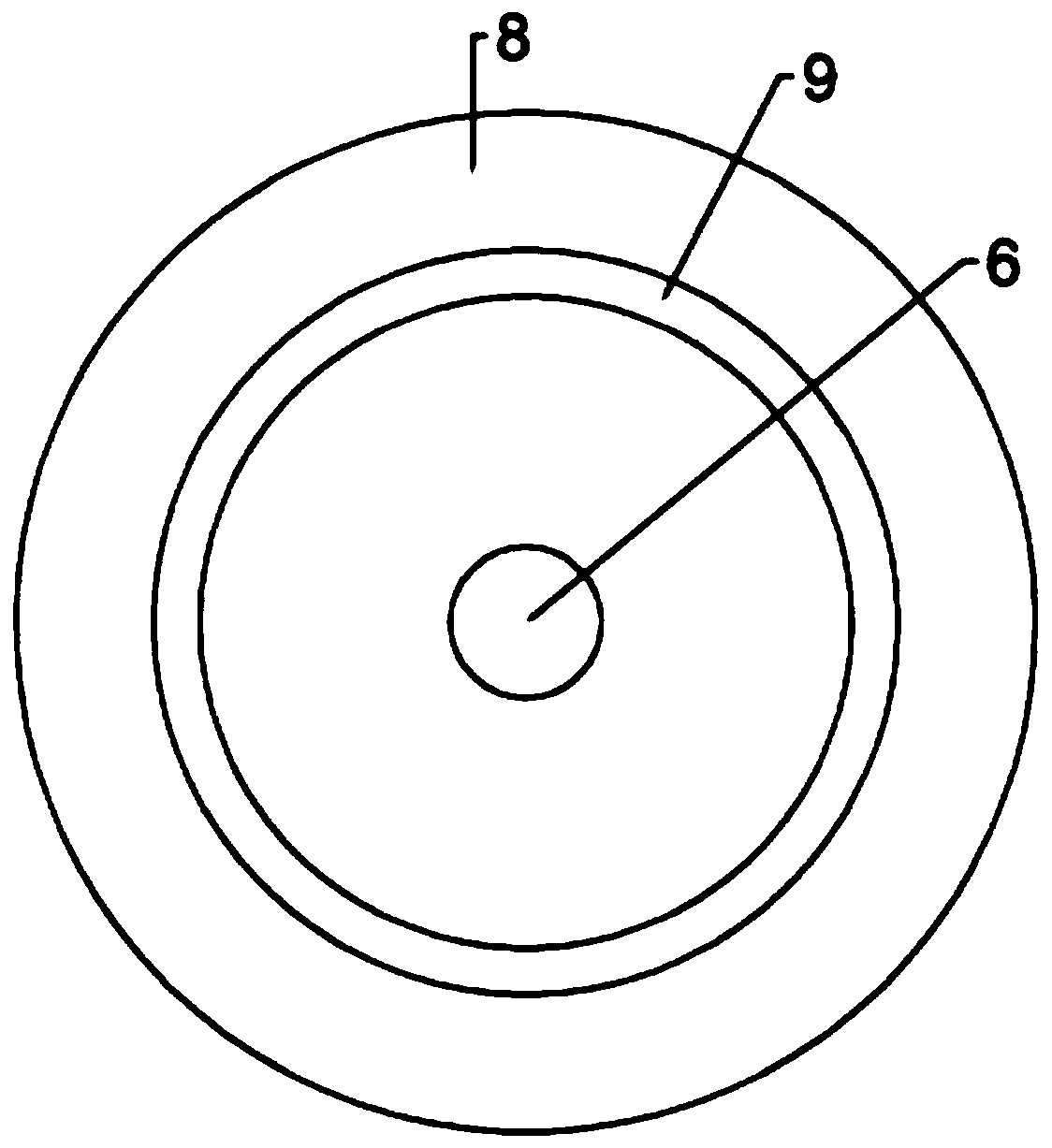

The invention discloses efficient and energy-saving bio-organic fertilizer screening equipment. The efficient and energy-saving bio-organic fertilizer screening equipment comprises a loading device, adispersing device, a screening device and a discharge device, wherein a movable frame is arranged below the loading device; a discharge hole of the loading device is connected with a charge hole of the dispersing device; a discharge hole of the dispersing device is connected with a circular hole in the top end of the screening device; a vibrating motor is mounted on the outer wall of the left side of the screening device; the vibrating motor is connected with a screen mounting frame through a vibrating shaft; a hot-air blower is mounted at the right end of the top of the screening device; anair inlet is formed in the right end of the top of the screening device; an air outlet of the hot-air blower is in sealing connection with the air inlet; a circular hole is formed in the right end ofthe bottom of the screening device; the circular hole is connected with one end of a bag type dust collector through a pipeline; and the other end of the bag type dust collector is connected with a heat exchanger through a pipeline. The efficient and energy-saving bio-organic fertilizer screening equipment is reasonable in design, can realize automatic loading, and improves working efficiency during screening; and the screened organic fertilizer particles are smaller and are more uniform.

Owner:霍邱金木鱼农业科技有限公司

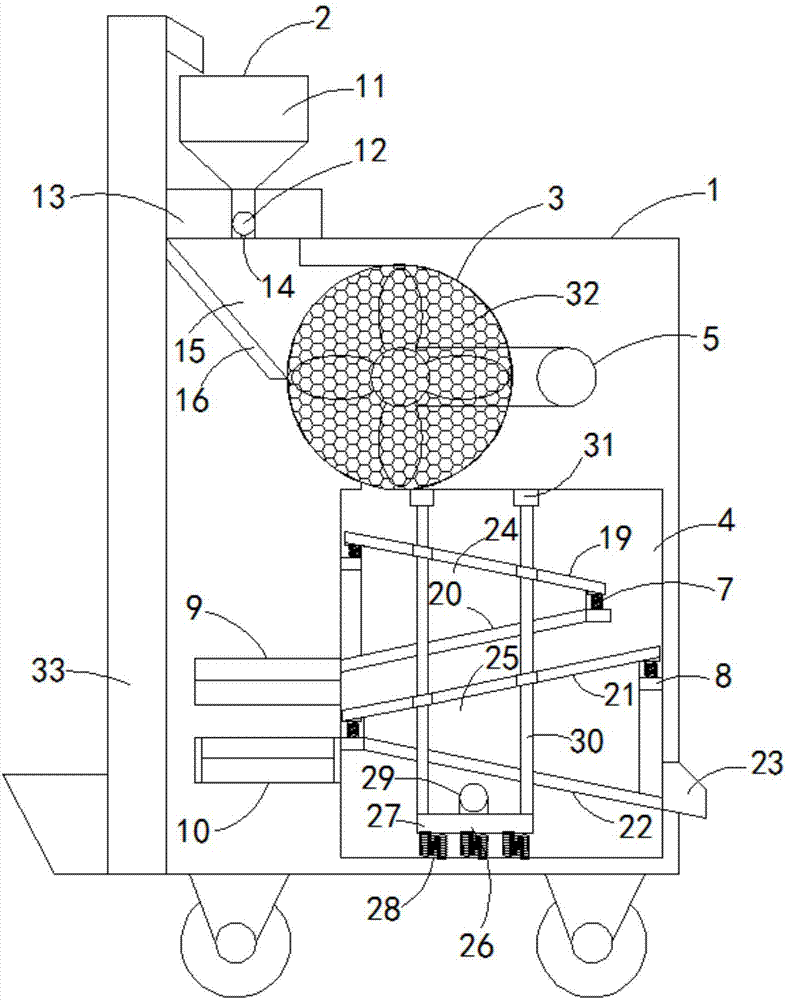

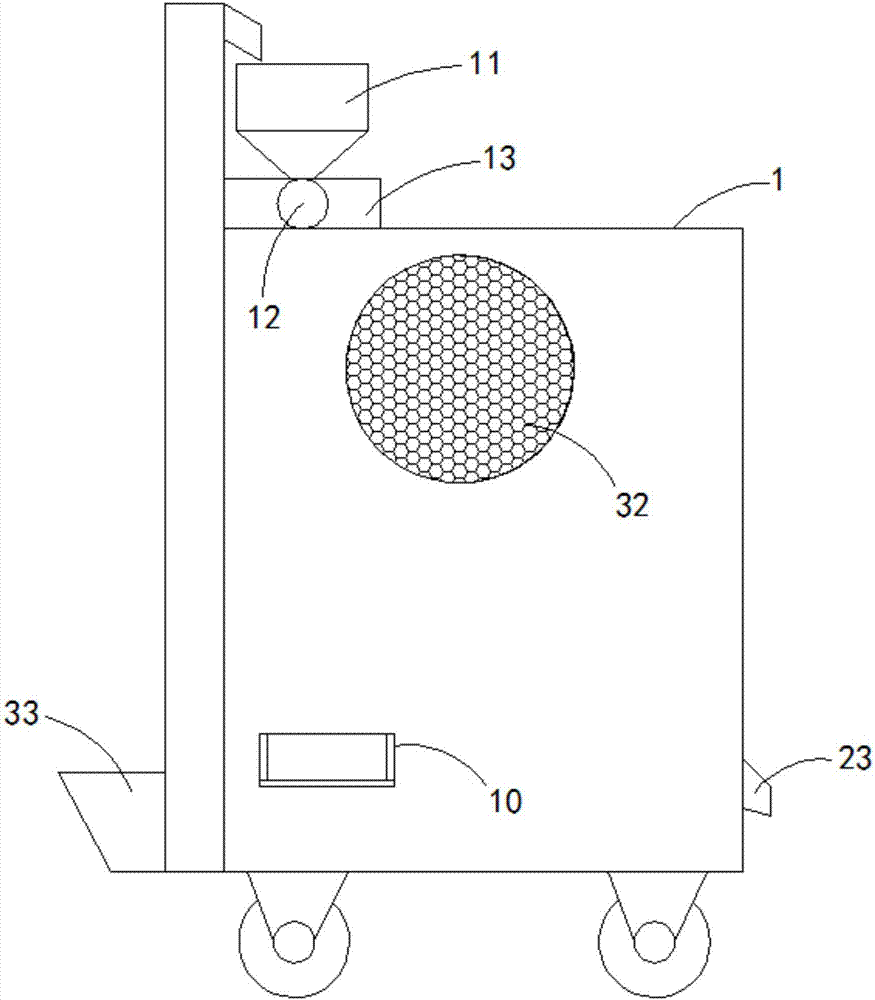

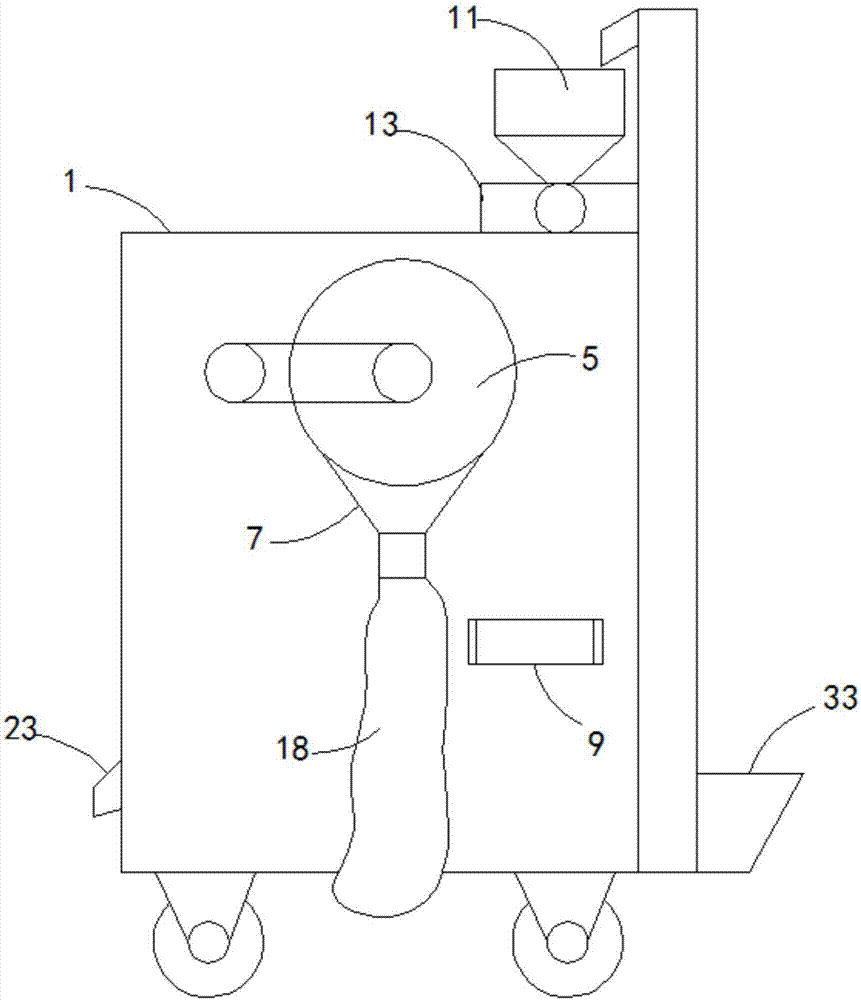

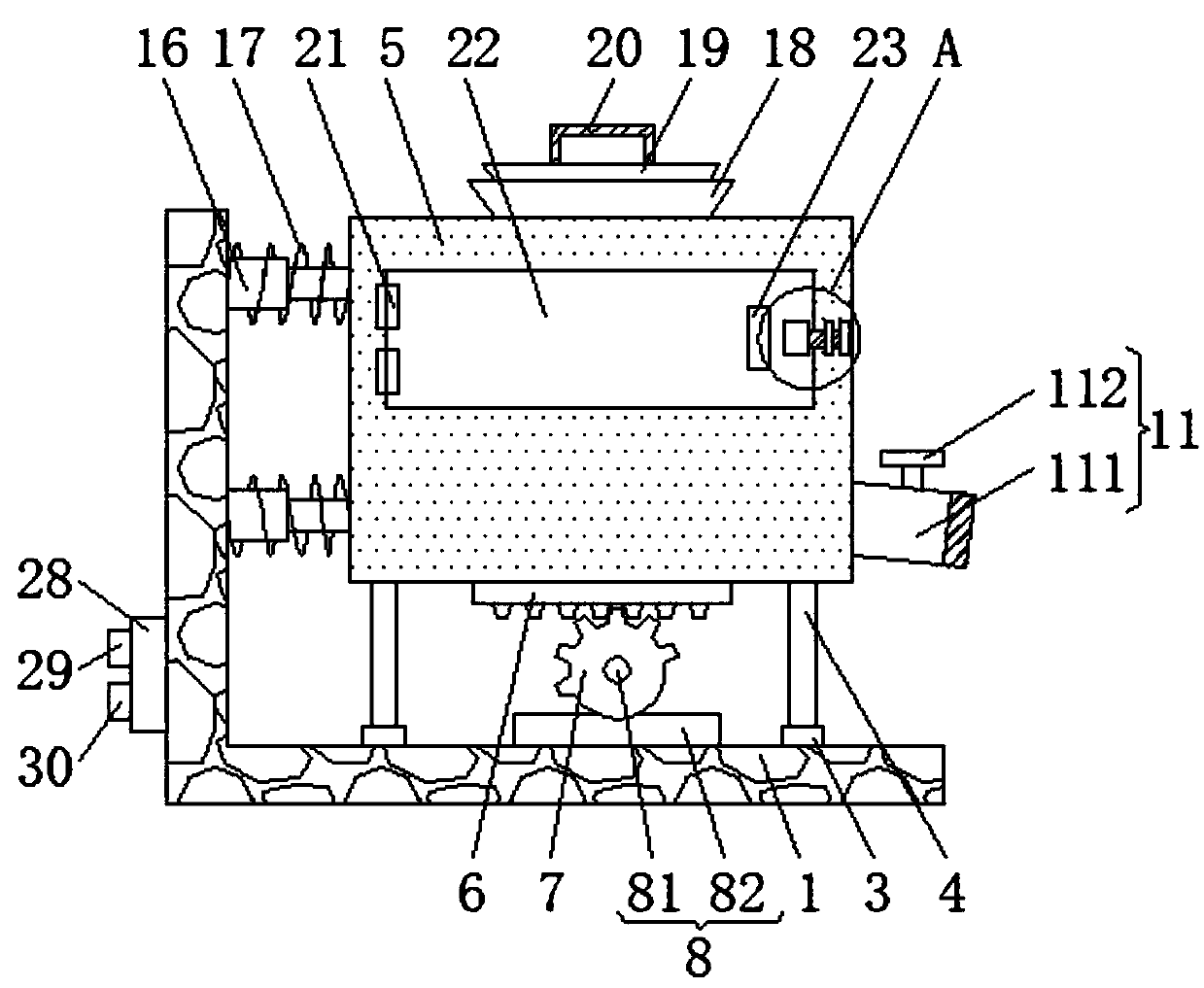

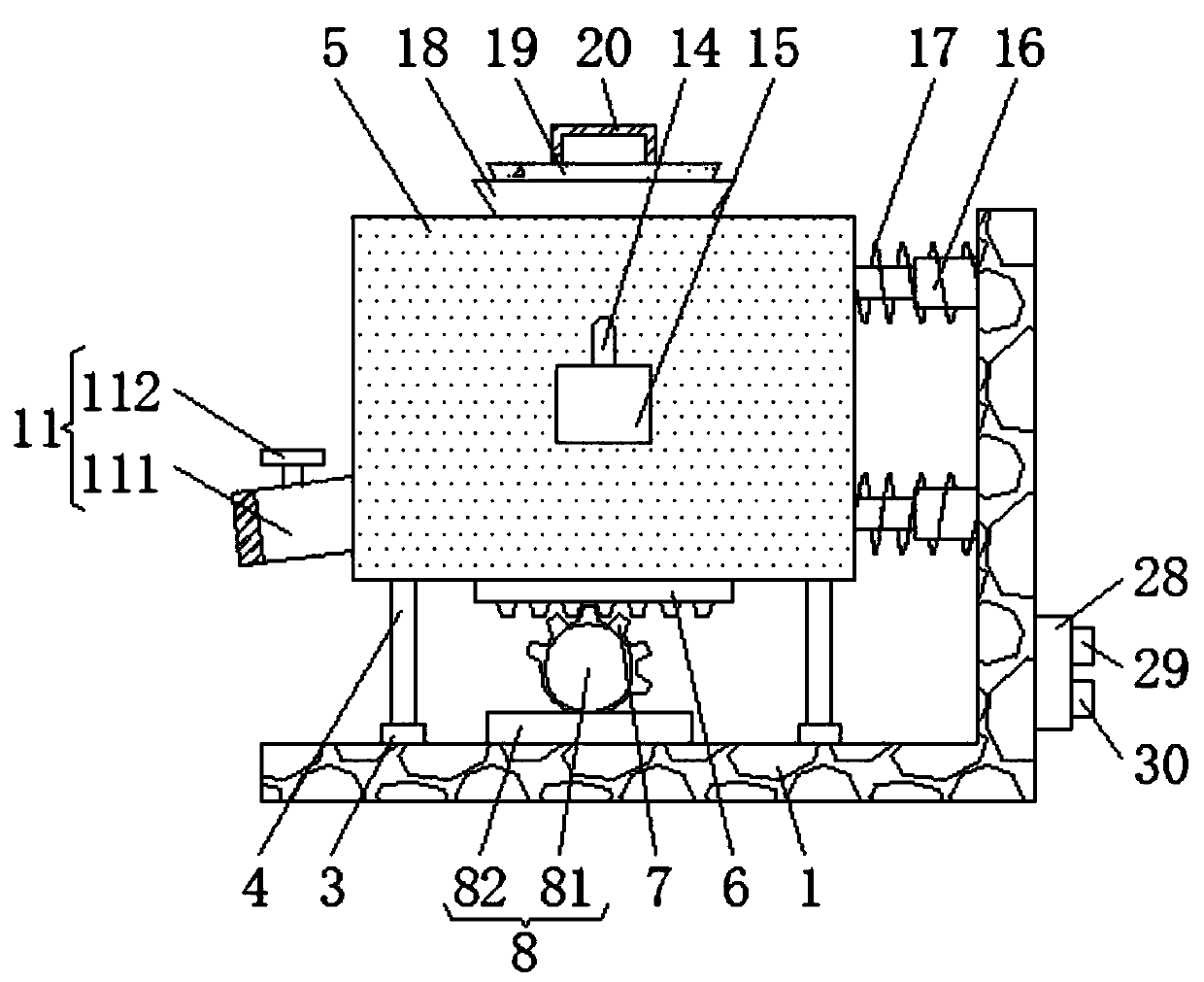

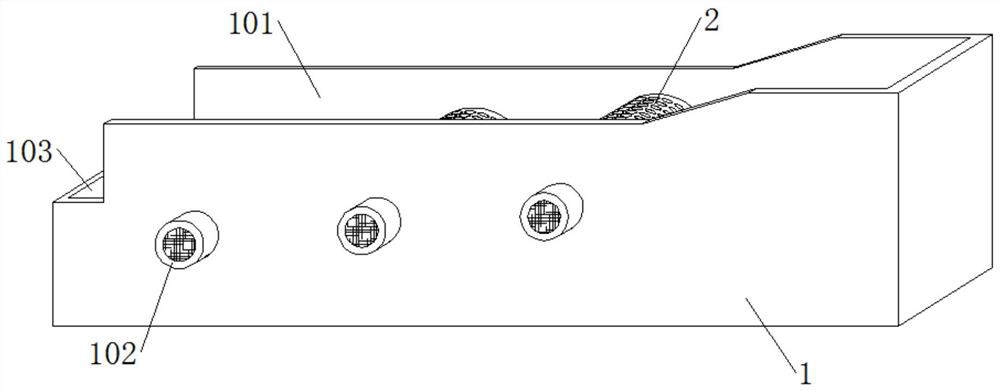

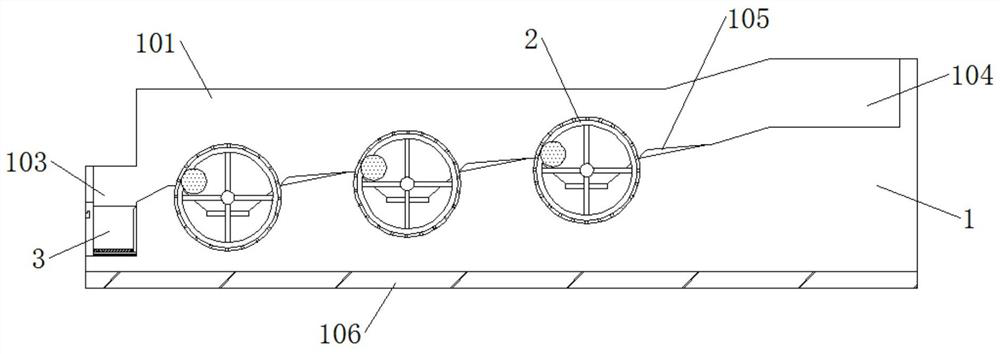

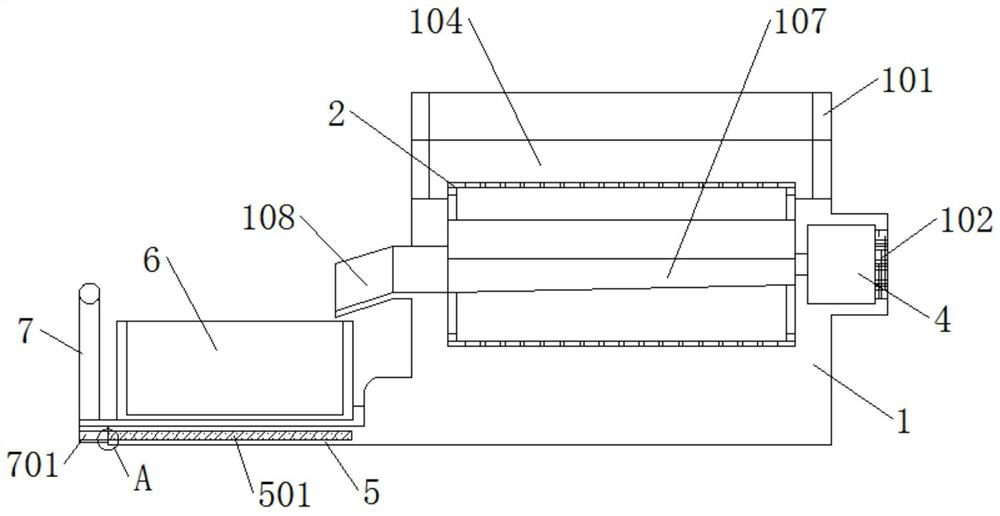

Crushing and screening integrated mine stone crusher

InactiveCN107138224AConvenient crushing workEasy to filter jobsSievingUsing liquid separation agentScreening effectCrushed stone

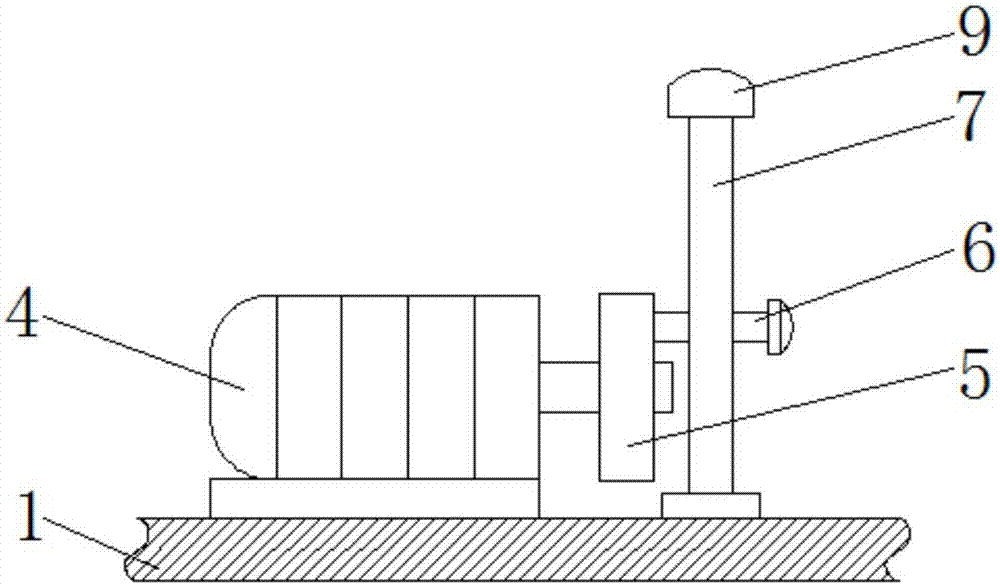

The invention discloses a crushing and screening integrated mine rock crusher, which comprises a screening box, a support plate is slidably connected between the top and bottom of the inner wall of the screening box, and a screen is fixedly connected between the two support plates. The bottom of the inner wall of the screening box and one side of the support plate are fixedly connected with a shaking motor, the outer surface of the output end of the shaking motor is covered with a turntable, and the side of the turntable away from the shaking motor is fixedly connected with a sliding rod. The bottom of the inner wall and one side of the shaking motor are rotatably connected to a swing plate through a connecting block. The invention relates to the technical field of mining crushing equipment. The crushing and screening integrated mine stone crusher greatly enhances the screening effect, and avoids the accumulation of crushed stones on the screen, which will cause the screen to be blocked, thus ensuring that the stone crusher can perform normal operation. Crushing and screening greatly facilitate people's ore crushing and screening work.

Owner:LIAONING TECHNICAL UNIVERSITY

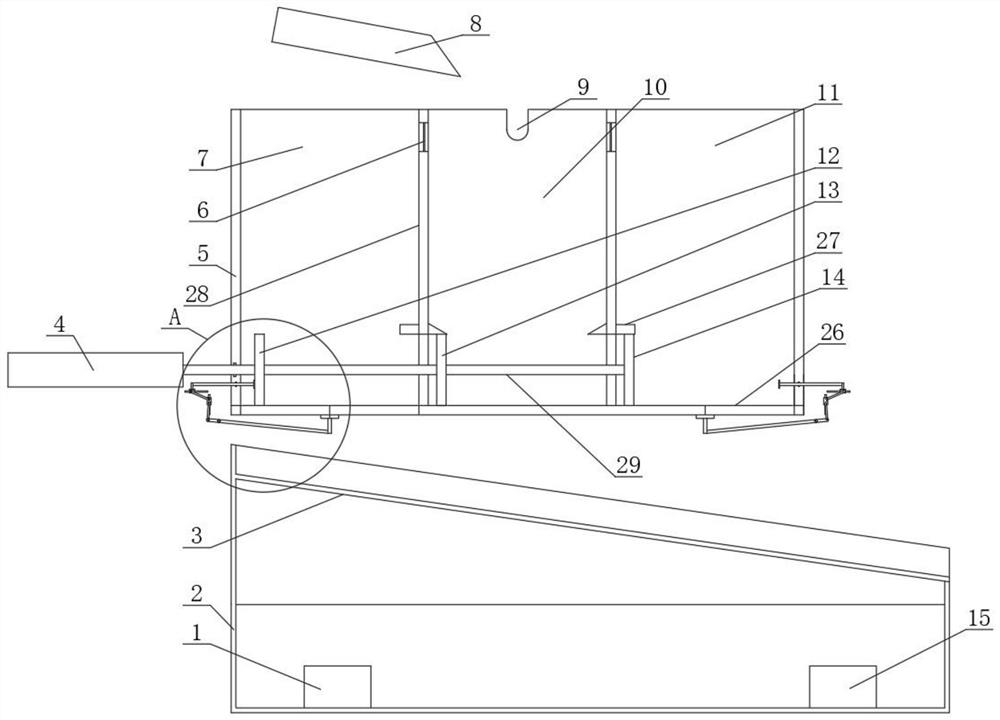

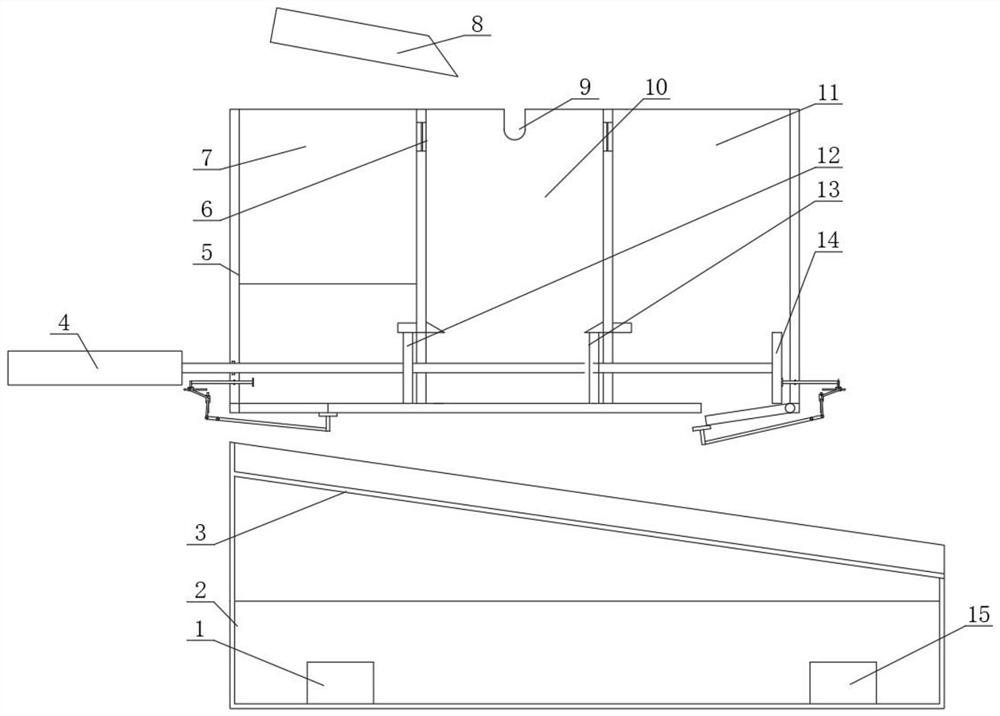

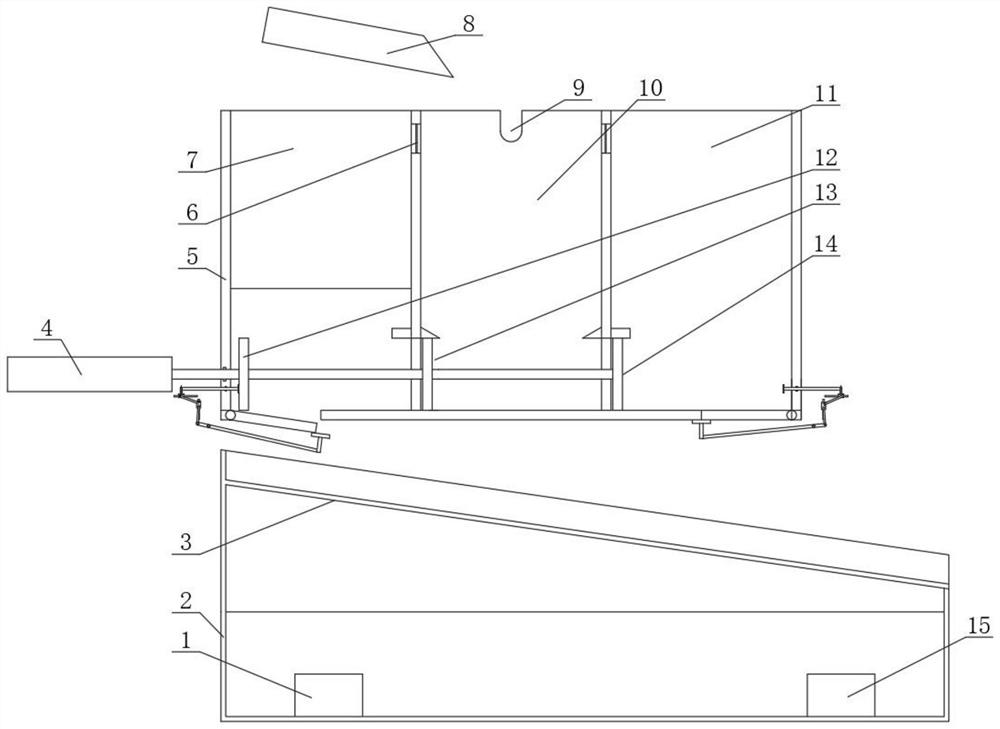

Raw material screening machine for production of new materials

InactiveCN108816362AMeet the needs of disassemblyEasy to filter jobsGrain treatmentsSolenoid valveEngineering

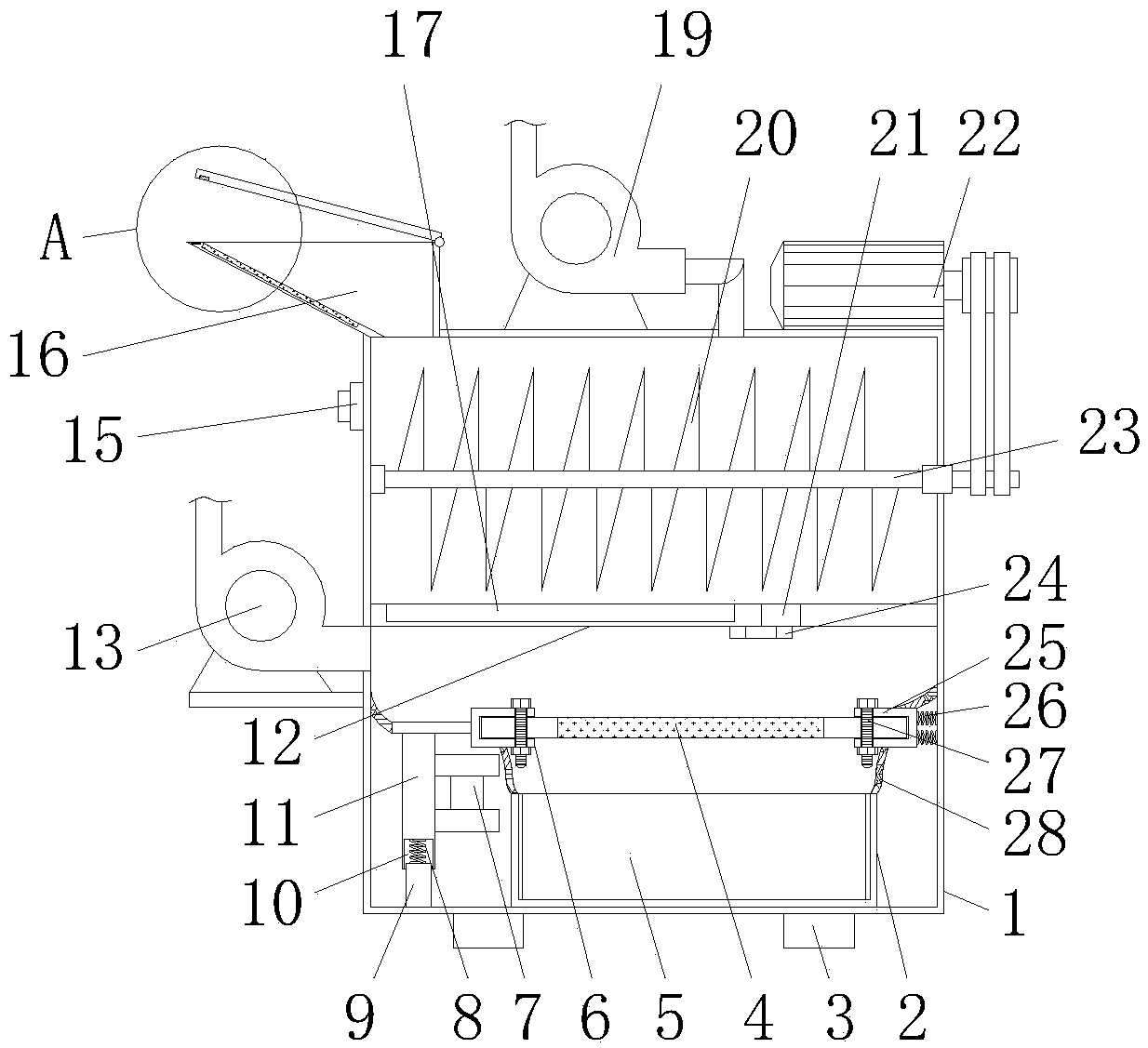

The invention discloses a raw material screening machine for the production of new materials. The raw material screening machine includes a shell and a second supporting rod, a crushing shaft is movably mounted at the upper end of an inner cavity of the shell, crushing teeth are fixedly connected with the outer surface of the crushing shaft, the middle of the inner cavity of the shell is fixedly connected with a partition plate, a heating plate is embedded in the left end of the top of the partition plate, and a discharging opening is formed in the right end of the inner surface of the partition plate; and a solenoid valve is movably mounted at the bottom of the discharging opening, and the right end of the bottom of the inner cavity of the shell is fixedly connected with a clamping seat.According to the raw material screening machine for the production of the new materials, screening nets are movably connected with the inner surface of a first clamping plate and a second clamping plate through fastening screws, through the action of a second spring, a moving door, a first supporting rod, a first spring, a groove, a second supporting rod and a vibrating motor, the detaching demandon the screening nets can be met, the screening nets can be replaced and washed, meanwhile, the raw materials of different particle sizes can be screened out, and the great convenience is brought tothe raw material screening of the new materials.

Owner:永春科盛机械技术开发有限公司

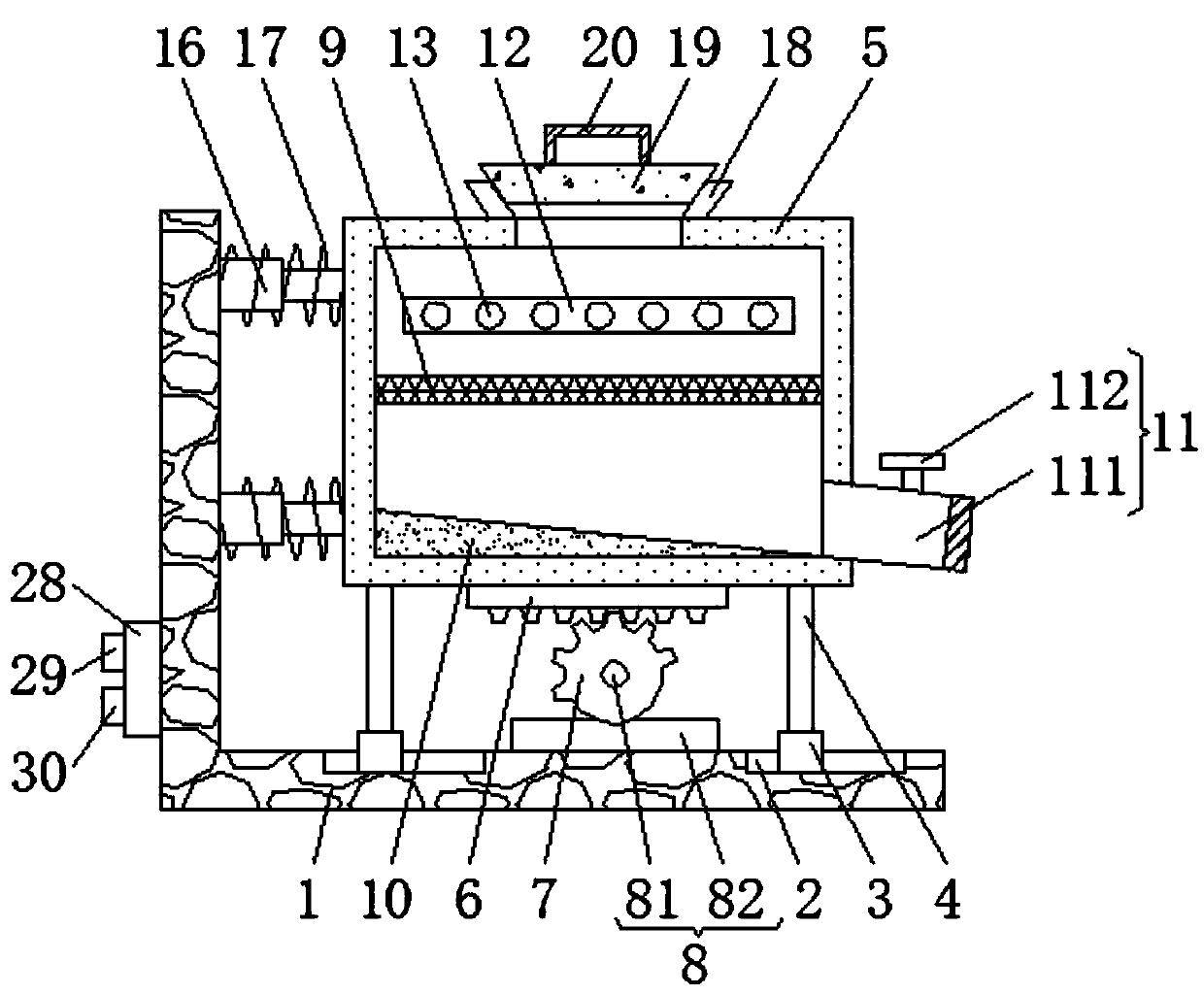

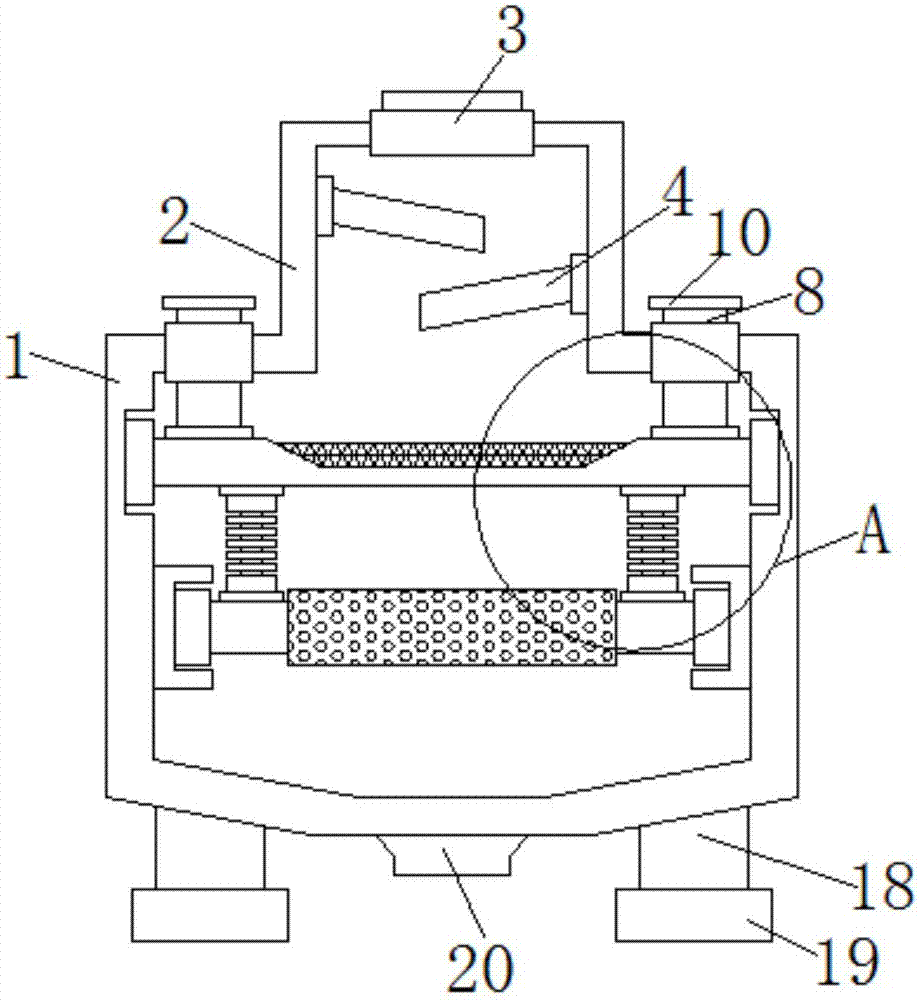

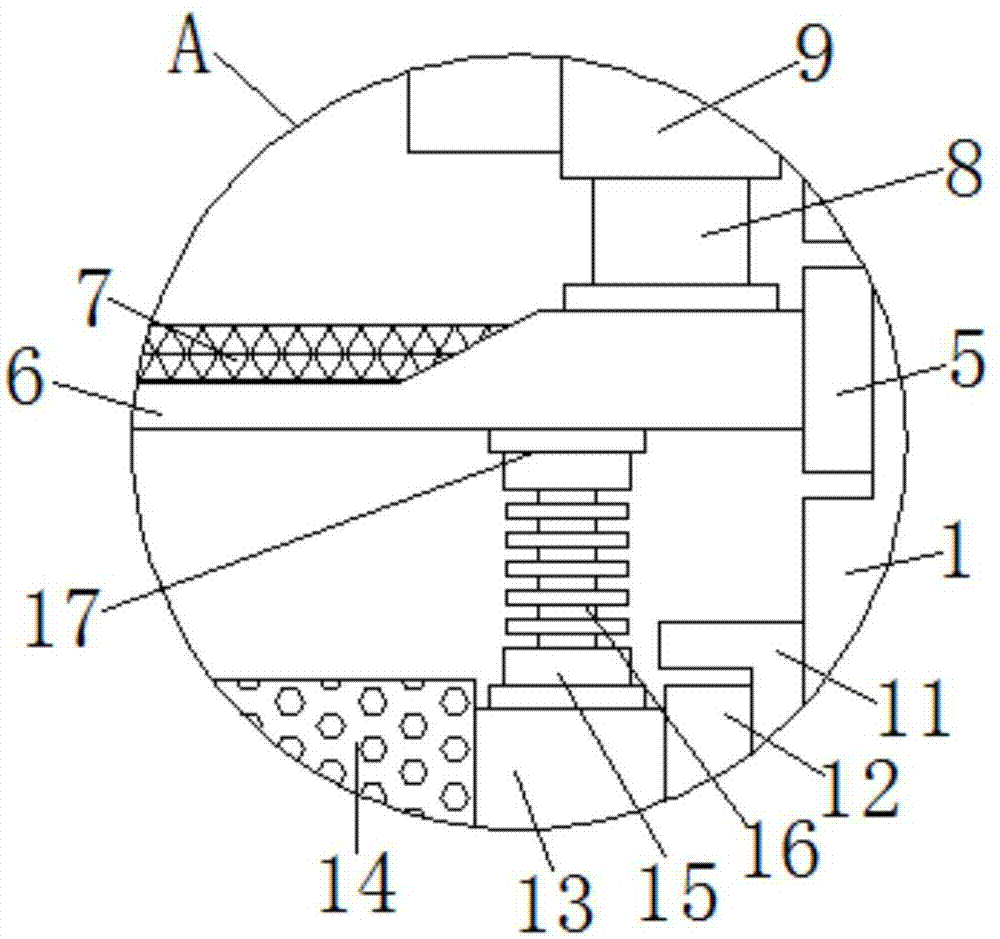

Vibrating screen for mine stone processing

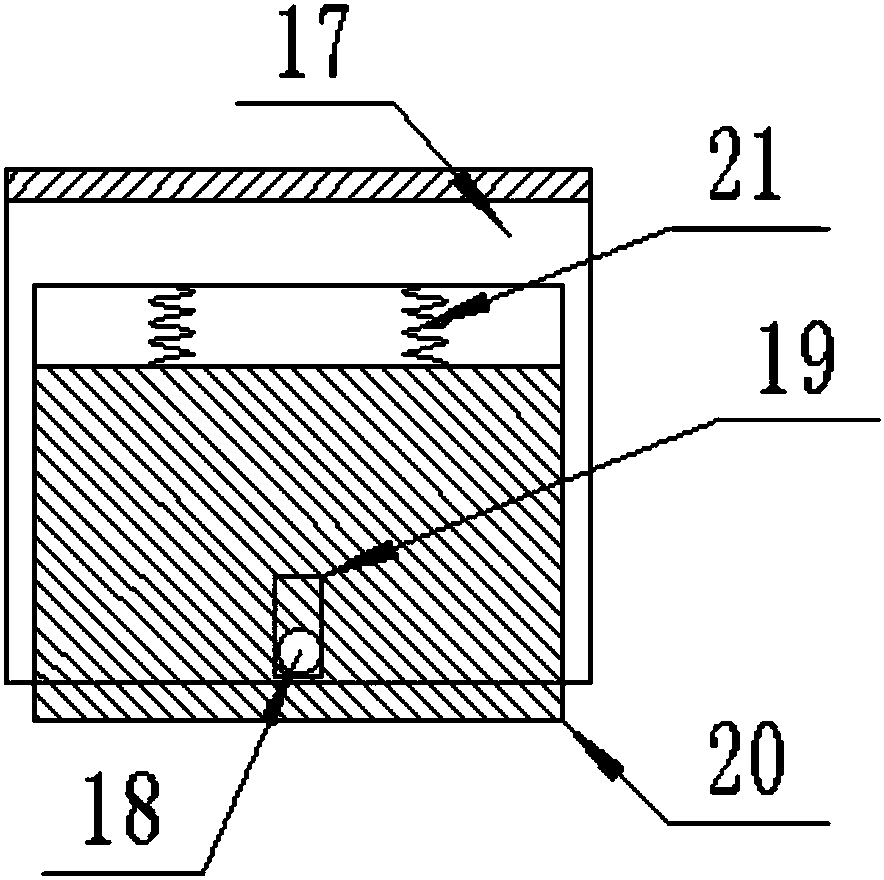

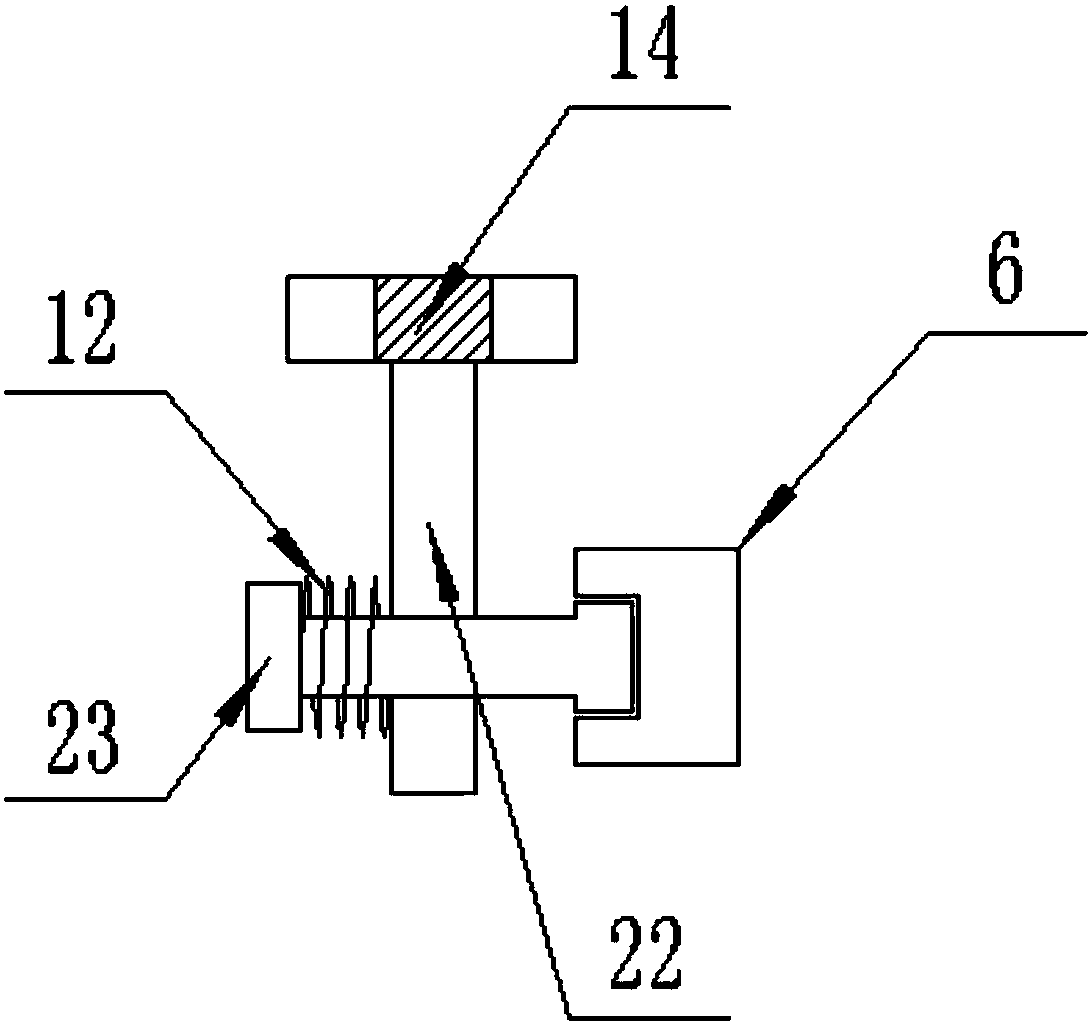

InactiveCN110882808AEasy to pass throughEasy to filter jobsSievingScreeningFixed frameClassical mechanics

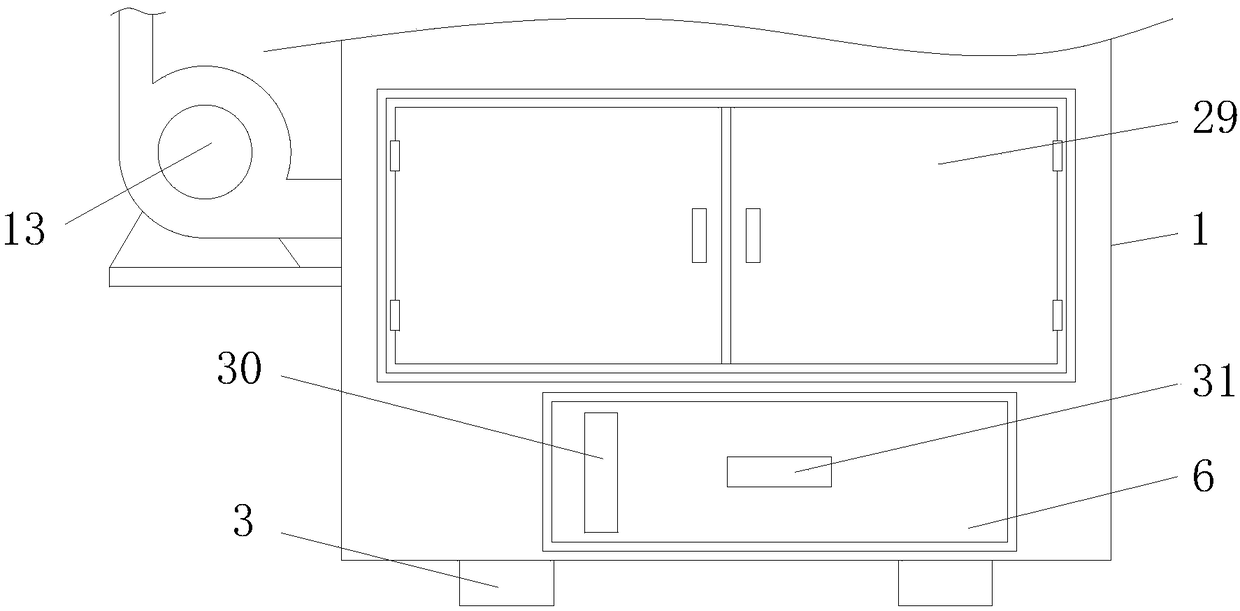

The invention relates to the field of mining machinery. More particularly, the present invention relates to a vibrating screen for mine stone processing. The vibrating screen comprises a shell, a feeding port, a sieve plate and a vibrating motor; a crushing plate is mounted in the shell; a crankshaft is mounted in the shell; the outer side wall of the shell is fixedly connected with a crushing motor; a connecting rod sleeves the shaft neck of the crankshaft; the sieve plate is mounted in the shell; the bottom of the sieve plate is fixedly connected with a guide plate; the vibrating motor is mounted at the bottom of the guide plate; a fixed frame is arranged below the guide plate; the upper surface of the fixed frame is fixedly connected with a spring; the top end of the spring is fixedly connected with the guide plate; and a crushing roller is mounted on the fixed frame. The crushing plate is used for crushing stone, and the vibrating motor is used for driving the sieve plate to vibrate up and down, so that ore can penetrate through the sieve plate advantageously, thereby improving the screening efficiency; meanwhile, the vibrating motor is used for driving the sieve plate to vibrate left and right, thereby further improving the screening efficiency, and facilitating the screening operation; and stone is further crushed through crushing blades on crushing rollers.

Owner:ZHUZHOU TIANQIAO SHUNCHEN COAL PREPARATION MACHINERY

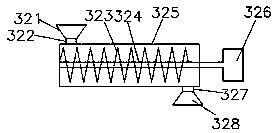

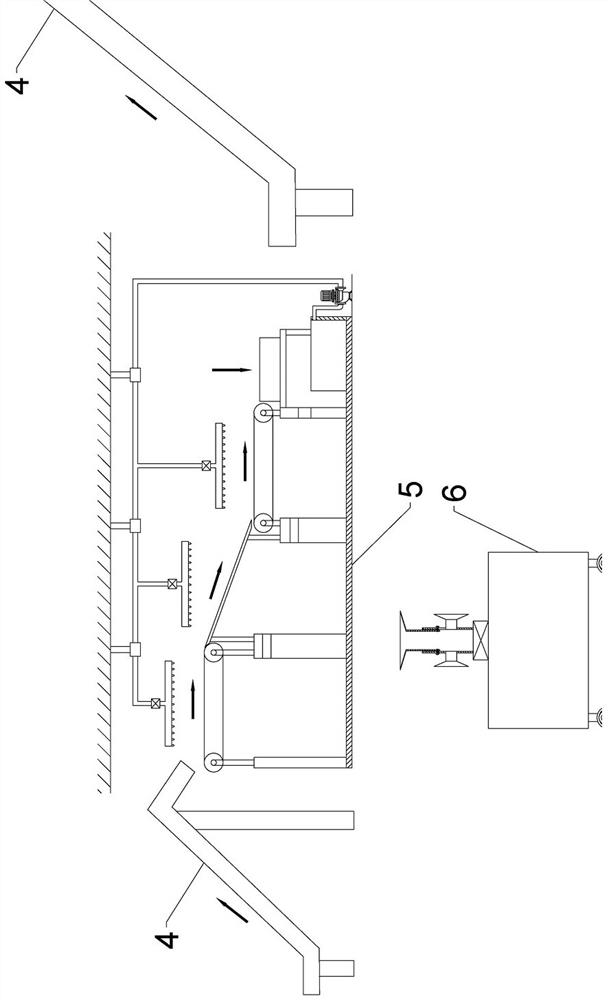

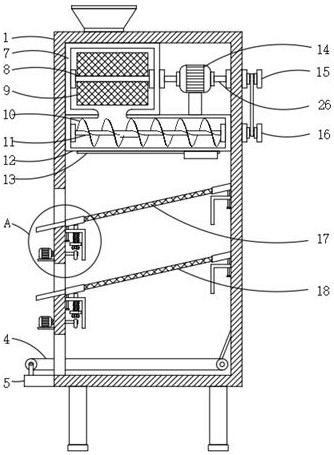

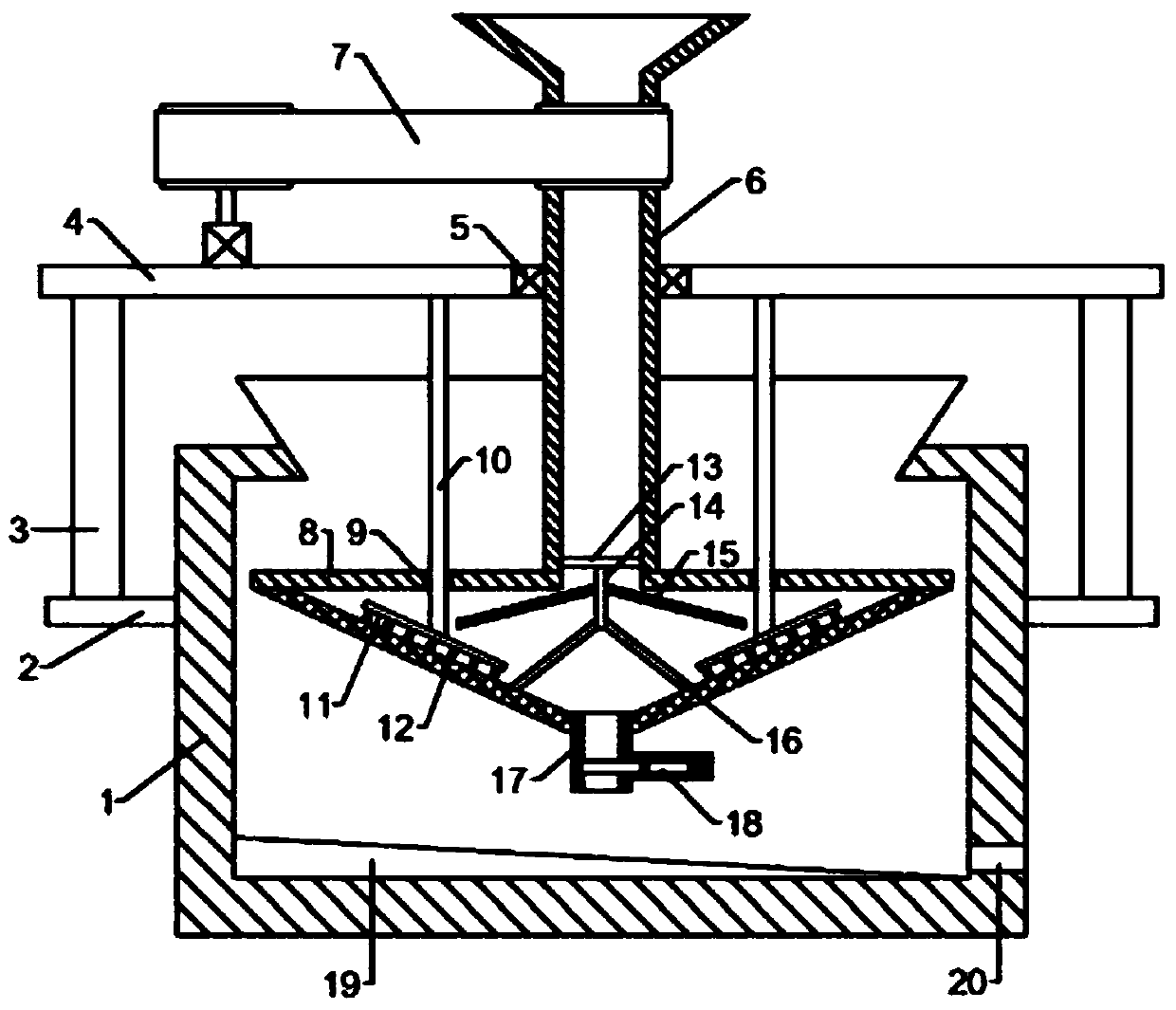

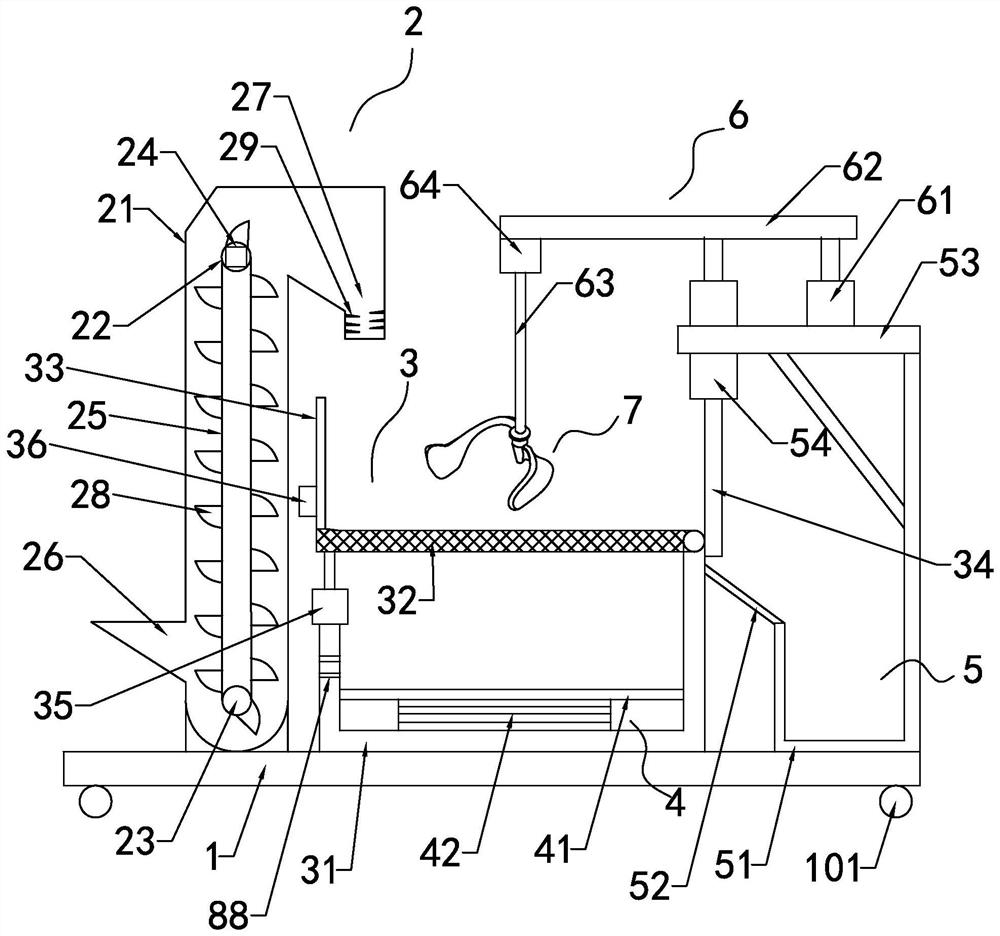

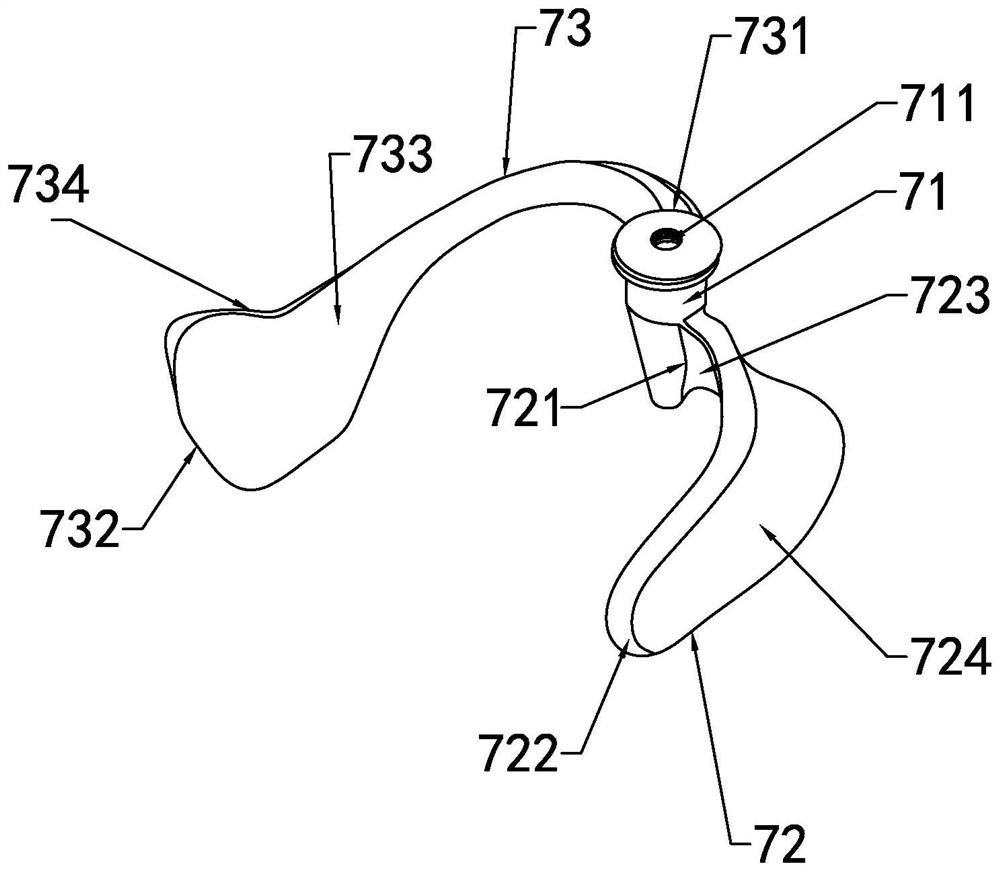

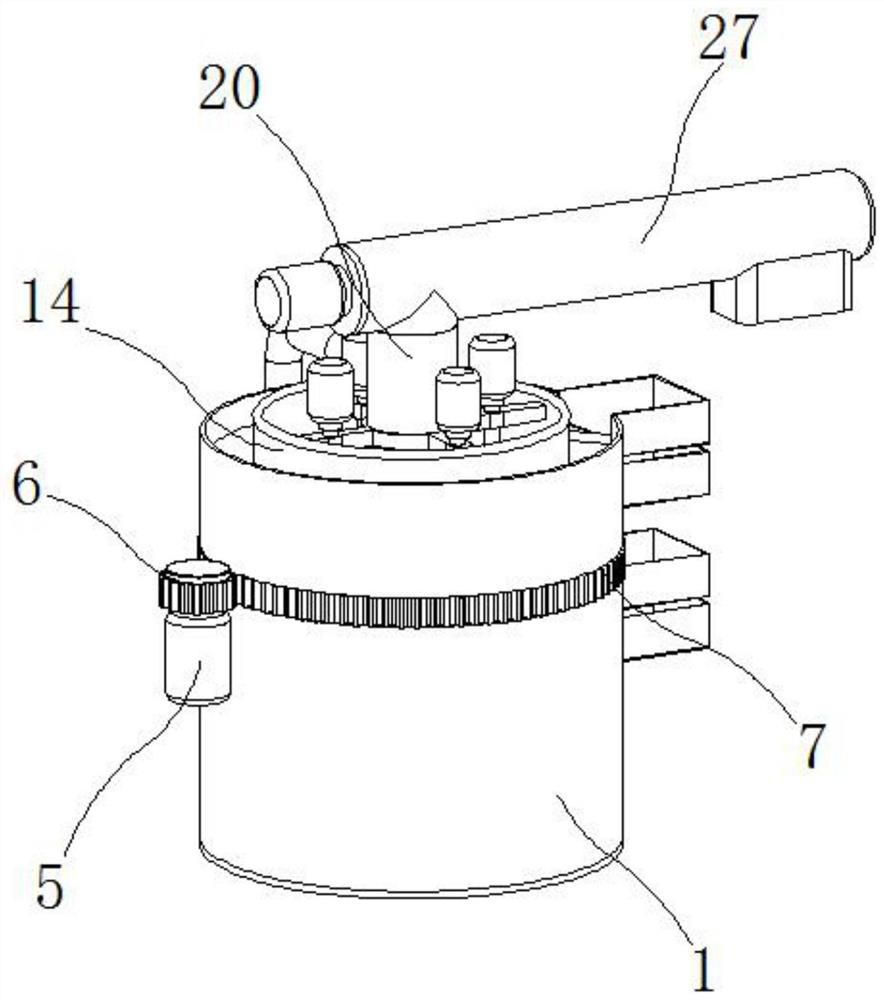

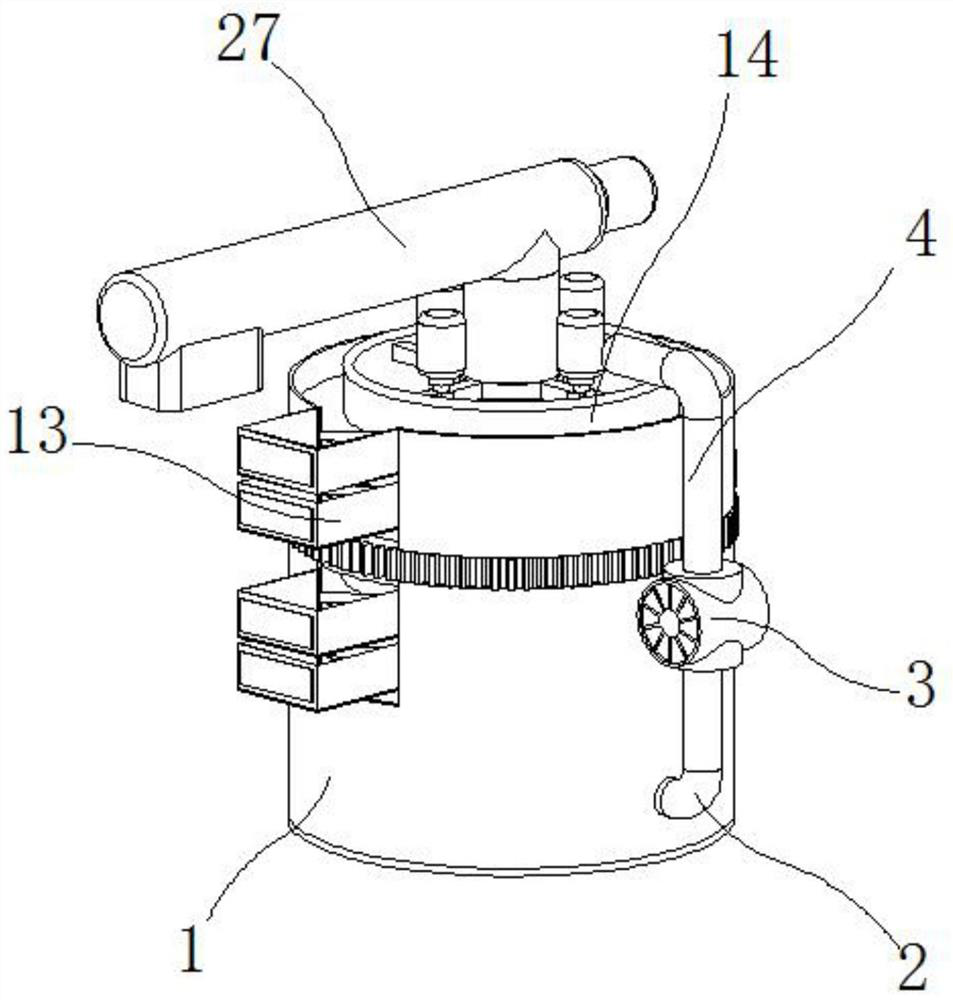

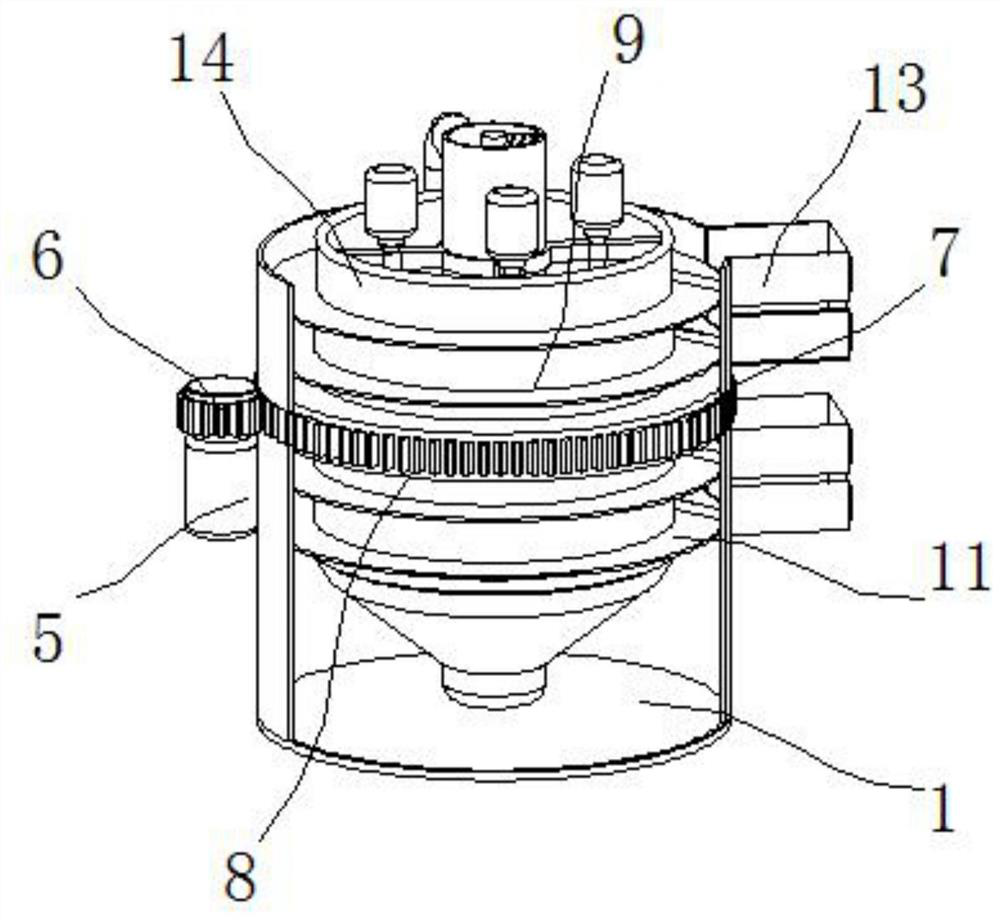

Negative pressure winnowing separation device for coix seed machining

The invention belongs to the technical field of barley processing equipment, and in particular relates to a barley processing negative pressure winnowing and separating device, which includes a machine body, a feeding mechanism is arranged on the upper side of the machine body, a negative pressure winnowing chamber and a vibrating screening chamber are arranged inside the machine body, and The lower end of the press air separation chamber is connected with the upper end of the vibrating screening chamber. The two sides of the negative pressure air separation chamber are respectively provided with an air inlet and an air outlet. The outside of the air outlet is connected with a negative pressure fan, and the lower end of the negative pressure fan is connected with a dust collection mechanism. ; There is a first-level brushing mechanism and a second-level screening mechanism in the vibrating screening chamber. The primary screening mechanism is connected with the second discharge chute, and a vibrating mechanism is also provided in the vibrating screening cavity, and the vibrating mechanism is respectively connected with the primary brushing mechanism and the secondary screening mechanism. The advantage is that the method can not only improve the sorting effect, but also save the cost of barley processing.

Owner:GUIZHOU HUATENG AGRI TECH CO LTD

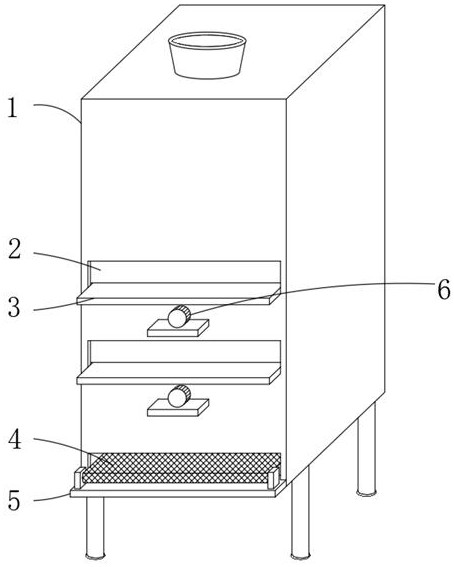

Soil screening machine

The invention mainly discloses a soil screening machine. According to the technical scheme, the soil screening machine comprises a bottom frame, a feeding port, discharging ports and a screening device. An adjusting inserting plate is arranged at the position of the feeding port. Springs are arranged on the bottom frame. The springs are connected with the screening device. A supporting frame is arranged on the two outer sides of a vibrating frame. A vibration motor is installed on the supporting frame. The two inner sides of the vibrating frame are each provided with at least two first sliding grooves. Vibrating screens are connected into the first sliding grooves in a sliding manner. The hole diameters of screen holes of the vibrating screens on different layers are sequentially reduced from top to bottom. The upper side of the vibrating frame is provided with a dustproof cover. A second sliding groove is formed in the bottom of the dustproof cover. The second sliding groove is provided with a rake connected with the second sliding groove in a sliding manner. An air cylinder is further arranged at the bottom of the dustproof cover. Baffles are arranged on the two sides of the discharging ports. The widths of the discharging ports are gradually reduced from the head portion to the tail portion, and the discharging directions of the discharging ports are different. The soil screening machine has the beneficial effects of being simple in structure, high in screening efficiency, convenient to use and capable of saving cost.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Roller sand screening machine for building

The invention discloses a drum sand screening machine for construction, which comprises a hopper, a turning arm, a motor I, a motor II, a motor III, a drum, a baffle I, a baffle II, a transmission device, Frame, transmission device frame, baffle IV, chain drive, gear III, gear IV, eccentric wheel; motor I is installed on the side below the hopper, and a turning arm is installed on the side of motor I, and motor I is installed on the bottom of the hopper On the outer wall, the motor I is connected with the turning arm to drive the turning arm to rotate in the hopper. The invention avoids the material blocking in the hopper, ensures the working efficiency of the drum sand screening machine, and prevents the materials moving with the drum from spilling outwards, reduces the manual workload in the later stage, and changes the drum The original motion trajectory realizes better separation of materials and increases the working efficiency of the drum sand screening machine.

Owner:邱善晓

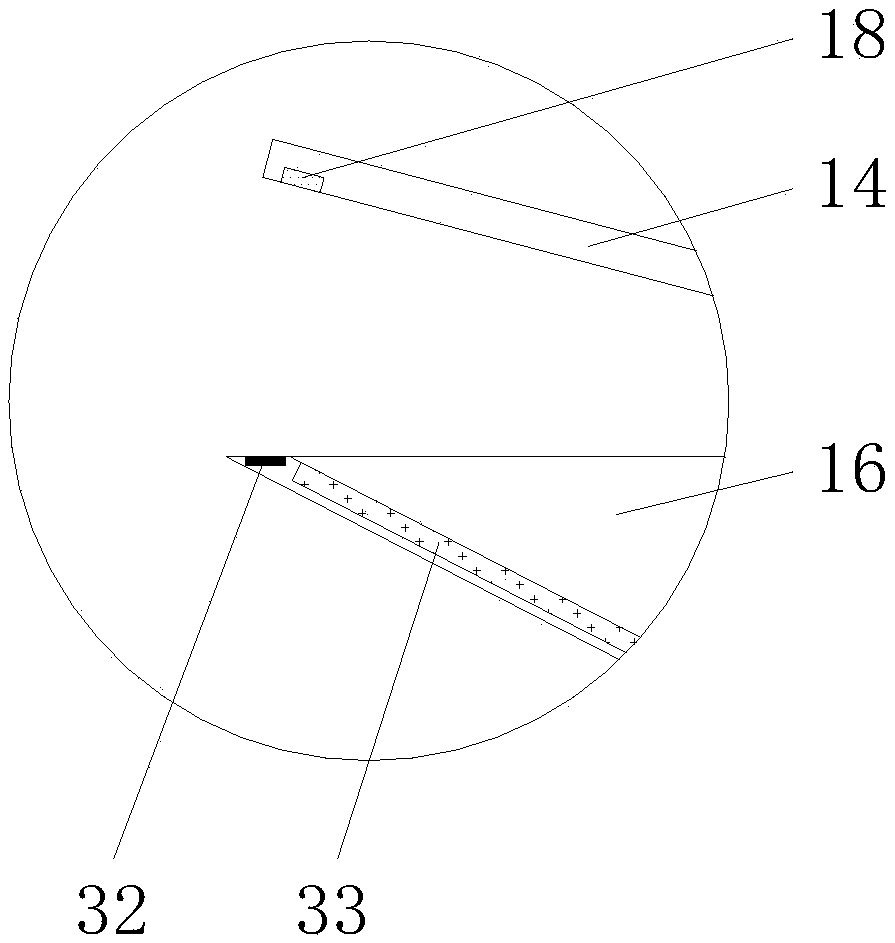

Apple screening device using centrifugal force for controlling screening

The invention provides an apple screening device using centrifugal force for controlling screening. The apple screening device comprises a bottom plate, a storage barrel, a screening cylinder and brackets. The top of the bottom plate is provided with the four brackets in a welded manner, the screening cylinder and the storage barrel are welded to the tops of the brackets, and the screening cylinder is welded to one side of the bottom of the storage barrel in an embedded manner; the storage barrel includes a damping motor, a disc and a circular hole, the bottom of the storage barrel is providedwith the damping motor in a welded manner, and the top of the damping motor is provided with the disc in a welded manner. According to a second screening plate and a first screening plate on the apple screening device, screening holes in the second screening plate and the first screening plate are different in size, apples in different sizes can be divided into three types, repeated screening isnot needed, time and effort are saved, clamping blocks in the screening holes can shrink outwards due to rotation of the second screening plate and the first screening plate, the positions of the clamping blocks in the screening holes can be adjusted by controlling the rotation speed of the motor, the screening holes are made to be suitable for screening the apples in various sizes, and the applescreening work is facilitated.

Owner:田雨琦

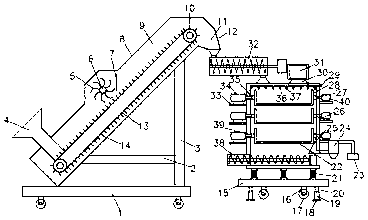

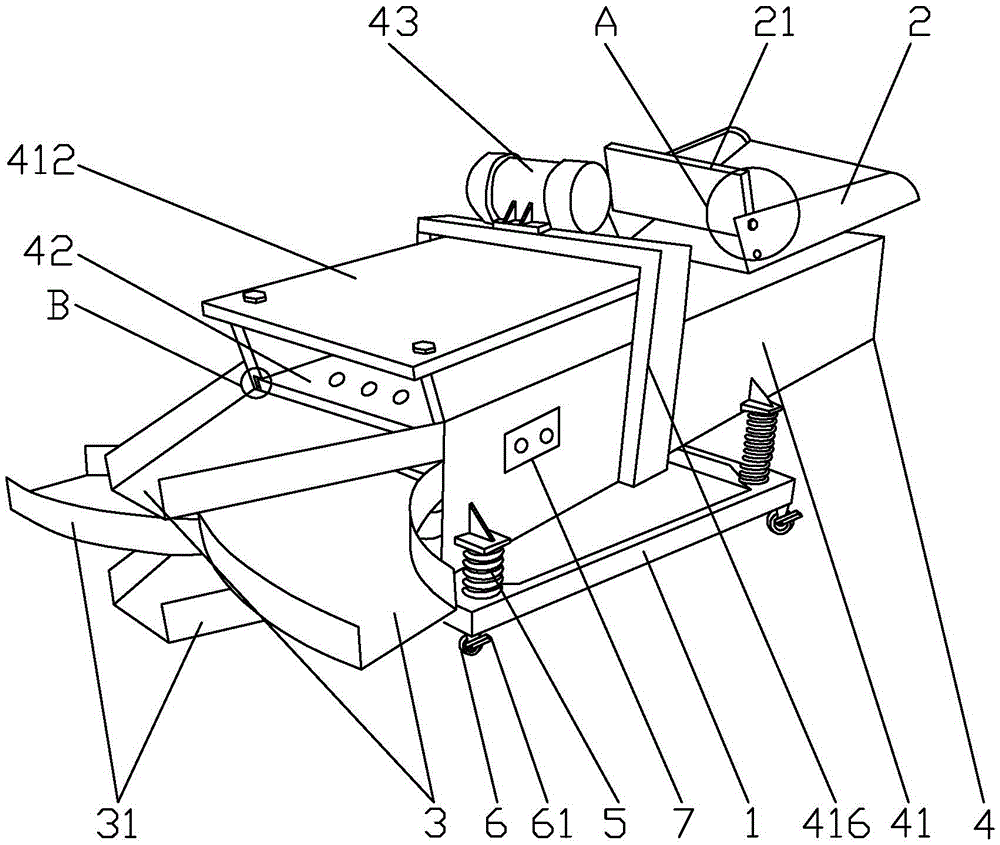

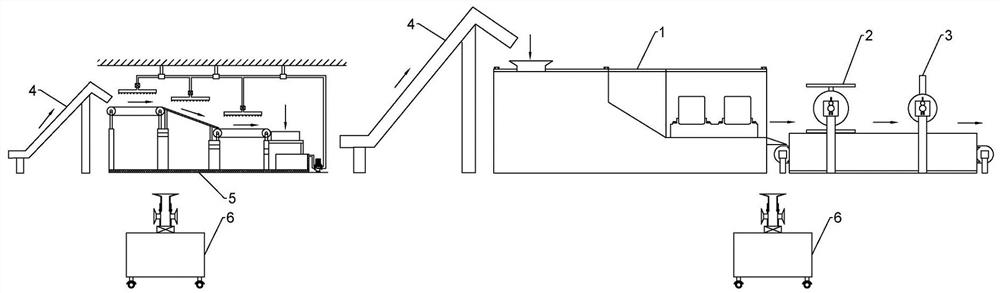

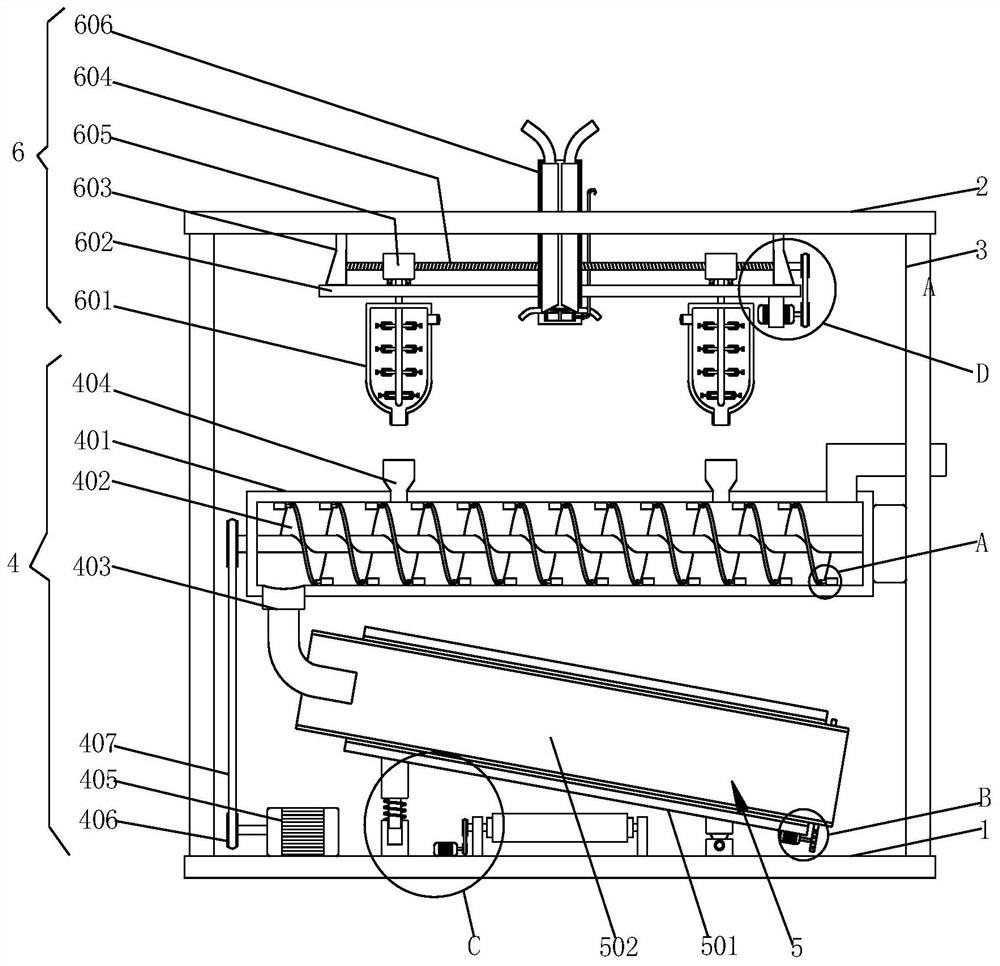

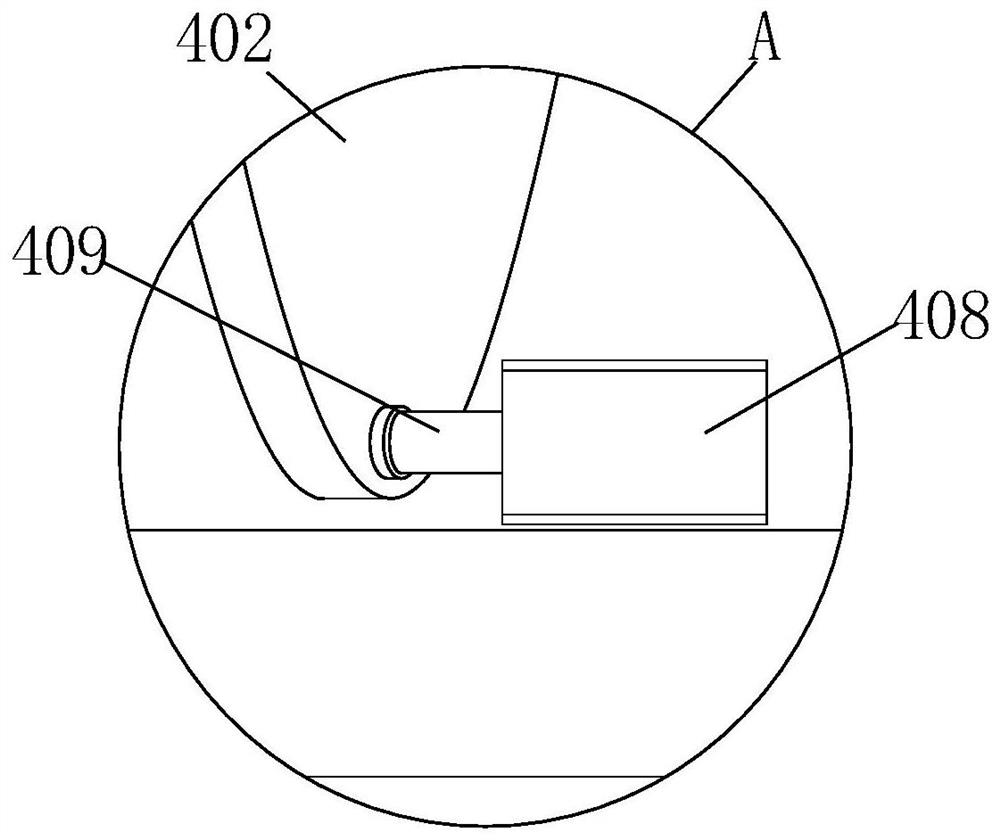

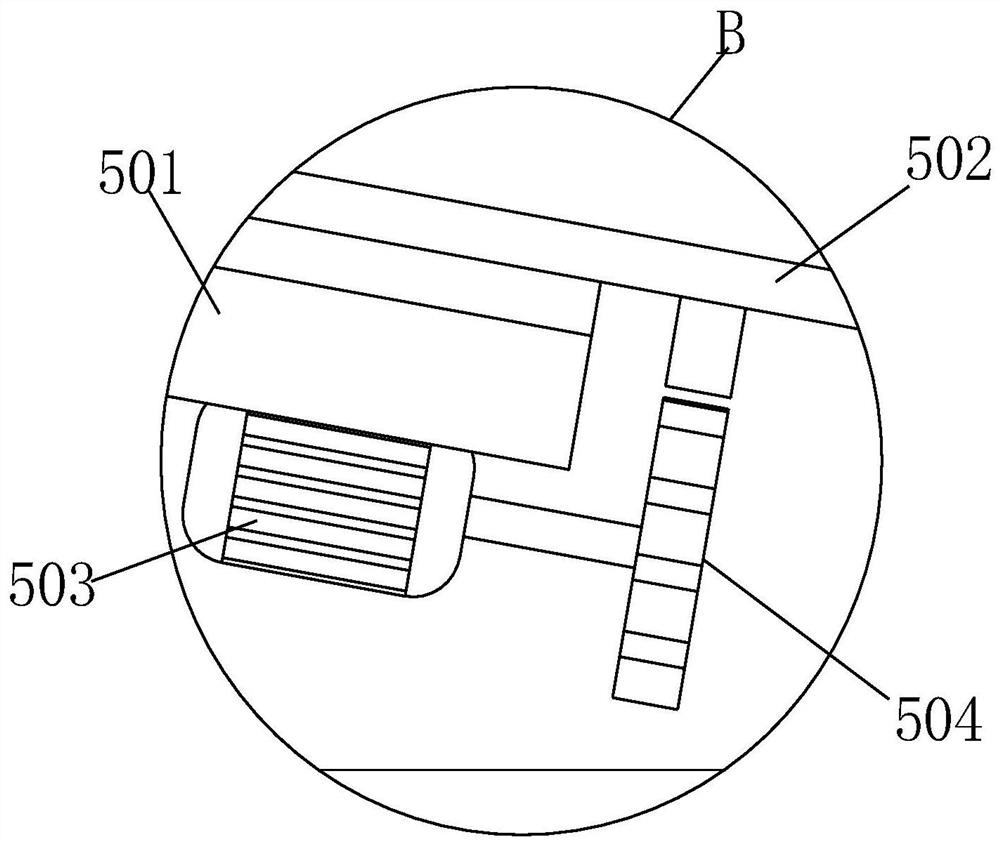

Earlier-stage treatment production line for construction waste resource utilization

ActiveCN112044925AThorough adsorption recoveryImprove the effect of adsorption recoverySolid waste managementTransportation and packagingWater useMetal impurities

The invention discloses an earlier-stage treatment production line for construction waste resource utilization, and belongs to the technical field of construction waste solid waste treatment. The production line comprises a soil separation part, a crushing part and a magnetic separation part, wherein the crushing part comprises a multi-level crushing device; the magnetic separation part comprisesa first magnetic separation device and a second magnetic separation device which are used for rough separation and fine separation respectively, a lifting conveying belt is connected to the rear portion of the magnetic separation part, and the soil separation part is connected to the rear portion of the lifting conveying belt; the soil separation part comprises a soil separation device, the soil separation device comprises multiple levels of vibratory conveying belts, a settling pond is arranged below each vibratory conveying belt, and a filtering channel is arranged between every two settlingponds; and dust removal devices are arranged beside the multi-level crushing device and the soil separation device respectively. According to the production line, metal impurities in raw materials can be removed thoroughly, water circulation of the soil separation device is realized, water consumption is greatly reduced, meanwhile, the air environment of a production base is guaranteed, and the air quality of the surrounding environment is prevented from being affected.

Owner:CHINA RAILWAY URBAN CONSTR GRP

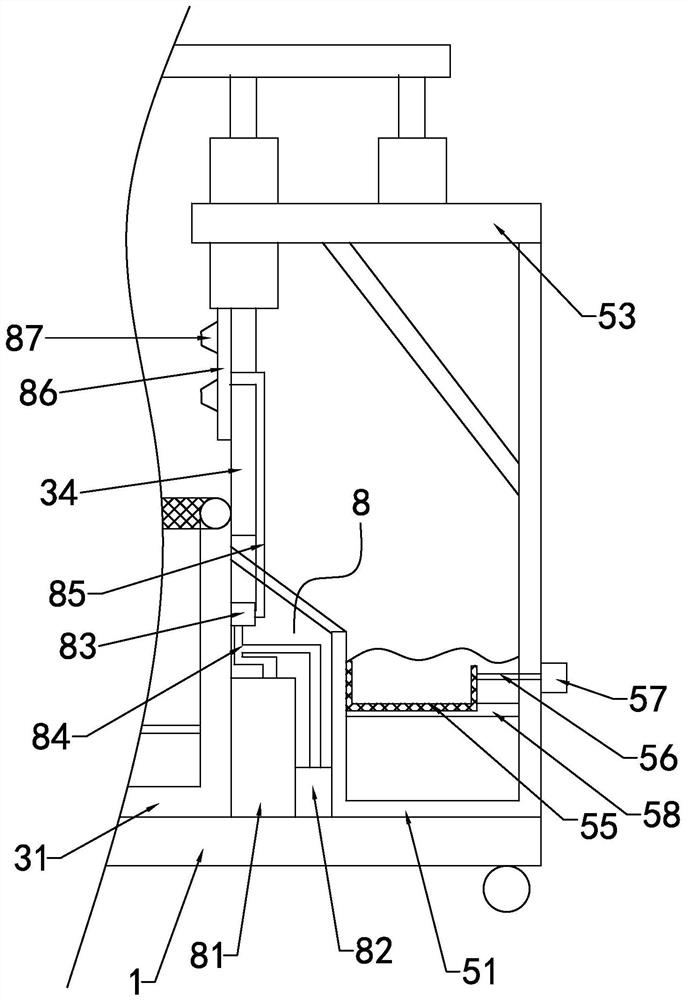

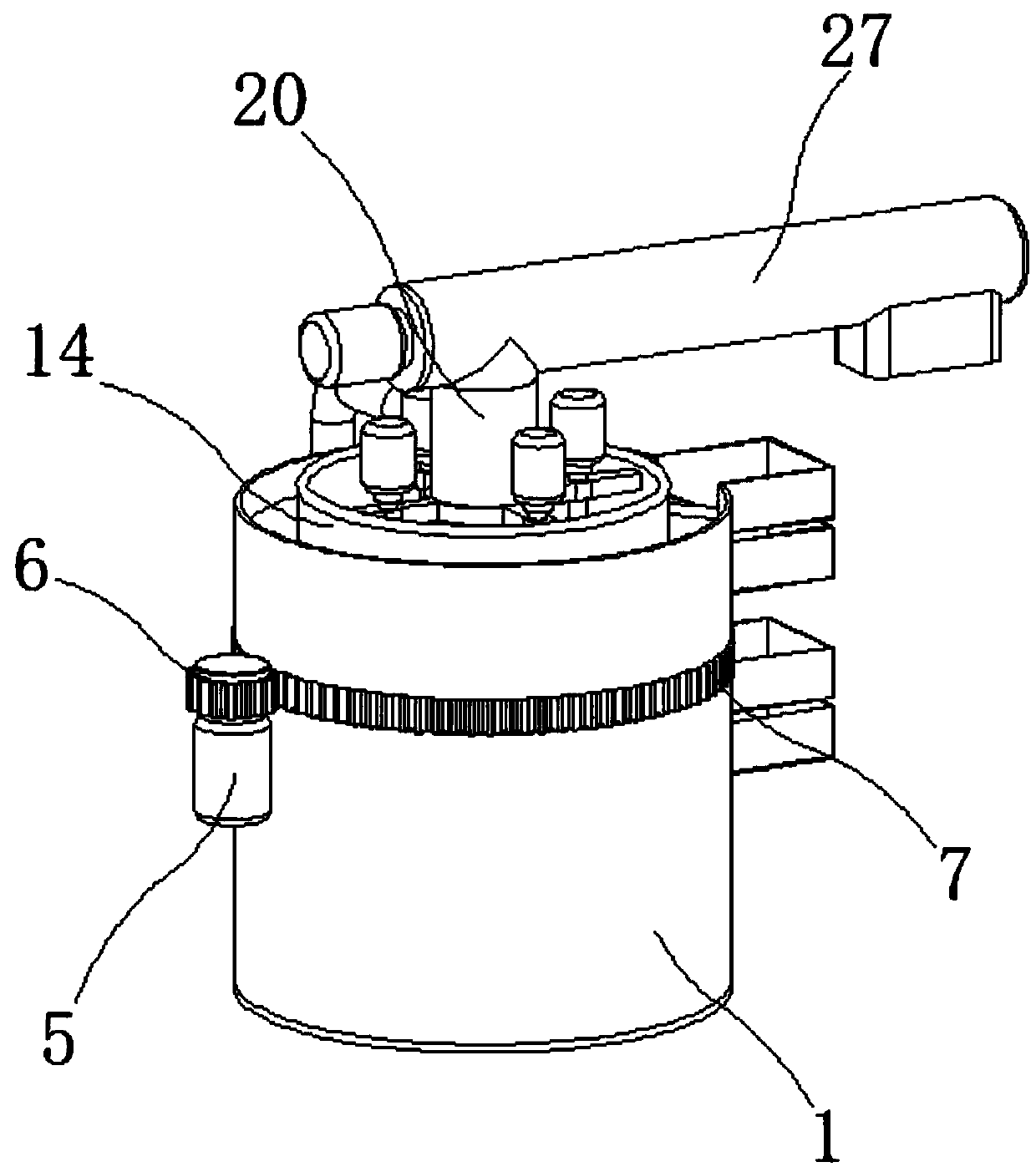

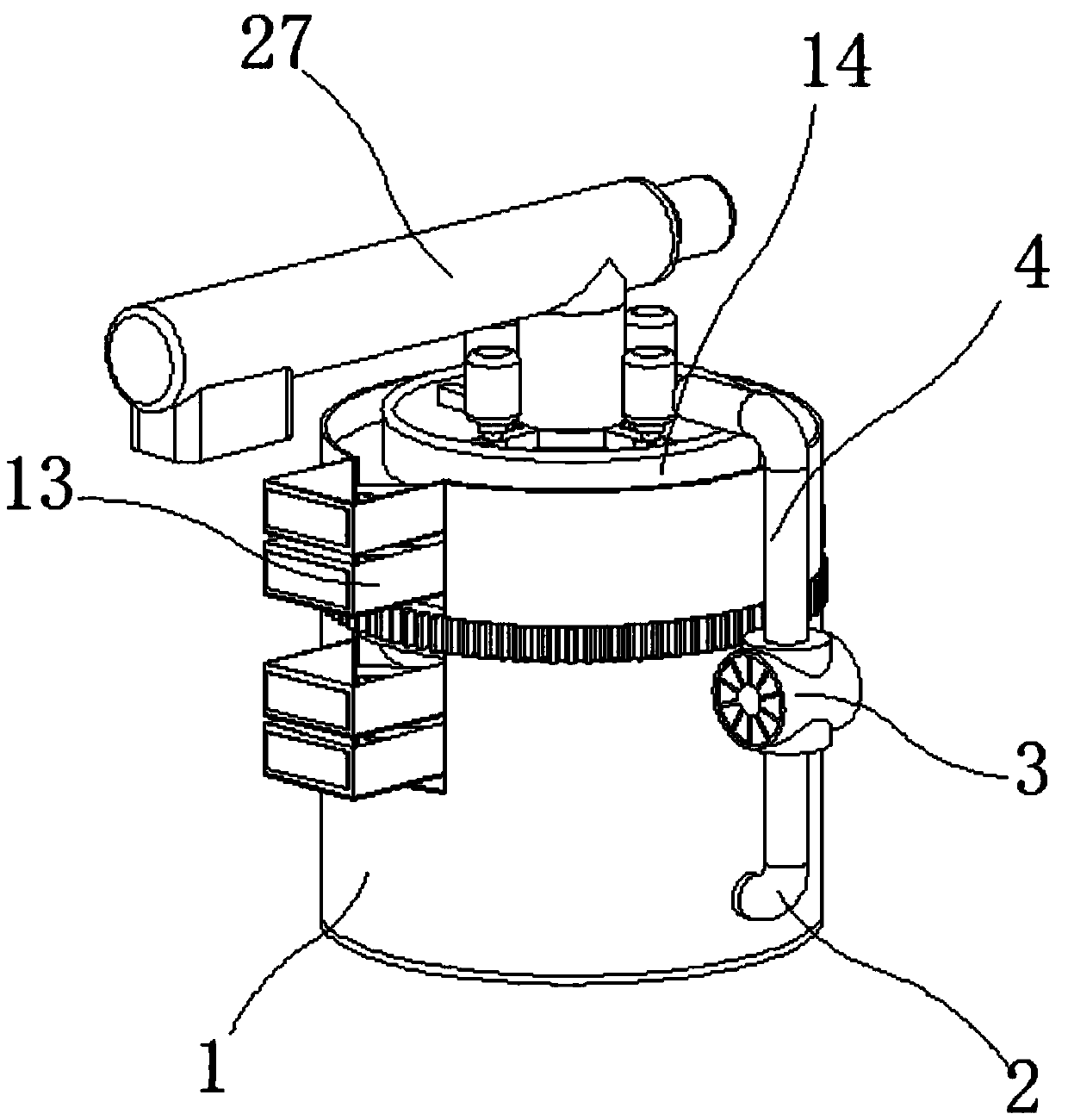

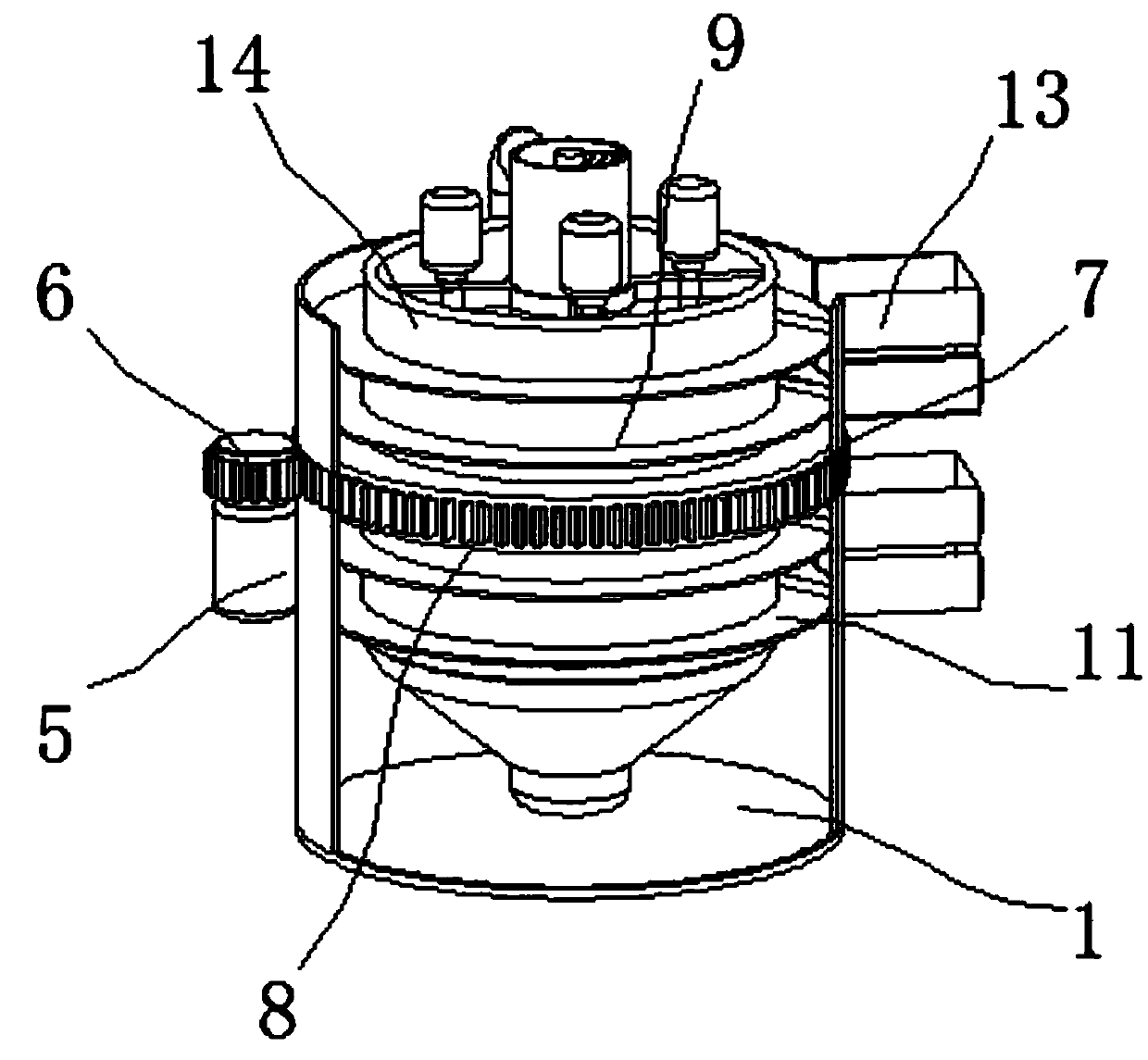

Novel machining and production device for feces decomposition agents

InactiveCN109675797AEasy to filter jobsWill not affect the results of the filterSievingScreeningDecompositionEngineering

The invention discloses a novel machining and production device for feces decomposition agents and relates to the technical field of production devices. The novel machining and production device comprises a supporting plate. Two sliding grooves are formed in the upper surface of the supporting plate. Sliding blocks are connected in the sliding grooves in a sliding manner, and the upper surfaces ofthe two sliding blocks are fixedly connected with the lower surface of the same screening box through first fixing plates. The lower surface of the screening box is fixedly connected with the upper surface of a toothed plate, and the toothed plate is engaged with a half gear. By means of the novel machining and production device for the feces decomposition agents, due to cooperation of a handle,a cover plate, a feeding hopper, the screening box, a motor, the half gear, the toothed plate, a spring, an air heater, a second hot air pipe, a first hot air pipe and a hot air opening, the phenomenon that the decomposition agents are agglomerated together due to humidity, and and the screening result is affected is avoided, the operation that working personnel conduct drying treatment on the large-particle decomposition agents and conduct screening again afterwards is not needed, and therefore convenience is brought to the screening work of working personnel on the decomposition agents.

Owner:LINYI UNIVERSITY

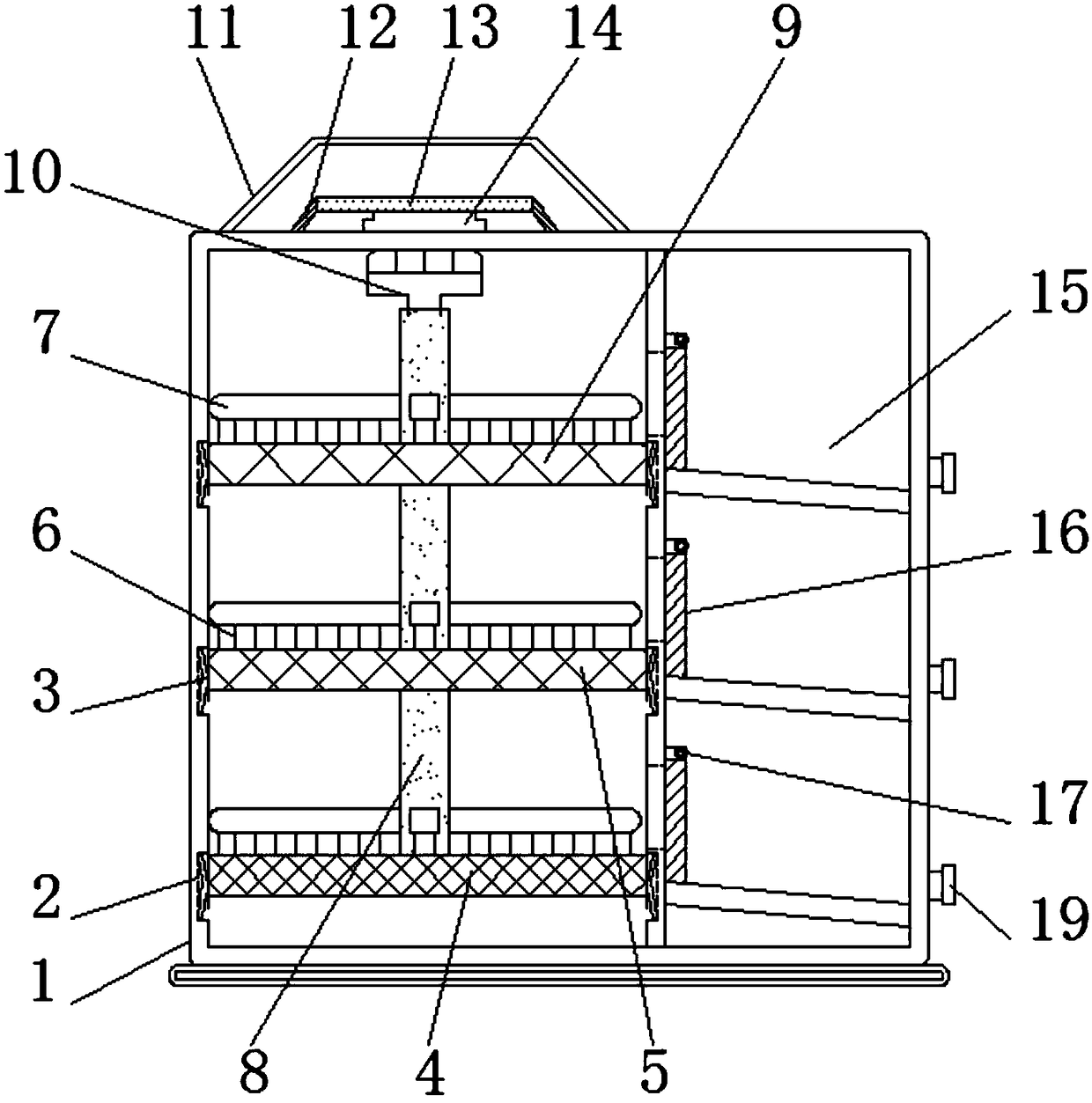

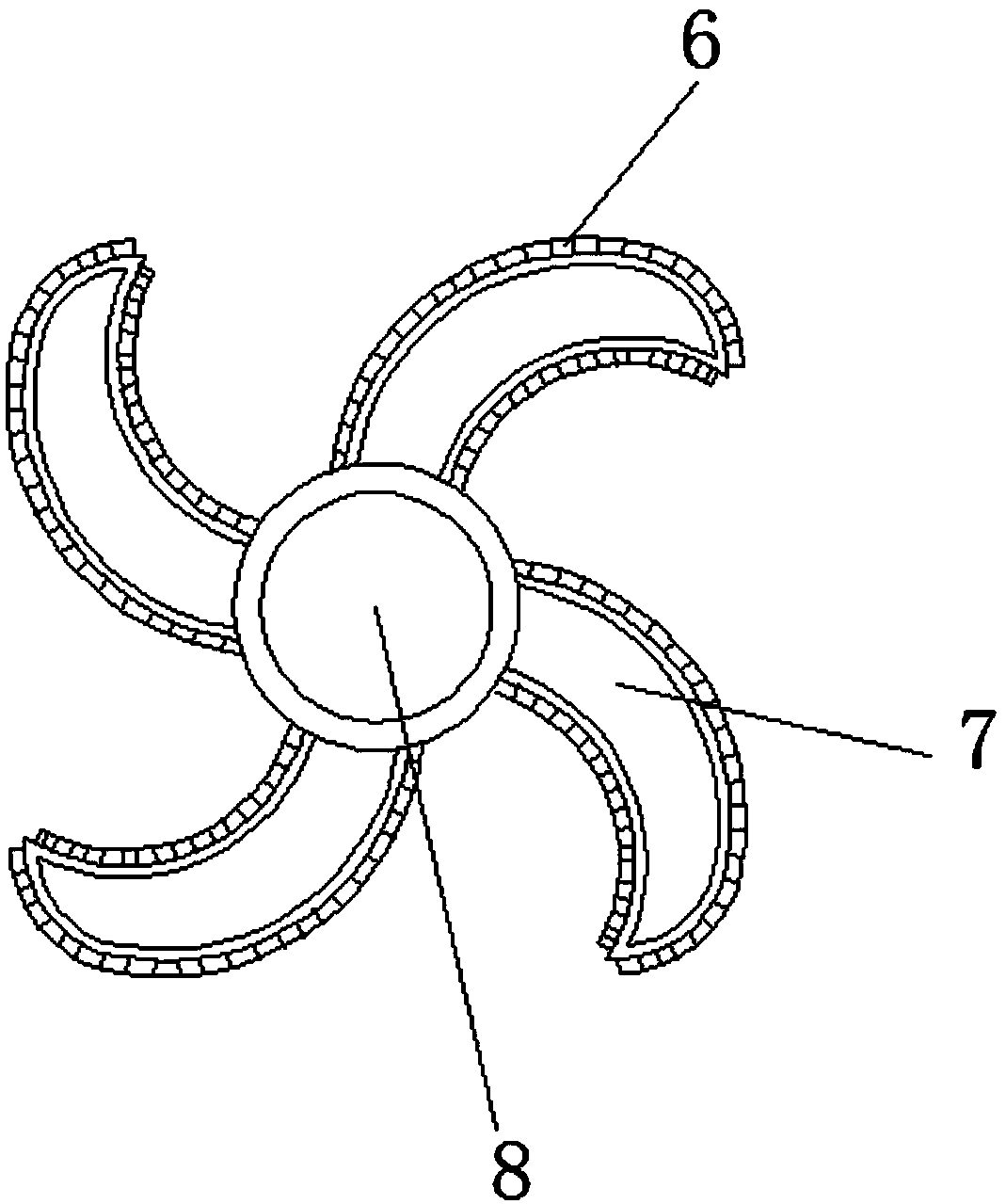

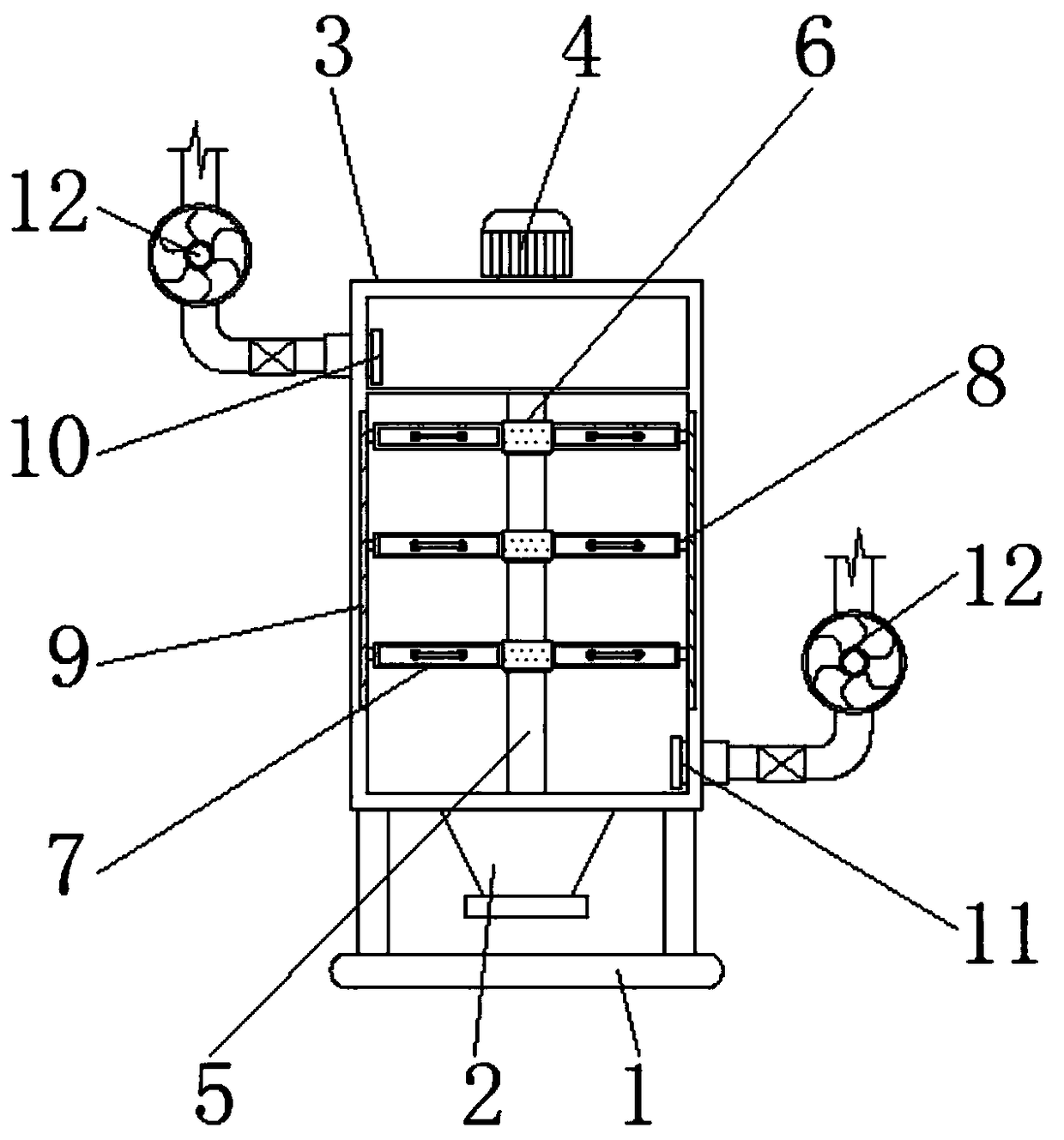

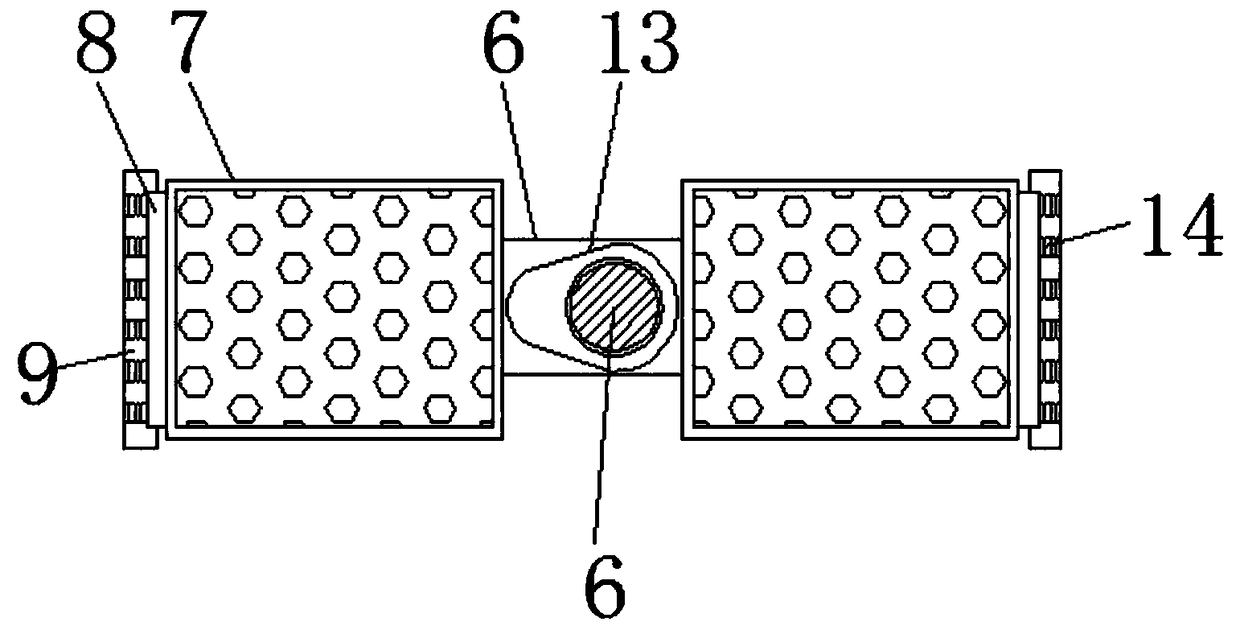

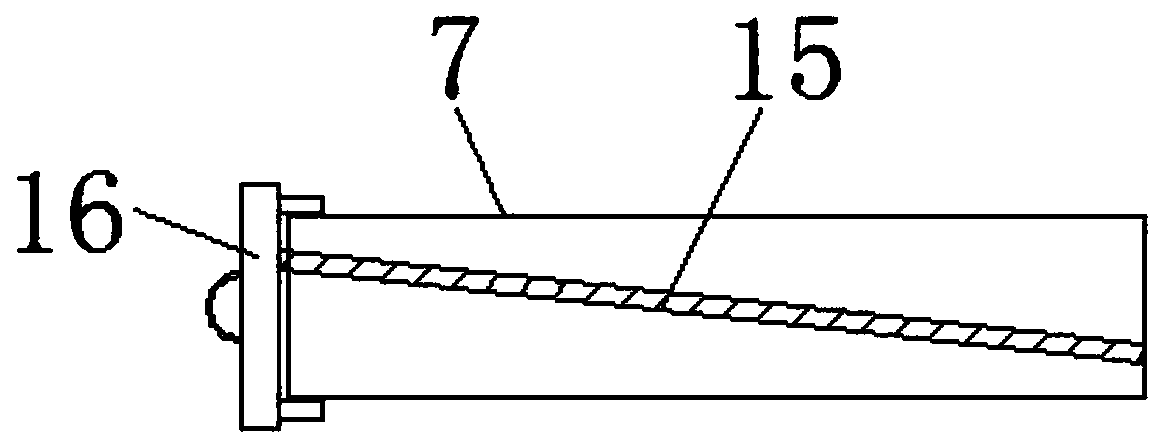

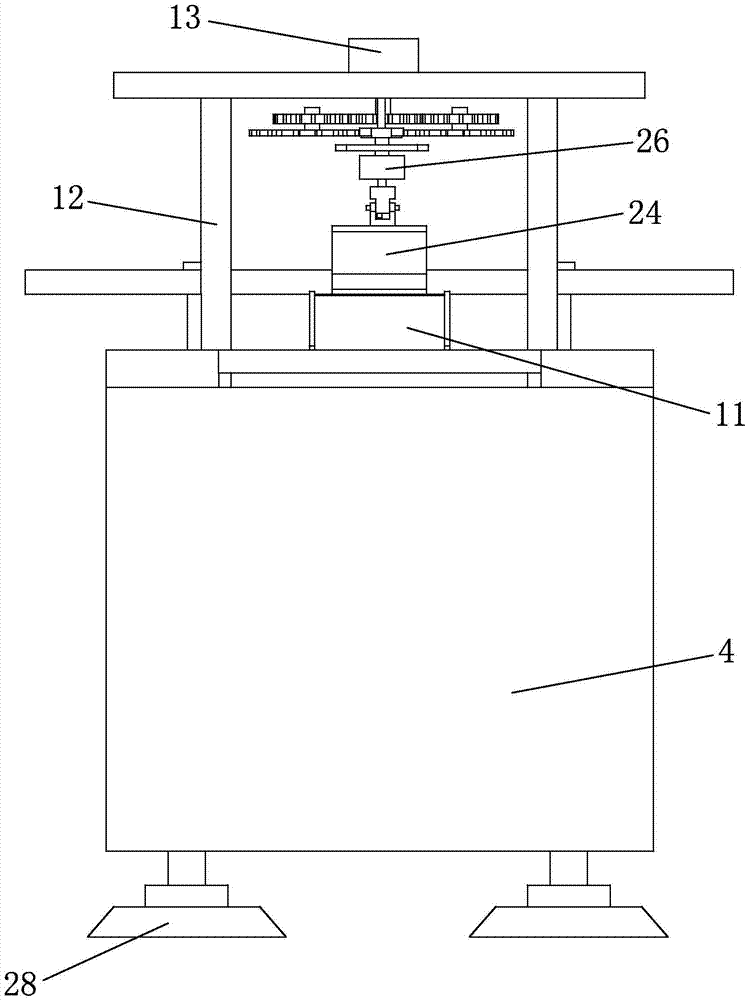

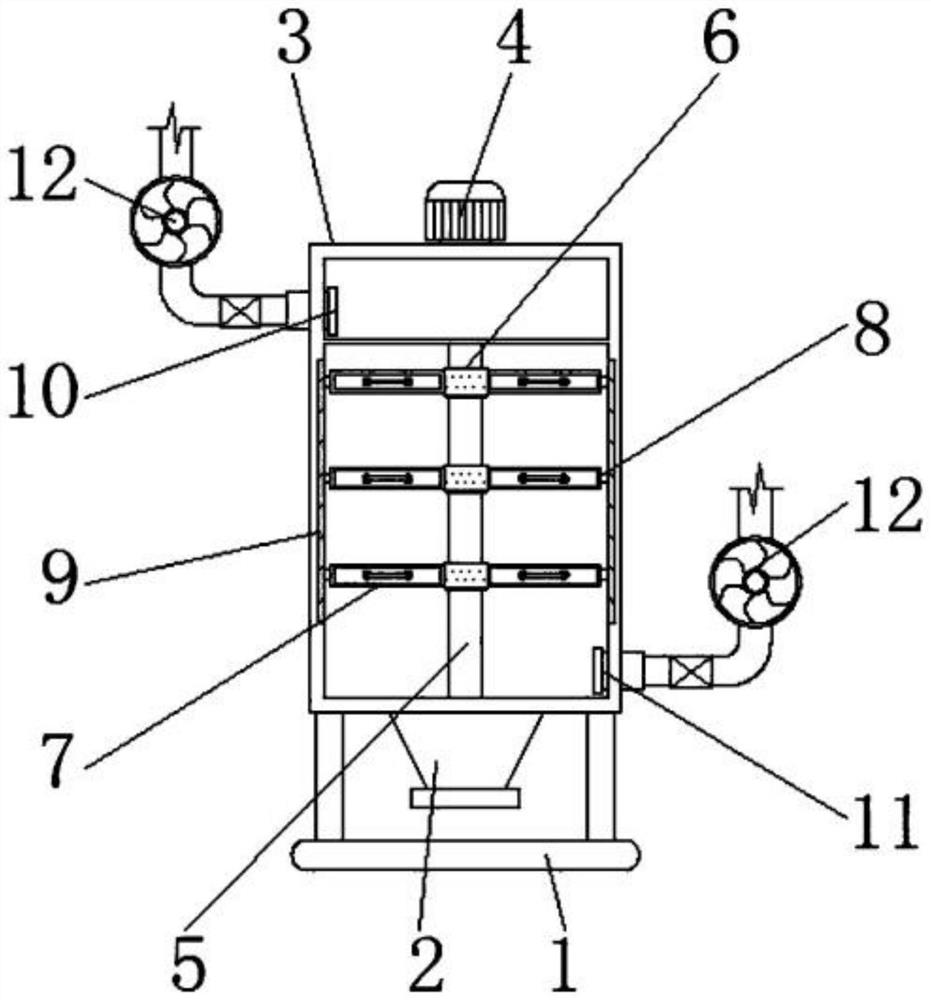

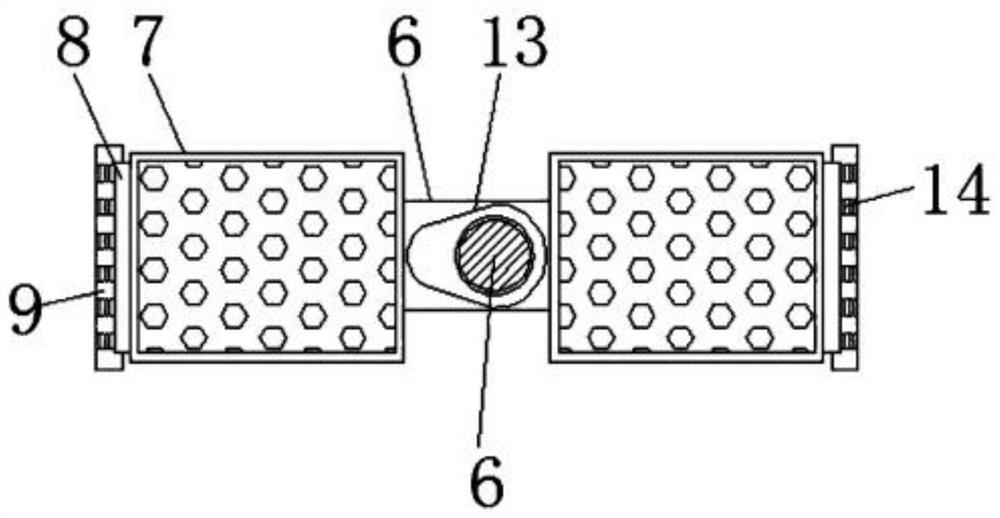

Efficient energy-saving bio-organic fertilizer screening equipment

InactiveCN107694913AImprove the vibration effectAvoid wastingSievingSpringsCombined useAgricultural engineering

The invention relates to the technical field of bio-organic fertilizer processing equipment and discloses efficient energy-saving bio-organic fertilizer screening equipment comprising a screening box.A funnel is fixedly connected to the top of the screening box. A feed inlet is fixedly connected to the middle of the top of the funnel. Baffles are fixedly connected to both the two sides of the inner wall of the funnel. The two sides of the inner wall of the top of the screening box are each fixedly connected with a locating seat. The two locating seats are fixedly connected through a locatingplate. A screening net is clamped in the middle of the inner side of the locating plate. The two sides of the top of the locating plate are each fixedly connected with a connecting column, and the tops of the two connecting columns are each fixedly connected with a shocking device. The two shocking devices are clamped to inner cavities in the two sides of the top of the screening box correspondingly. According to the efficient energy-saving bio-organic fertilizer screening equipment, when a user puts bio-organic fertilizer into the funnel, through matched use of the two baffles, the bio-organic fertilizer can be scattered, thus later screening work can be more convenient, and then screening treatment is conducted through the screening net.

Owner:江苏恒源生物有机肥有限公司

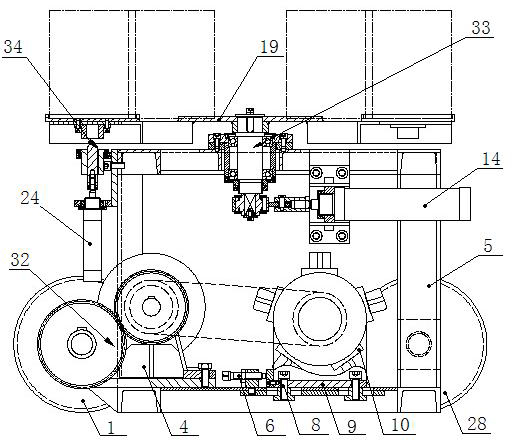

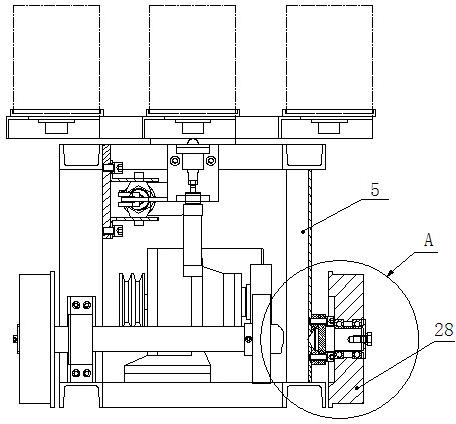

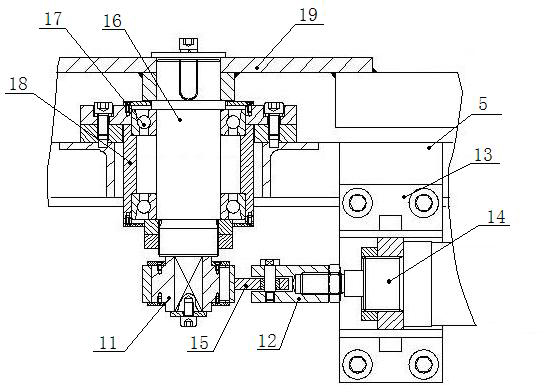

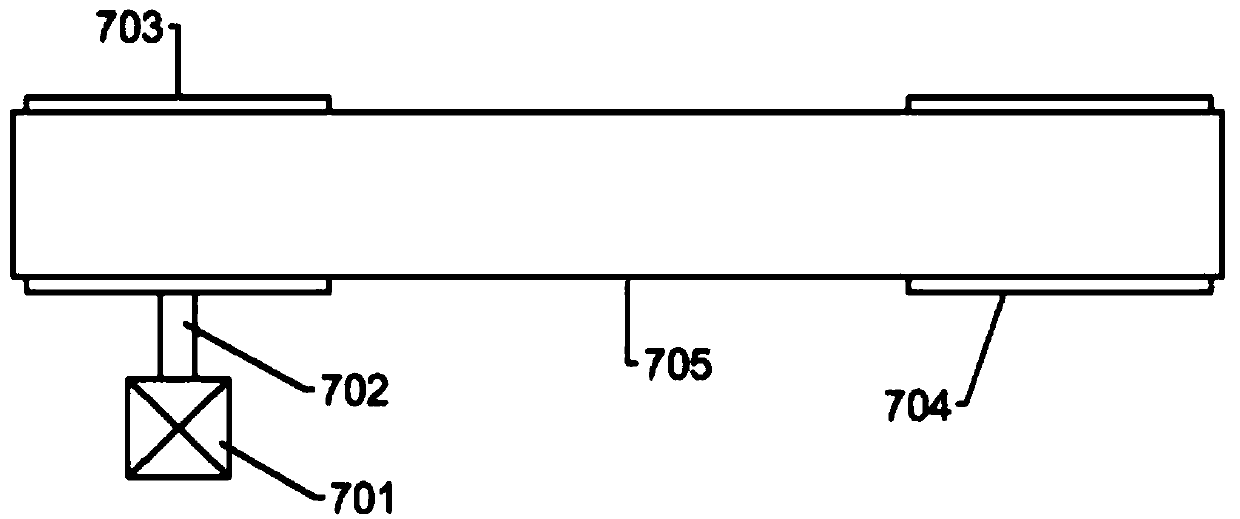

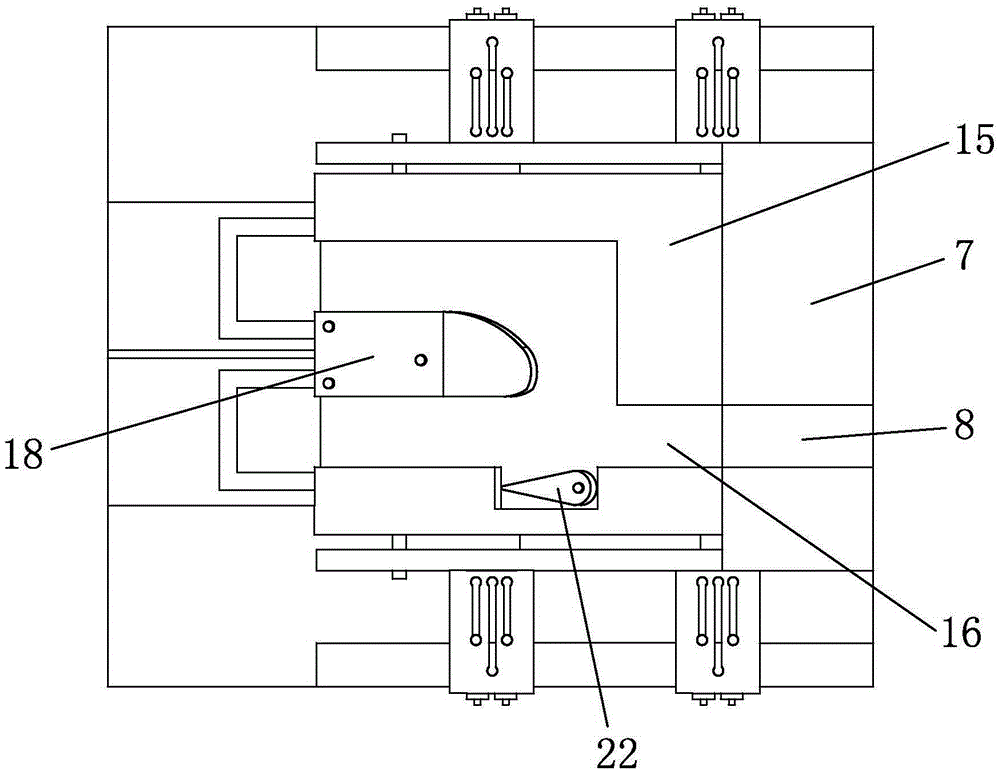

Pneumatic multi-station moving platform

InactiveCN102616542ARealize pneumatic handlingImprove securityMechanical conveyorsDrive wheelVehicle frame

The invention discloses a pneumatic multi-station moving platform and relates to a moving platform system applied to flammable and explosive dangerous mining conditions such as explosive handling and screening. The pneumatic multi-station moving platform comprises a frame, an index plate, a pneumatic driving system, a pneumatic indexing system and a pneumatic positioning system, wherein the pneumatic driving system is positioned at the bottom of the frame and consists of a pneumatic motor, a speed reducer, a belt pulley, a belt, a pinion, a gear wheel, a wheel driving shaft, a driving wheel, a wheel axle seat and a driving wheel assembly; the pneumatic indexing system is positioned at the top end inside a stand and consists of an index plate, a rotating shaft, an angle contact bearing assembly, a bearing block, a ratchet mechanism, a push rod, an air cylinder and a connector; and the pneumatic positioning system is positioned on the lateral surface of the frame and consists of an air cylinder, a positioning pin, a positioning sleeve and a fixing seat. The pneumatic multi-station moving platform disclosed by the invention can be driven by the pneumatic motor to reciprocate along a guide rail to finish handling work and can also rotate the index plate at the part between every two different stations for bringing convenience to screening of the explosives. Therefore, the pneumatic multi-station moving platform is suitably applied to occasions of handling and operating of the flammable and explosive articles.

Owner:山东卓越冠宏智能工业设备有限公司

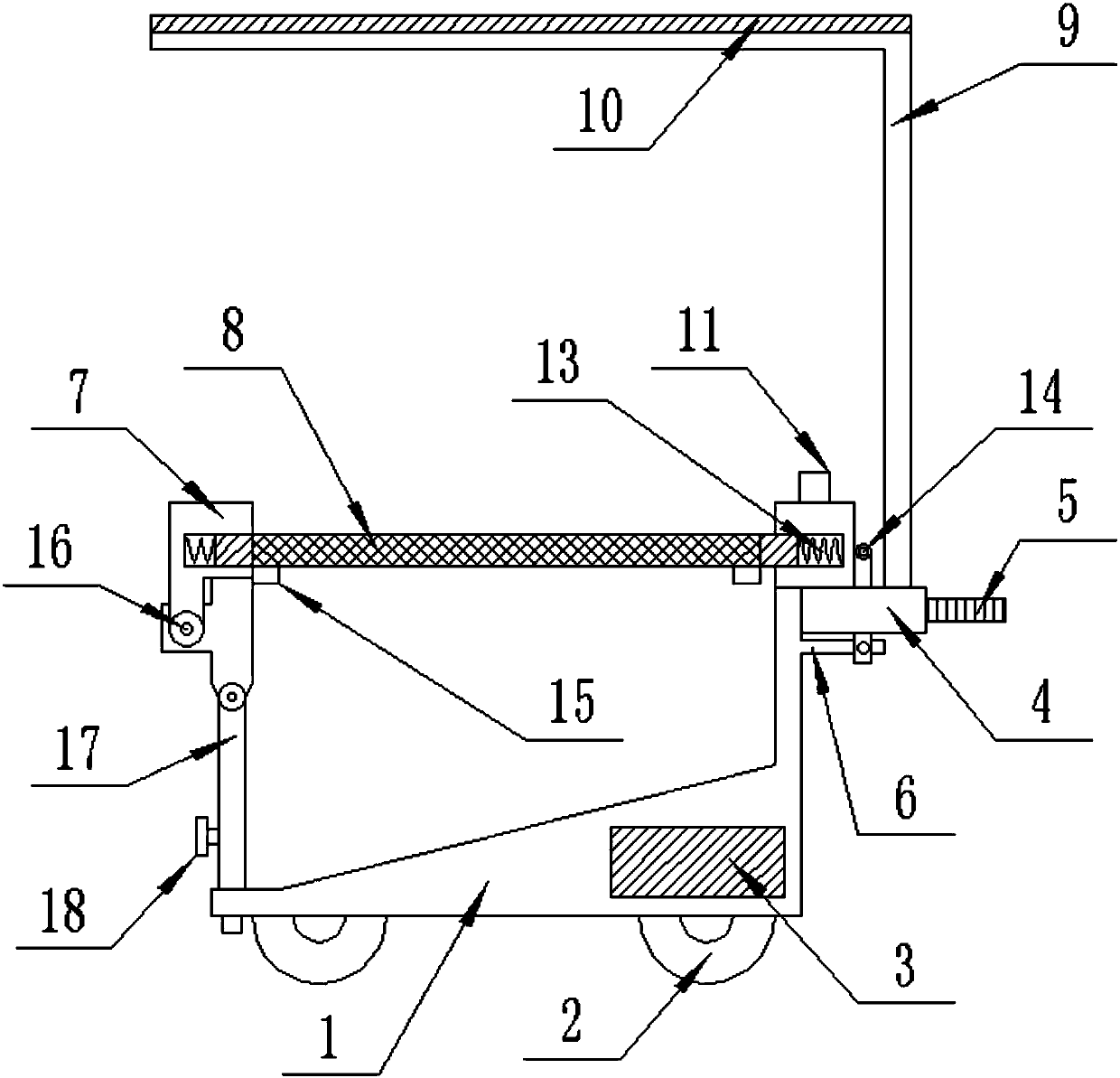

Sand sieving vehicle for construction and convenient in cleaning and transportation

The invention provides a sand sieving vehicle for construction and convenient in cleaning and transportation and belongs to construction equipment. The sand sieving vehicle comprises a vehicle body, ascreen and a movable plate and is characterized in that moving wheels are fixedly connected to positions at two ends of the bottom of the vehicle body; a storage battery is arranged at the right bottom inside the vehicle body; a push rod is horizontally fixedly connected above the right end of the vehicle body; an extension rod located below the push rod is fixedly connected to the vehicle body;a rain-shielding plate is vertically fixedly connected to the right of the push rod; a solar panel is arranged at the upper end of the rain-shielding plate; the movable plate is arranged on the left of the vehicle body, and the upper end of the movable plate is fixedly connected to the vehicle body; a retaining plate is connected to the lower end of the movable plate in a sleeved manner, and the lower end of the retaining plate extends out of the movable plate and is connected to the left end of the vehicle body in a clamped manner; two first springs are connected between the upper end of theretaining plate and the upper wall inside the movable plate. The sand sieving vehicle has the advantages that the vehicle can move conveniently by the moving wheels; electric energy can be stored conveniently by the storage battery and supplied for the vehicle; the moving direction of the vehicle body can be conveniently controlled through a first handle; rainwater can be shielded by the rain-shielding plate.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Tea processing screening device with function of improving screening efficiency

InactiveCN108372098AImprove screening efficiencyGood in removing impuritiesSievingScreeningHydraulic cylinderAgricultural engineering

The invention discloses a tea processing screening device with a function of improving screening efficiency. The device comprises a main shell body and a motor, a groove is formed in the main shell body, the right side of the groove is provided with fixing springs, the right side of each fixing spring is fixedly provided with a first screening plate, a hairbrush is installed at the upper portion of each first screening plate, and the upper portion of each hairbrush is fixedly provided with a rotating blade; a connecting rod is arranged at the right side of each rotating blade, a second screening plate is installed above the connecting rod, a third screening plate is fixedly arranged above the second screening plate, a hydraulic cylinder is arranged above a motor, a transverse plate is fixedly arranged above the hydraulic cylinder, a fixing belt is installed at the left side of the transverse plate, and a feeding port is formed in the upper portion of the transverse plate. According tothe tea processing screening device with the function of improving the screening efficiency, a filtering plate is embedded in the main shell body, the transverse plate is driven by the hydraulic cylinder to ascend or descend, and therefore tea on the transverse plate is scattered.

Owner:贵州开阳雅义杰富硒茶果有限公司

Agricultural soybean screening device

ActiveCN111229595ARealize the left and right swing functionEasy flipSievingScreeningAgricultural engineeringStructural engineering

The invention belongs to the technical field of agricultural mechanical equipment, and particularly relates to an agricultural soybean screening device. The agricultural soybean screening device has an automatic screening function and is convenient to operate. The agricultural soybean screening device comprises a base, a square frame, a moving mechanism, mounting plates, mounting frames, a screening box, a cylindrical sleeve, a cylindrical rod, a first elastic piece, a supporting plate, a wedge-shaped block, a slideway and the like. The square frame is arranged in the center of the top of thebase. The moving mechanism is arranged in the square frame. The mounting plates are installed on the two sides of the moving mechanism, the mounting frames are installed in the centers of the tops ofthe two mounting plates, and the screening box is rotationally arranged between the two mounting frames through a rotating rod. The agricultural soybean screening device has the effects of being easyto operate and capable of achieving automatic screening.

Owner:龙王致新(北京)科技有限公司

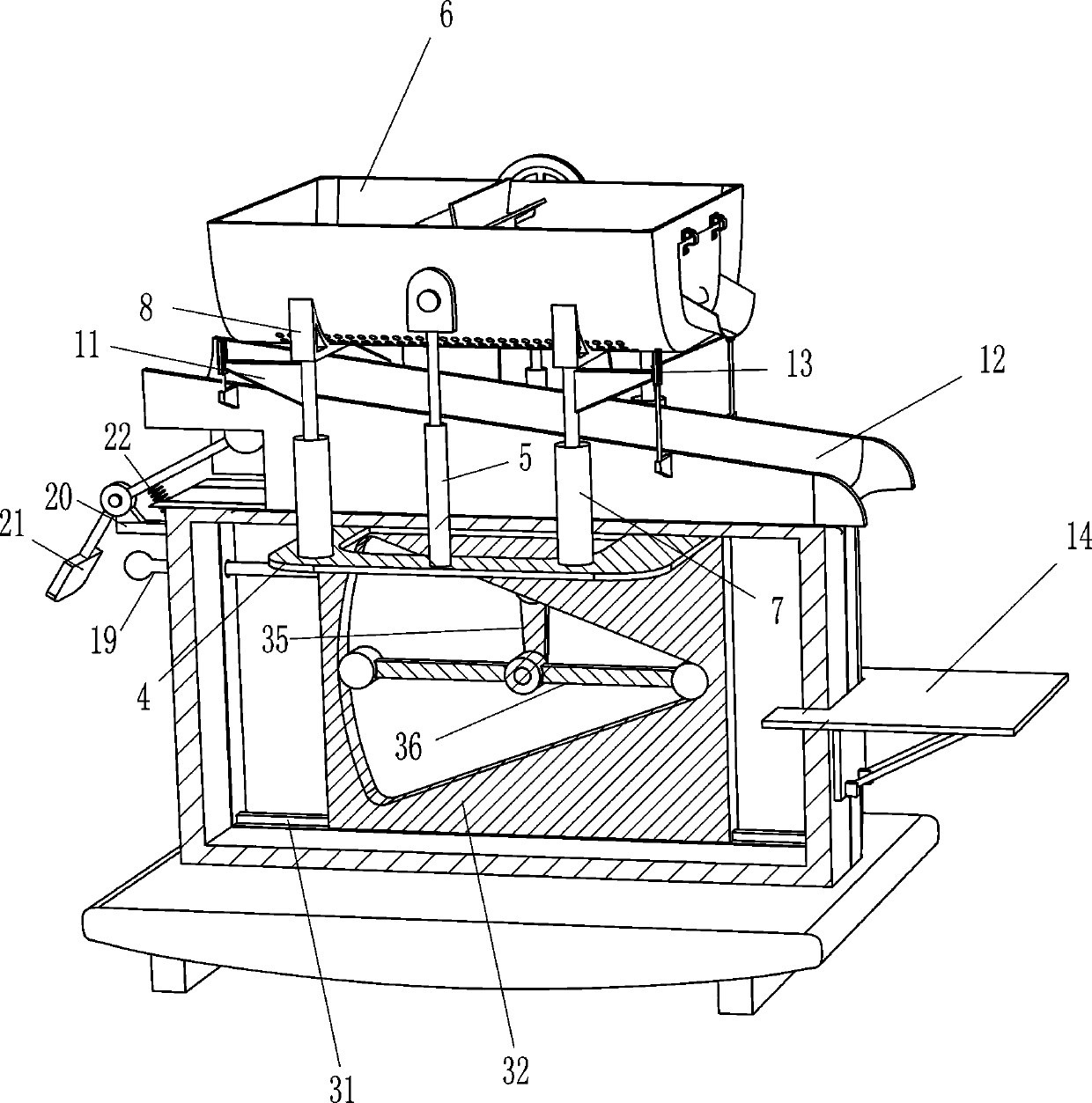

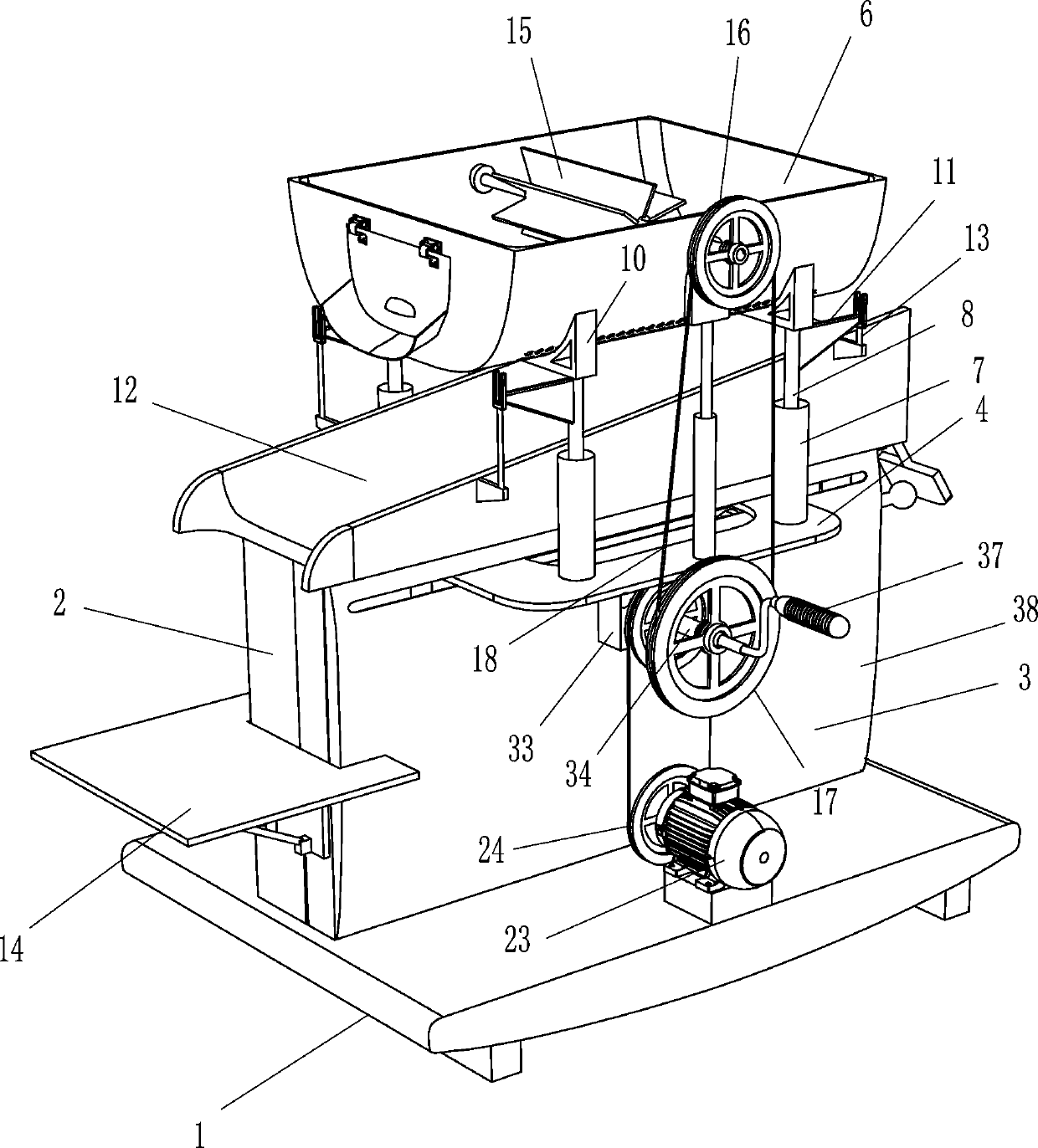

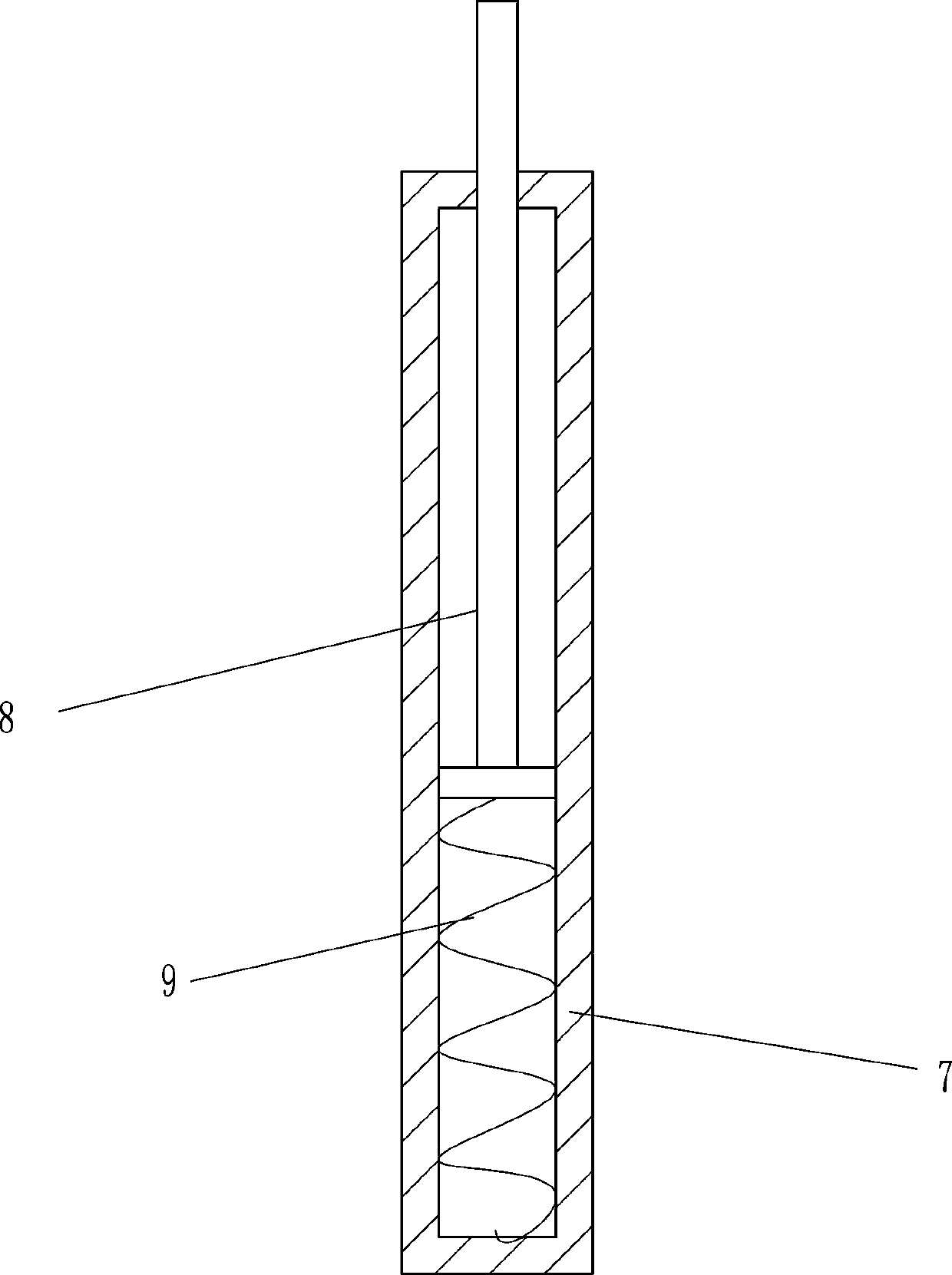

Highly-throwing rice sieving machine

InactiveCN105214945AAchieve the purpose of screeningScreen thoroughlyGas current separationAgricultural engineeringMechanical equipment

The invention belongs to the technical field of agricultural mechanical equipment, and specifically discloses a highly-throwing rice sieving machine. The highly-throwing rice sieving machine comprises a highly-throwing frame, wherein a charge port is formed in the top end of the highly-throwing frame, a discharge port is formed in the bottom end of the highly-throwing frame, an opening used for discharging vacant shells is formed in one sidewall of the highly-throwing frame, a vertical slide way is formed in a sidewall opposite to the opening, of the highly-throwing frame, a fan is installed on the slide way, and the fan is slidably connected with the highly-throwing frame; and the distance between the top end and the bottom end of the highly-throwing frame is 1-3m. Compared with the traditional fan sieving, the equipment is capable of throwing and dispersing rice, capable of greatly achieving a sieving purpose by matching with a position design for a fan, thorough in sieving, capable of sieving according to the proportions of impurities contained in rice to meet different sieving needs, and high in practicability.

Owner:CHONGQING ZHIRUIDE TECH

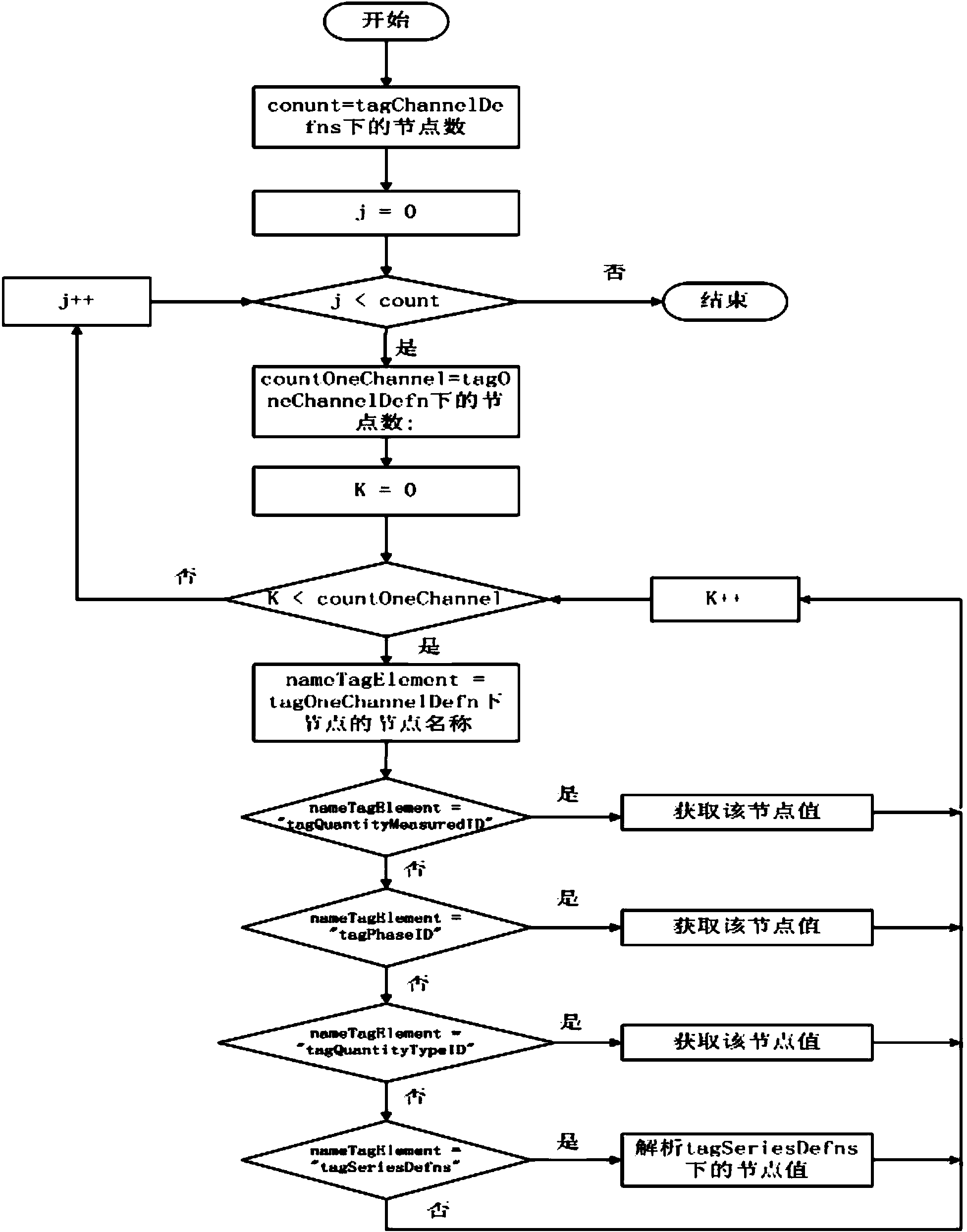

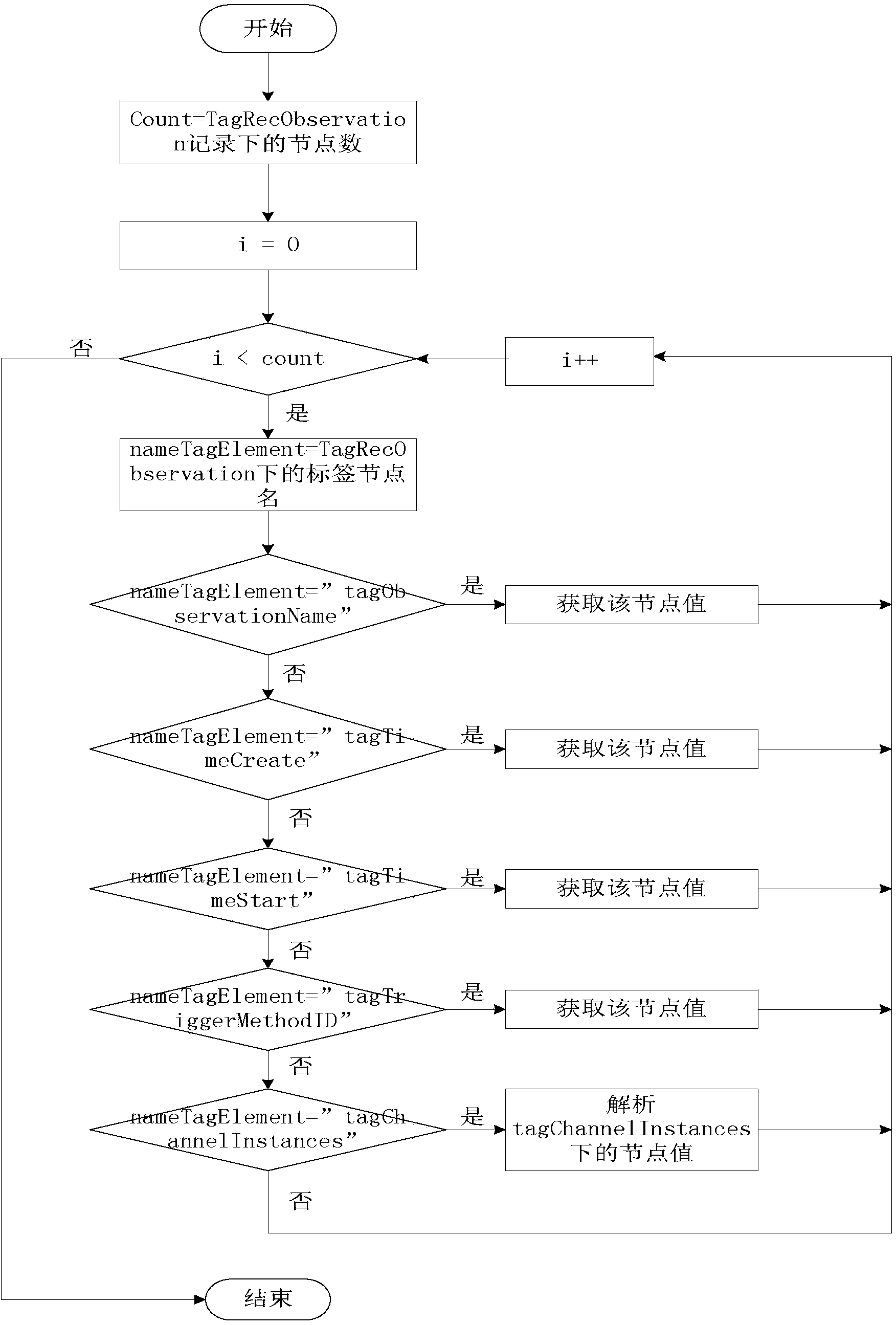

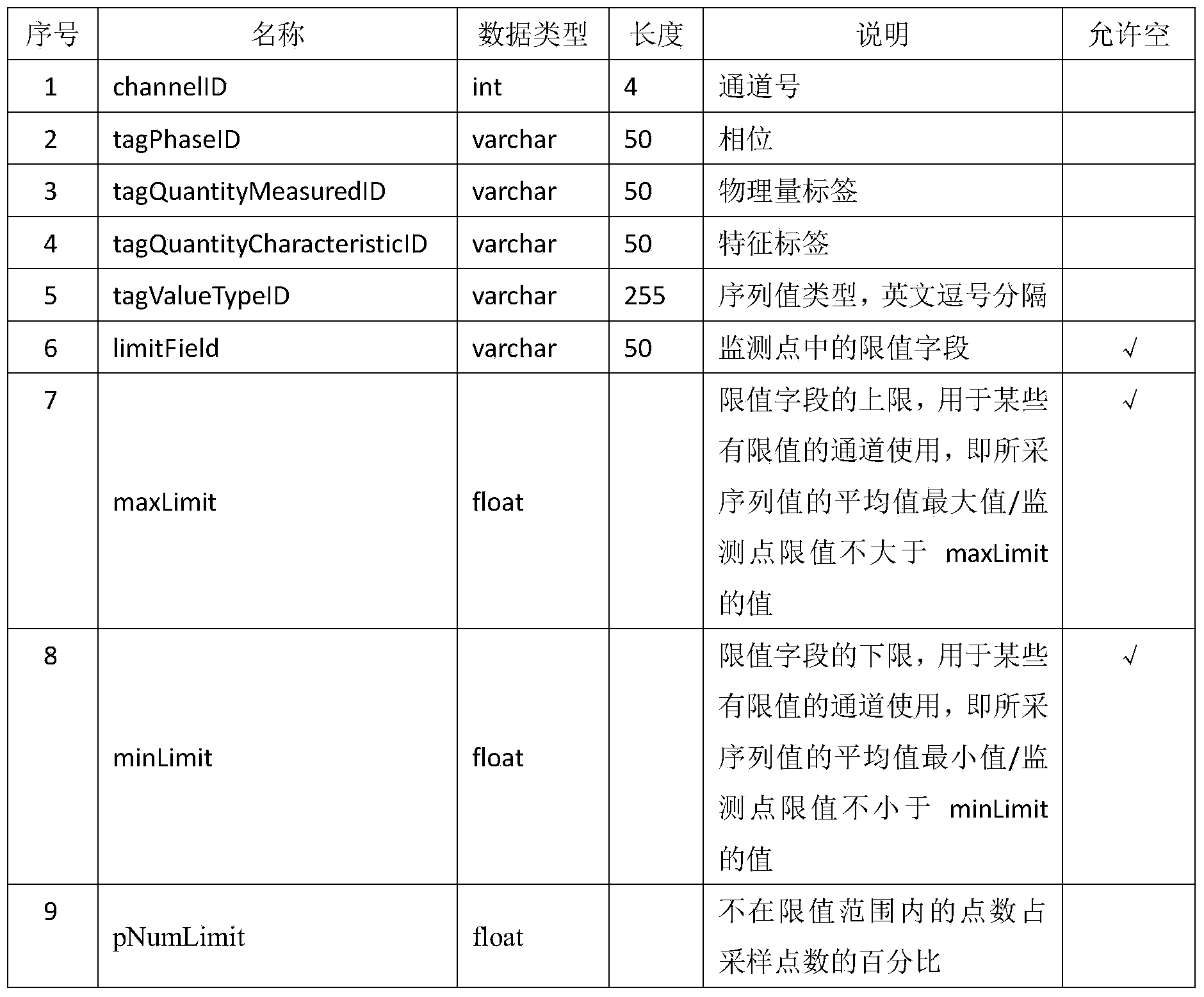

Detection method, equipment and system for power quality monitoring data

InactiveCN104237680AEasy to filter jobsSimplify screeningElectrical testingPower qualityMonitoring data

The invention discloses a detection method for power quality monitoring data. The method includes the following steps that A, the power quality monitoring data are acquired from a power quality monitoring terminal, and one or more steps of the step B, the step C and the step D are executed; B, a channel label is acquired from the power quality monitoring data, and the channel label is compared with a prestored standard channel label; C, a sequence property is acquired from the power quality monitoring data, and the sequence property is compared with a prestored standard sequence property; D, sequential value error detection is conducted on the power quality monitoring data; E, the comparison and / or detection results of one or more steps of the step B, the step C and the step D are fed back to a power quality analysis server, data which meet the on-line monitoring system requirement are analyzed and then stored into a foundation database, serving as advanced calculation basic data, the data which cannot meet the requirement are fed back to the monitoring terminal, and a PQDIF file is generated again according to the standard definition. By the adoption of the method, the detection data of the monitoring terminal can be detected quickly, and screening of the monitoring terminal can be simplified.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Collection device with screening function applied to dust detection

ActiveCN109269945AEasy accessConvenient detection workDispersed particle filtrationTransportation and packagingDust detectionEngineering

The invention discloses a collection device with a screening function applied to dust protection. The device comprises a pedestal, an air inlet and a cam; the top end of a holding groove is connectedwith a compression spring via a connection block, and the compression spring is arranged in a fixing groove; the cam is arranged at the outer part of a rotation shaft, and arranged at the middle position of a connection hood; a filtering dust collection plate is arranged in the holding groove, and a baffle plate is fixedly installed at the top end of the filtering dust collection plate; sliding blocks are fixedly connected with both the upper and lower sides of the fixing groove, and connected with sliding chutes on the upper and lower sides of the connection block in a sliding manner; and rubber sealing strips are arranged on the upper sides of the top ends of the sliding chutes. During a collection process, the collection device with the screening function applied to dust protection canwell screen dust, and convenient to take the screened dust; the great amount of dust is not remained in the device, and thus the device is convenient to clean.

Owner:JIANGSU JINGKE TOTAL SOLUTIONS LTD

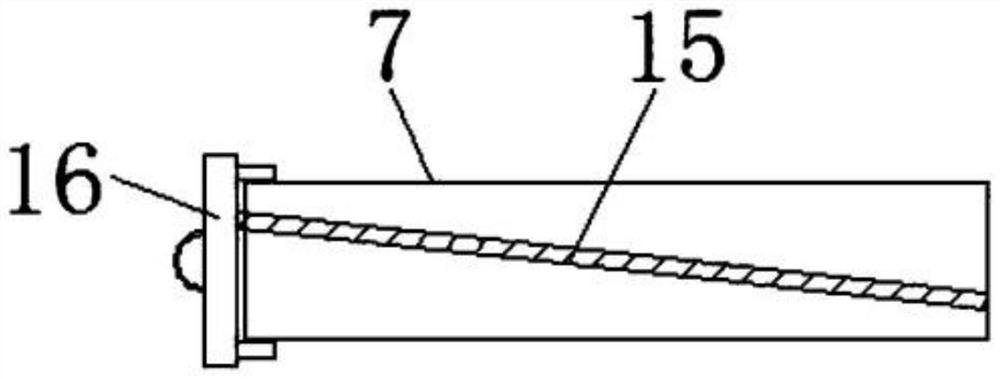

Raw material screening device for fertilizer production

InactiveCN111822331AImprove the heating effectImprove drying effectSievingScreeningThermodynamicsElectric machine

The invention discloses a raw material screening device for fertilizer production and relates to the technical field of fertilizer production. The raw material screening device comprises a box body. Afeeding hopper is fixedly connected to the top of the box body. A scattering box is fixedly connected to the inner top wall of the box body. The upper end of the scattering box is fixedly communicated with the feeding hopper. A scattering mechanism is arranged in the scattering box. A material conveying cylinder is arranged in the box body. The two ends of the material conveying cylinder are fixedly connected to the two inner side walls of the box body. When in use, through a double-shaft motor, the output end of the double-shaft motor drives a rotating shaft I to rotate through a belt and atransmission wheel I and a transmission wheel II, so that a spiral blade is driven to rotate, the spiral blade can drive the raw materials to rotate in the material conveying cylinder, the heating time of the raw materials in the conveying process is prolonged, the raw materials are in more sufficient contact with the heat, and the heating effect of electric heating wires on the raw materials is improved, so that the effect of drying the raw materials before screening is better.

Owner:宿州市东方红肥业有限公司

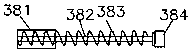

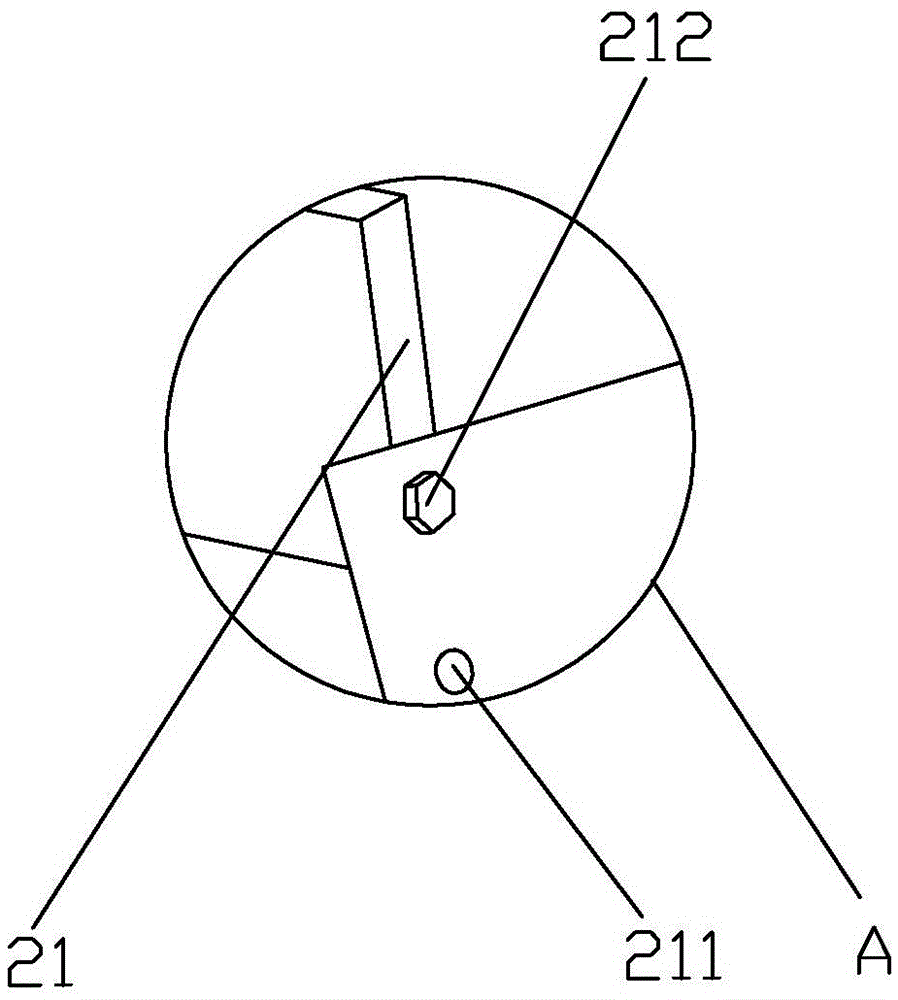

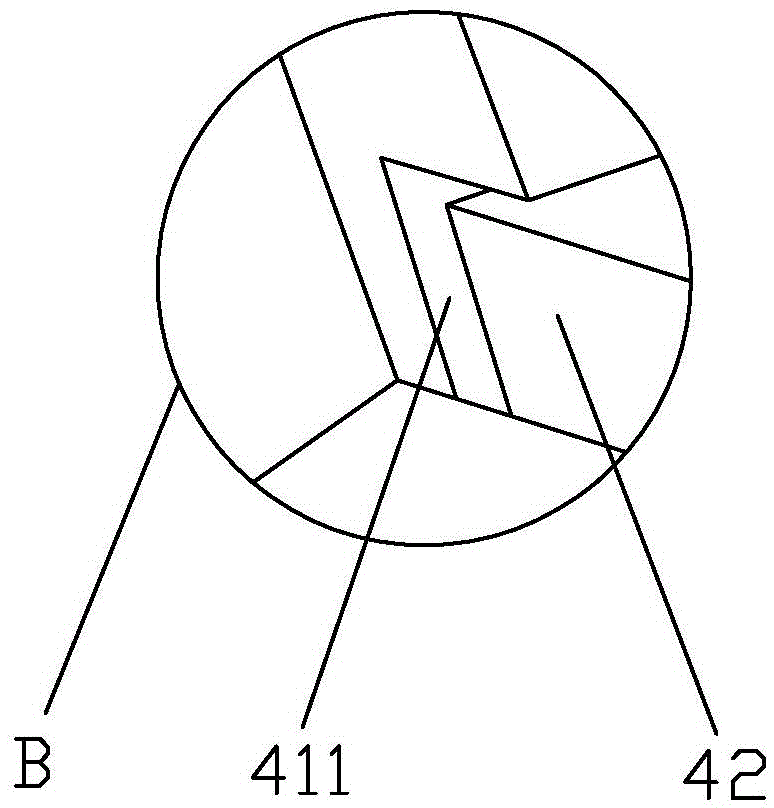

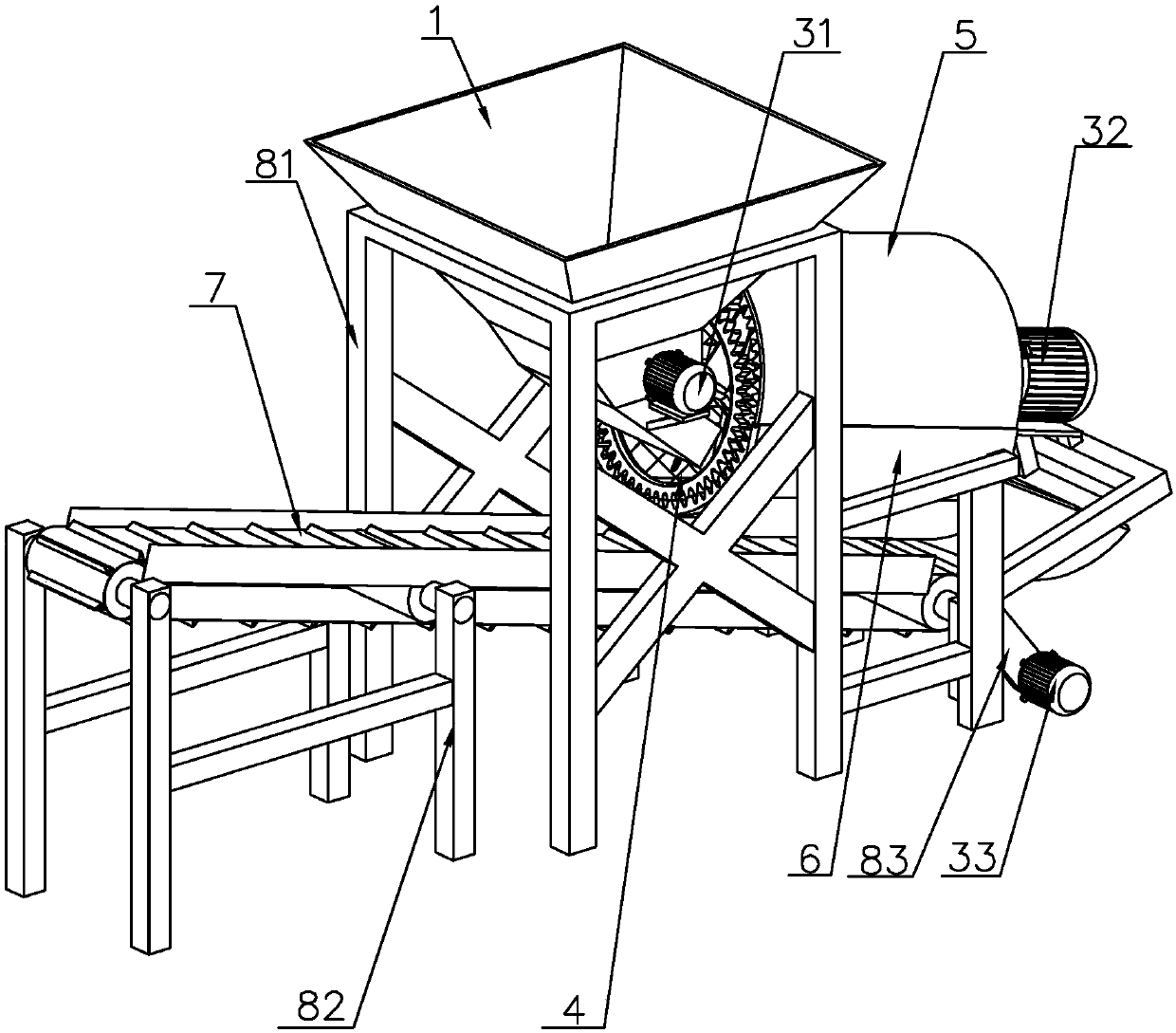

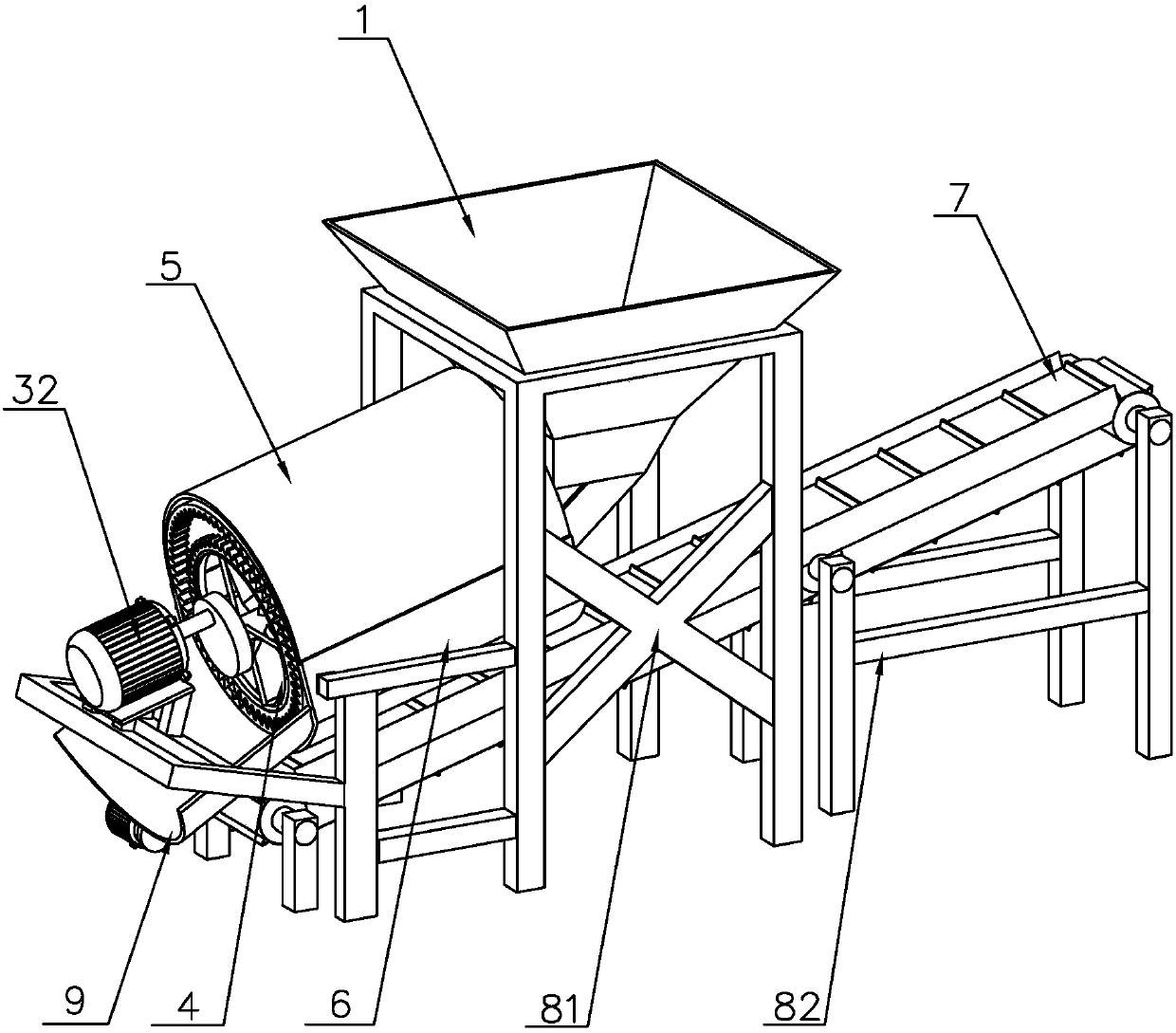

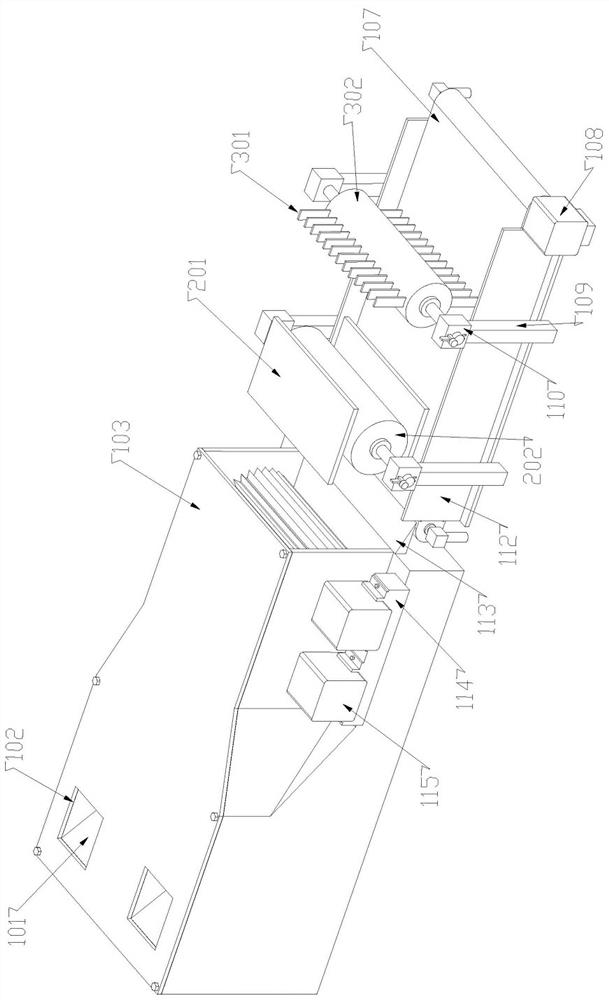

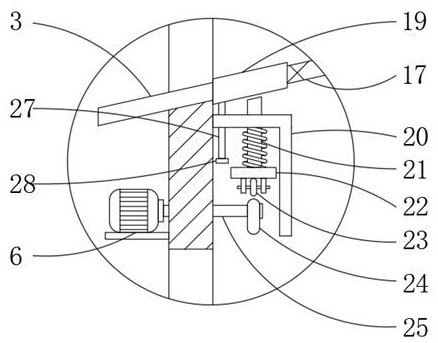

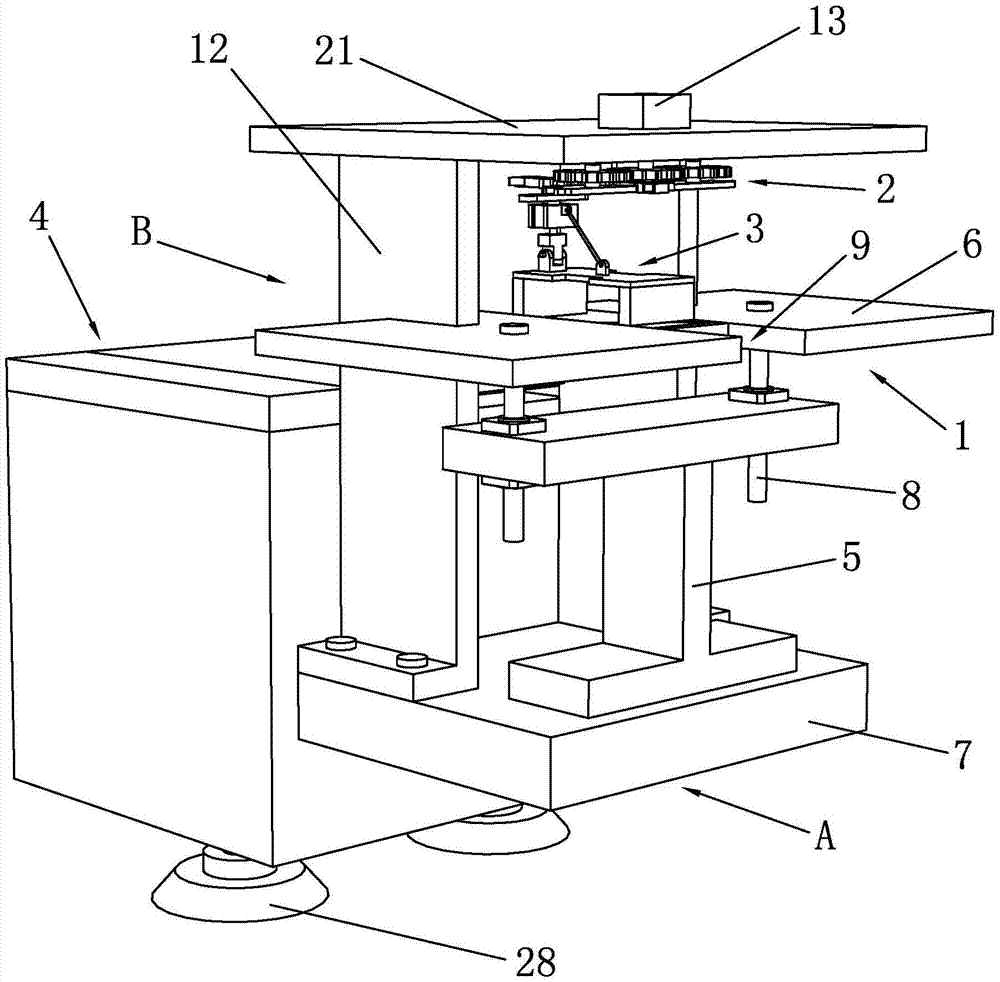

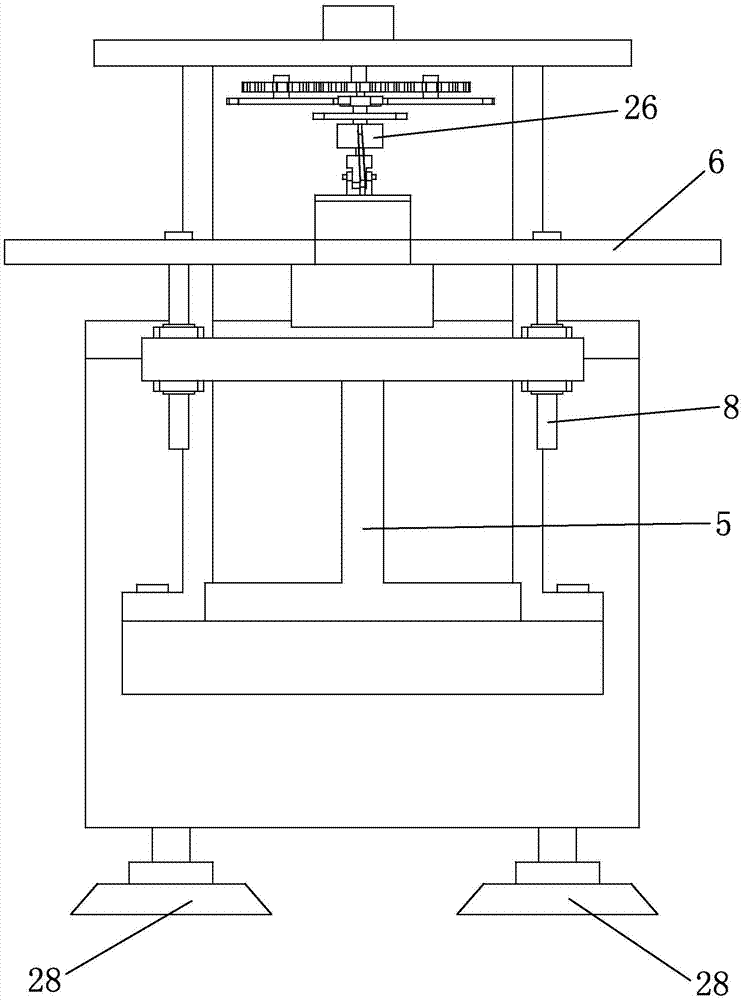

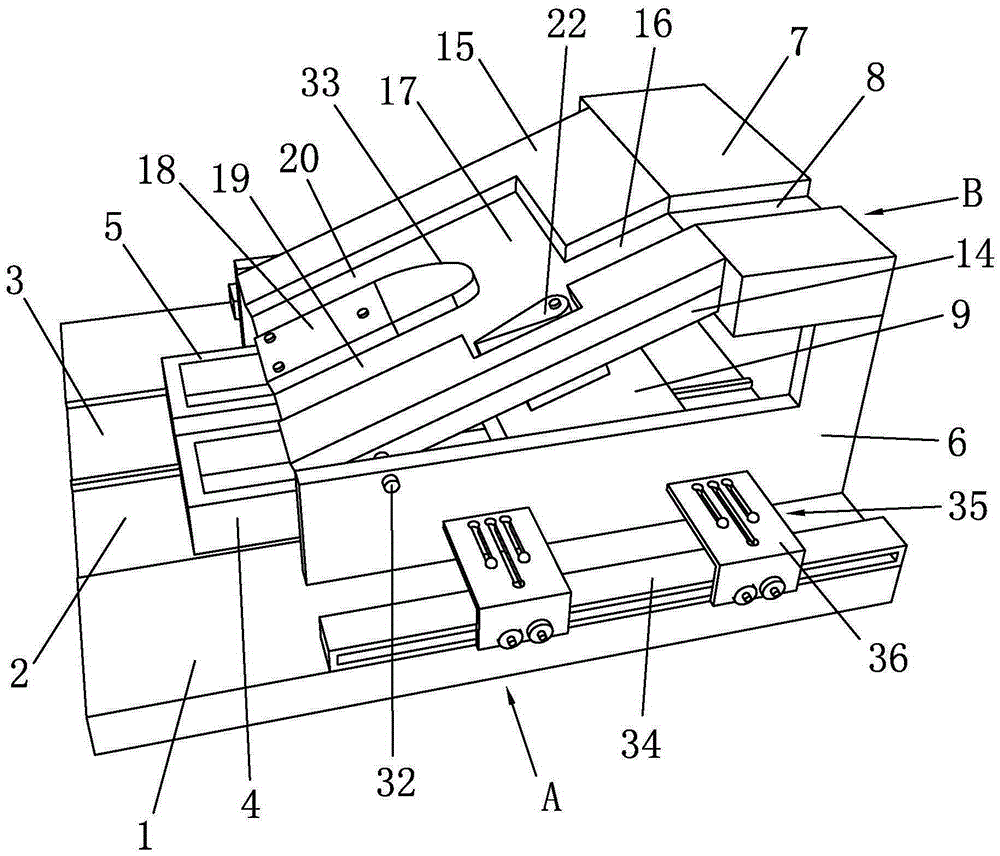

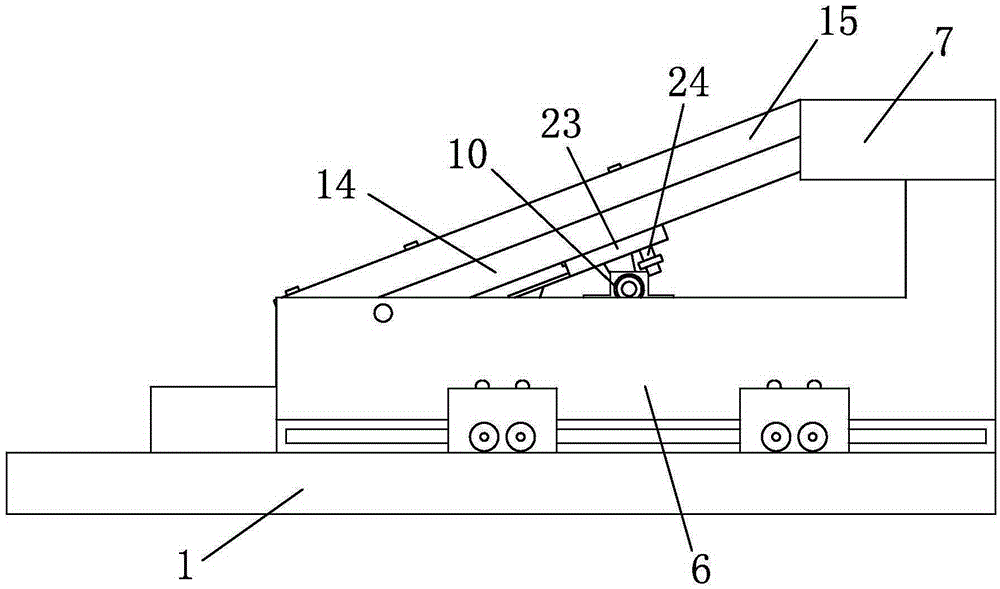

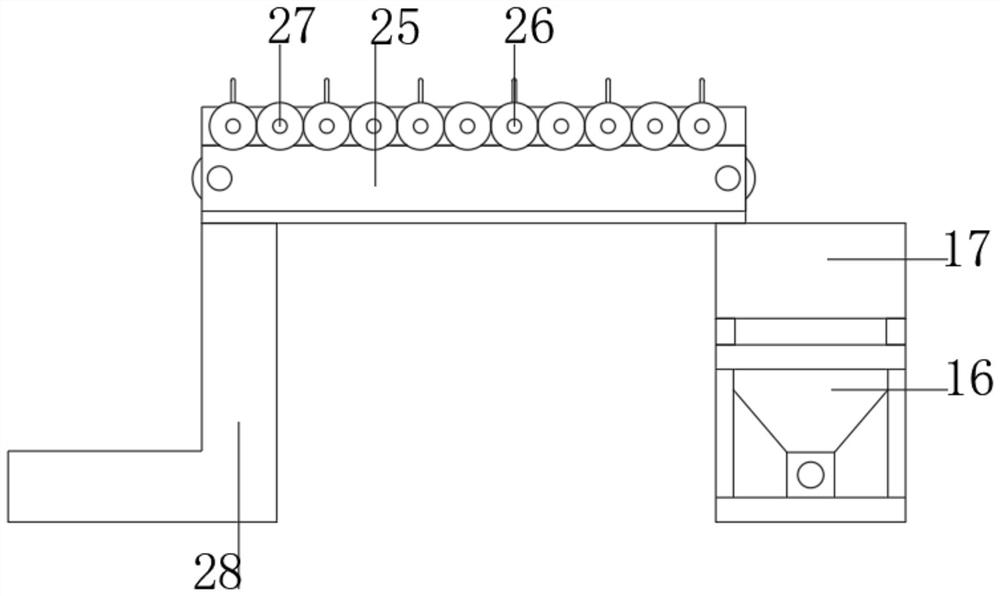

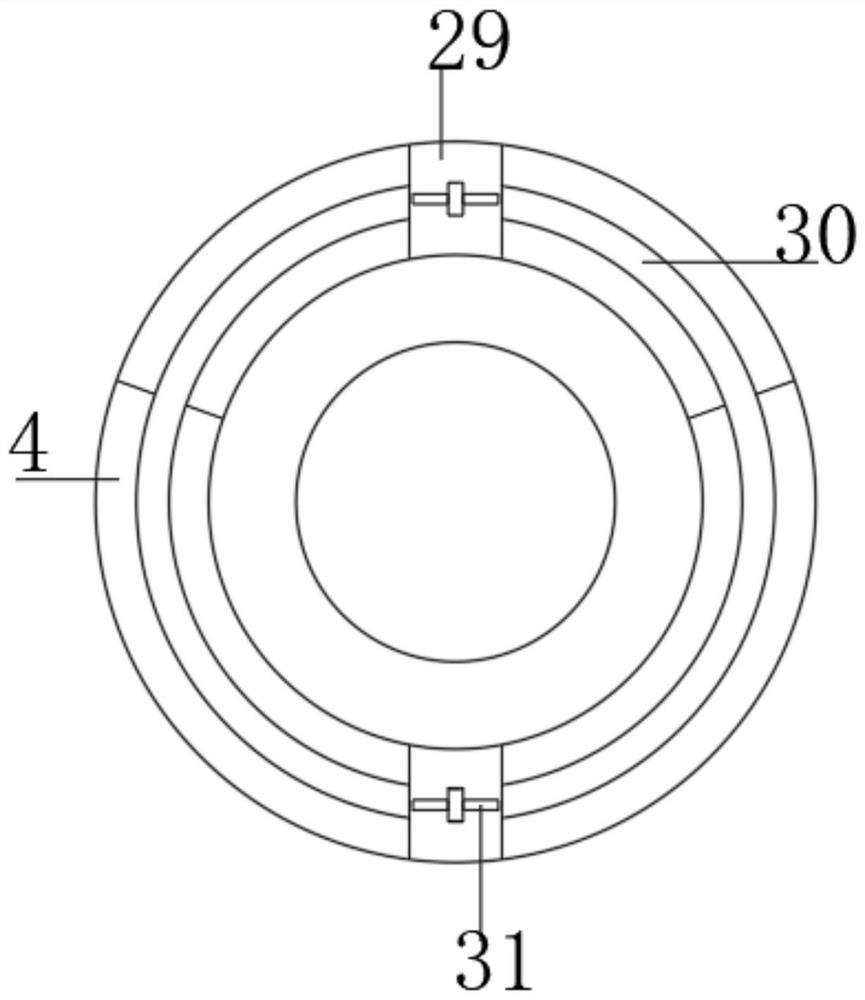

Quantitative screening mechanism of stampings for motor production

The invention discloses a quantitative screening mechanism of stampings for motor production. The quantitative screening mechanism comprises a feeding unit, a driving unit, a screening unit and a conveying unit; the feeding unit comprises a feeding base and a feeding stand; an adjusting rod is arranged on the feeding base; a tilting table is arranged on the feeding stand and a discharging table is fixedly connected between the tilting table and the conveying unit; the driving unit comprises a motor, a driving gear, a driven gear and a driving rod; a driving disc is arranged on the driven gear; a cover plate is arranged on a top end of the supporting table and a supporting rod is arranged on the bottom of the cover plate; the screening unit comprises a screening base, a first screening plate and a second screening plate; a positioning block is arranged on the bottom of the driving rod; and a connecting block is arranged on the bottom of the positioning block. The quantitative screening mechanism of stampings for motor production is capable of quantitatively feeding stampings different in specification for screening and then discharging the stampings different in specification by classes; an operator can select stampings according to desired specifications on a production line and the operation of selecting the stampings of the desired specifications is reduced, and therefore, the production efficiency is improved.

Owner:嵊州市强丰机电有限公司

Screening equipment for rubber processing based on centrifugal force principle

The invention relates to the technical field of rubber processing, in particular to screening equipment for rubber processing based on centrifugal force principle. The screening equipment for rubber processing based on the centrifugal force principle includes a shell body, the outside wall of the shell body is fixedly connected with two mounting seats in a symmetrical mode, the mounting seats arefixedly connected with supporting rods, top ends of the two supporting rods are both fixedly connected with a supporting plate, the middle of the supporting plate is fixedly connected with a bearing,the inner ring of the bearing is fixedly connected with a rotary sleeve, and the upper part of the rotary sleeve is connected with a driving device; and the bottom end of the rotary sleeve is fixedlyconnected with a screening frame, the screening frame is in an inverted triangular pyramid shape, and the slope of the screening frame is prepared from filter screens. The screening equipment for rubber processing based on the centrifugal force principle has the beneficial effects that the rotary sleeve rotates constantly, under the centrifugal force action, materials positioned at the bottom of the screening frame is constantly threw to the slope of the screening frame and filtered out, thus the selection effect is improved; and meanwhile a disturbance rod is arranged, so that the selection effect of the materials is better.

Owner:史青青

Navel orange sorting and packaging device for electronic commerce logistics

InactiveCN111701862AAvoid breakingAffect qualityPackaging fruits/vegetablesFood treatmentLogistics managementAgricultural engineering

The invention provides a navel orange sorting and packaging device for electronic commerce logistics. The navel orange sorting and packaging device comprises a frame, screening columns, a collecting box, motors, a bottom rail, a convex groove sliding rail, a box body and a cart. The screening columns are arranged on the inner side of the frame. The motors are arranged in the middles of the front ends of the screening columns. The collecting box is arranged at the bottom of the left side of the frame. The bottom rail is integrally arranged at the bottom of the rear side of the frame. The top ofthe bottom rail is movably connected with the cart through the convex groove sliding rail. The box body is arranged at the top of the cart. The whole device is stable in structure, the navel orangescan be accurately classified, the classification speed is high, the efficiency is high, the time and labor are saved, storage and packaging operation is facilitated, and the use and operation are convenient and fast.

Owner:贺兰香

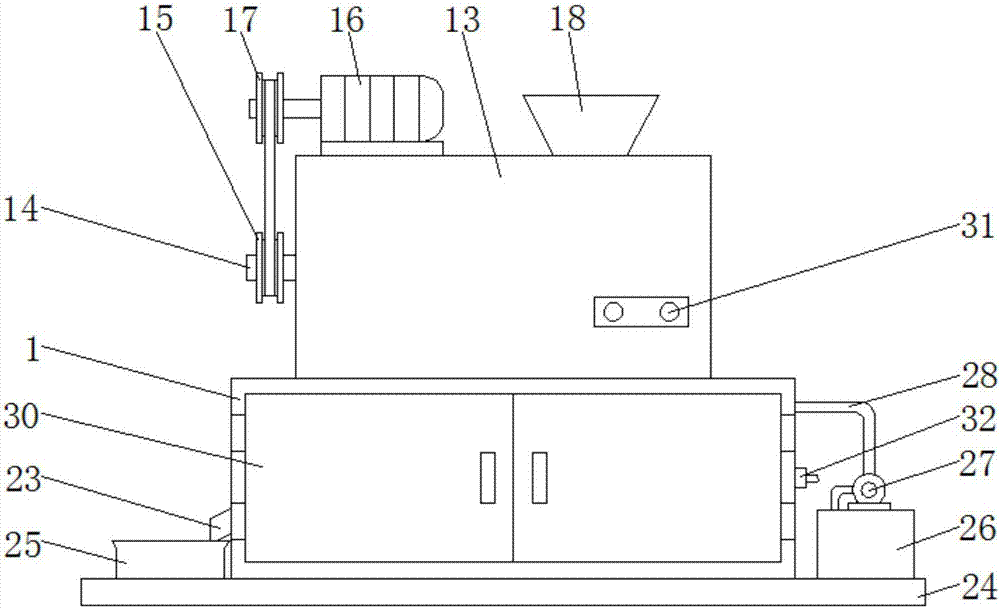

Sand screening system for engineering supervision construction and screening method thereof

InactiveCN112275625APrevent outflowAvoid cloggingSievingScreeningDrive shaftArchitectural engineering

The invention discloses a sand screening system for engineering supervision construction and a screening method thereof. According to the technical scheme, the sand screening system for engineering supervision construction comprises a sand screening device, a feeding device, an impurity storage device and a spraying device which are arranged on a base plate; universal wheels are arranged at the lower end of the base plate; the feeding device comprises a shell, a driving shaft, a driven shaft, a lifting belt and a first motor, wherein the shell is provided with an inner cavity, the driving shaft, the driven shaft and the lifting belt are arranged in the shell, and the first motor is arranged outside the shell; a feeding port and a discharging port are formed in the shell; and a plurality ofconveying hoppers which are evenly arranged are connected to the lifting belt. The system and the method have the beneficial effects that the sand screening efficiency is high, conveying is convenient, and dust flying can be avoided in the sand screening process.

Owner:浙江正和监理有限公司

Screening mechanism for decoration block installation

ActiveCN105414048AAvoid structural damageEasy to snapSortingConnection tableAgricultural engineering

The invention discloses a screening mechanism for decoration block installation. The screening mechanism for decoration block installation comprises a workbench, wherein installation plates are arranged on the workbench; a connection table is arranged between the installation plates; rotary bases are arranged on the connection table; a fixed shaft is arranged between the rotary bases; a rotary panel is rotationally connected to the fixed shaft, and limited on the connection table; a fixed support is arranged on the rotary panel; a support frame is fixedly connected to the fixed support, and fixedly connected to the installation plates; a screening table is arranged on the support frame; a connection channel is arranged in the screening table, and communicated with a charge channel; a groove is formed in the screening table, and communicated with the connection channel; a guide block is arranged on the screening table; an accommodating groove is formed in the screening table; and a screening block is arranged in the accommodating groove. According to the invention, decoration blocks which do not meet standards are screened out one by one, and the unqualified decoration blocks and qualified decoration blocks are classified and collected, thus the screening accuracy is improved, the qualified rate of the decoration blocks is increased, and the working efficiency is increased.

Owner:GUANGZHOU SNIMAY HOME FURNITURE CO LTD

A separation device for separating soil and microplastics in soil

The invention discloses a device for separating microplastics from soil, and relates to the field of microplastic separation. The device specifically comprises a sealed case and a central transport tube, and the rear side of the sealed case is connected with a connecting pipe; the upper side of the connecting pipe is connected with a water pump, and a circulating water pipe is installed above thewater pump; the left side of the sealed case is provided with a motor of which the upper side is connected with a gear, and the right side of the gear is provided with a gear ring; the gear is engagedwith the gear ring, and the inner side of the gear ring is fixedly provided with a connecting ring; a rotary drum is installed at the middle of the connecting ring, and connected with the connectingring fixedly; and a clamping ring is arranged below the rotary drum. According to the device for separating the microplastics from the soil, through cooperation of the gear ring and the gear, the rotary drum of the device can be driven to rotate, thereby nesting of the rotary drum on a separation and settling pond for rotation; and thus, an annular filter plate on the outer side of the rotary drumis driven to rotate, and used for filtration and separation.

Owner:FOSHAN UNIVERSITY

Full-automatic seed sorting device and using method thereof

InactiveCN113578516ARealize blanking workAchieve recyclingSeed and root treatmentStationary filtering element filtersHydraulic cylinderAgricultural engineering

The invention discloses a full-automatic seed sorting device and a using method thereof. The full-automatic seed sorting device comprises a separation box, two partition plates are arranged in the separation box, the separation box is divided into a left separation space, a middle separation space and a right separation space from left to right through the partition plates, and a material leakage opening is formed in the upper portion of the middle separation space; gauze elements are arranged above the partition plates, through holes are formed in the lower portions of the partition plates, the separation box is slidably connected with a driving rod, the driving rod is connected with a hydraulic cylinder, and the driving rod is connected with a left sealing push plate, a middle sealing push plate and a right sealing push plate which are all matched with the through holes from left to right; the left separation space and the right separation space are rotationally connected with discharging doors, the discharging doors are connected with driving mechanisms, the driving mechanisms are used for driving the discharging doors to be opened, and a water tank is further arranged below the separation box; and a leaking plate for filtering seeds is arranged in the water tank, and a left water pump and a right water pump are arranged in the water tank. The full-automatic seed sorting device is easy to operate, full-automatic screening work of seed quality is achieved, and the screening efficiency and quality are greatly improved.

Owner:戚甫山

Camellia oleifera seed screening device for camellia oleifera processing

InactiveCN112588564AEasy to filter jobsGuaranteed screening qualitySievingScreeningScreening proceduresCamellia oleifera

The invention discloses a camellia oleifera seed screening device for camellia oleifera processing. The camellia oleifera seed screening device comprises a base seat, a material feeding machine and aconveying device, wherein the base seat is located on the left side of the material feeding machine, the conveying device is located on the rear side of the material feeding machine, a material feeding table is fixedly installed at the lower portion of the rear end of the conveying device, a plurality of screening paddles are rotatably connected to the upper side of the conveying device, the leftends of the screening paddles are all fixedly connected with first transmission gears, and meshed second transmission gears are arranged between every two adjacent first transmission gears. Accordingto the camellia oleifera seed screening device for the camellia oleifera processing, by means of the arrangements of first two screening procedures of carding impurity removing and vibrating screening, camellia oleifera seeds are subjected to impurity removing in advance, finally, structures in a screening barrel are matched with a second screening net to remove fine foreign matter from the camellia oleifera seeds, the screening quality of the camellia oleifera seeds is guaranteed, and meanwhile, the camellia oleifera seed screening device is high in screening efficiency and worthy of wide application.

Owner:安徽滋申生态农林综合开发有限公司

Dust detection collecting mechanism with screening function

InactiveCN112924338AEasy accessConvenient detection workDispersed particle filtrationTransportation and packagingRotational axisDust detection

The invention discloses a dust detection collecting mechanism with a screening function. The mechanism comprises a base, an air inlet and a cam. The top end of a containing groove is connected with a compression spring through a connecting block, the compression spring is arranged in a fixing groove, the cam is arranged outside a rotating shaft, and the cam is arranged in the middle of a connecting cover. A filtering dust collecting plate is arranged in the containing groove, a baffle is fixedly installed at the top end of the filtering dust collecting plate, sliding blocks are fixedly connected to the upper side and the lower side of the fixing groove correspondingly, the sliding blocks are in sliding connection with the sliding grooves in the upper side and the lower side of the connecting block, and sealing rubber strips are arranged above the top ends of the sliding grooves. According to the dust detection collecting mechanism with the screening function, dust can be well screened in a collecting process, the screened dust can be taken conveniently, a large amount of dust residues cannot exist in the device, and cleaning work is facilitated.

Owner:徐晨

Production equipment of refractory material

ActiveCN112452493AEasy to filter jobsReduce transmissionSievingTransportation and packagingRefractoryElectric machinery

The invention relates to the technical field of refractory material production, and discloses production equipment of a refractory material. The production equipment comprises a bottom plate and a topplate, a supporting rod is fixedly connected between the bottom plate and the top plate, a mixing mechanism is arranged between the bottom plate and the top plate, a screening mechanism is arranged below the mixing mechanism, and a batching mechanism is arranged above the mixing mechanism; and the mixing mechanism comprises a mixing box, a screw rod is arranged in the mixing box, and the screw rod is made of a stainless steel material. According to the production equipment, materials enter from a feeding pipe at the top of the mixing box, then the screw rod in the mixing box is driven by a first motor to rotate so that the materials can be mixed, the materials are conveyed to the left end of the mixing box while being mixed, and then the materials are conveyed out of the mixing box so that screening work can be conducted conveniently; and a pressing roller is arranged at one side of a spiral piece, so that the materials adsorbed on the inner wall of the mixing box can be crushed.

Owner:营口镁菱盛元耐火材料有限公司

Device for separating microplastics from soil

The invention discloses a device for separating microplastics from soil, and relates to the field of microplastic separation. The device specifically comprises a sealed case and a central transport tube, and the rear side of the sealed case is connected with a connecting pipe; the upper side of the connecting pipe is connected with a water pump, and a circulating water pipe is installed above thewater pump; the left side of the sealed case is provided with a motor of which the upper side is connected with a gear, and the right side of the gear is provided with a gear ring; the gear is engagedwith the gear ring, and the inner side of the gear ring is fixedly provided with a connecting ring; a rotary drum is installed at the middle of the connecting ring, and connected with the connectingring fixedly; and a clamping ring is arranged below the rotary drum. According to the device for separating the microplastics from the soil, through cooperation of the gear ring and the gear, the rotary drum of the device can be driven to rotate, thereby nesting of the rotary drum on a separation and settling pond for rotation; and thus, an annular filter plate on the outer side of the rotary drumis driven to rotate, and used for filtration and separation.

Owner:FOSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com