Soil screening machine

A screening machine and soil technology, applied in screening, solid separation, chemical instruments and methods, etc., can solve the problem that manual screening cannot meet the requirements of the development of the times, and achieve the effect of reducing the intensity of screening work, reducing costs, and facilitating screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

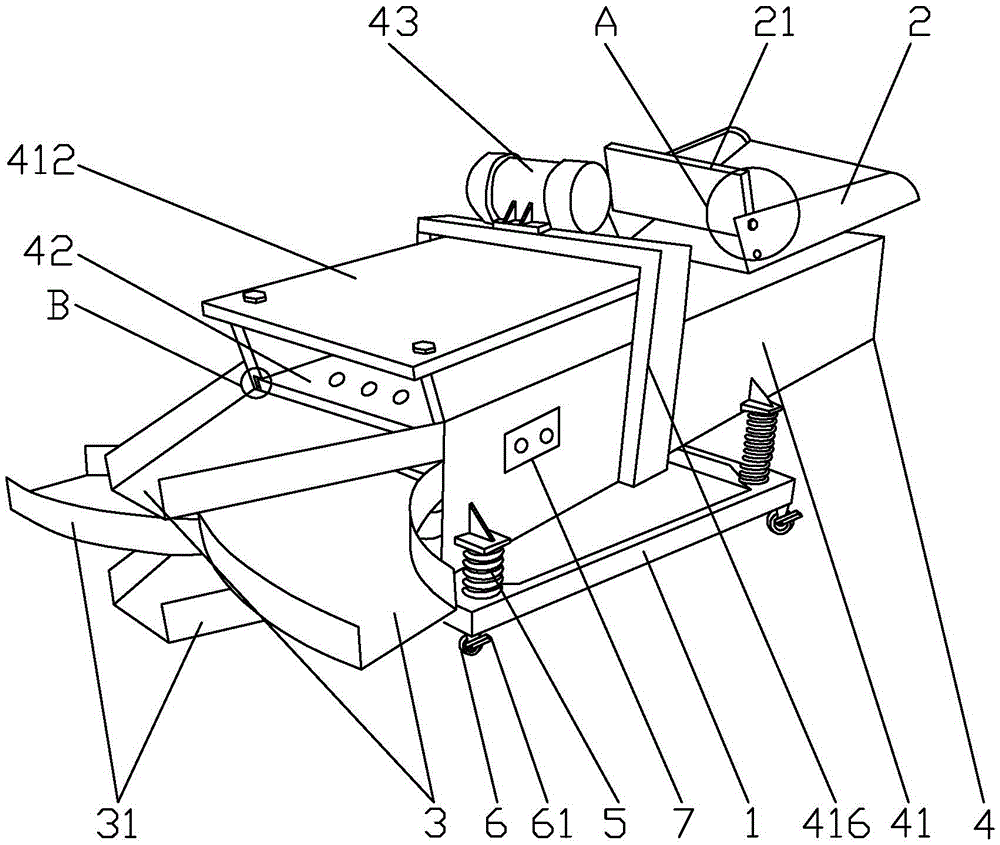

[0017] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

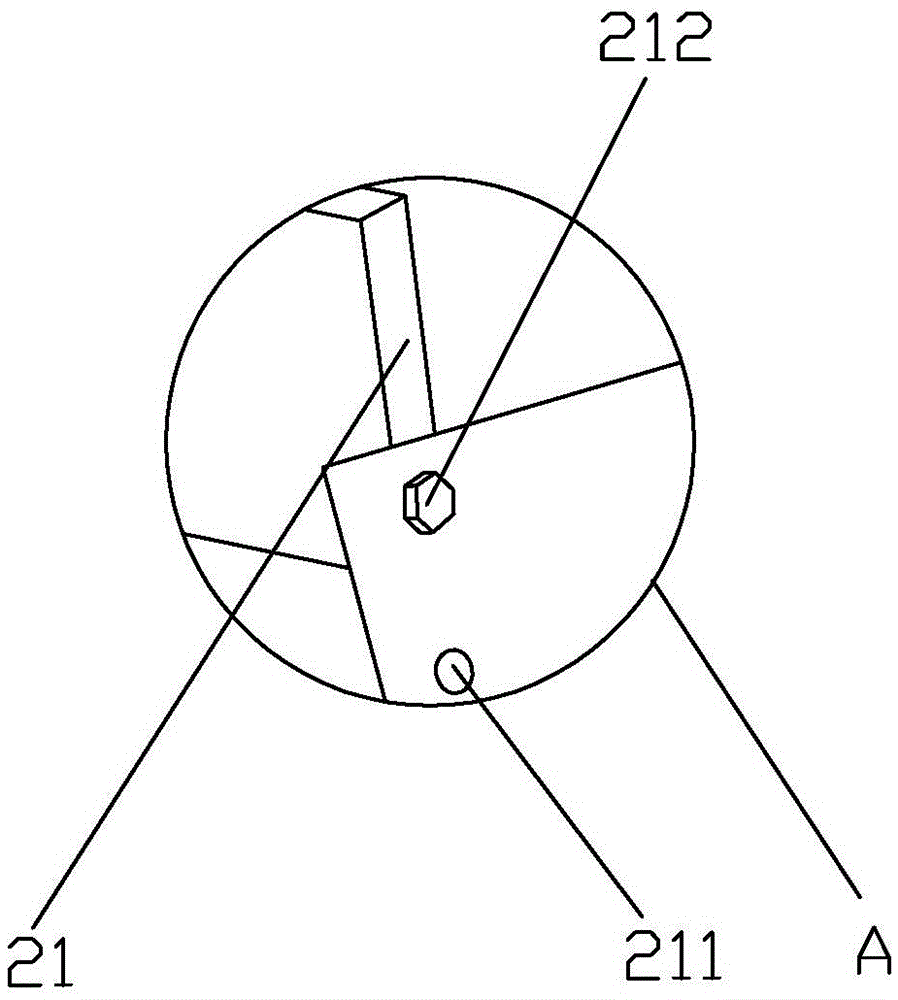

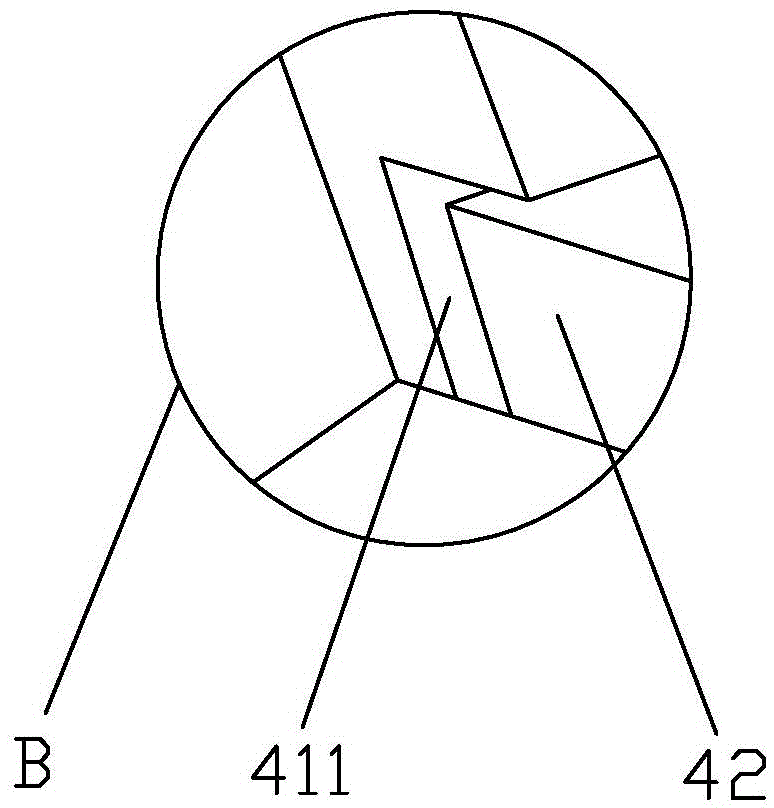

[0018] like Figure 1-4 Shown, a kind of soil screening machine comprises base frame 1, feed port 2, discharge port 3 and screening device 4, and described screening device 4 is installed on the bottom frame 1 top, and described feed port 2 is installed on the screening device 4. On the upper side of the head, the outlet 3 is installed at the tail of the screening device 4, the inlet 2 is provided with an adjustment board 21, and both sides of the adjustment board 21 are provided with a jack 211 , both sides of the feed port 2 are provided with at least two sockets 211, the feed port 2 and the adjusting plate 21 are connected together in the socket 211 by screwing the bolts 212, and the bolts 212 are inserted into the sockets 211. In the different jacks 211 of the feed port 2, the size of the feed port 2 can be adjusted to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com