Vibrating screen for mine stone processing

A vibrating screen and stone technology, applied in the field of mining machinery, can solve the problems of inability to crush stones and low screening efficiency, and achieve the effect of improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

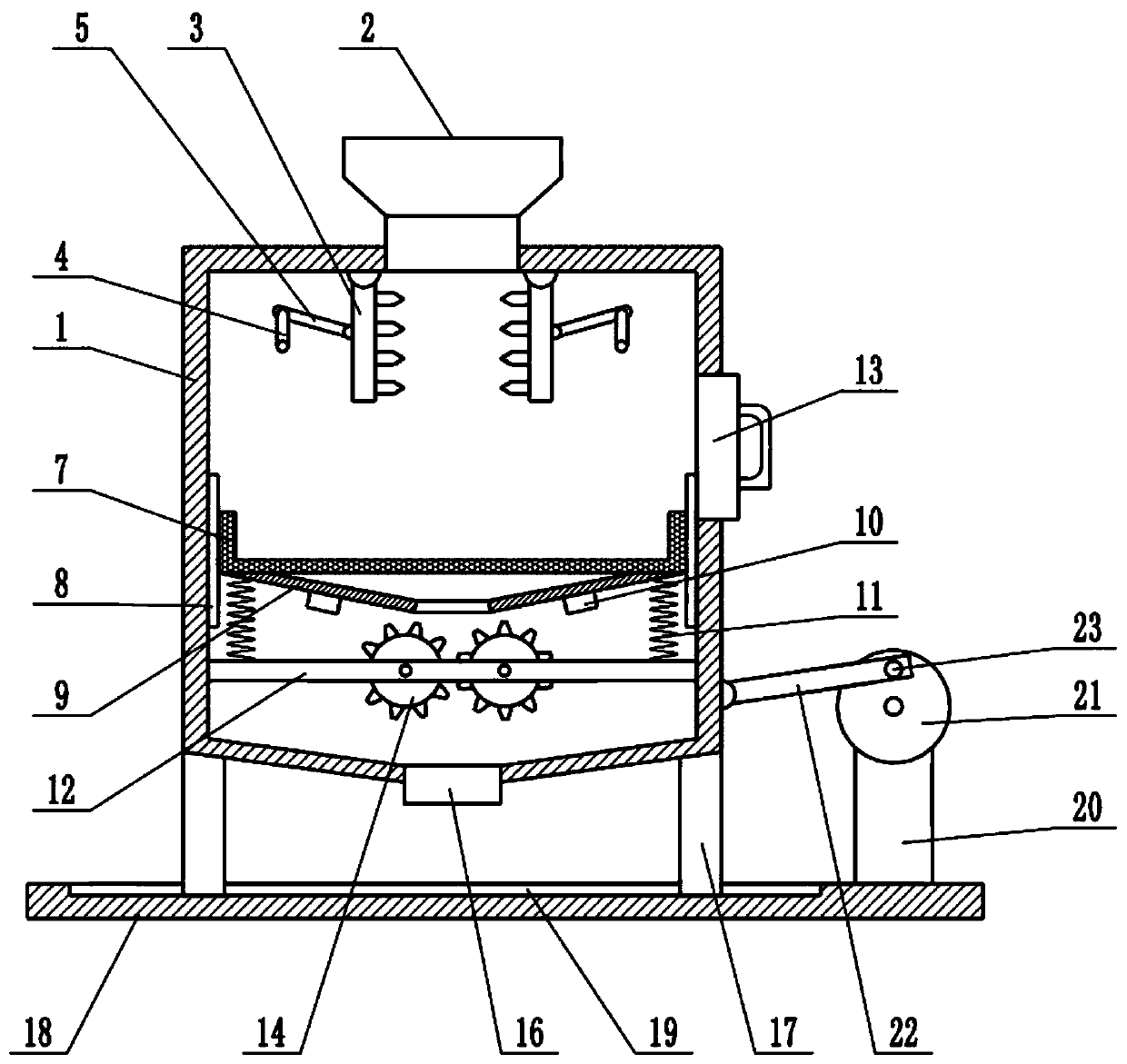

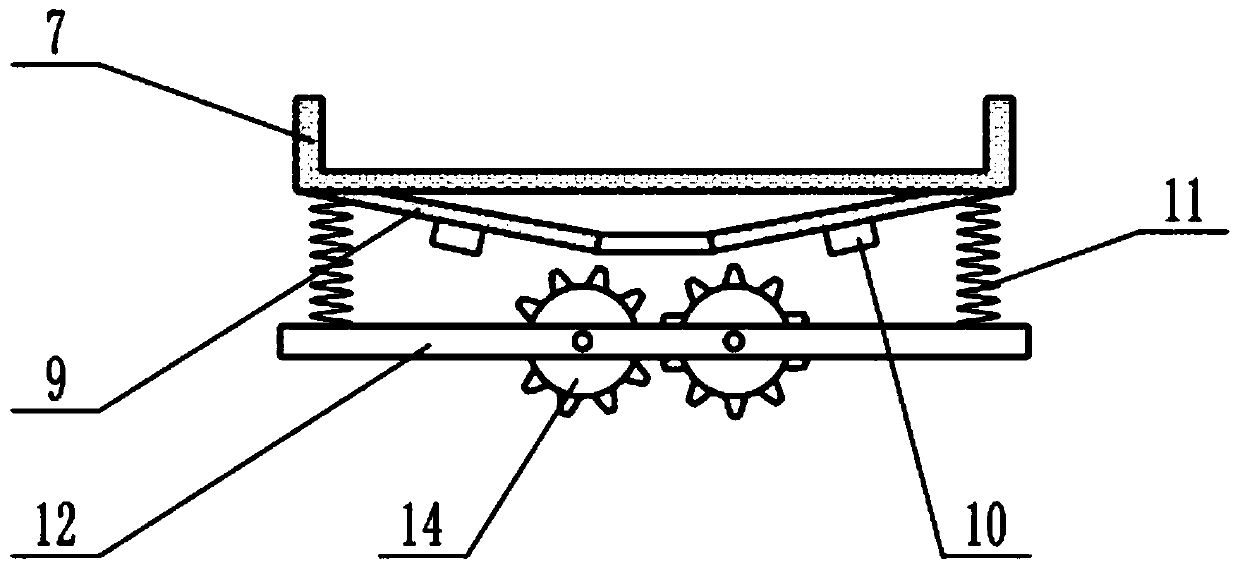

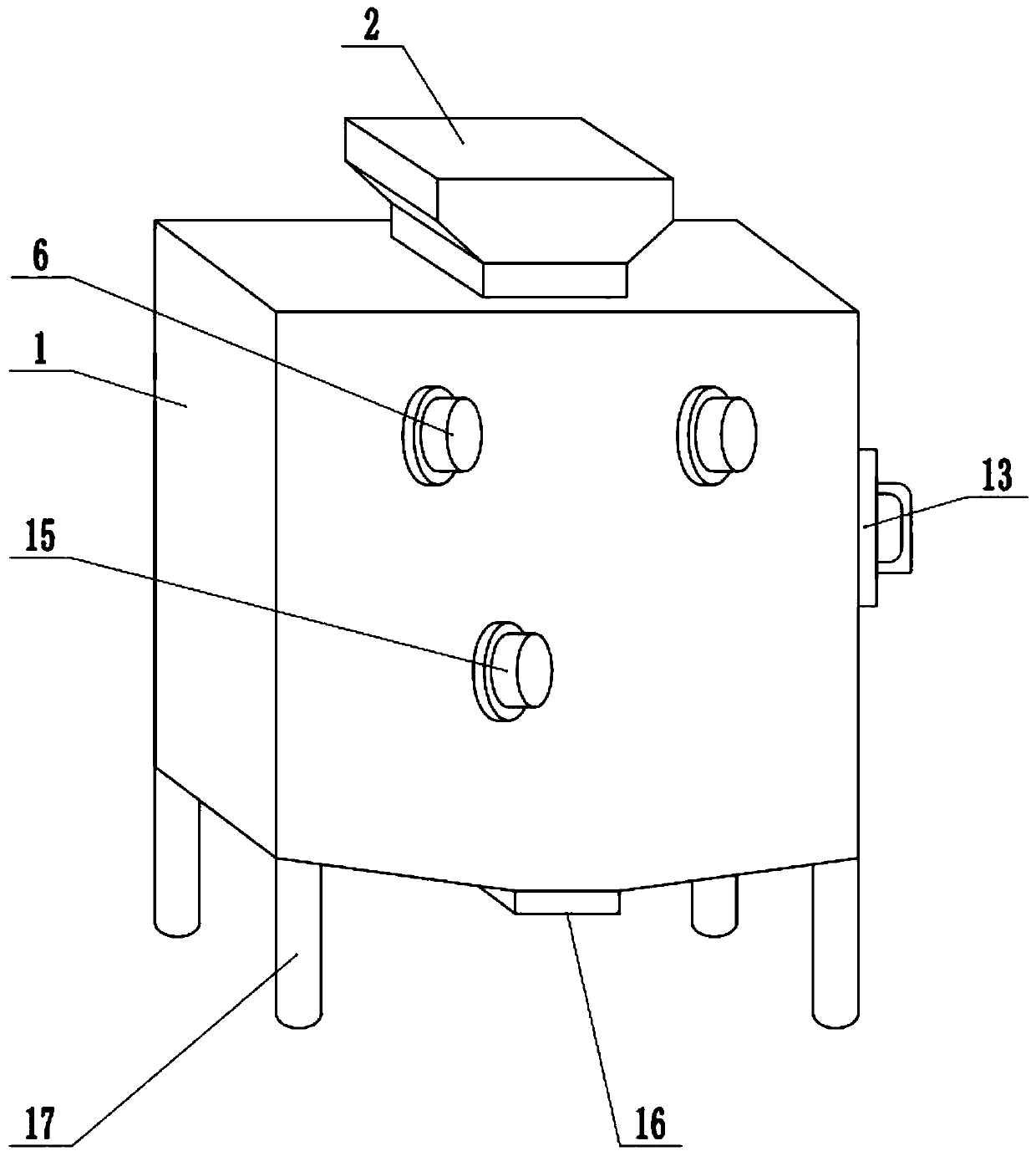

[0022] see Figure 1-3 , in an embodiment of the present invention, a vibrating screen for mine stone processing includes a casing 1, a feeding port 2, a sieve plate 7 and a vibrating motor 10, a feeding port 2 is installed on the top of the casing 1, and stones are fed into the casing 1 through the feeding port 2 Inside, the shell 1 is equipped with a crushing plate 3. There are two crushing plates 3, which are arranged symmetrically on the left and right. The crushing teeth are distributed on the crushing plate 3. The top of the crushing plate 3 is hinged with the top of the shell 1. The inside of the shell 1 is installed with The crankshaft 4, the two ends of the crankshaft 4 are respectively connected to the side wall of the shell 1 in rotation, the outer wall of the shell 1 is fixedly connected with the crushing motor 6, the shaft extension end of the crushing motor 6 is connected with the crankshaft 4, and the crankshaft 4 is driven by the crushing motor 6 Rotate, the jo...

Embodiment 2

[0024] On the basis of Embodiment 1, a foot 17 is installed on the bottom of the casing 1, a support plate 18 is provided below the casing 1, and a chute 19 is opened on the upper surface of the support plate 18, and the lower end of the foot 17 is embedded in the chute 19. 17 is slidingly connected with the chute 19, the housing 1 can slide left and right, the upper surface of the support plate 18 is fixedly connected with a shaking motor 20, the shaft extension end of the shaking motor 20 is provided with a turntable 21, and the surface of the turntable 21 is fixedly connected with a Fixed rod 23, fixed rod 23 is provided with rocking rod 22, and rocking rod 22 is connected with fixed rod 23 in rotation, and the left end of rocking rod 22 is hinged with the side wall of housing 1, starts shaking motor 20, drives turntable 21 to rotate, thereby passes The shaking rod 22 drives the housing 1 to shake from side to side, and then drives the sieve plate 7 to shake from side to sid...

Embodiment 1、 Embodiment 2

[0025] Combined with Embodiment 1 and Embodiment 2, the working principle of the present invention is: put the stone to be screened into the casing 1 through the feeding port 2, start the crushing motor 6, and drive the crankshaft 4 to rotate, thereby driving the crushing plate 3 through the connecting rod 5 Swing, use the crushing plate 3 to crush the stone, the crushed stone falls on the sieve plate 7, start the vibration motor 10, and with the cooperation of the spring 11, it can drive the sieve plate 7 to vibrate up and down, which is beneficial for the ore to pass through the sieve plate 7 , so as to improve the screening efficiency, start the shaking motor 20 at the same time, drive the turntable 21 to rotate, thereby drive the shell 1 to shake left and right through the shaking rod 22, and then drive the sieve plate 7 to shake left and right, further improve the screening efficiency, and facilitate the screening operation. The final stone falls on the material guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com