Quantitative screening mechanism of stampings for motor production

A technology for punching and screening devices, which is applied in solid separation, classification, chemical instruments and methods, etc., and can solve problems such as reducing production efficiency and increasing operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

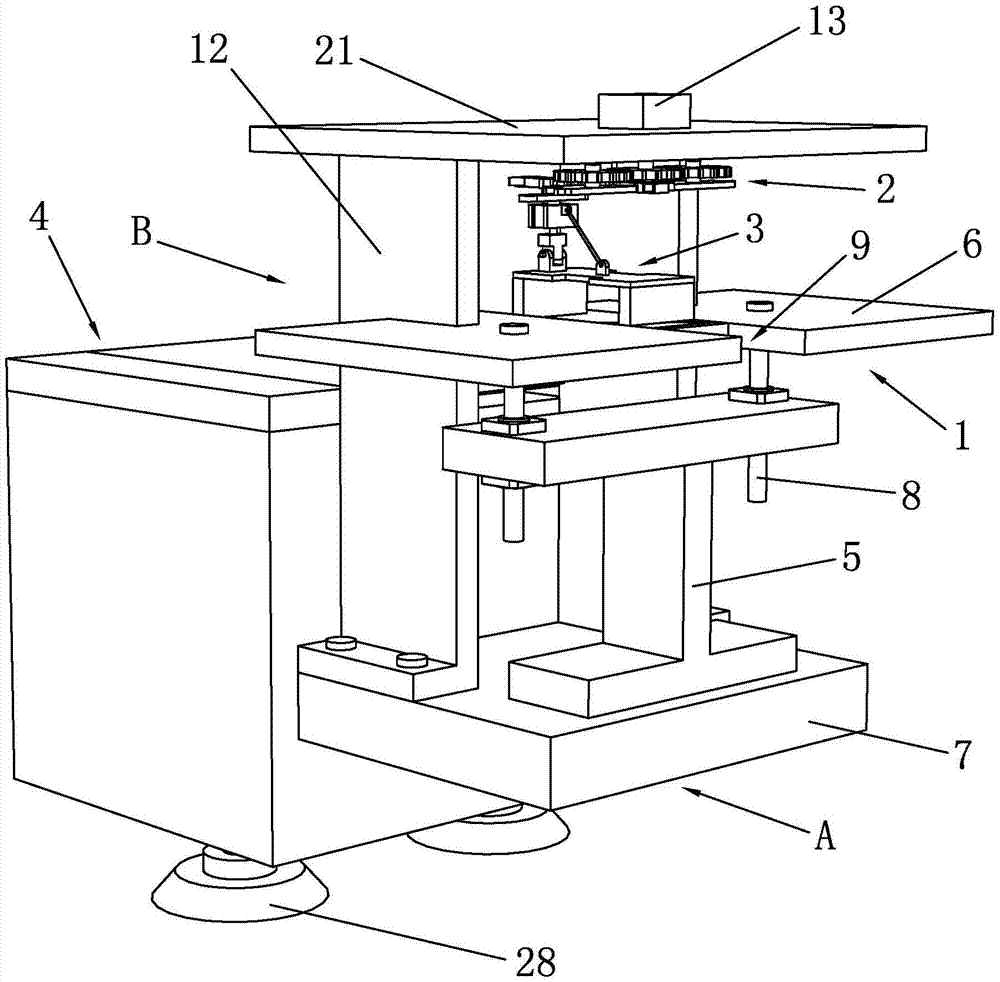

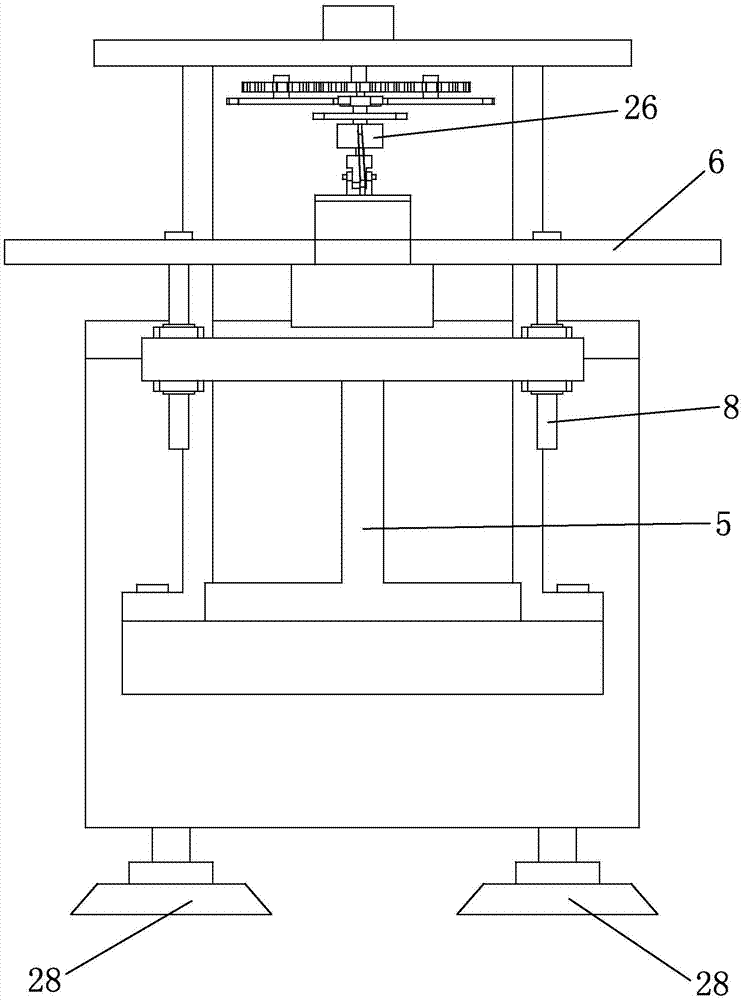

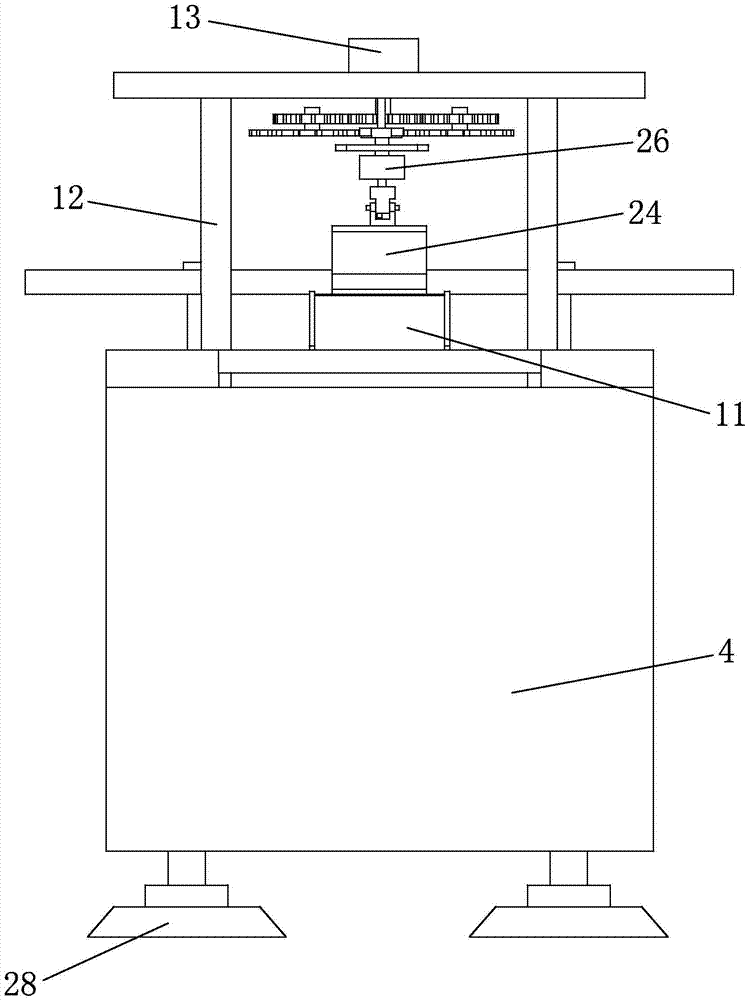

[0025] Such as Figure 1 to Figure 8 Shown is a quantitative screening mechanism for punching sheets used in motor production according to the present invention, including a feeding device 1 , a driving device 2 , a screening device 3 and a conveying device 4 . The bottom of the conveying device 4 is provided with feet 28 . Support foot 28 comprises adjusting rod and plastic base, can adjust the overall height of supporting foot 28 by adjusting rod, can lift whole conveying device 4 off the ground like this to a certain height, avoids conveying device 4 and the ground directly contacting and causes the bottom of conveying device 4 to wear phenomenon, and the plastic base can increase friction and improve the stability of the delivery device 4 .

[0026]The feeding device 1 comprises a feeding base 5 and a feeding table 6, the feeding base 5 is I-shaped, the conveying device 4 is provided with a mounting table 7, the feeding base 5 is located on the mounting table 7, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com