Sand screening system for engineering supervision construction and screening method thereof

A sand and supervision technology, applied in the field of sand screening, can solve the problems of resource waste, dust flying, unsuitable for fine construction, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

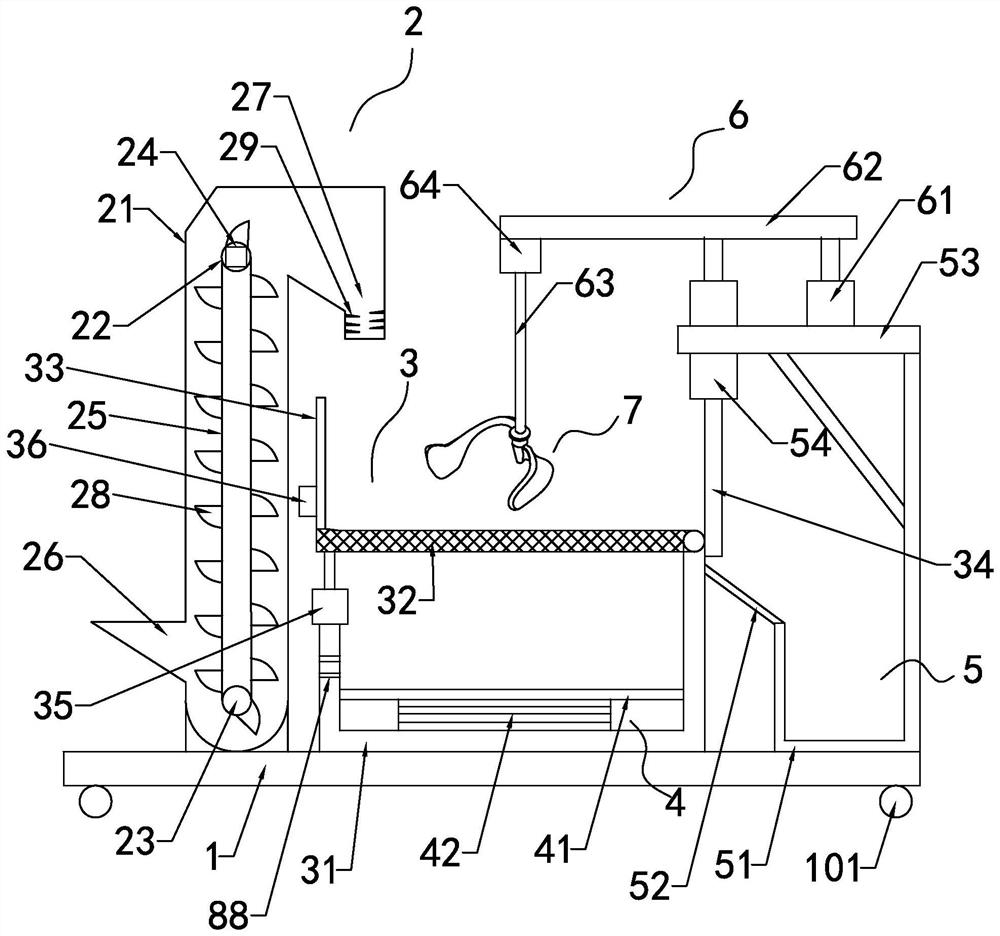

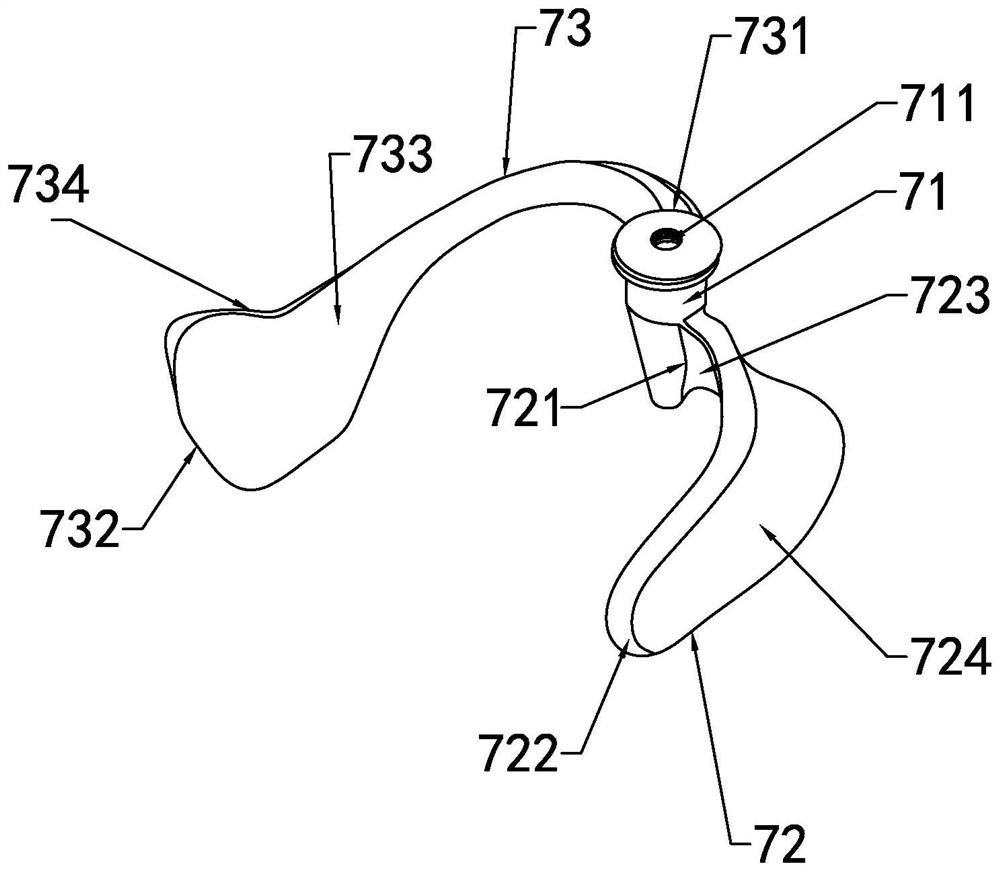

[0029] Such as Figure 1~2 As shown, the present invention discloses a sand screening system for engineering supervision and construction. In a specific embodiment of the present invention, it includes a sand screening device 3 for separating sand and impurities, and is used to transport sand from a low place to the sand screening device 3 The feeding device 2 on the top, the miscellaneous storage device 5 for collecting the impurities separated by the sand screening device 3, and the spraying device 8 for spraying water mist above the sand screening device 3; the sand screening device 3, the feeding Device 2, miscellaneous storage device 5, and spraying device 8 are all arranged on the bottom plate 1, and the lower end of the bottom plate 1 is equipped with a universal wheel 101; the feeding device 2 is located on the left side of the sand screening device 3, and the feeding device 2 includes a housing 21 with an inner cavity, a driving shaft 22 arranged in the housing 21, a ...

Embodiment 2

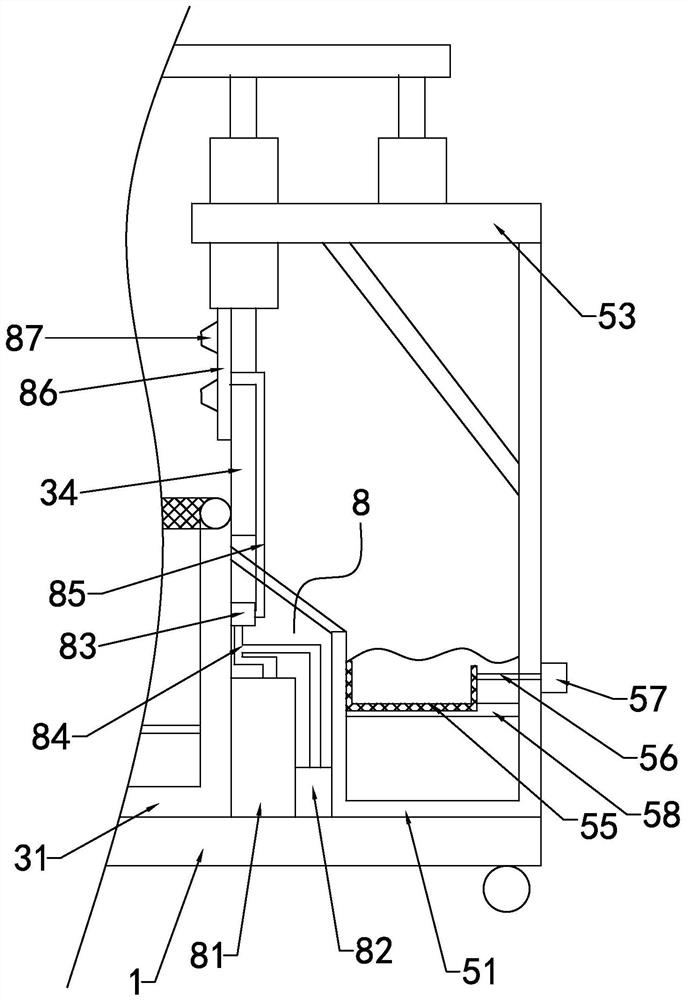

[0046] Such as image 3 As shown, the difference between this embodiment and the above embodiments is that in this embodiment, the spray device 8 is located between the sand screening frame 31 and the miscellaneous storage frame 51, and the spray device 8 includes water storage Box 81, air storage tank 82, delivery pump 83, first water delivery pipe 84, second water delivery pipe 85 and spray pipe 86, described water storage tank 81 and air storage tank 82 are installed on the base plate 1, and described delivery pump 83 is installed on the outer wall of the sand screening frame 31, one end of the first water delivery pipe 84 communicates with the output end of the water storage tank 81 and the gas storage tank 82 respectively, and the other end of the first water delivery pipe 84 communicates with the input of the delivery pump 83 One end of the second water delivery pipe 85 communicates with the output end of the delivery pump 83, and the other end of the second water delive...

Embodiment 3

[0051] A sand screening method for engineering supervision and construction, suitable for the sand screening system for engineering supervision and construction according to claim 1, characterized in that it includes the following steps:

[0052] S1: Feeding: Put sand into the feeding device 2 from the feeding port 26, and the feeding device 2 transports the sand from a low place to a high place, and then discharges it from the discharge port 27 to the sand screening device 3;

[0053] S2: Screening: the sand enters the first screen 32, the sand screening device 3 controls the first screen 32 to move up and down, and stirs the sand through the stirring device 6, the stirring device 6 fully stirs the sand, and the spraying device 8 sprays water Mixed with dust and falls on the first screen 32, the fine sand passes through the first screen 32 and enters the screen frame to complete the screening of the sand, and the screened fine sand is dried in the sand screen frame 31. Use di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com