Earlier-stage treatment production line for construction waste resource utilization

A technology for pre-processing and construction waste, applied in construction waste recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of easily missing metal impurities, affecting the efficiency of processing, product quality, and easy to miss metal impurities. To achieve the effect of adsorbing and recovering metal impurities thoroughly, facilitating cleaning or disassembly and replacement, and improving continuity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further illustrated by the following examples.

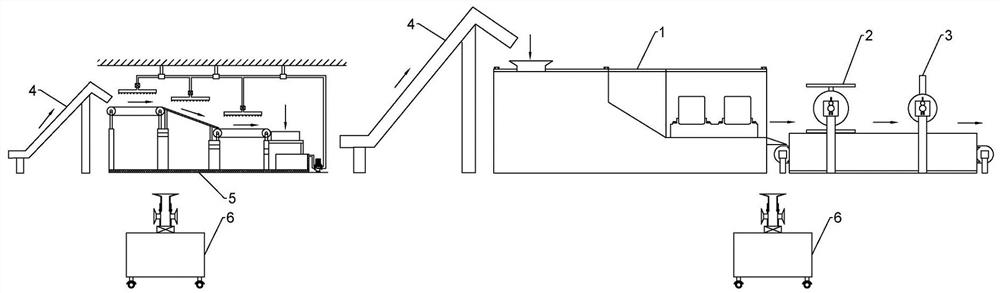

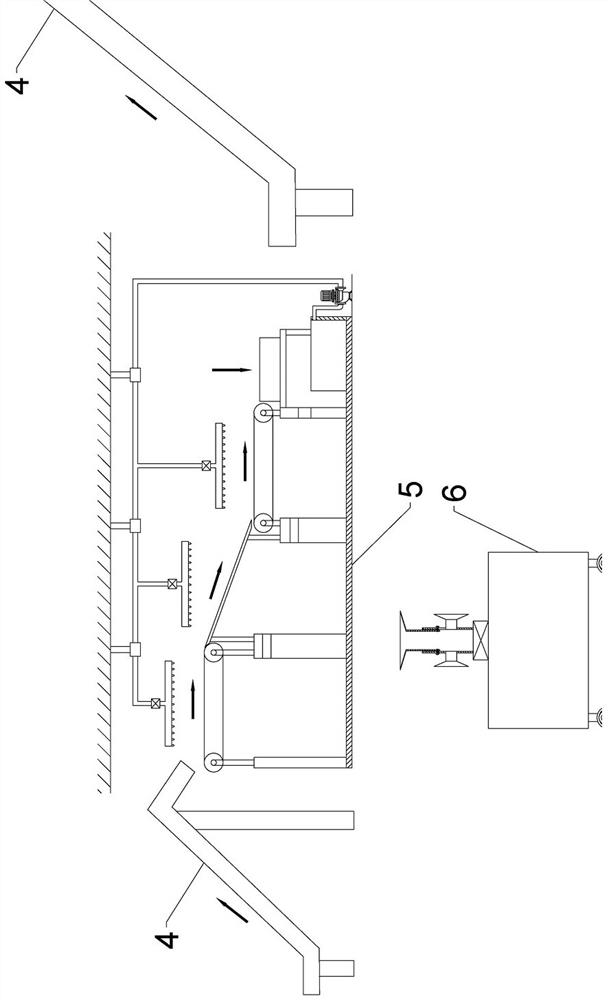

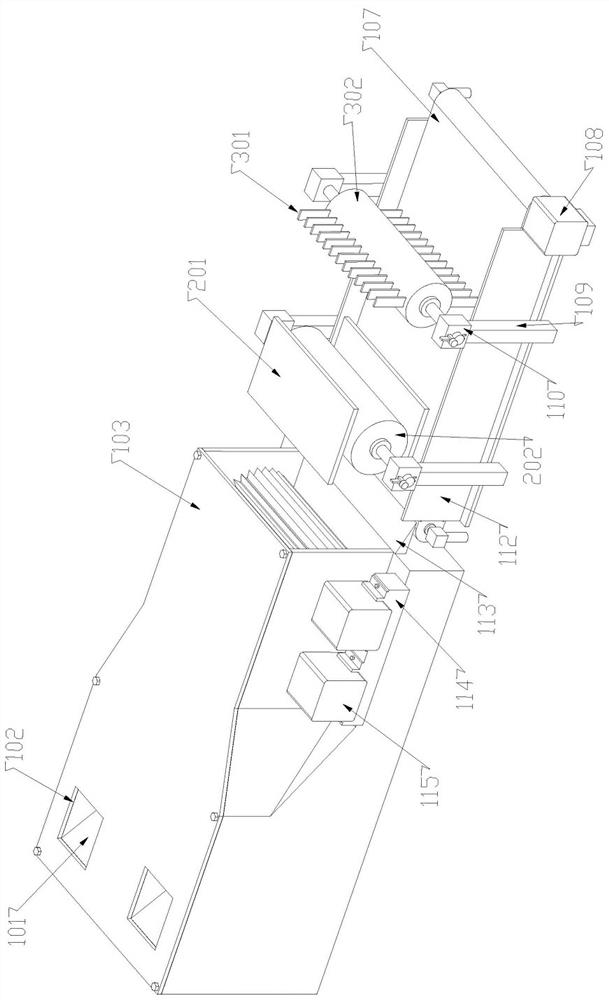

[0043] A construction waste resource utilization pre-processing production line, including a soil separation part, a crushing part and a magnetic separation part, characterized in that the soil separation part includes a soil separation device 5, and the soil separation device 5 is preceded by a lifting conveyor belt 4, The soil separation device 5 comprises a multi-stage vibrating conveyor belt, spraying devices 521 are arranged above the vibrating conveyor belts of all levels, and sedimentation tanks are arranged below the vibrating conveyor belts of all levels. A filter channel is arranged between them; the crushing part includes a multi-stage crushing device 1, and the multi-stage crushing device 1 includes a workbench 133 with a multi-stage platform structure, and two feeding ports 102 are provided on one side of the top cover 103 of the workbench 133 , one side of the workbench 133 is the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com