Active carbon for organic solvent recovery and preparation method thereof

An organic solvent and activated carbon technology, applied in the field of activated carbon for organic solvent recovery and its preparation, can solve problems such as environmental and human health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

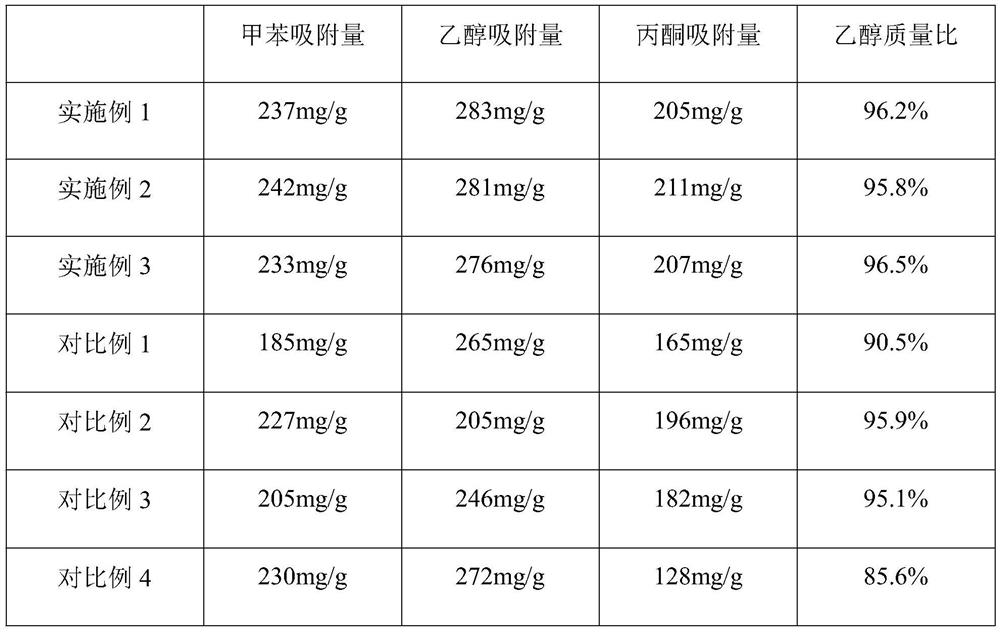

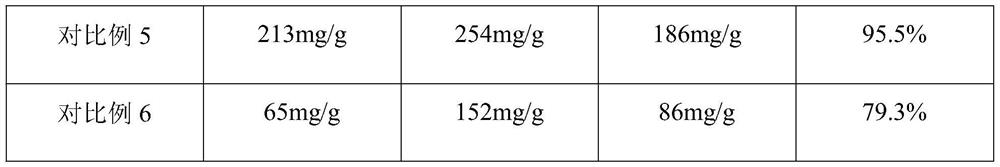

Examples

Embodiment 1

[0030] An activated carbon for organic solvent recovery, mainly comprising: 12 parts of modified carbon powder, 3 parts of benzamide folded body, 8 parts of 2-monochloromethyl terephthalic acid and 6 parts of 1,12- Dodecanediamine.

[0031] A preparation method of activated carbon for organic solvent recovery, the preparation method of said activated carbon for organic solvent recovery mainly comprises the following preparation steps:

[0032] (1) Carbonized grinding: Soak the sycamore leaves in 5% sodium hydroxide solution for 3 minutes, wash them with pure water for 3 times, dry them at 60°C for 6 hours, and preheat them at 100°C for 40 minutes in a nitrogen atmosphere , and then at 5°C / min, heat up to 360°C and keep it warm for 4 hours, then grind and pass through a 20-mesh sieve to obtain carbon powder, and mix the carbon powder with concentrated sulfuric acid with a mass fraction of 98% in a mass ratio of 1:10 Uniformly, add potassium permanganate 1 times the mass of car...

Embodiment 2

[0038] An activated carbon for organic solvent recovery, mainly including 11 parts of modified carbon powder, 4 parts of benzamide folded body, 9 parts of 2-monochloromethyl terephthalic acid and 7 parts of 1,12-deca Dioxanediamine.

[0039] A preparation method of activated carbon for organic solvent recovery, the preparation method of said activated carbon for organic solvent recovery mainly comprises the following preparation steps:

[0040] (1) Carbonized grinding: Soak the sycamore leaves in 5% sodium hydroxide solution for 4 minutes, wash them with pure water for 4 times, dry them at 65°C for 5 hours, and preheat them at 110°C for 35 minutes in a nitrogen atmosphere , then at 5°C / min, raise the temperature to 380°C and keep it warm for 3 hours, then grind and pass through a 20-mesh sieve to obtain carbon powder, and then mix the carbon powder and concentrated sulfuric acid with a mass fraction of 98% in a mass ratio of 1:10 Mix evenly, add potassium permanganate 1 times...

Embodiment 3

[0046] An activated carbon for organic solvent recovery, mainly comprising: 10 parts of modified carbon powder, 5 parts of benzamide folded body, 10 parts of 2-monochloromethyl terephthalic acid and 8 parts of 1,12- Dodecanediamine.

[0047] A preparation method of activated carbon for organic solvent recovery, the preparation method of said activated carbon for organic solvent recovery mainly comprises the following preparation steps:

[0048] (1) Carbonized grinding: Soak the sycamore leaves in a 5% sodium hydroxide solution for 5 minutes, wash them with pure water for 5 times, dry them at 70°C for 4 hours, and preheat them at 120°C for 30 minutes in a nitrogen atmosphere , then at 5°C / min, raise the temperature to 400°C and keep it warm for 3 hours, then grind and pass through a 20-mesh sieve to obtain carbon powder, and then mix the carbon powder and concentrated sulfuric acid with a mass fraction of 98% in a mass ratio of 1:10 Mix evenly, add potassium permanganate 1 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com