Negative pressure winnowing separation device for coix seed machining

A technology of separation equipment and negative pressure air, which is applied in the direction of solid separation, separation of solids from solids by air flow, and filtering and sieving, which can solve the problem of incomplete separation of rice and shell, increase of barley processing cost, and limit processing efficiency, etc. problems, to achieve the effect of improving the sorting effect, improving market competitiveness, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

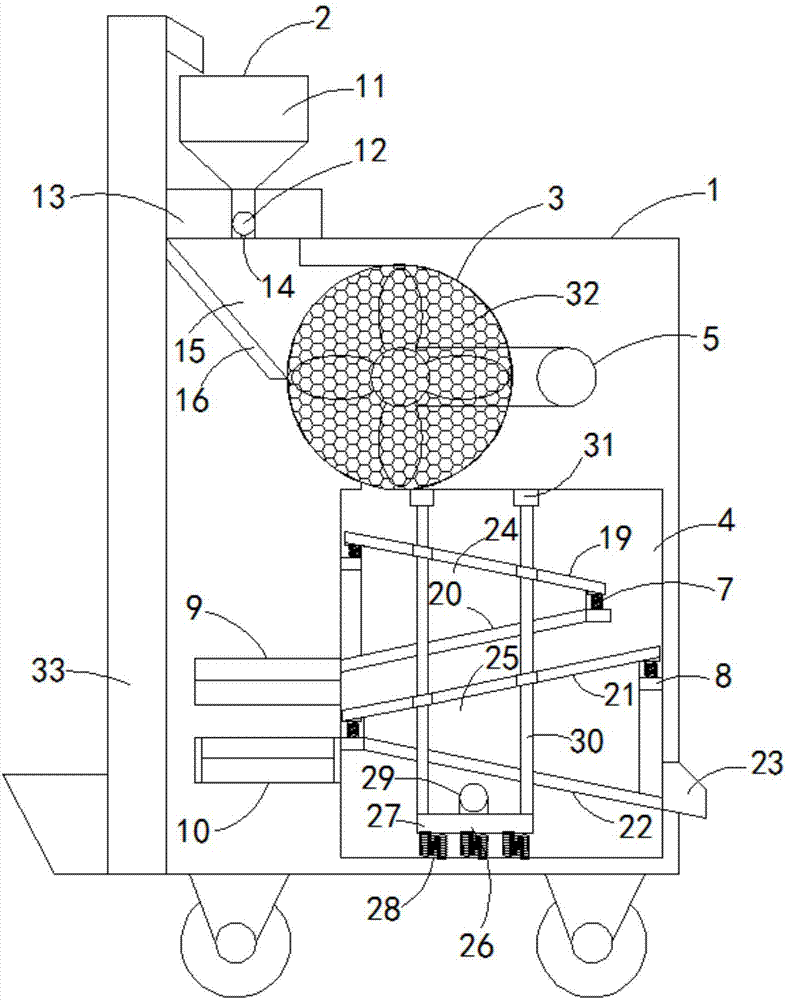

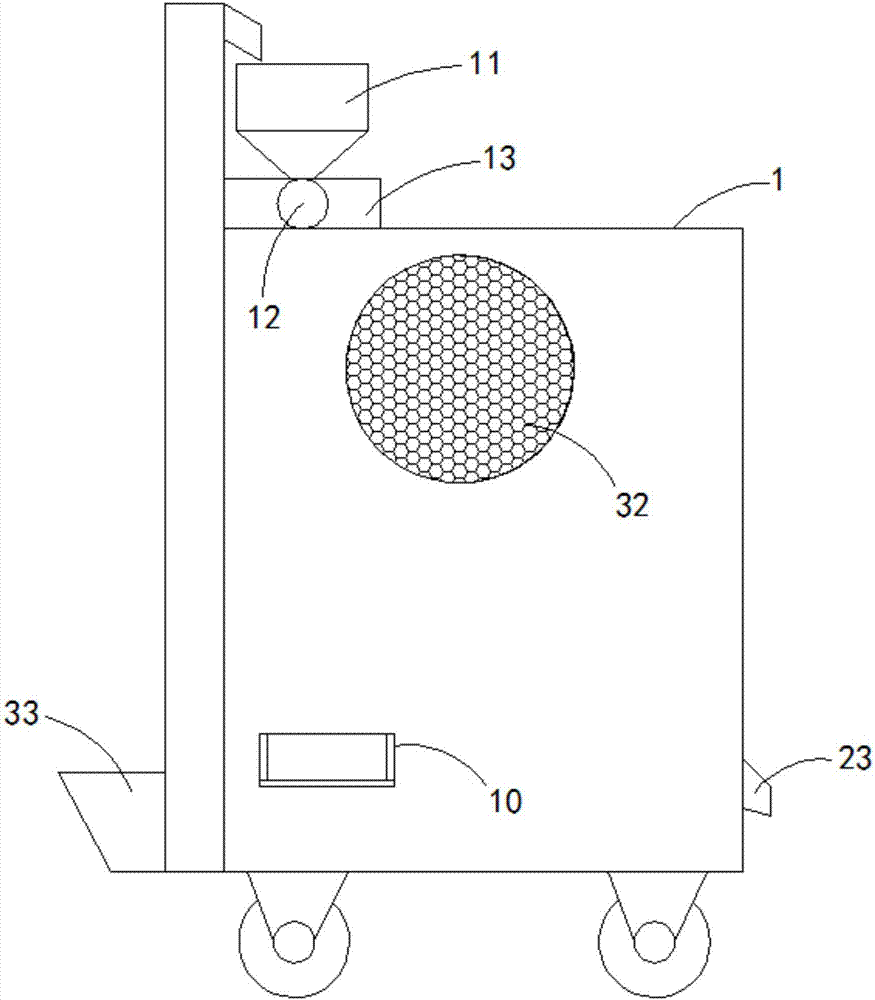

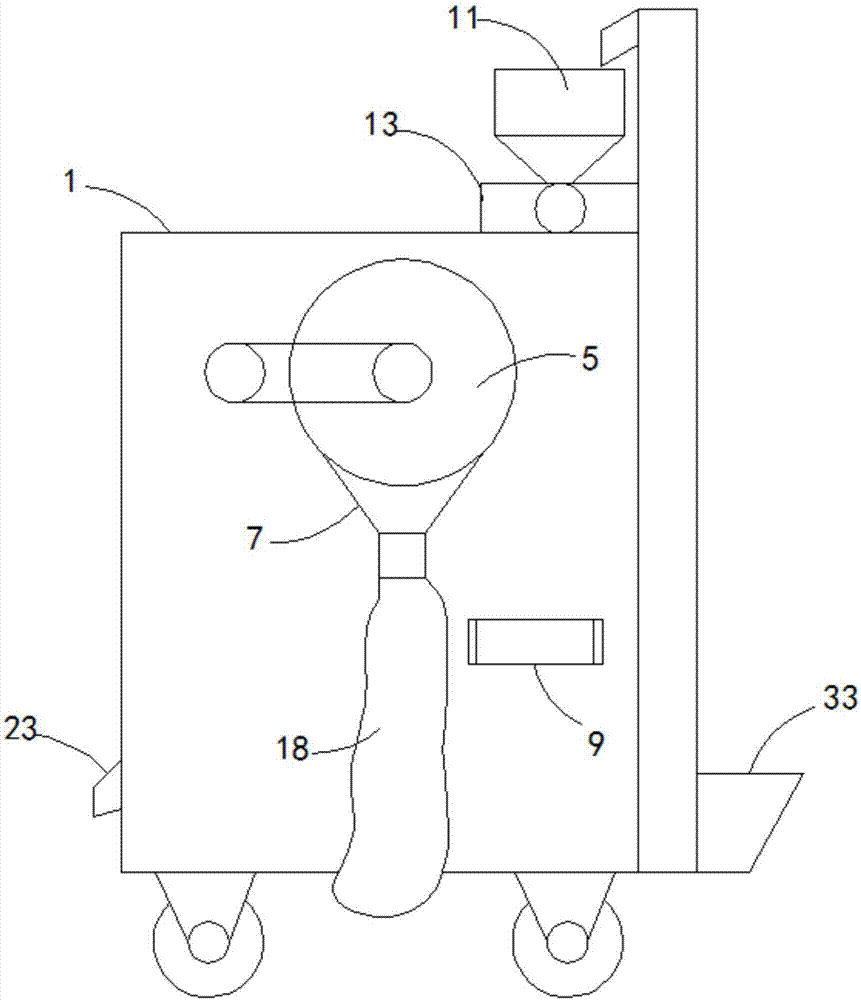

[0024] Such as Figure 1-4 As shown, a kind of negative pressure winnowing separation equipment for barley processing includes a body 1, a feeding mechanism 2 is provided on the upper side of the body 1, a negative pressure winnowing chamber 3 and a vibrating screening chamber 4 are arranged inside the body 1, and the negative pressure winnowing The chamber 3 is located on the upper side of the vibration screening chamber 4, and the lower end of the negative pressure air separation chamber 3 communicates with the upper end of the vibration screening chamber 4, and the two sides of the negative pressure air separation chamber 3 are respectively provided with an air inlet and an air outlet. It should be noted that , the air inlet and the air outlet of the negative pressure winnowing chamber 3 are evenly equipped with a filter screen 32, and the diameter of the filter pack 32 is smaller than the diameter of the seed of Job's tears, which can prevent the seed of Job's tears from sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com