A multi-rotor straw grinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

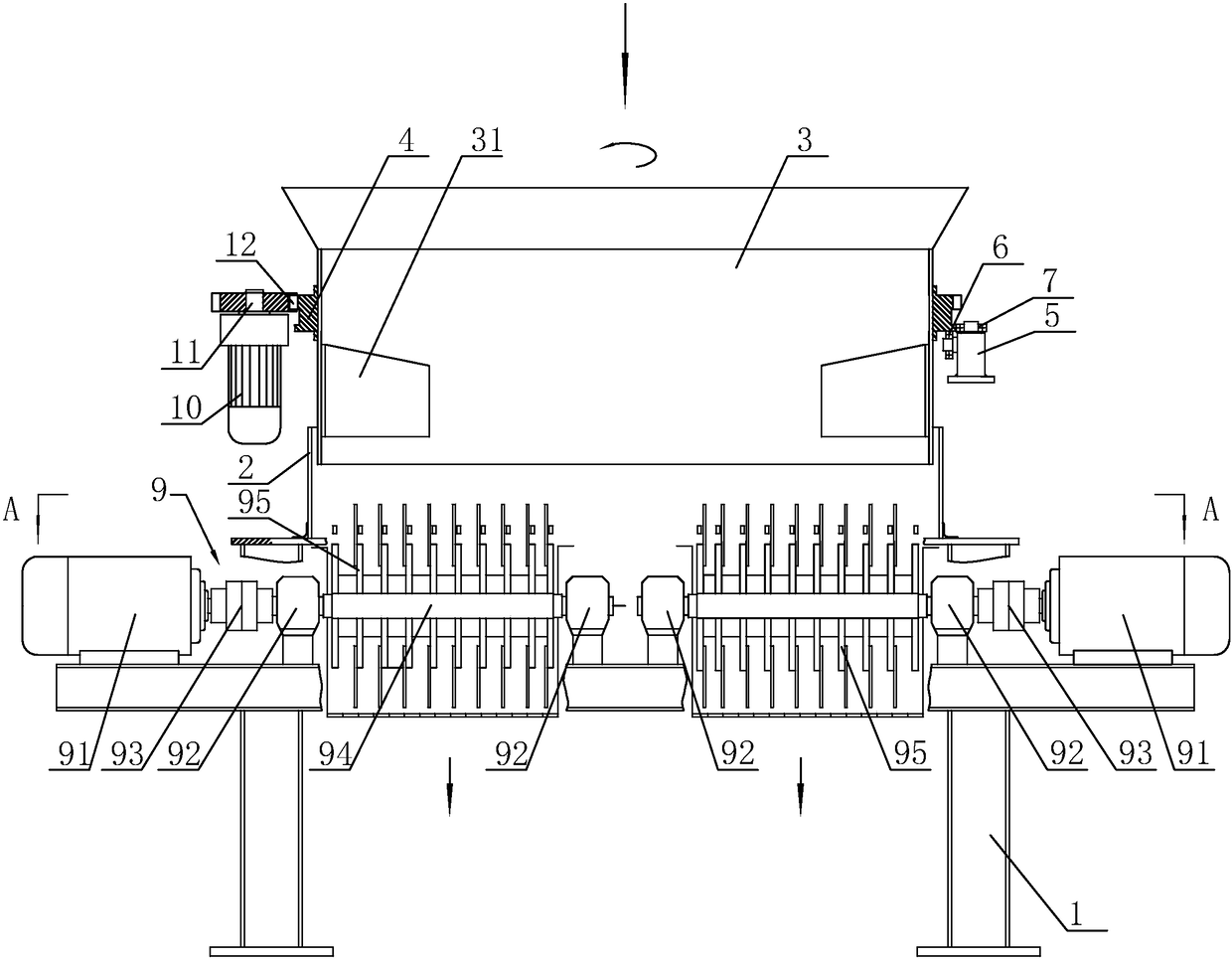

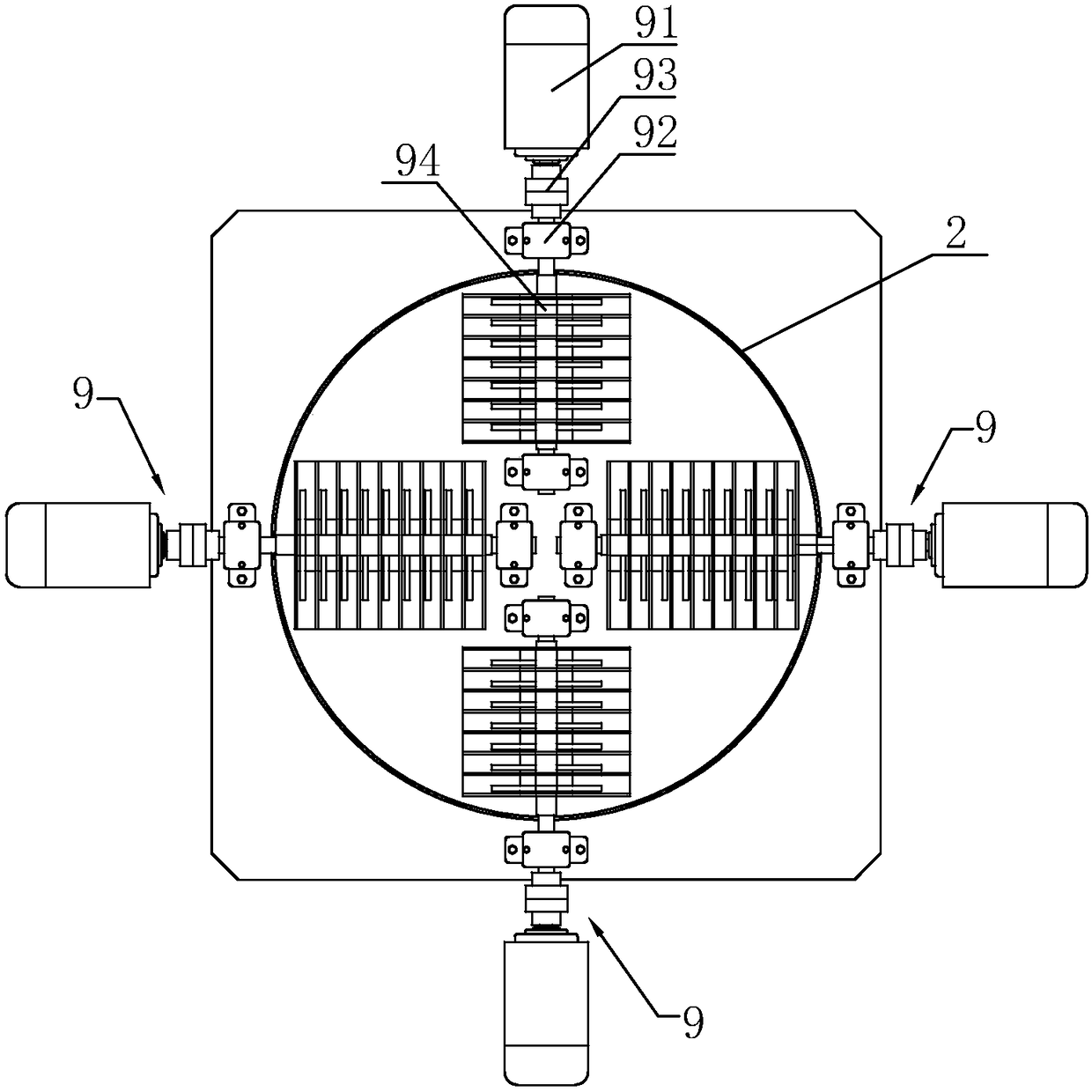

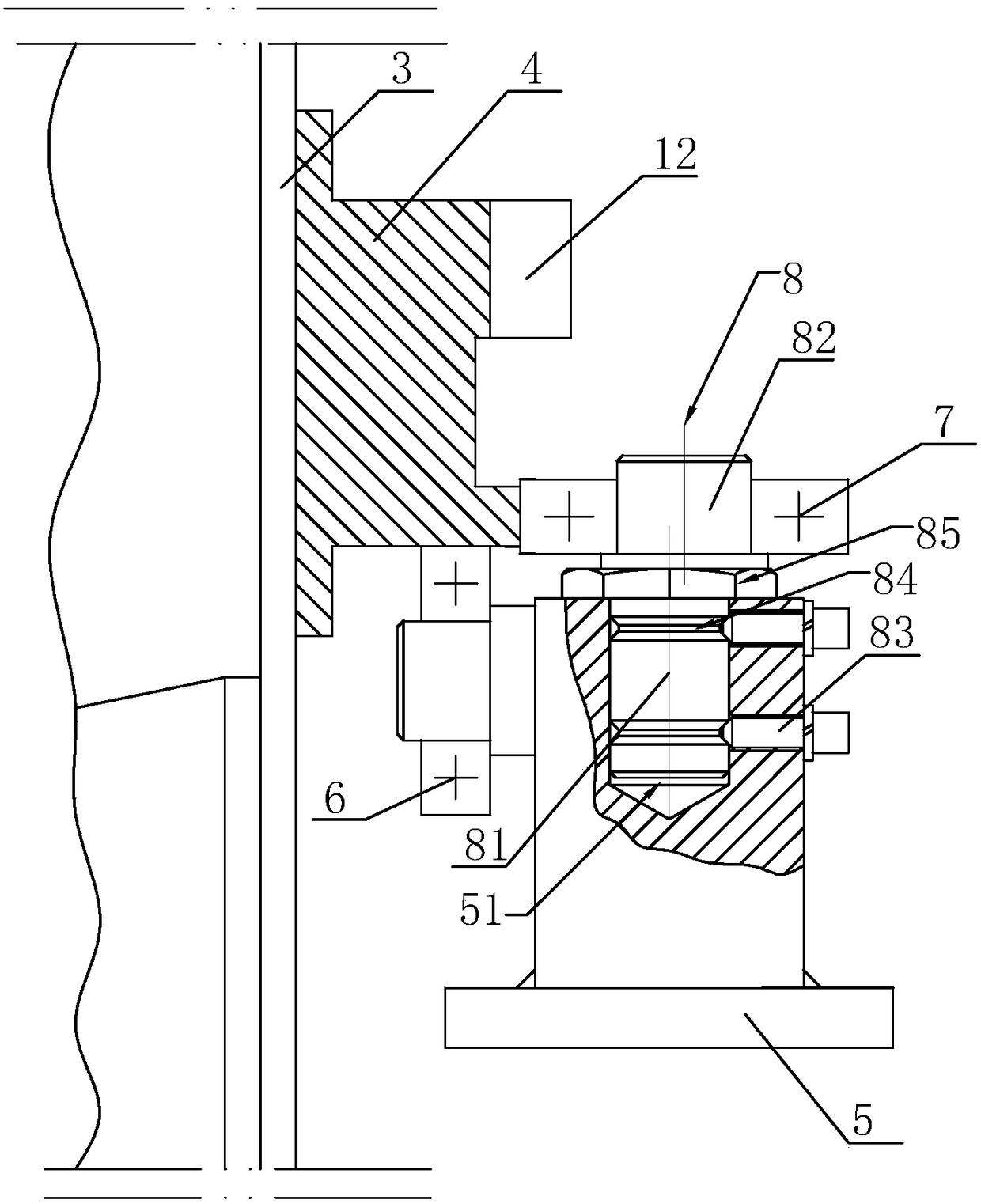

[0023] Such as Figure 1 to Figure 5 As shown, a multi-rotor straw pulverizer according to the present invention includes a frame 1, a pulverizing device 9 installed on the frame 1 and a feeding device, the feeding device is located above the pulverizing device 9, and the The feeding device includes a fixed material cylinder 2 fixedly installed on the frame 1, a rotating material cylinder 3 rotatably arranged on the upper part of the fixed material cylinder 2, and a driving mechanism for driving the rotating material cylinder 3 to rotate. The rotating material cylinder 3 is a circular material cylinder, and the rotating material cylinder 3 can rotate around its own vertical centerline, and a circular flange 4 is arranged on the outer periphery of the rotating material cylinder 3 . The upper opening of the fixed material cylinder 2, the rotating material cylinder 3 extends into the fixed material cylinder 2 from the upper opening of the fixed material cylinder 2, the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com