Clamp for milling spiral groove on surface of shaft type work piece

A shaft workpiece and spiral groove technology is applied in the field of fixtures for milling spiral grooves on the surface of shaft workpieces. , the effect of reducing the milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

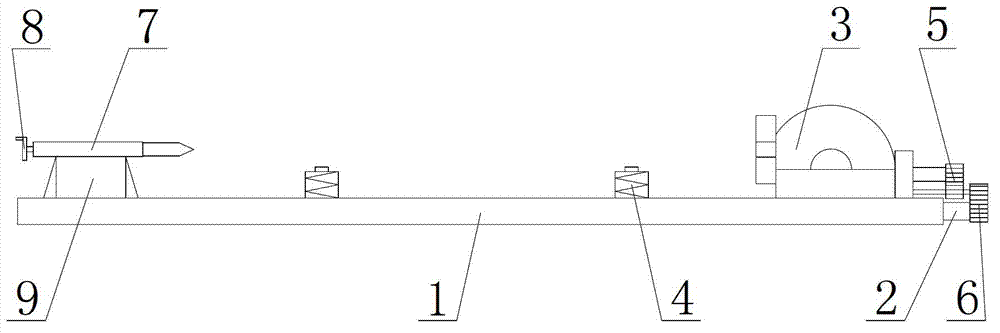

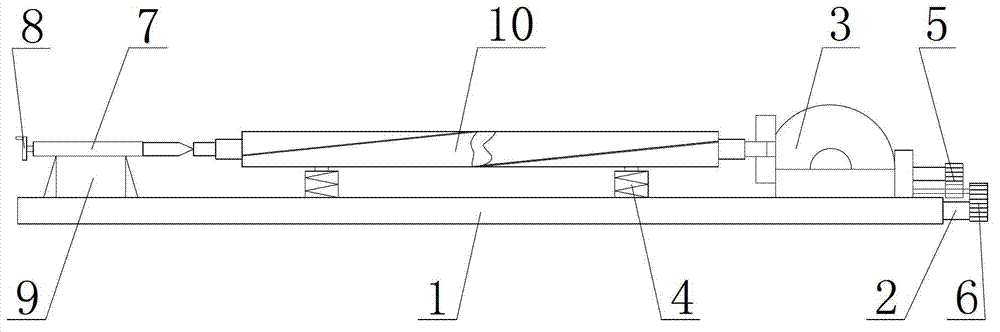

[0014] as attached figure 1 The shown fixture for milling a spiral groove on the surface of a shaft workpiece according to the present invention includes a milling machine table 1, a screw rod 2 is arranged inside the milling machine table 1, and a universal indexing device is provided at one end of the milling machine table The head 3 and the other end are provided with a positioning tailstock; the universal indexing head 3 and the positioning tailstock are located on the same horizontal line; the milling machine table 1 is provided with an automatic adjustment shock absorber 4; the automatic adjustment shock absorber The device 4 is located between the positioning tailstock and the universal indexing head 3; the outer end of the universal indexing head 3 is provided with a slave gear 5; the screw mandrel 2 is provided with a master gear 6 cooperating with the slave gear 5; The positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com