Patents

Literature

41results about How to "Improve milling accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

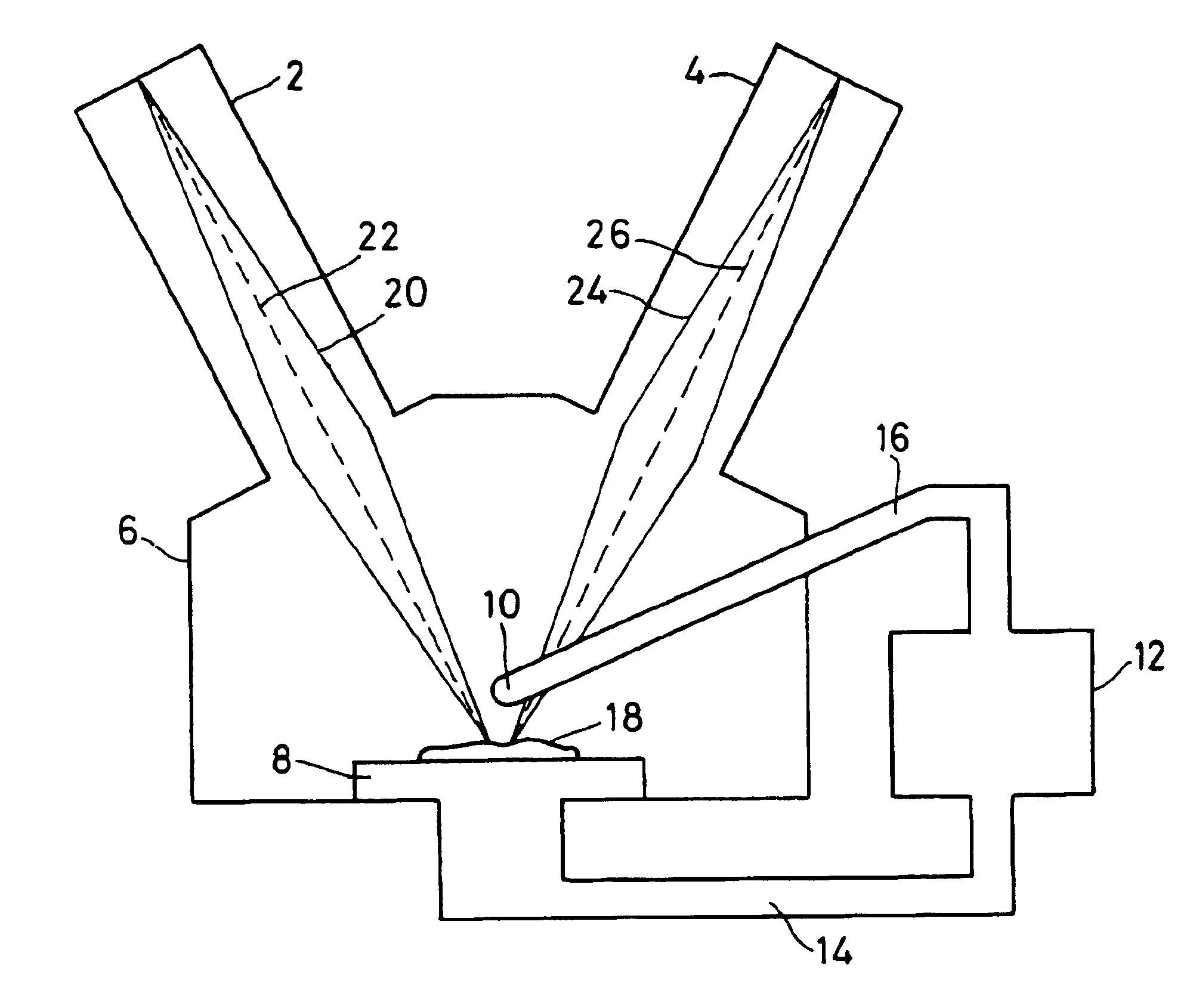

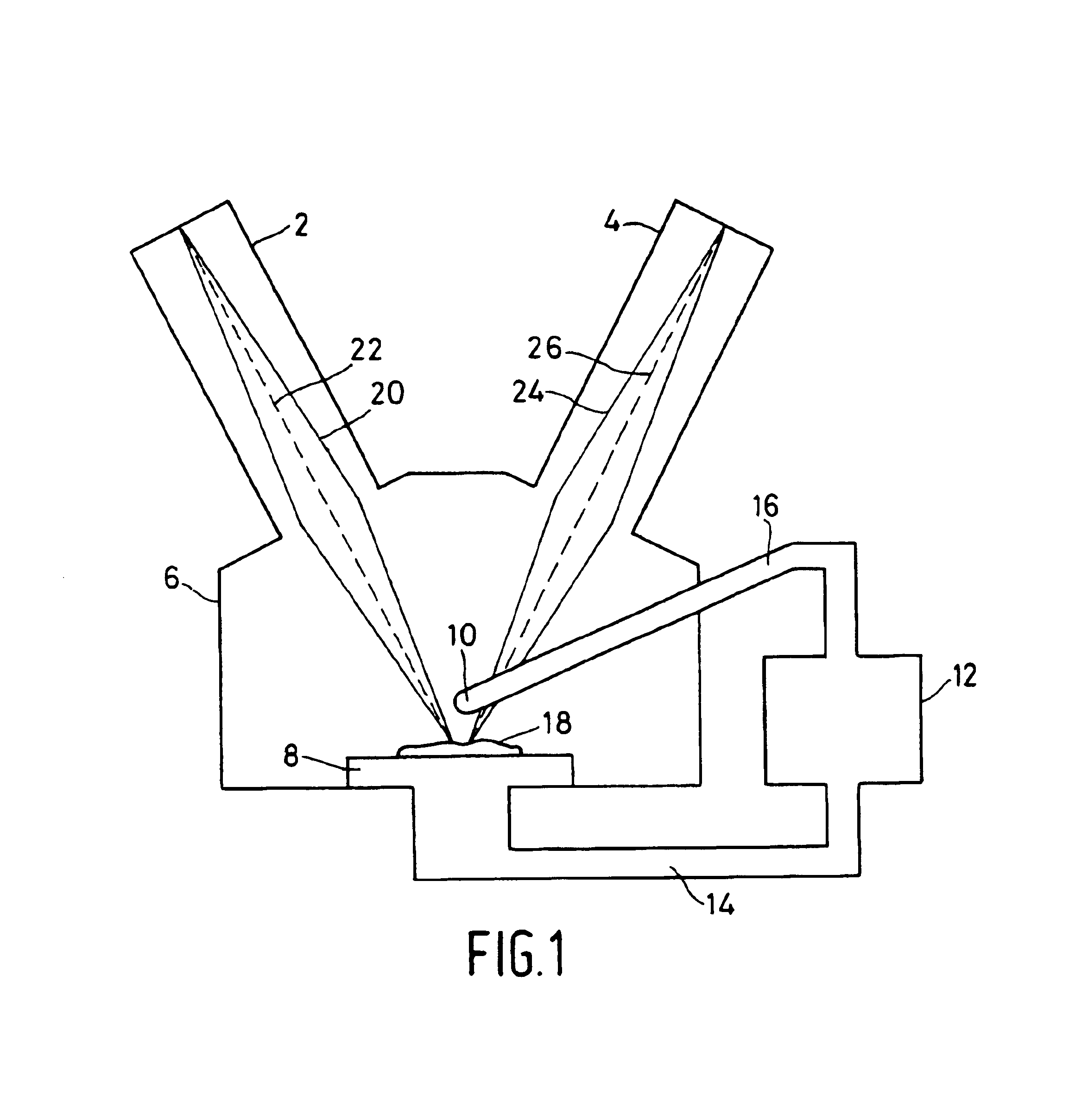

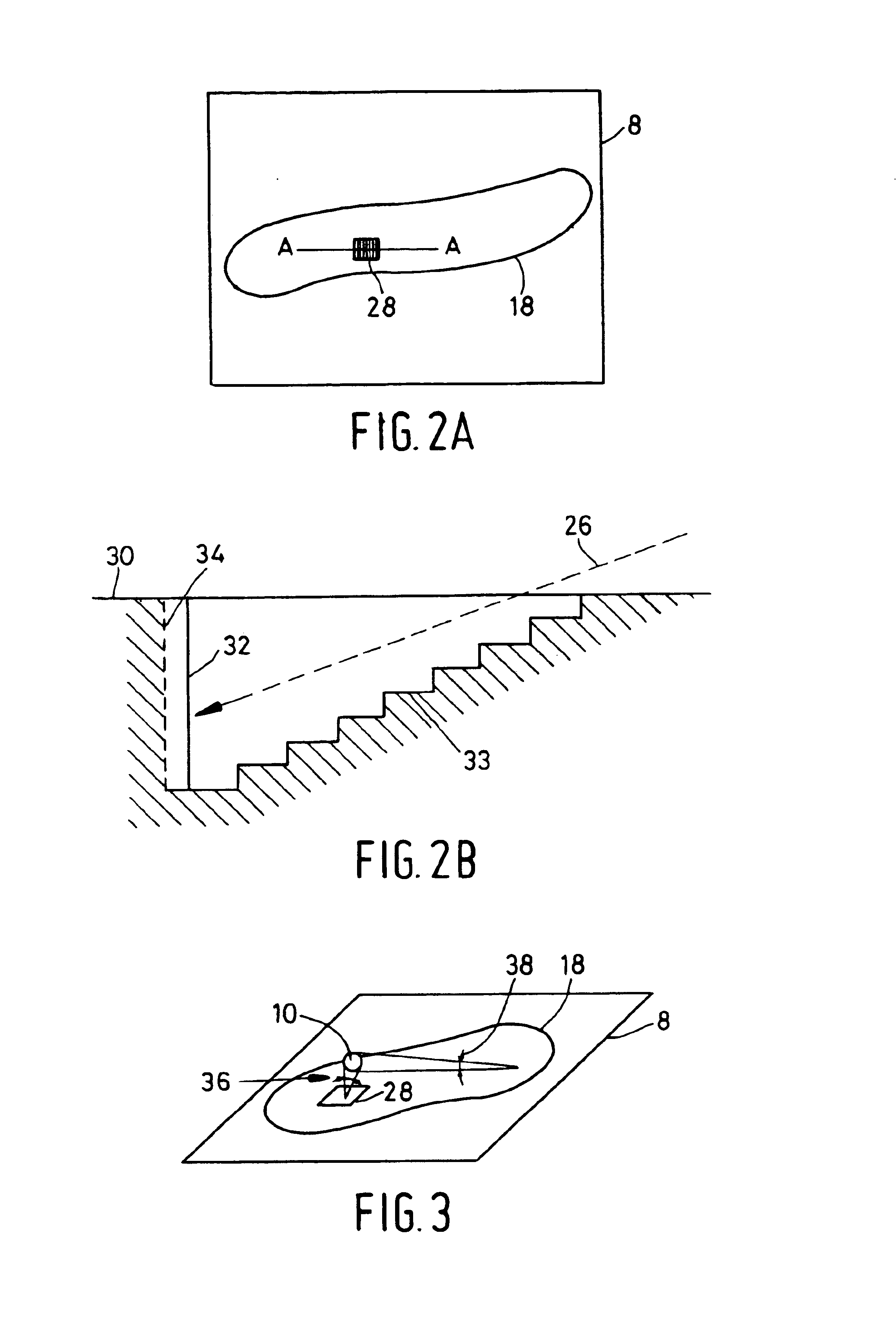

Method of obtaining a particle-optical image of a sample in a particle-optical device

InactiveUS6888136B2Easy to placeEasy to adjustMaterial analysis using wave/particle radiationElectric discharge tubesControl mannerElectron microscope

In relatively thick samples for electron microscopy imaging, details of interest are often located in the bulk of the sample, so that they cannot be directly imaged in the form of a SEM image. According to the invention, so as to expose the cross-section containing the details of interest, the frozen sample is subjected to ion milling, in such a manner that the desired cross-section is exposed. Thereafter, the exposed cross-section is further eroded in a controlled manner via sublimation, whereby the detail of interest is approached in a very accurate manner, and its fine details become visible. Hereafter, the finally desired SEM image can be made. By repetition of this process, a large number of successive cross-sections can be imaged, so that a spatial representation of the sample is obtained.

Owner:FEI CO

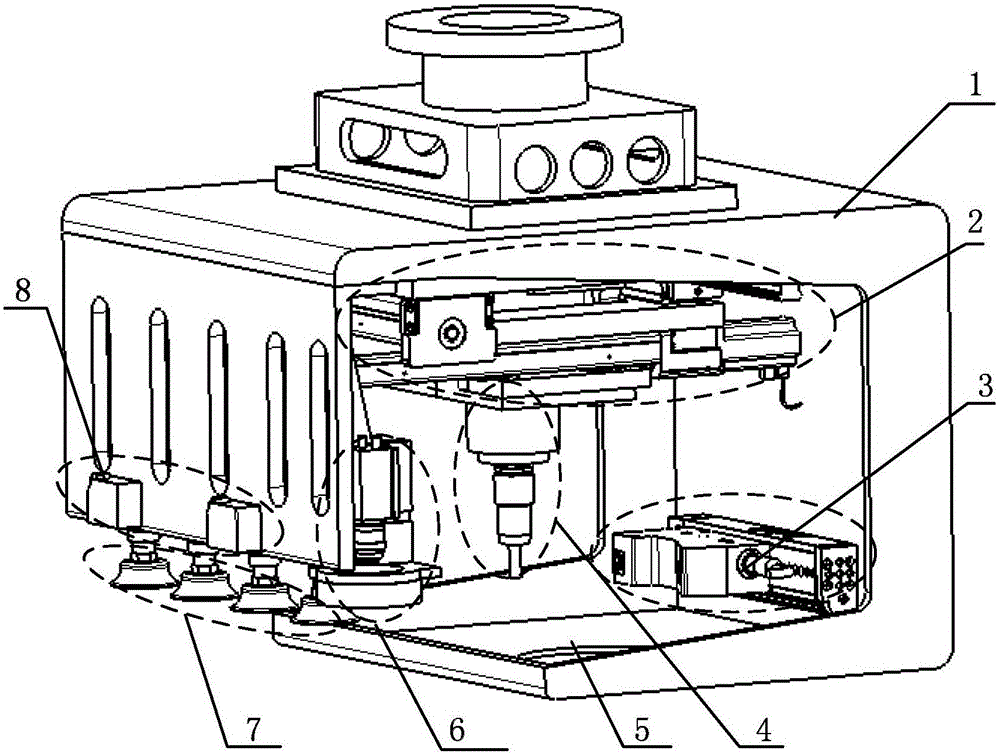

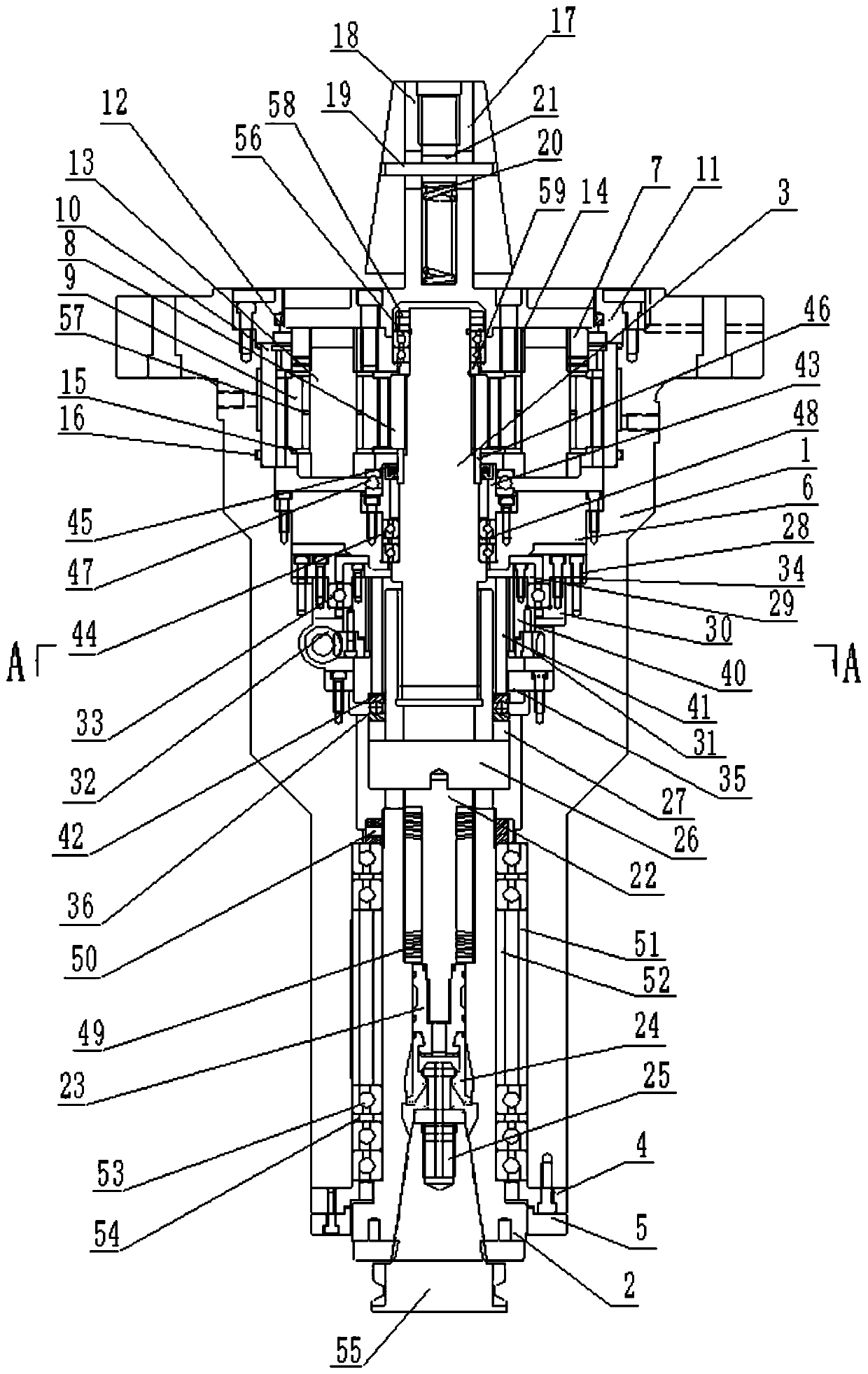

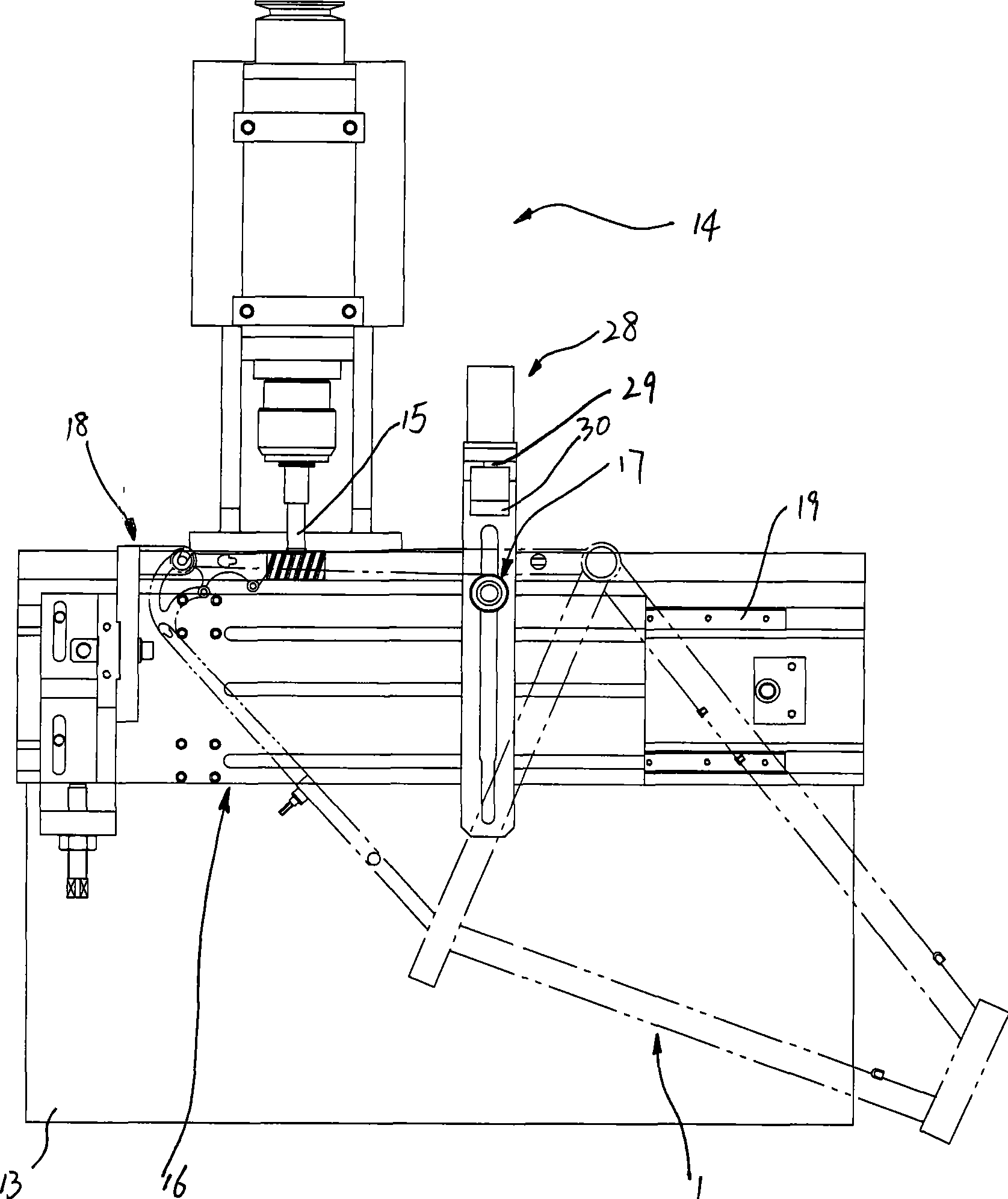

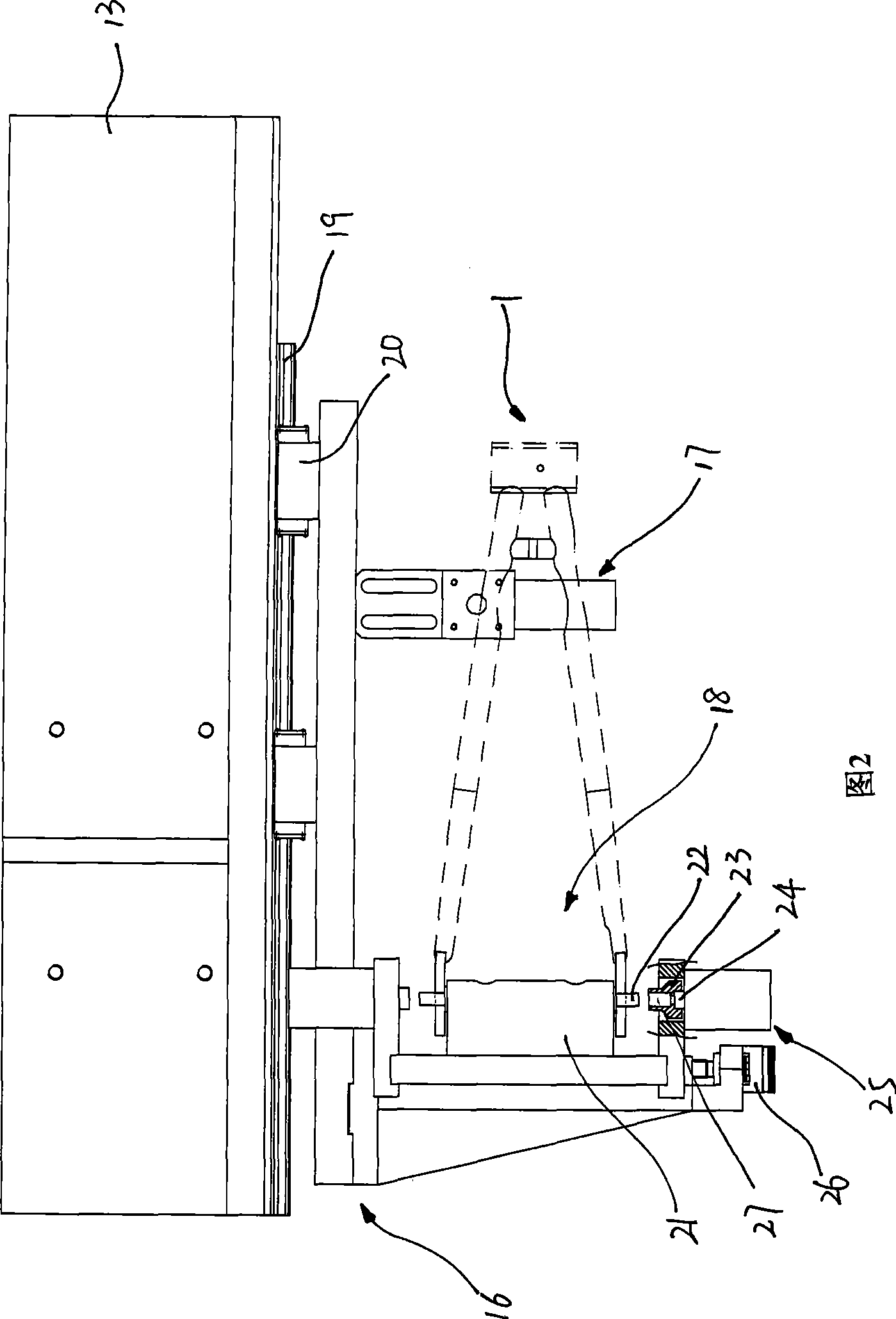

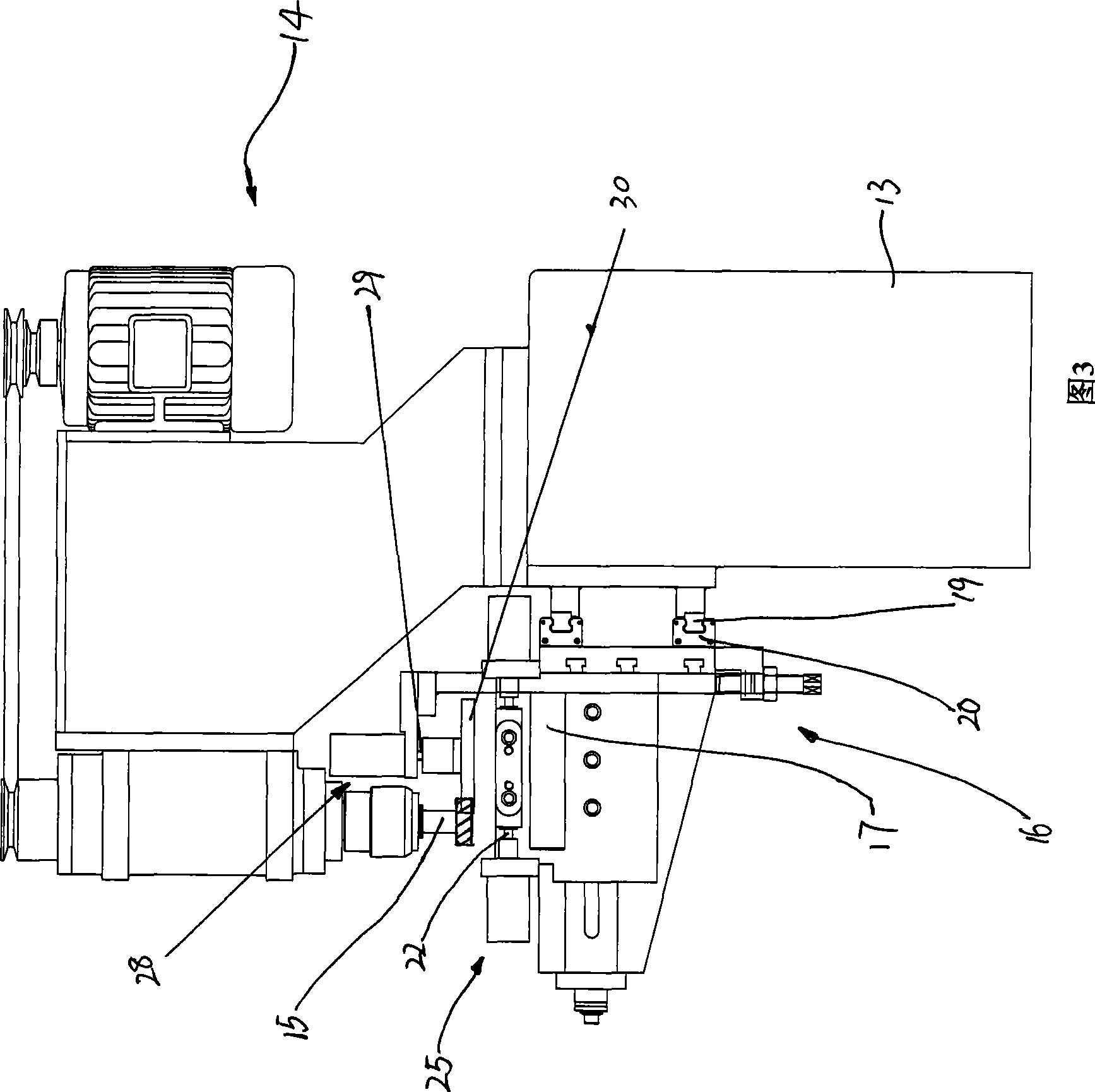

Automatic high-precision edge milling device and method for aircraft skin

ActiveCN104999122ANo incision skewSmall amount of deformationAutomatic control devicesWorkpiecesNumerical controlAutomatic control

The invention relates to an automatic high-precision edge milling device and method for an aircraft skin. Point position alignment, normal leveling, flexible clamping, trajectory planning of a milling cutter, numerical control code generation and other functions on a region to be milled are achieved in an automatic control mode, and accordingly the size precision, normal precision and notch roughness of the skin are guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

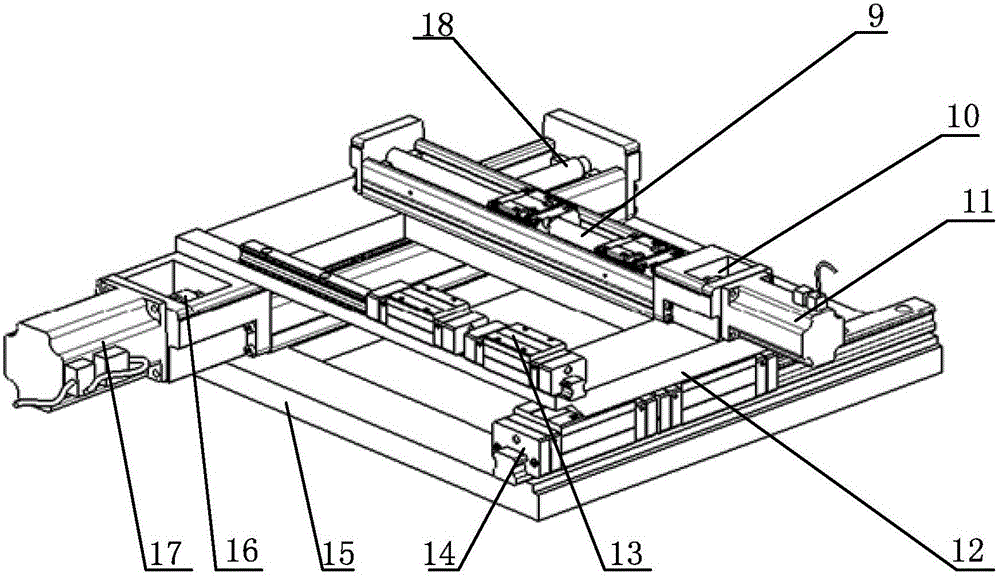

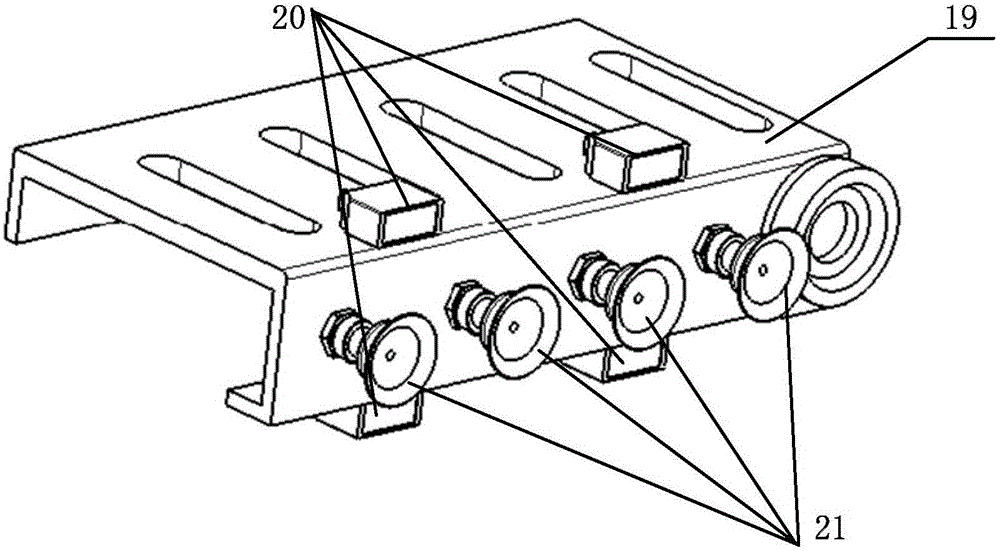

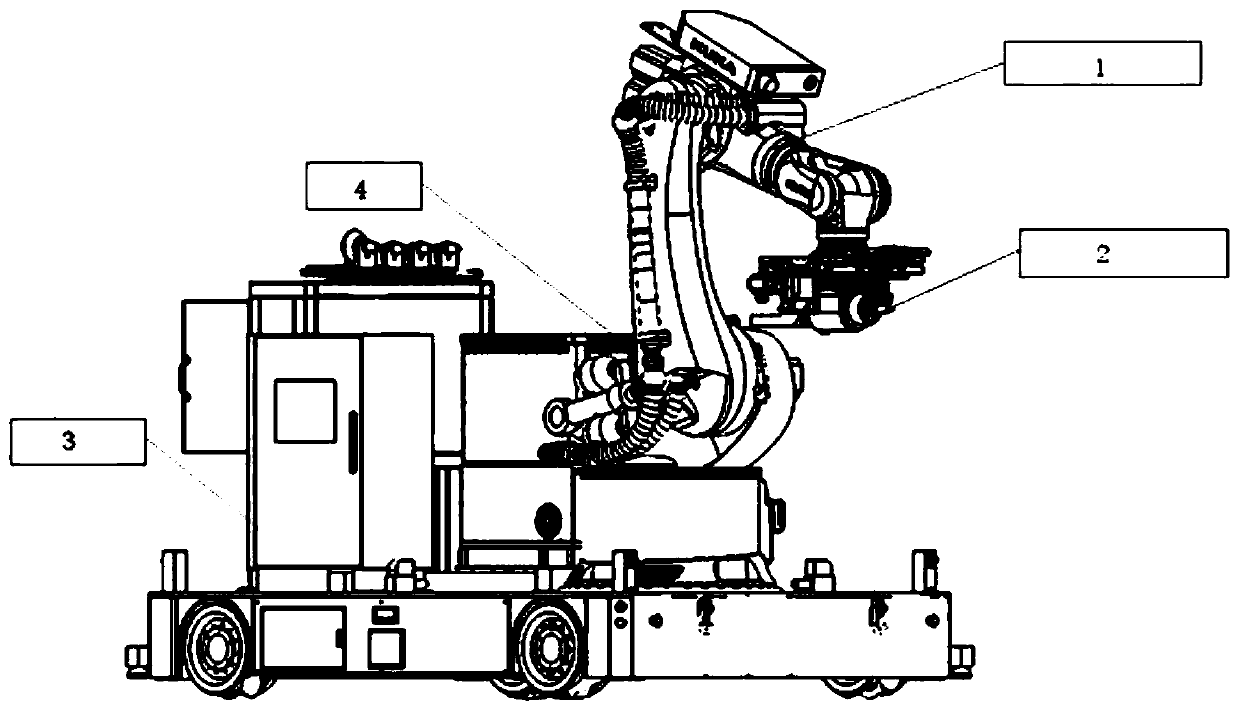

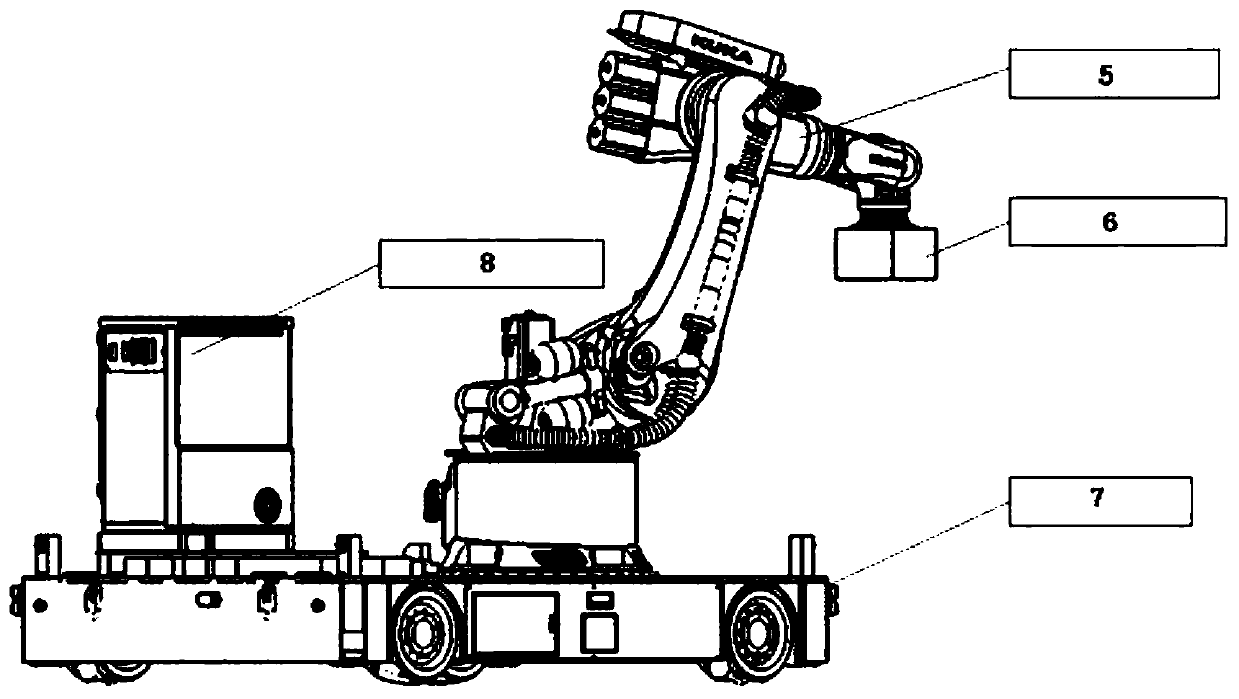

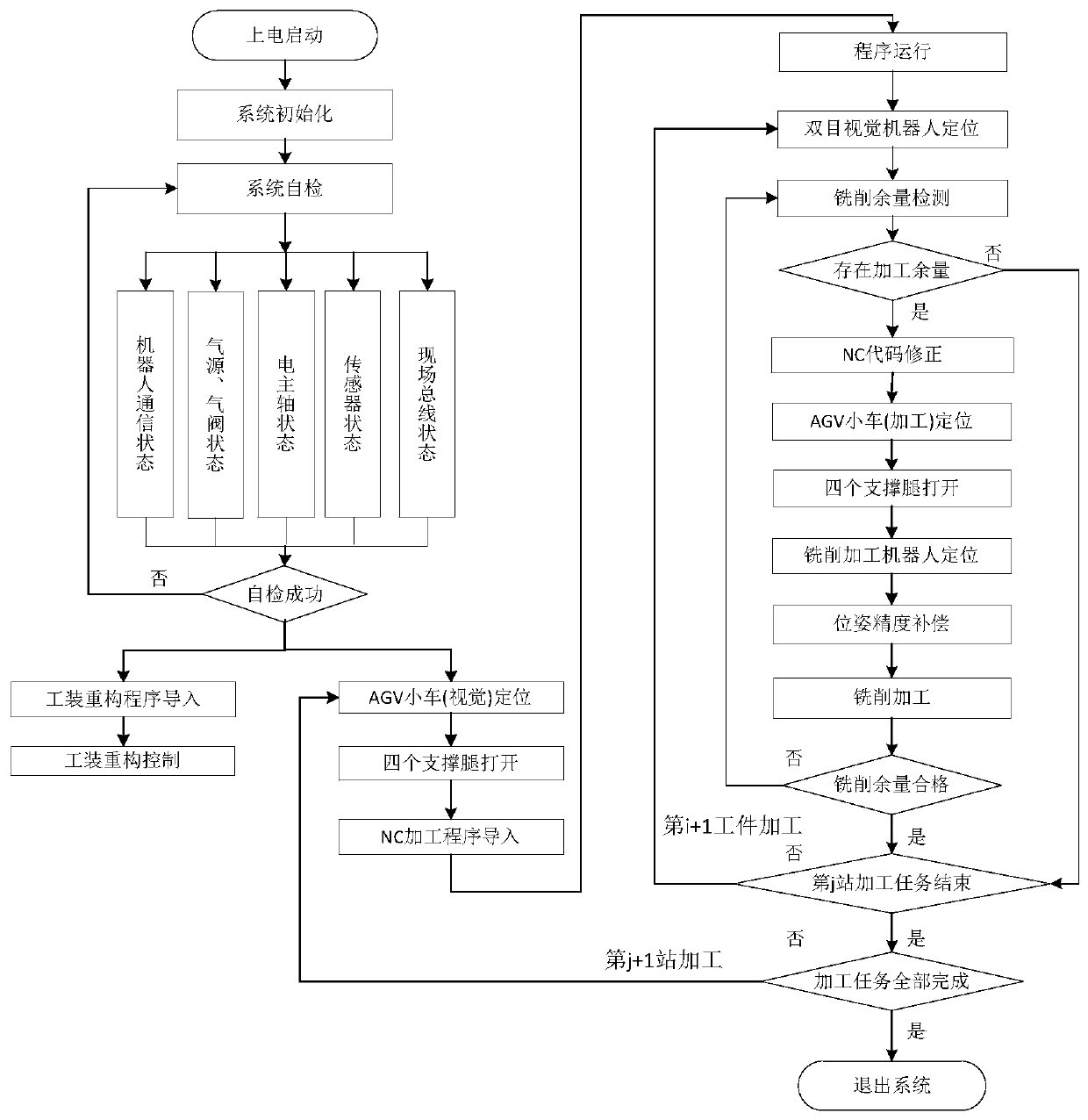

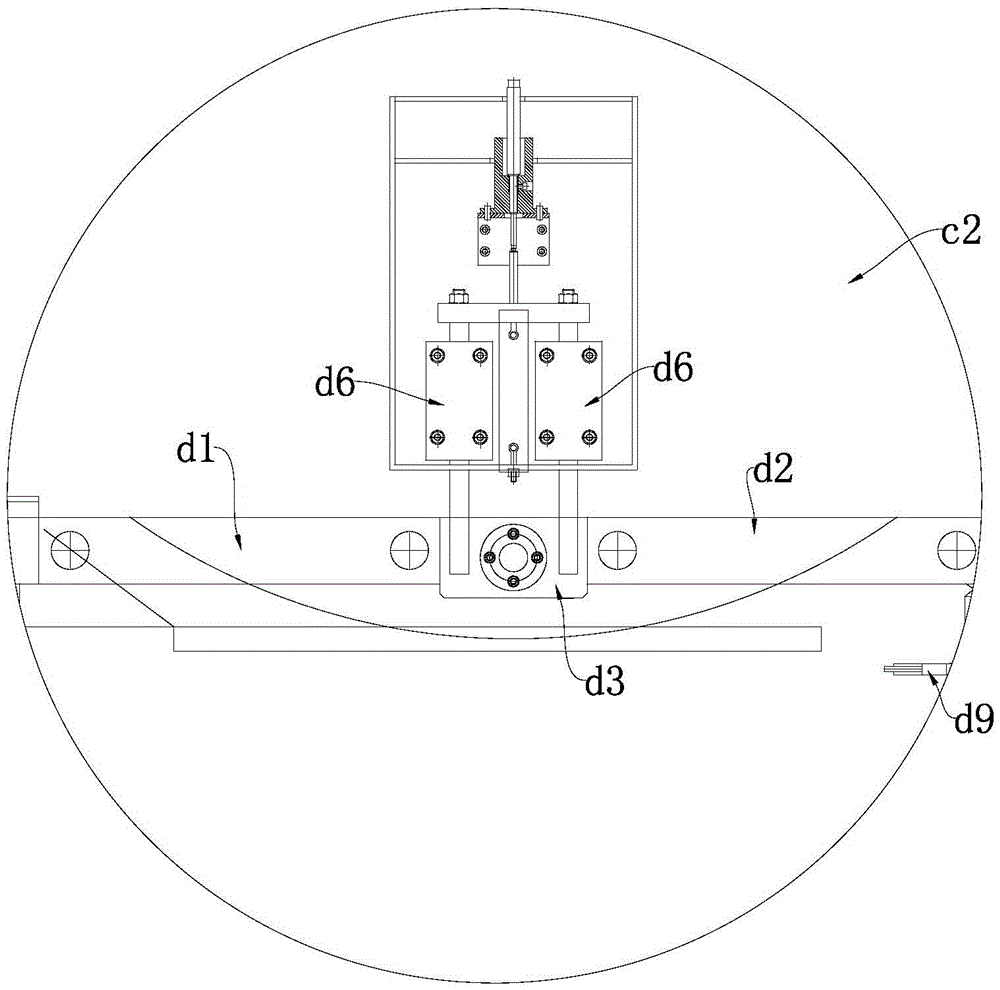

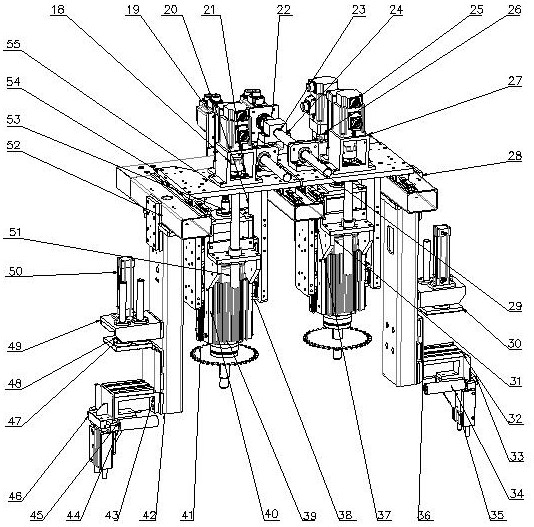

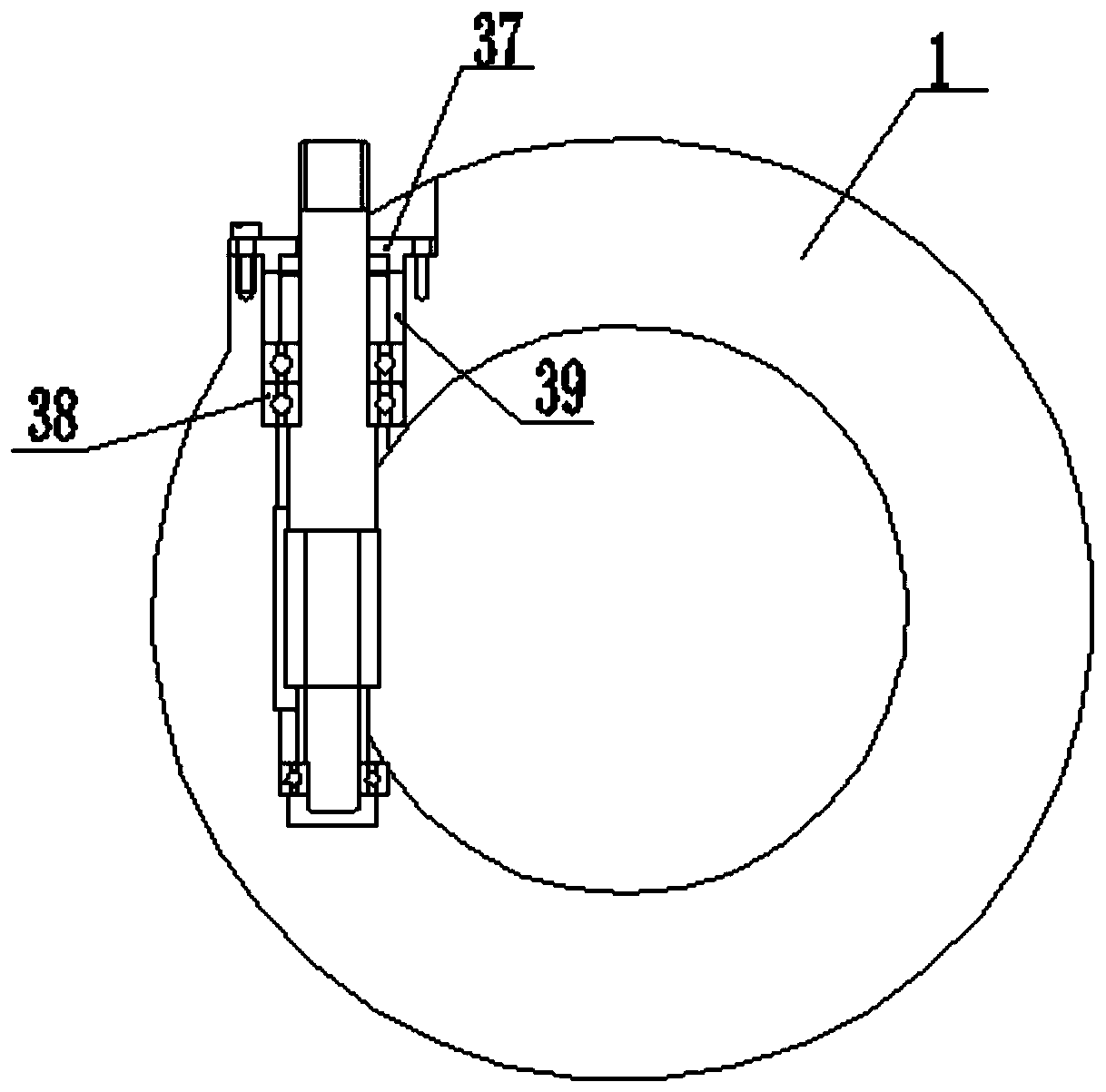

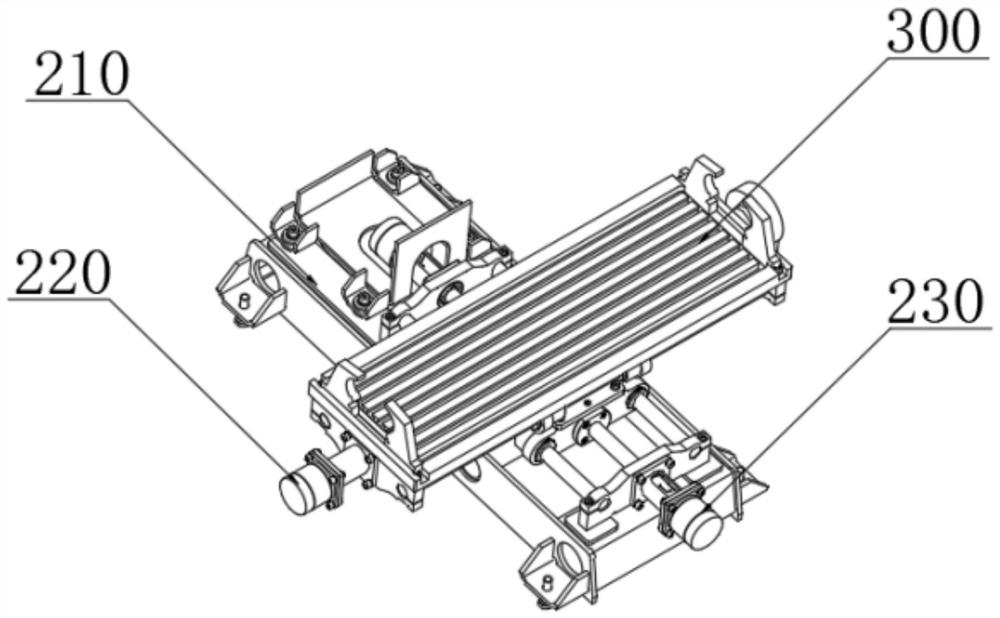

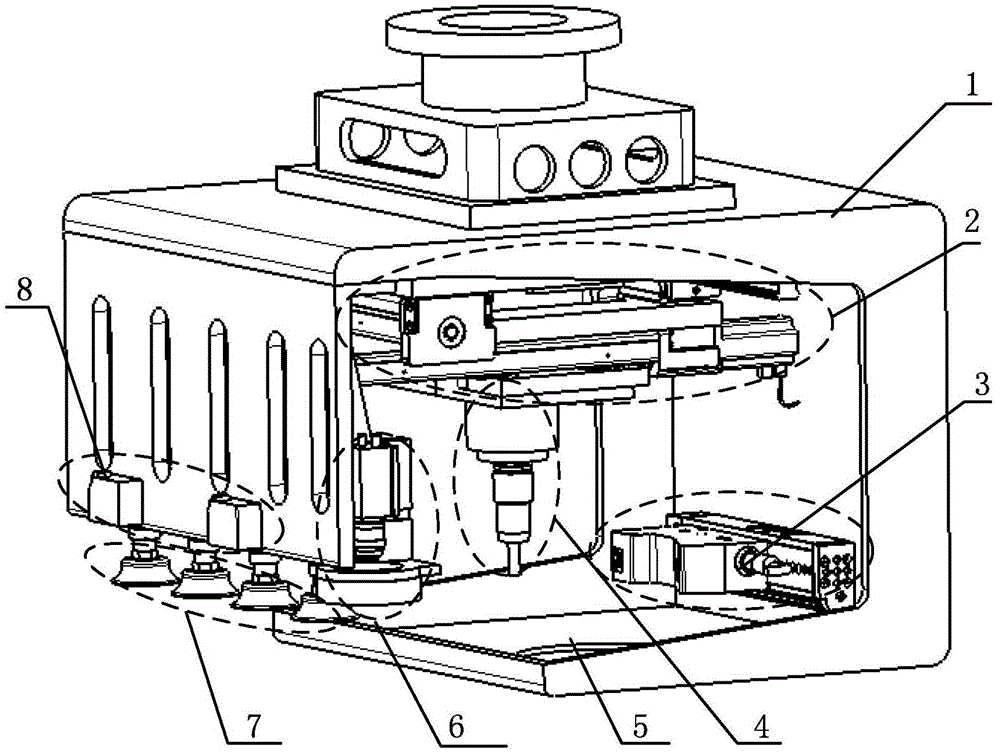

Movable double-robot automatic milling type intelligent flexible production line and running method thereof

InactiveCN109746928ACorrection of pose deviationImprove milling accuracyProgramme-controlled manipulatorProduct processingMobile robot

The invention discloses a movable double-robot automatic milling type intelligent flexible production line and a running method thereof. The production line comprises free moving platforms, a millingprocessing robot, a binocular vision robot, a laser cutter aligning device, an industrial robot control cabinet, a main control cabinet, a moving panel and a cooling machine, wherein the binocular vision robot and the industrial robot control cabinet are arranged on a first free moving platform; the milling processing robot, the main control cabinet and the cooling machine are mounted on a secondfree moving platform; two movable robots are correspondingly used for milling and measuring online; the binocular vision robot is loaded to a preset station through the first free moving platform; a binocular vision measuring instrument at the tail end of the binocular vision robot is used for scanning and detecting a workpiece to be processed so as to obtain processing milling tolerance; and themilling processing robot is loaded to perform milling through the second free moving platform. The production line realizes highly intelligent control, and is large in working space and high in positioning accuracy; the product processing quality is high, and the stability is high; the product processing efficiency is high; and a complex milling processing task can be performed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

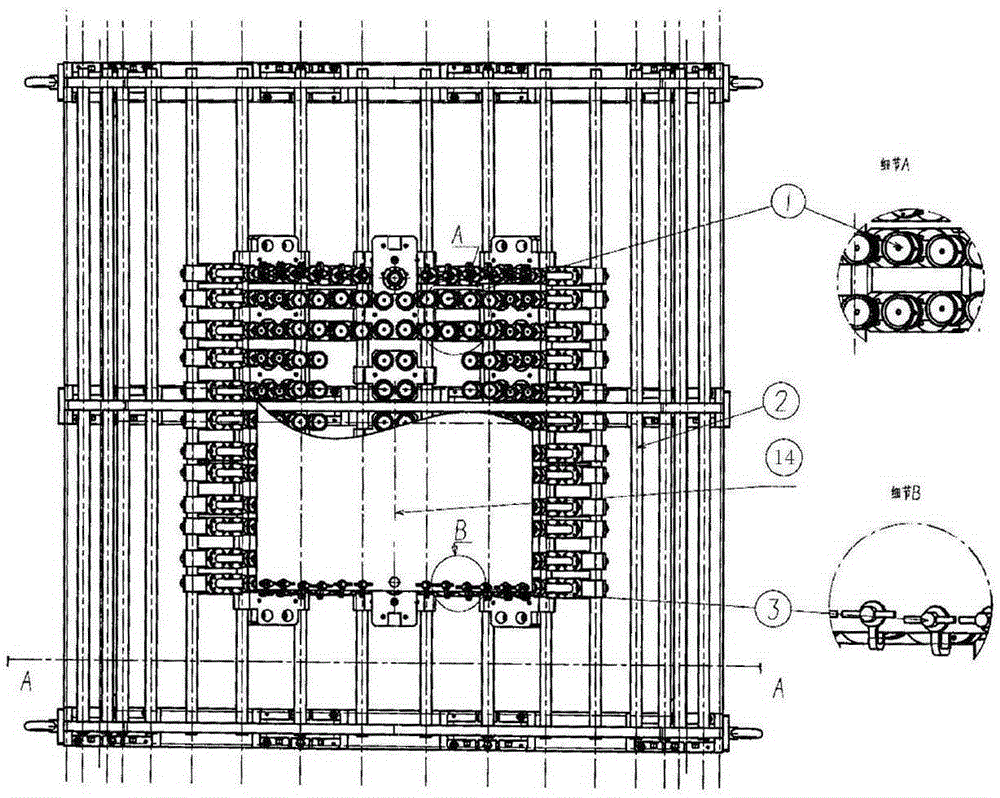

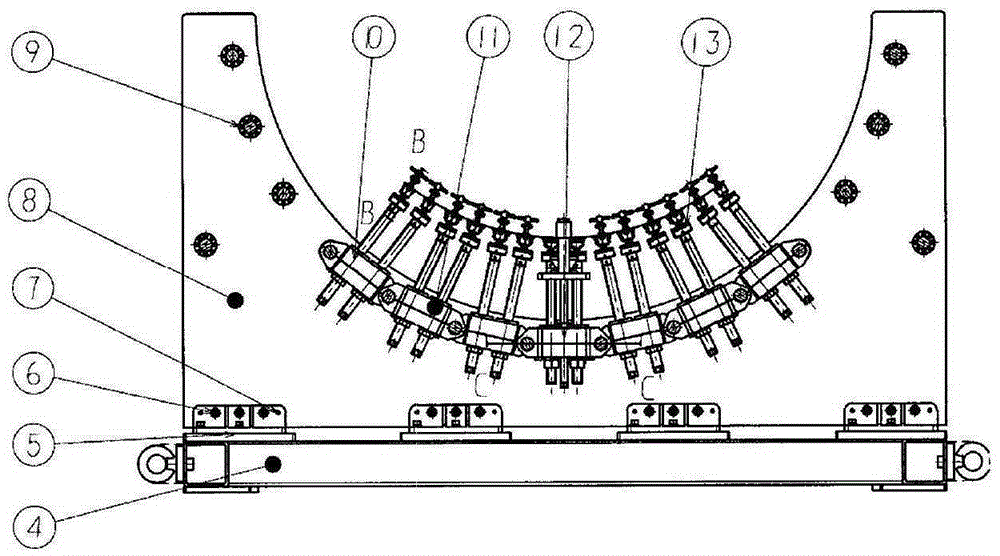

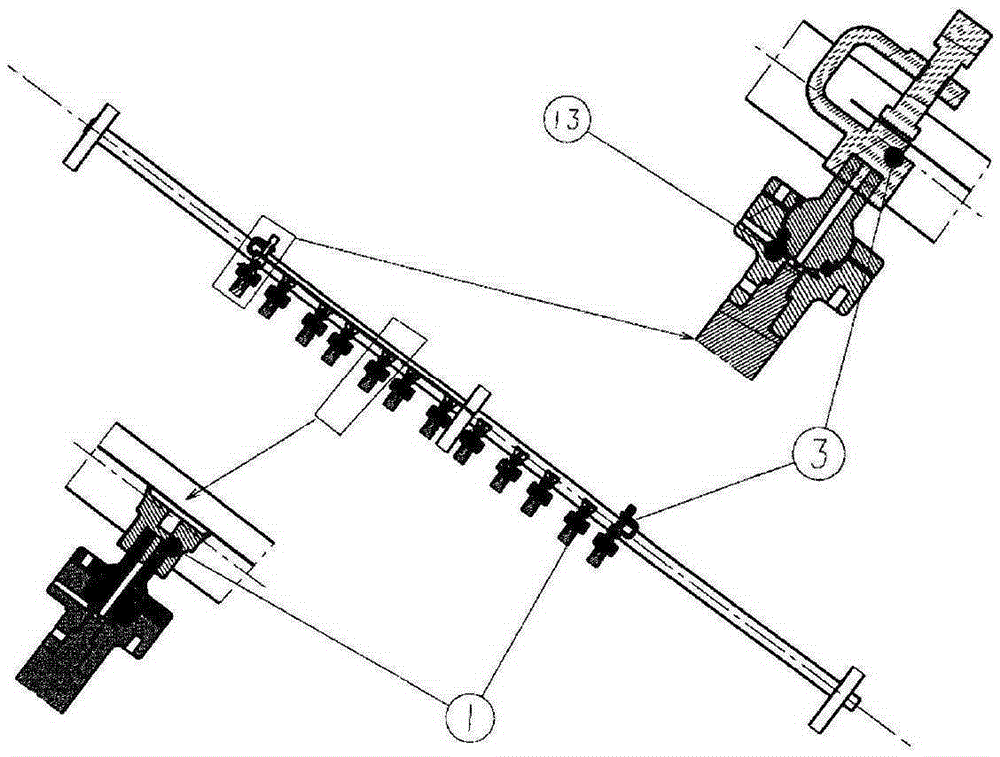

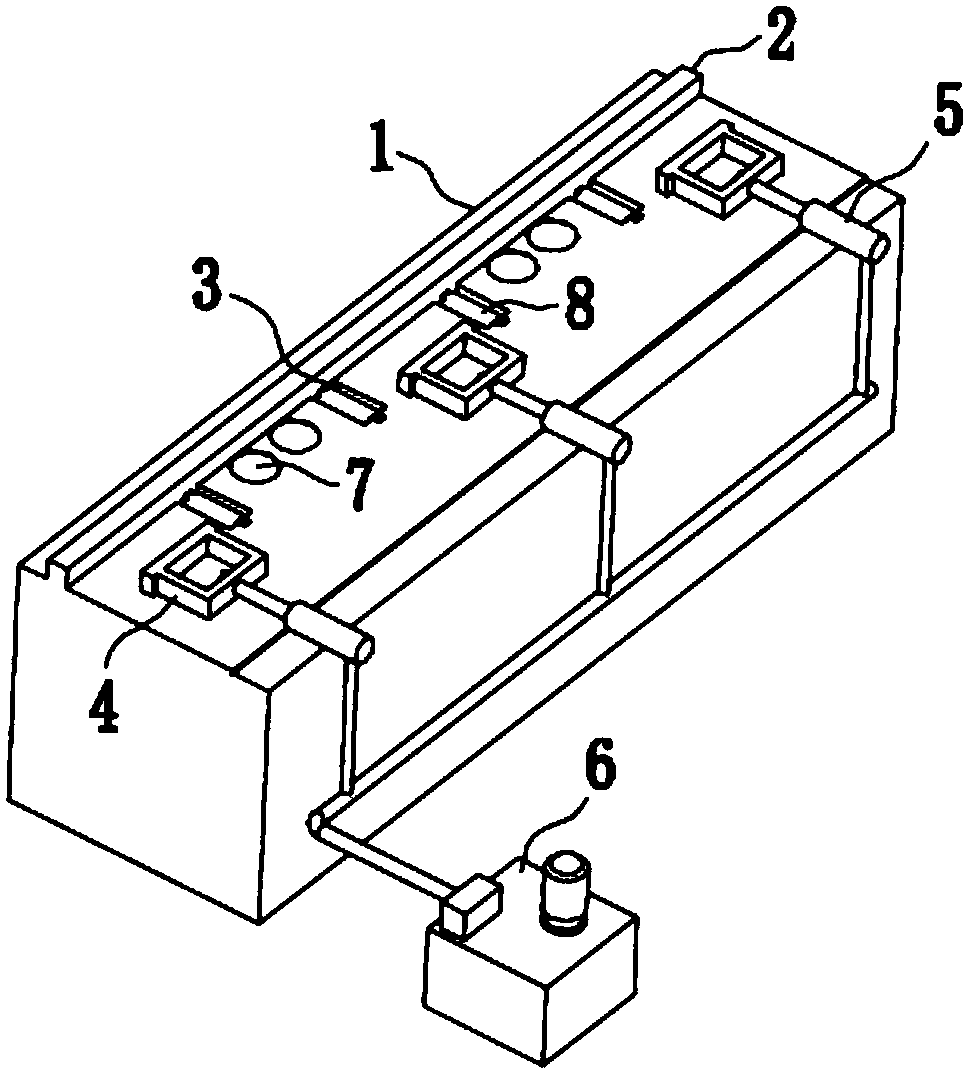

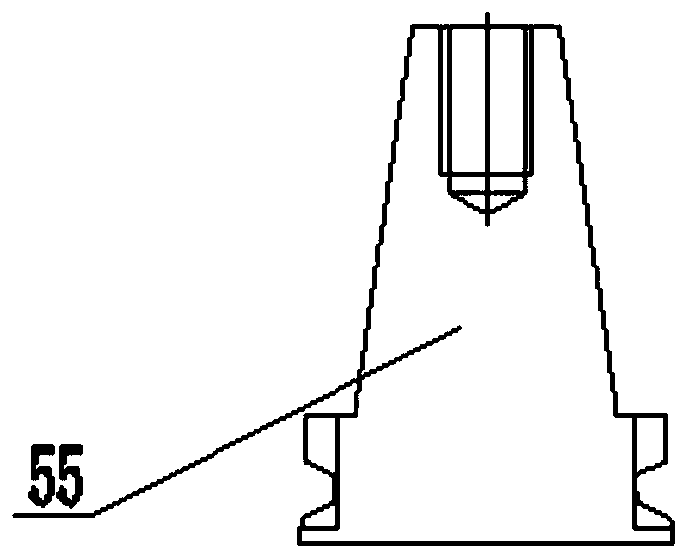

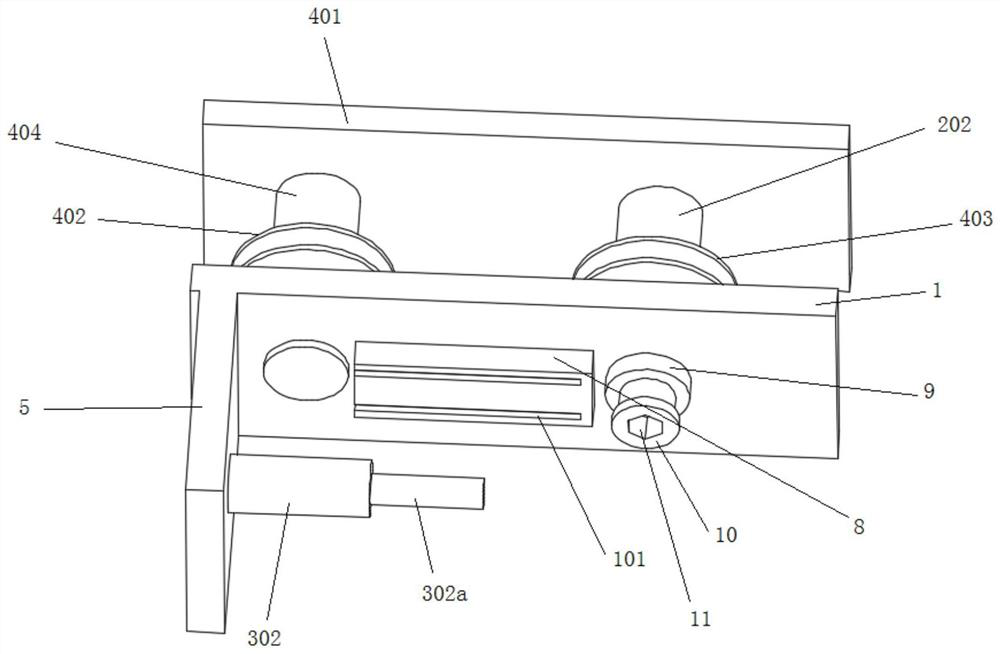

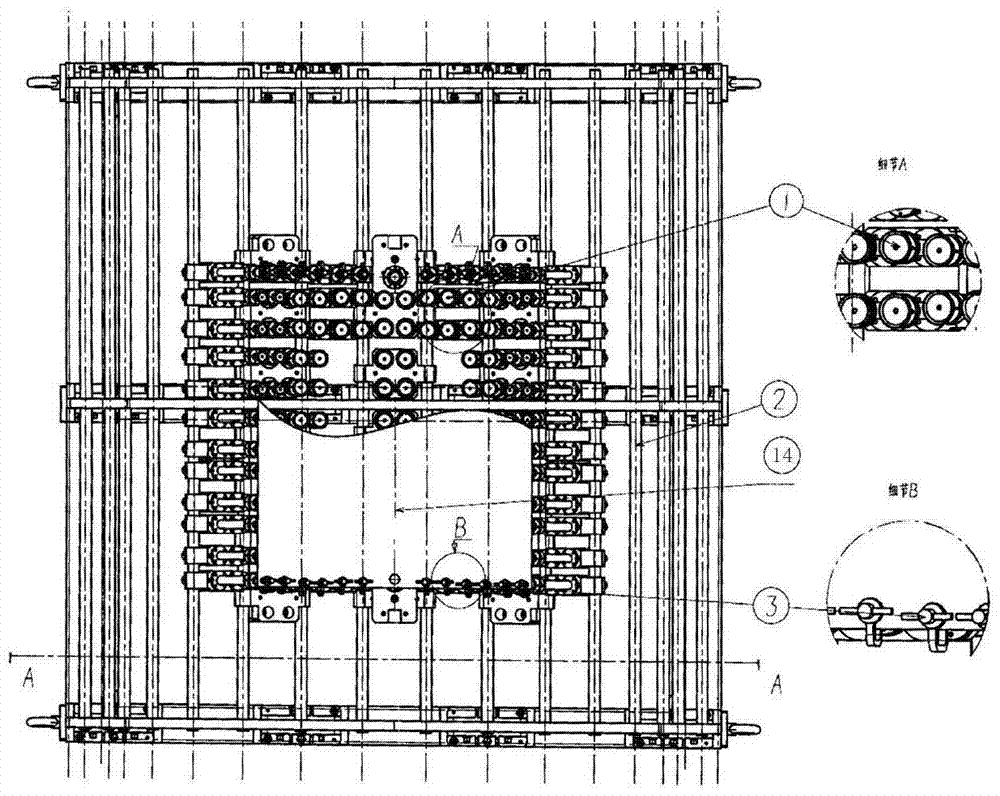

Aircraft skin no-allowance milling flexible tool and application method thereof

ActiveCN105290841ASimple structureLow costWorkpiecesMilling equipment detailsExtensibilityLocking mechanism

The invention discloses an aircraft skin no-allowance milling flexible tool. Multiple double-rod support units, multiple four-rod support units and multiple reference support units are arranged on a tool frame; bulb locking mechanisms are mounted on the double-rod support units and the four-rod support units; suckers or edge clampers are mounted on the bulb locking mechanisms; machining zero adaptors and assembly hole adaptors are arranged on the reference support units; the tool frame has a base; a connecting bracket is arranged on the base; a random support plate is arranged on the connecting bracket; multiple mounting holes are formed in the random support plate; expansion sleeves are mounted in the mounting holes; connecting rods are inserted in the coaxial mounting holes, and are locked through the expansion sleeves, so that the connecting rods and the random support plate are fastened; and the double-rod support units, the four-rod support units or the reference support units are mounted on the connecting rods. The aircraft skin no-allowance milling flexible tool has the advantages of simple structure, low cost, extensibility of modular structure, high clamping rigidity of thin-wall skin and convenience for application and promotion.

Owner:SHENYANG AIRCRAFT CORP

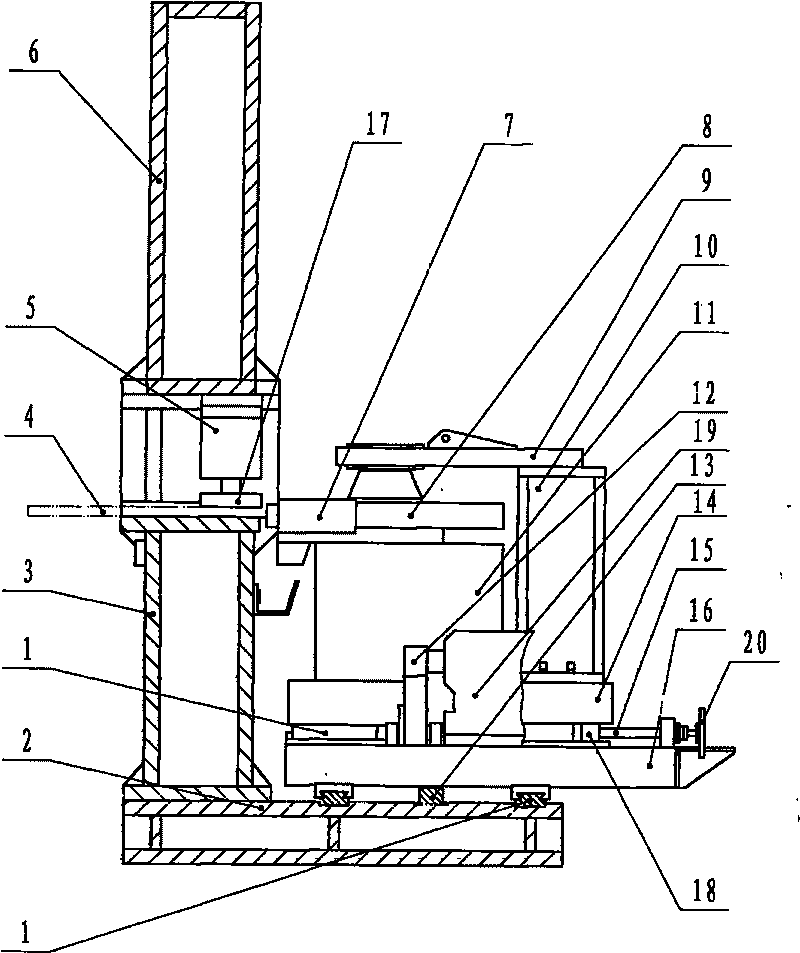

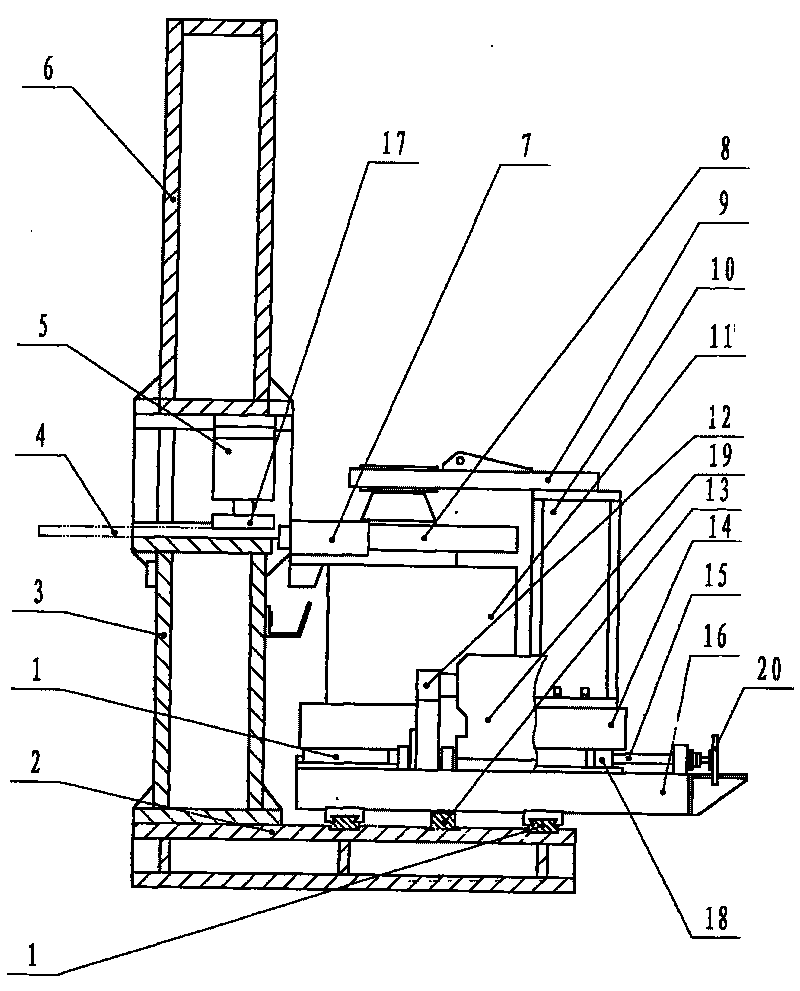

Edge milling machine

InactiveCN101758277AHigh precisionGood clamping rigidityFeeding apparatusLarge fixed membersGear wheelReducer

The invention provides an edge milling machine, which relates to an edge milling device for steel plates and is mainly designed for solving the problems of low edge milling precision and short service life of the prior edge milling machine. The edge milling device comprises a lathe bed, a base and an upper beam, wherein an oil cylinder is fixed on the upper beam, and clamp plate presser pins are arranged under the oil cylinder; a main machine is fixed on a transverse supporting plate, and a main shaft thereof is provided with a cutterhead; the lower part of a longitudinal supporting plate is fixed on a slide block guideway component on a lower layer, and the slide block guideway component is fixed on the base; an electric machine speed reducer is fixed on the longitudinal supporting plate, gear wheels on the electric machine speed reducer are meshed with rackbars, screws are fixed on a horizontal supporting plate, and a screw rod is screwed in the screw; the end of the screw rod is provided with a handwheel, and slide block guideway components on upper layers are fixed on the horizontal supporting plate and the longitudinal supporting plate; the outer end of the main shaft of the main machine is fixed on the horizontal supporting plate by a shaft, a support frame and a support seat; the diameter of the cutterhead is 1000 mm, the main machine adopts the speed reducer with curved tooth bevel gears and hard tooth surfaces, and the slide block guideway components adopt linear rolling guideways. The edge milling device has the advantages of high milling precision and long service life.

Owner:王及元

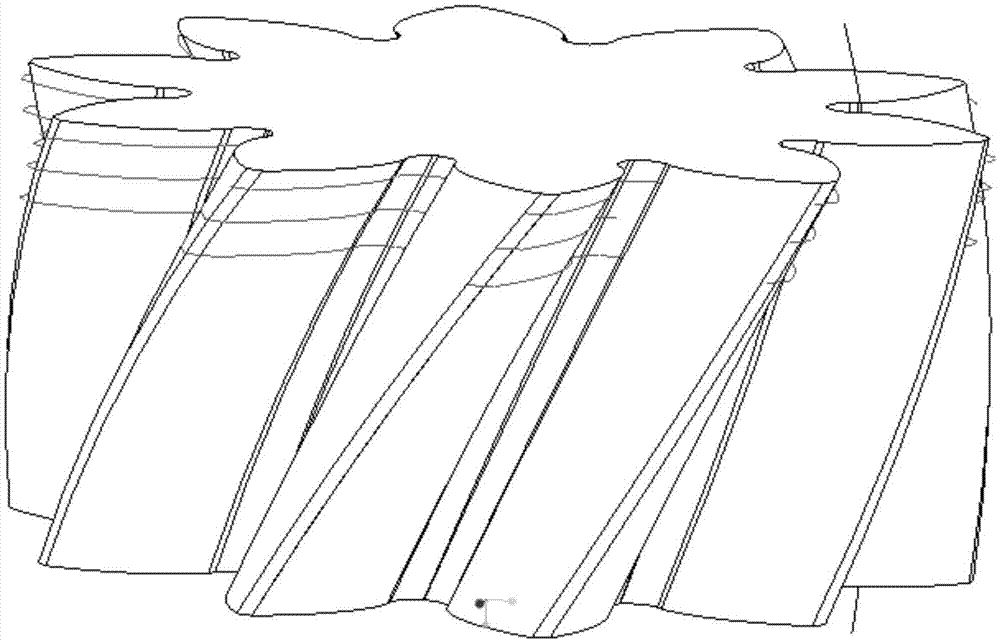

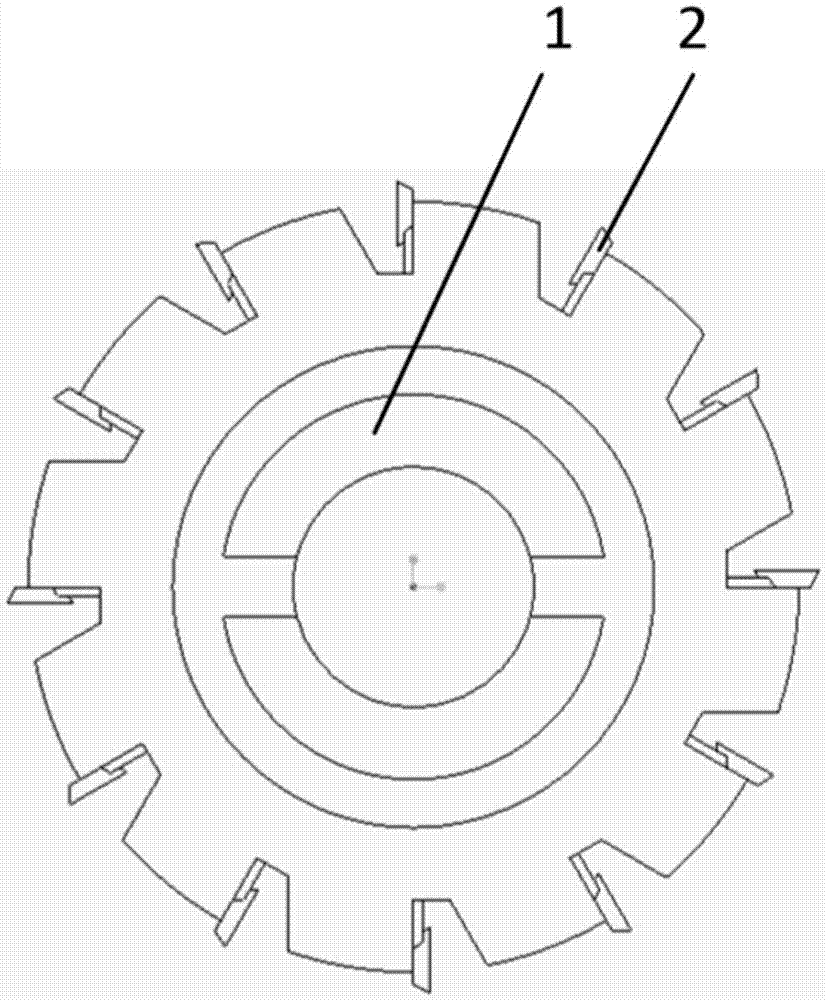

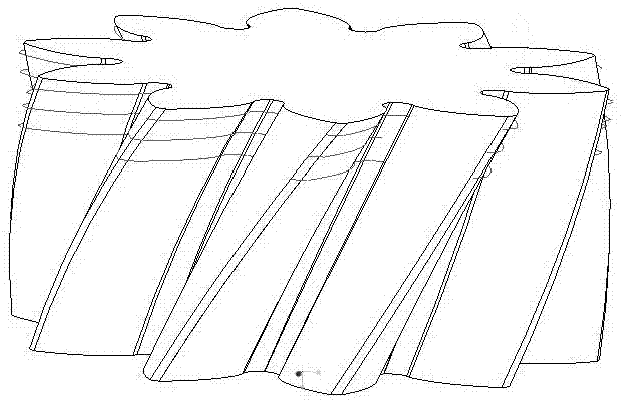

Method for processing hard tooth surface of medium-precision large-modulus cylindrical gear

ActiveCN105436623AGood fixationImprove cutting rigidityGear teeth manufacturing toolsGear teethDynamic stiffnessHelical line

A method for processing a hard tooth surface of a medium-precision large-modulus cylindrical gear is characterized in that a double-parameter non-instantaneous-pole enveloping method is carried out to perform tooth surface generating enveloping and hard milling, namely, a cutter is used for performing weft enveloping along the circumference contour direction of the gear and then performing warp enveloping along a helical line direction of the tooth surface of the gear. According to the method, a large-diameter disc milling cutter, which is provided with a large-space chip storing groove and is high in cutting stiffness and convenient and reliable in blade fixing manner, is utilized, so that a cutter disc is outstanding in comprehensive high-speed hard milling performance; a coated carbide blade is used for achieving high-speed hard milling of hardened steel; the form of the geometric structure of the blade can effectively improve the dynamic stiffness and thermal stiffness and can also reduce the influence of force and heat on a workpiece and the blade, and as a result, the durability of the blade can be improved.

Owner:NANJING GONGDA CNC TECH +1

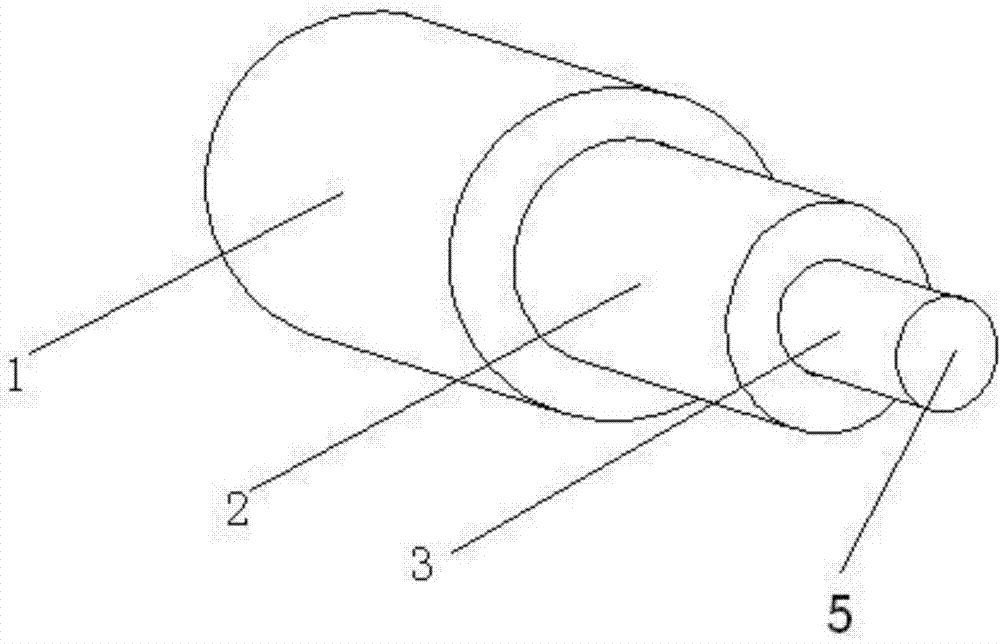

Processing method of round elastic body for sensor

The invention discloses a processing method of a round elastic body for a sensor. The processing method of the round elastic body for the sensor includes the following steps: firstly, preparing a section of cylindrical steel bar, secondly, roughly lathing three sections of outer circles to the steel bar, thirdly, numerical control rough-milling a plane, fourthly, numerical control finish-milling a plane, fifthly, drilling a hole, sixthly, milling a patch groove, seventhly, plating nickle, and eighthly, polishing a nickle plate at the patch groove. The processing method of the round elastic body for the sensor has the advantages that the problems of low processing quality and low processing accuracy in the existing processing methods are solved, clamping stability is improved by mounting a filling block under a stepped shaft when milling three sections of squares, milling accuracy is improved greatly, and service life of a cutter is prolonged.

Owner:汉中市如松弹性体有限责任公司 +1

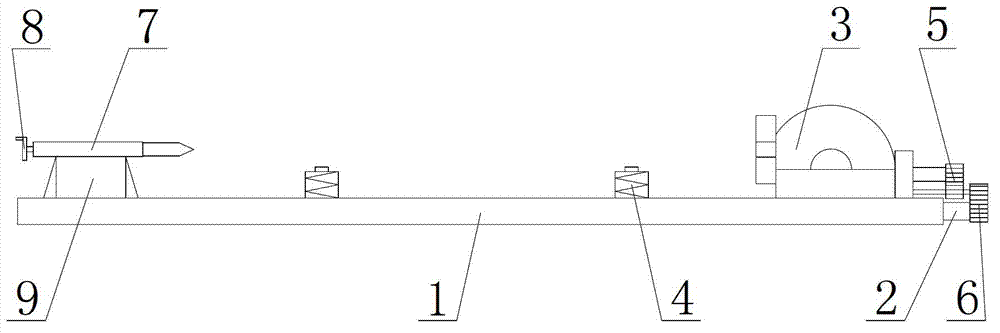

Clamp for milling spiral groove on surface of shaft type work piece

InactiveCN102848203AAchieve the purpose of rotationEasy to operateLarge fixed membersPositioning apparatusEngineeringTailstock

The invention discloses a clamp for milling a spiral groove on the surface of a shaft type work piece. The clamp comprises a milling machine table, wherein one end of the milling machine table is provided with a universal indexing head, and the other end of the milling machine table is provided with a locating tailstock; the universal indexing head and the locating tailstock are located at the same horizontal straight line; the milling machine table is provided with self-regulating dampers; the self-regulating dampers are located between the locating tailstock and the universal indexing head; the locating tailstock comprises a centre, a crank and a base; the base is arranged on the milling machine table; the base is provided with the centre; the centre is connected with the crank; and the number of the self-regulating dampers is two. The clamp for milling the spiral groove on the surface of the shaft type work piece disclosed by the invention is simple to operate, and can reduce milling difficulty so as to reduce milling time and milling cost; the clamp is suitable for batch machining; and the self-regulating damper can effectively reduce the vibration caused by the contact of the shaft type work piece and a tool, thus improving milling precision.

Owner:SUZHOU CITY JIANJUN TEXTILE MACHINERY PARTS FACTORY

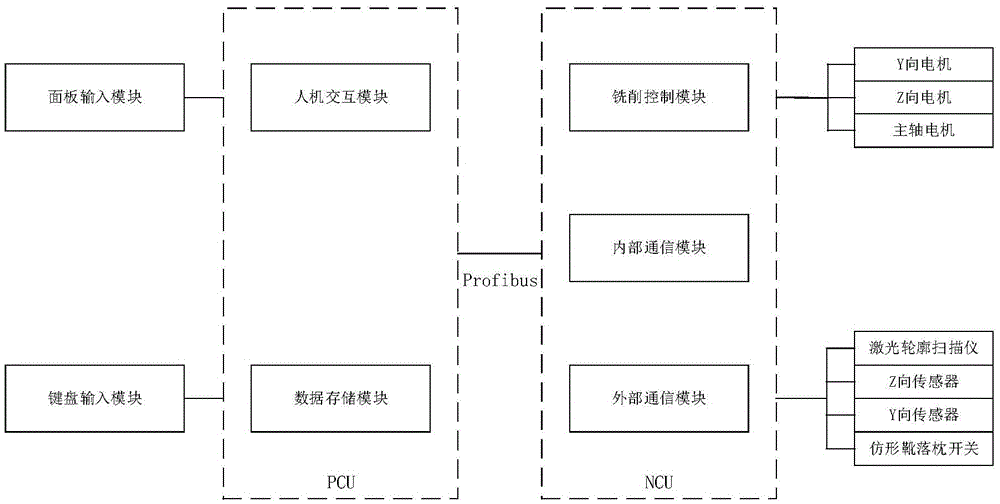

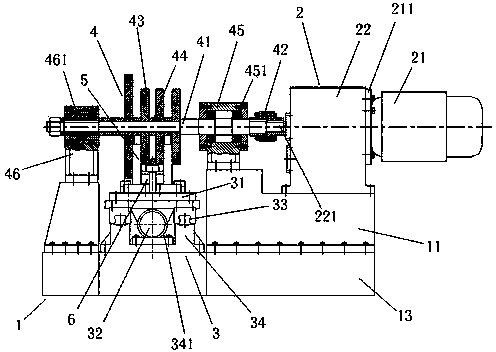

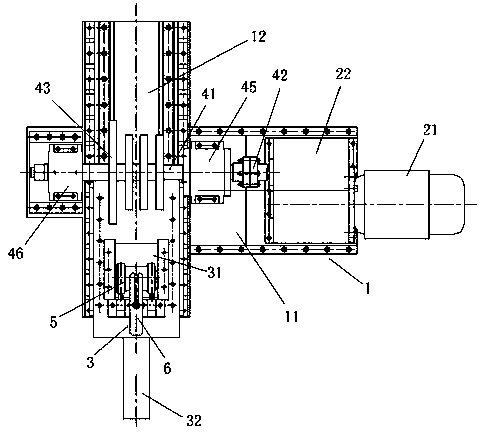

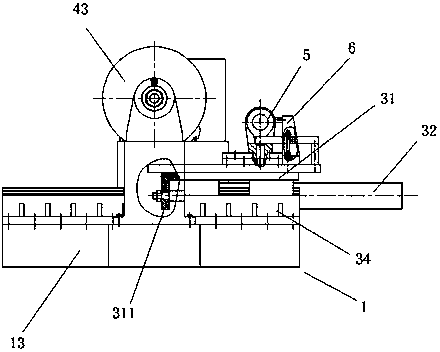

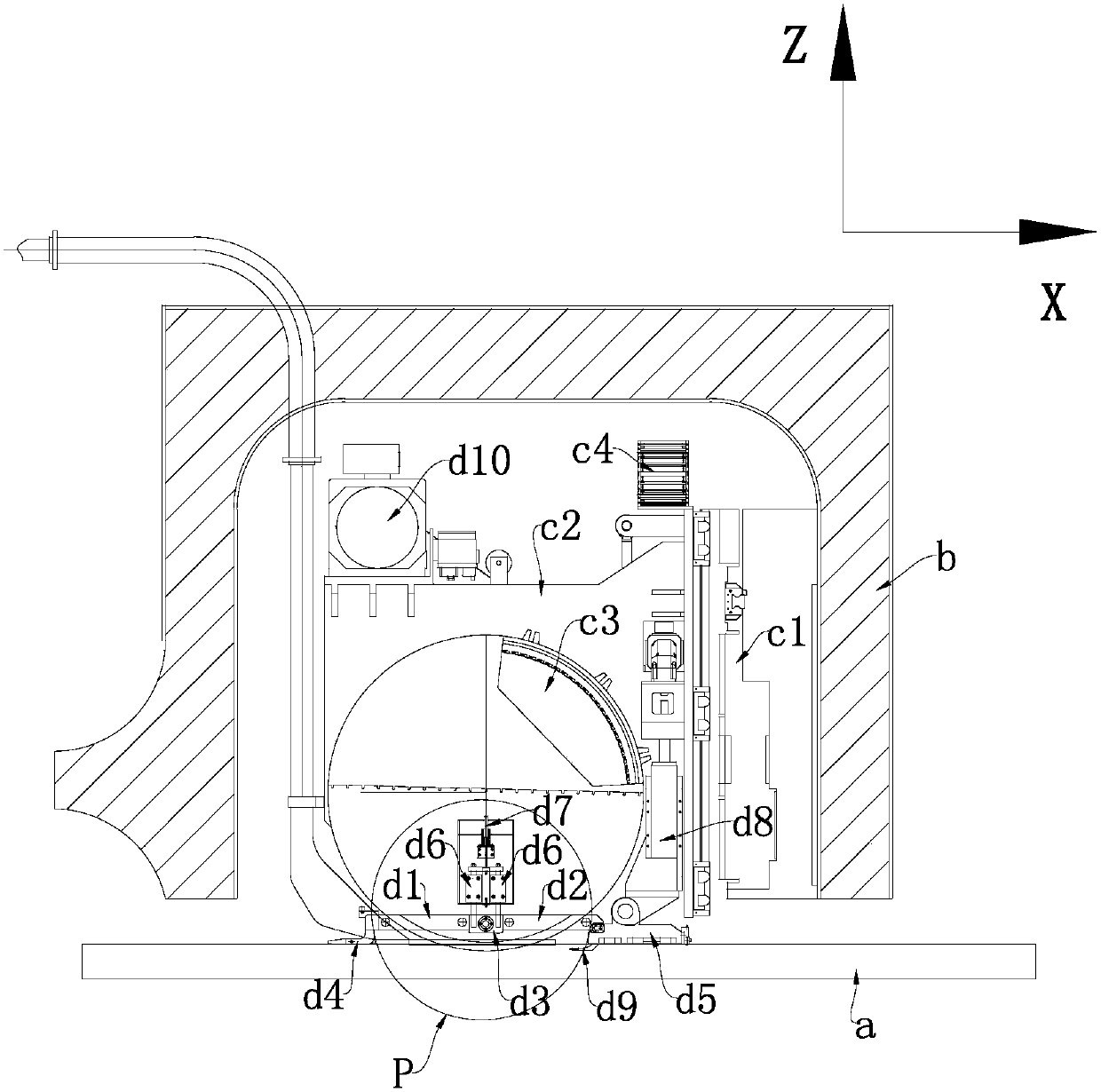

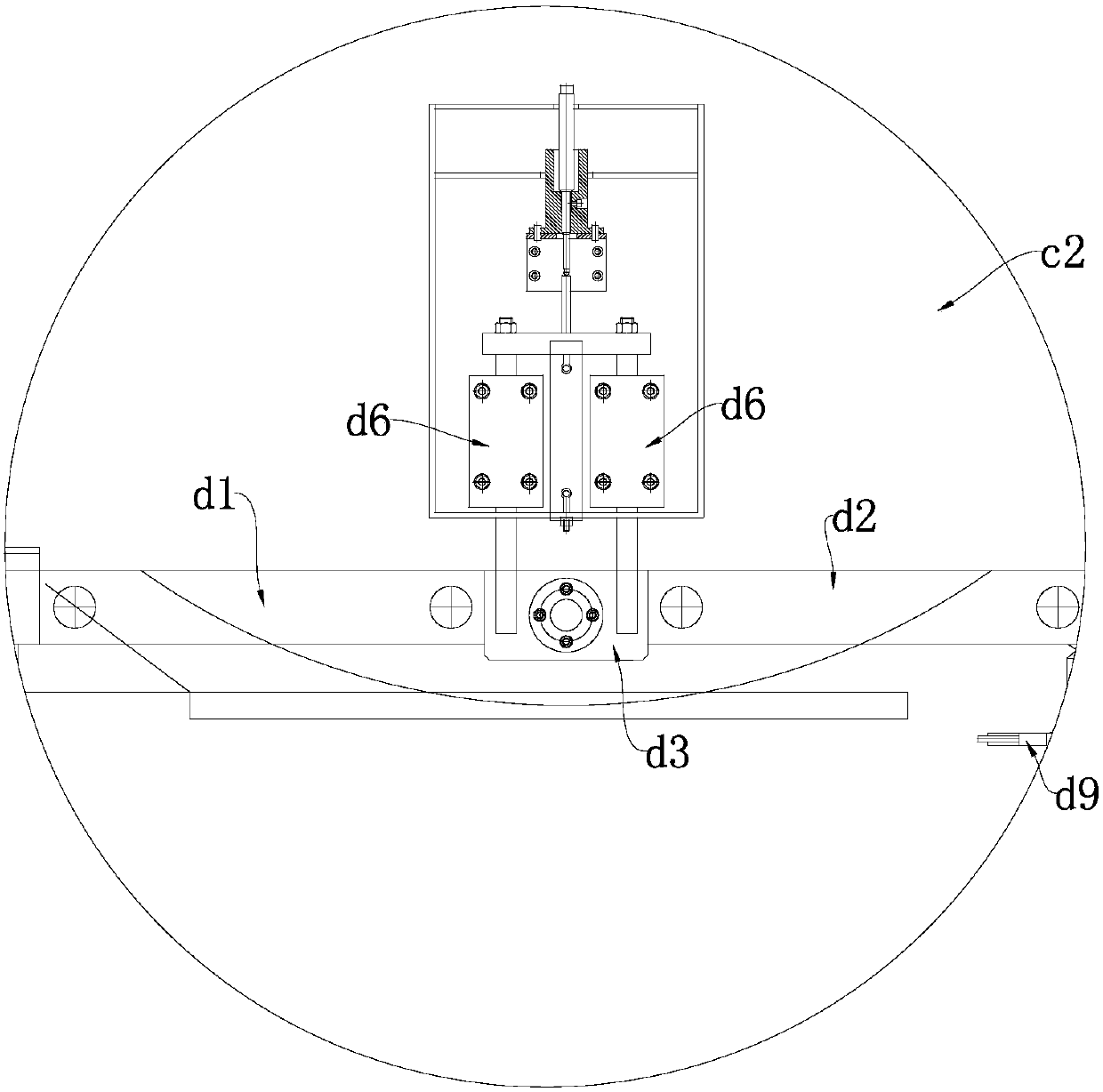

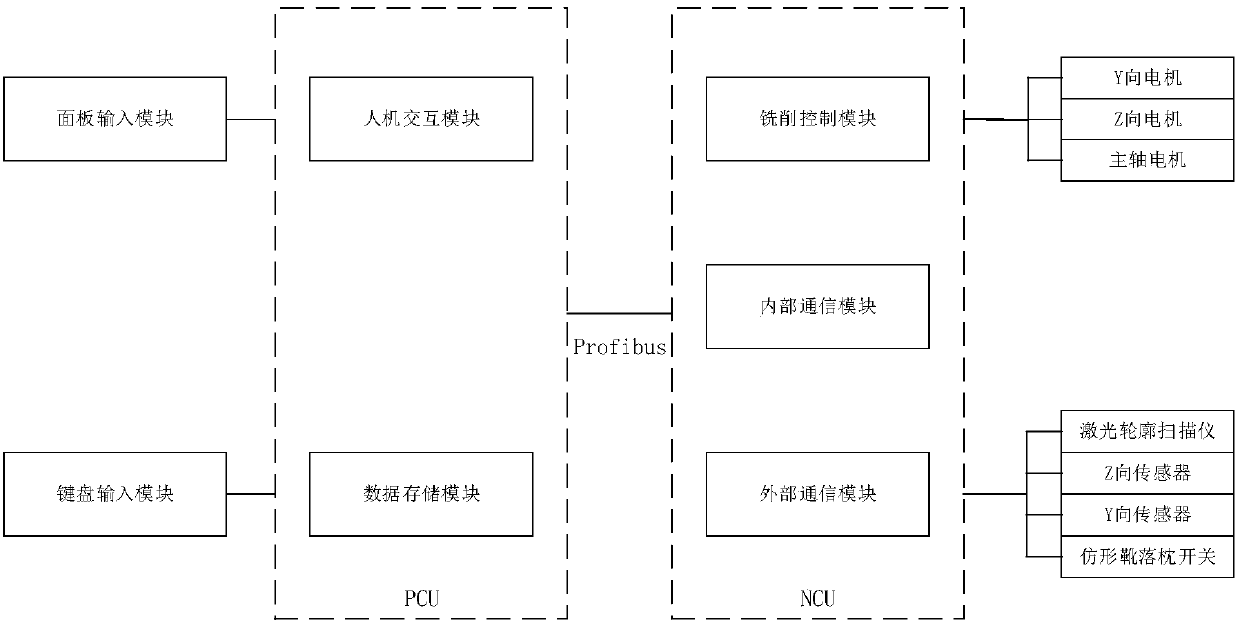

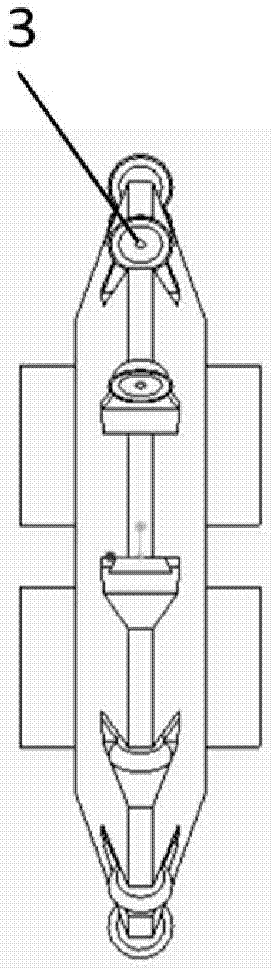

Control method of steel rail milling work

ActiveCN105598513AImprove milling accuracyReduced generation of metal dustFeeding apparatusMilling equipment detailsEngineeringConstant speed

The invention provides a control method of a steel rail milling work and relates to a method for repairing a steel rail, aiming at providing the control method of the steel rail milling work, which has high milling precision and high milling efficiency, little pollution and low energy consumption. The control method comprises the following steps: S1: acquiring steel rail outline parameters; S2: carrying out tool setting; S3: initializing an auxiliary positioning device; and S4: carrying out the milling work, and starting a main shaft motor and a vehicle body. Under the driving of the vehicle body, a steel rail milling system moves at a constant speed along the direction of the steel rail, a right contact piece and a left contact piece are controlled to be in contact with the upper surface of the steel rail, and a lateral contact piece is controlled to be in contact with the lateral surface of the steel rail; a Z-directional sensor is used for measuring the height of a cutter disc in the Z direction in real time; a Y-directional sensor is used for measuring the distance between a finger tip of the lateral contact piece and the cutter disc in the Y direction in real time, so that a road condition is judged in real time; and furthermore, the cutter disc is continuously adjusted by a milling executing unit according to the road condition, and thus milling repairing of the steel rail is realized.

Owner:BEIJING TUOBOER TRACK MAINTENANCE TECH CO LTD

Special machine tool for multi-surface mill

InactiveCN103692005AGuaranteed verticalityCompact structureMilling equipment detailsCouplingMilling cutter

The invention discloses a special machine tool for a multi-surface mill. The special machine tool comprises a machine body, a power device, a feeding device and a milling cutter device, wherein the machine body comprises a longitudinal base and a horizontal base which are integrally connected; the power device is arranged at one end of the longitudinal base and comprises a drive motor and a transmission gear case, and an output shaft of the transmission gear case is fixedly connected with the milling cutter device; the feeding device is arranged at one end of the horizontal base; the milling cutter device comprises a cutter bar and supporting seats arranged at the two ends of the cutter bar; one end of the cutter bar is fixedly connected with the output shaft of the transmission gear case through a shaft coupler; multiple rows of milling cutter disks are arranged in parallel in the middle of the cutter bar at an interval; the two ends of the cutter bar are supported in corresponding bearing seats through bearings respectively. The special machine tool is compact in structure and high in milling precision; the rows of milling cutter disks on the cutter bar are capable of achieving clamping in one time and feeding in one time to finish milling of a plurality of side surfaces, so that the verticality between the side surfaces and central lines of horizontal pin holes of processed parts is guaranteed and the processing efficiency is greatly improved.

Owner:JIANGSU ZHENJI MACHINERY MFG

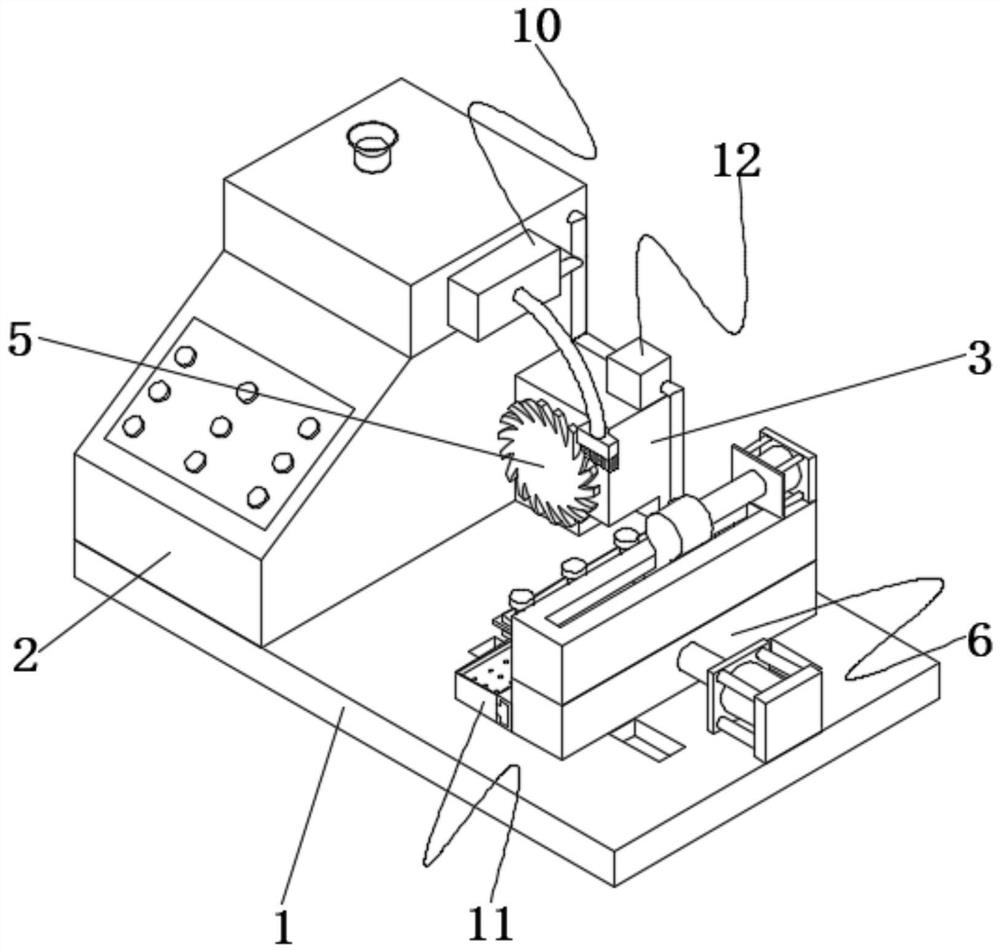

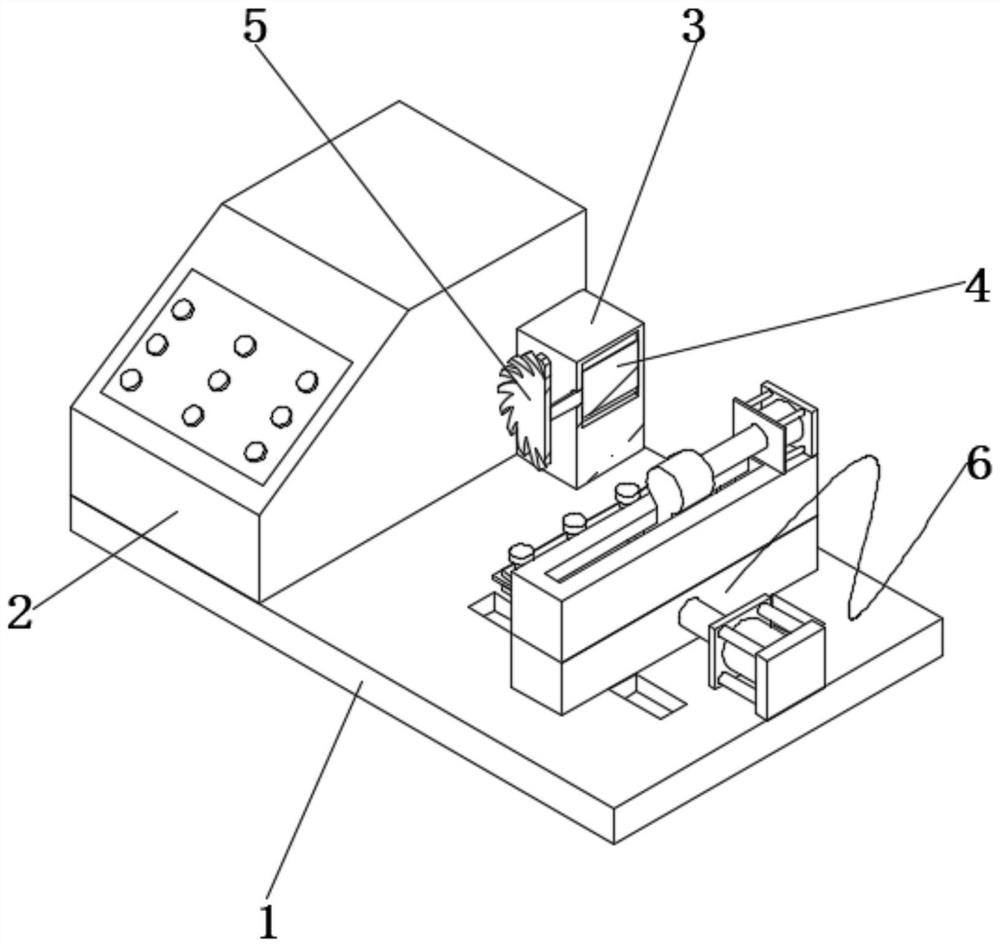

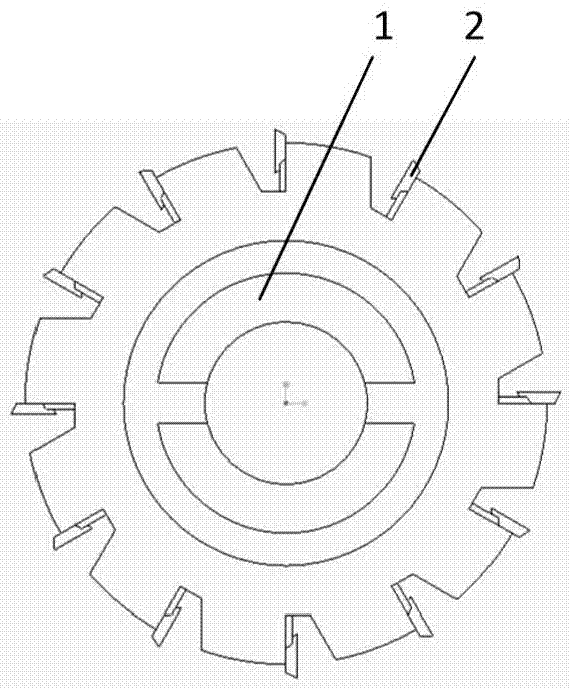

Milling device for metal saw blade machining

PendingCN113210734AImprove milling accuracyEasy to cleanMetal sawing tool makingMilling equipment detailsMilling cutterElectric machinery

The invention discloses a milling device for metal saw blade processing. The milling device comprises an operation table, wherein a control table is fixedly connected to one end of the upper part of the operation table, a case is fixedly connected to one side of the control table, a motor is mounted in the case, a milling cutter is connected to a fixing nail at the output end of the motor, a feeding mechanism is arranged at one end of the upper part of the operation table far away from the control table, the feeding mechanism is fixedly connected with a connecting arm, the connecting arm is fixedly connected with a clamp, a saw blade is fixedly connected into the clamp, the upper portion of the control table is fixedly connected with a cooling mechanism, the end, away from the control table, of the cooling mechanism is located above the milling cutter, a collecting mechanism is arranged on one side of the feeding mechanism, and the cooling mechanism and the collecting mechanism are connected through a circulating mechanism. The invention relates to the technical field of saw blade machining. According to the milling device for metal saw blade machining, chippings in gaps of a milling cutter are brushed through the bristles on a connector, so that the chippings on the milling cutter are cleaned more cleanly, and the milling precision of the milling cutter is improved.

Owner:江苏天硕合金材料有限公司

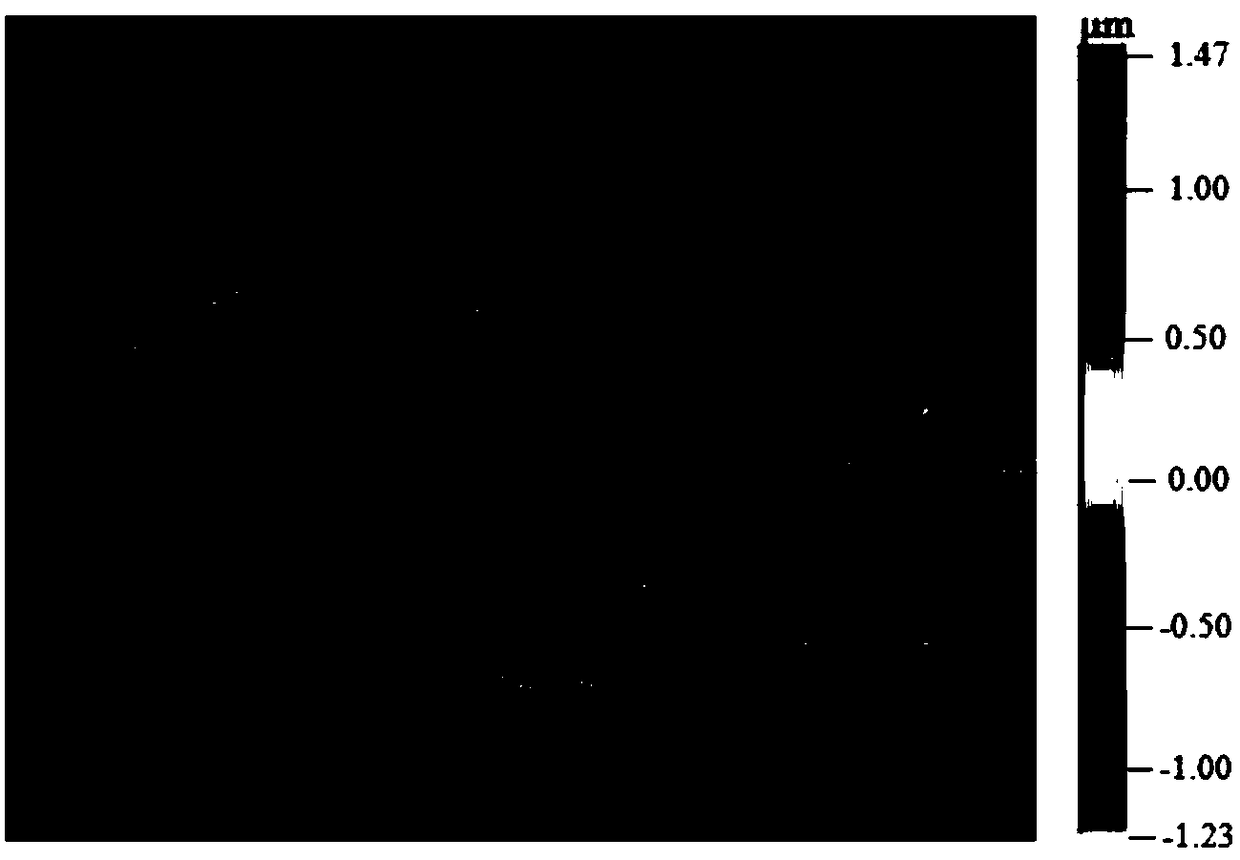

Anti-fatigue efficient milling parameter optimization control method for titanium alloy thin-wall component

InactiveCN108563849AEfficient Surface IntegrityImprove surface integrityGeometric CADConstraint-based CADMaterial removalMATLAB

The invention discloses an anti-fatigue efficient milling parameter optimization control method for a titanium alloy thin-wall component. The method comprises the following steps that: establishing the primary election technological parameter domain of a titanium alloy thin-wall component; carrying out an orthogonal test; testing the surface integrity parameter of a test component; establishing acharacteristic relational expression of a titanium alloy thin-wall component milling technological parameter and surface integrity; according to the relational expression of the titanium alloy thin-wall component milling technological parameter and the surface integrity, a target function and a milling technological parameter constraint condition, establishing an optimization model for the anti-fatigue efficient milling parameter of the titanium alloy thin-wall component; and through an optimization tool in MATLAB, solving the optimization model for the anti-fatigue efficient milling parameterof the titanium alloy thin-wall component to obtain the anti-fatigue efficient milling parameter of the titanium alloy thin-wall component. By use of the method, the problems of poor surface integrity characteristic and low material removal rate in a milling process of the titanium alloy thin-wall component are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

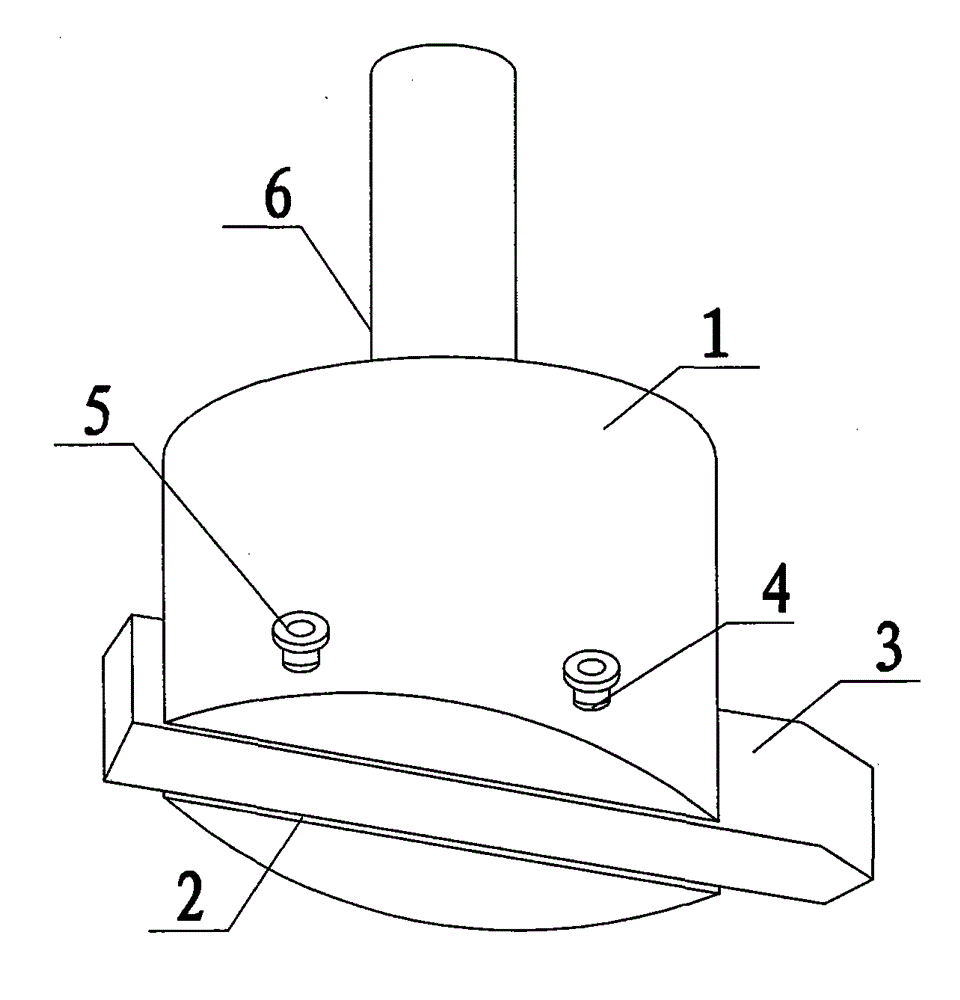

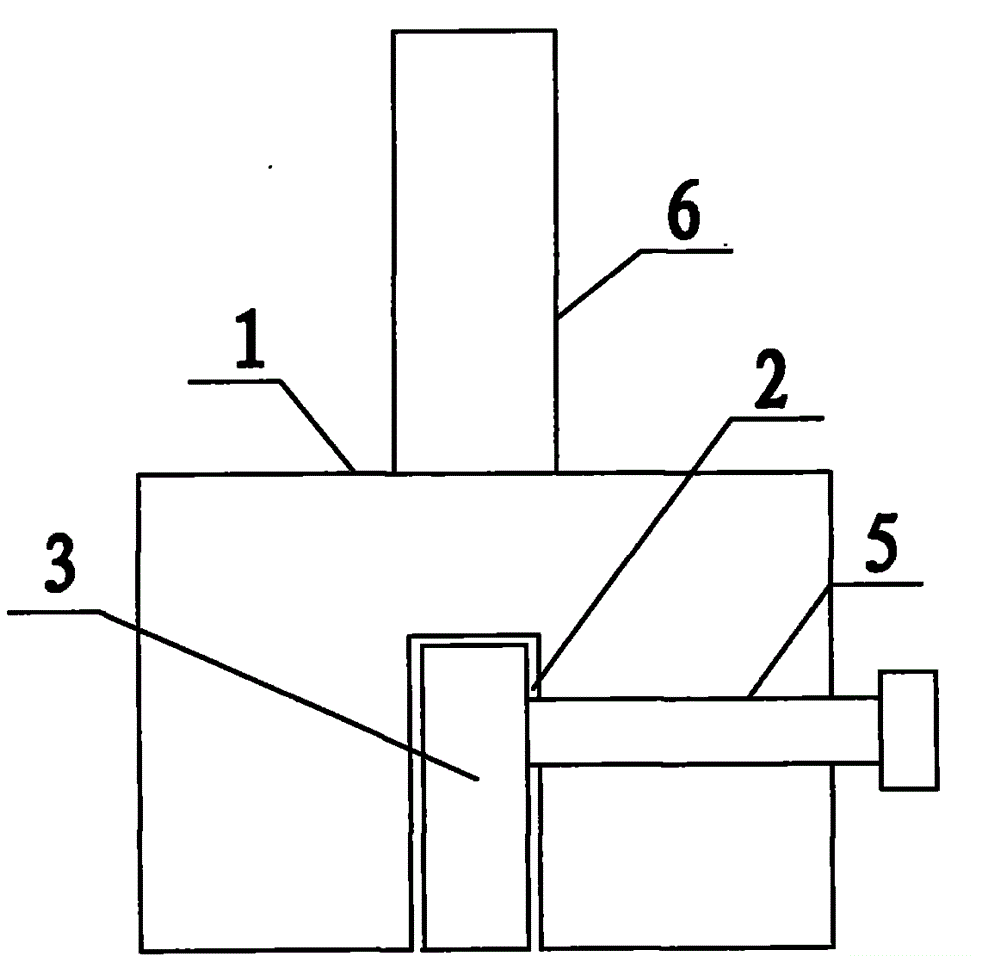

Milling cutter

The invention discloses a milling cutter which comprises a fixed end and a cutter body, the fixed end is arranged on the cutter body, a groove is arranged at the bottom of the cutter body, screw holes are arranged on the lateral side, bolts are arranged in the screw holes which are communicated with the groove, and a cutter bade is movably embedded in the groove. When the milling cutter is used for milling, the position of the cutter blade in the groove can be adjusted according to actual needs, the milling range is changed, the structure is simple, the operation is simple, and the processing efficiency and the milling accuracy can be well improved.

Owner:赵立平

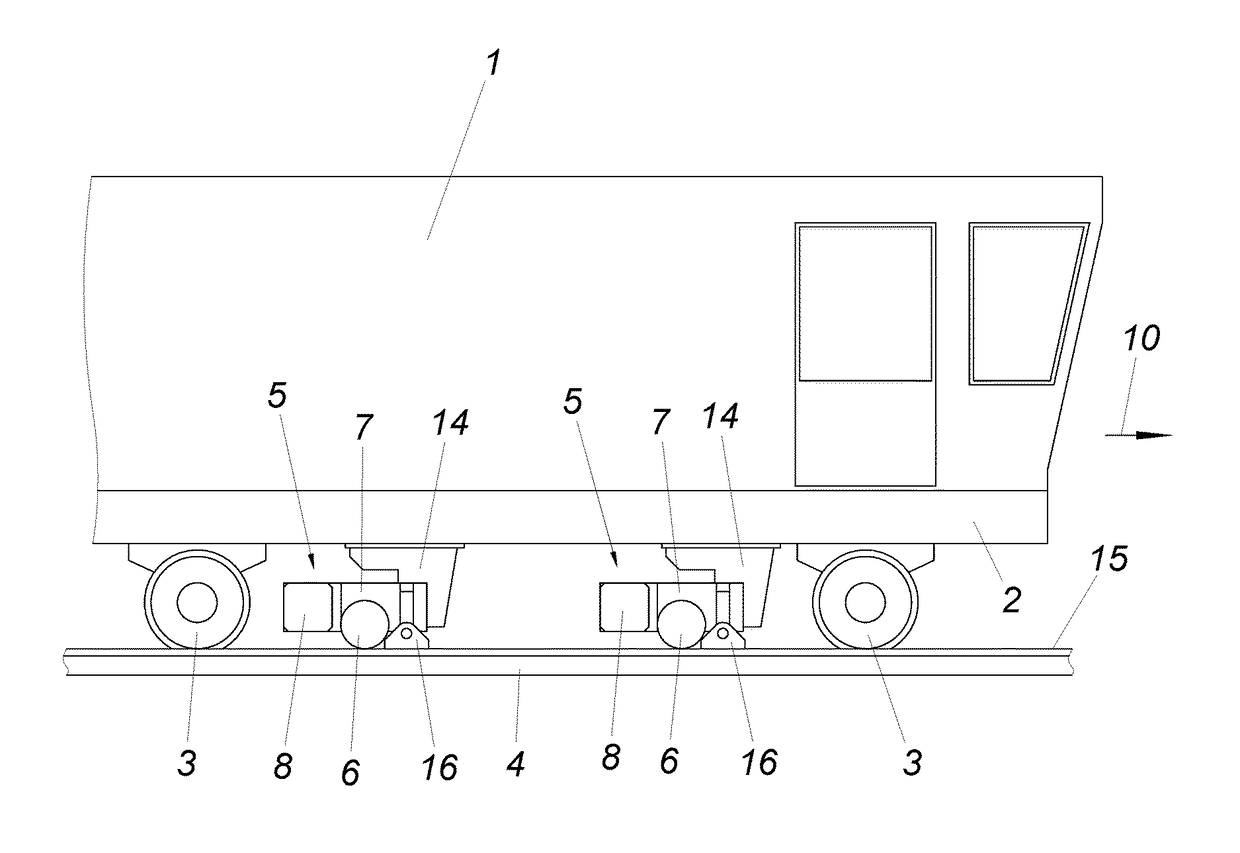

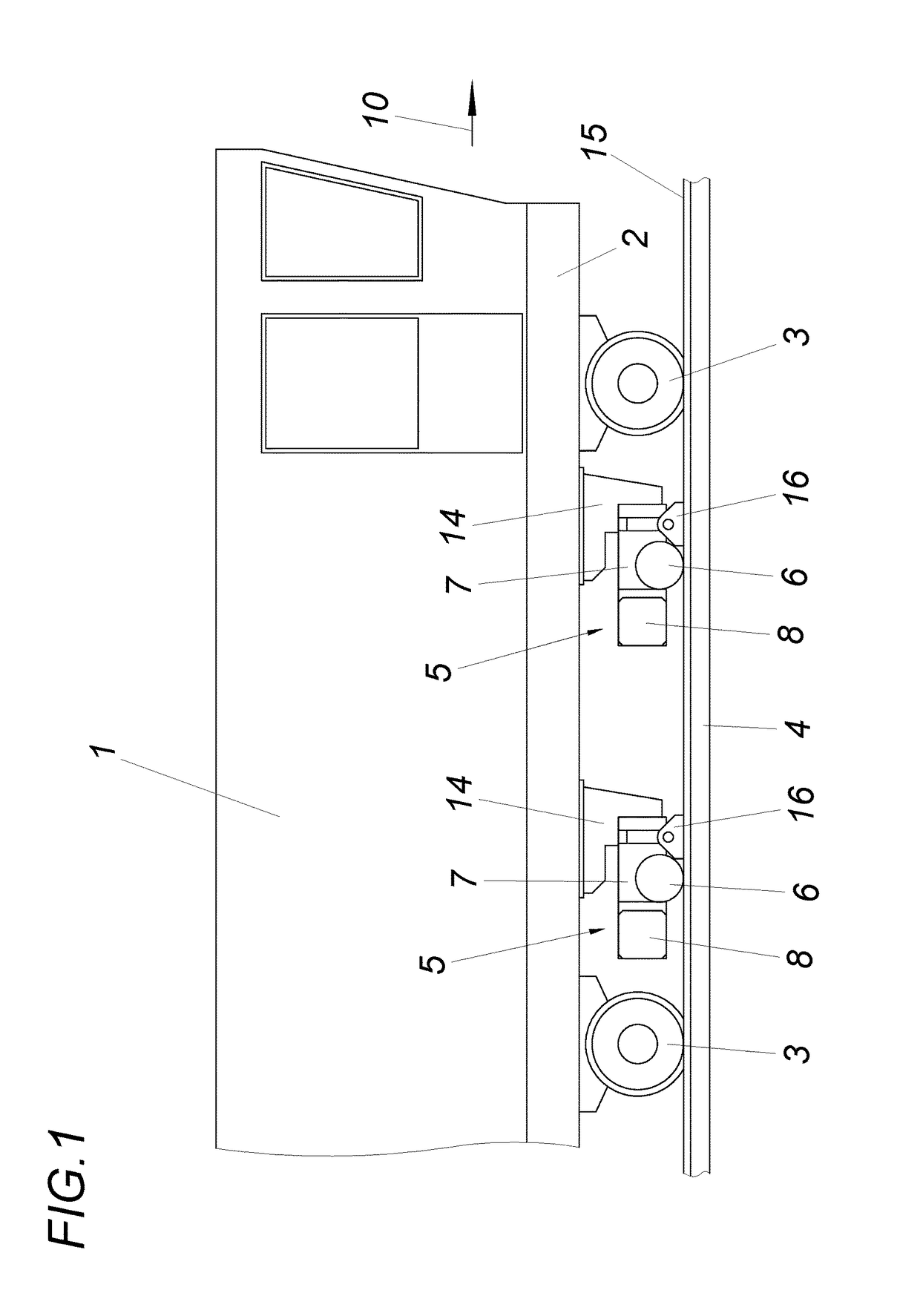

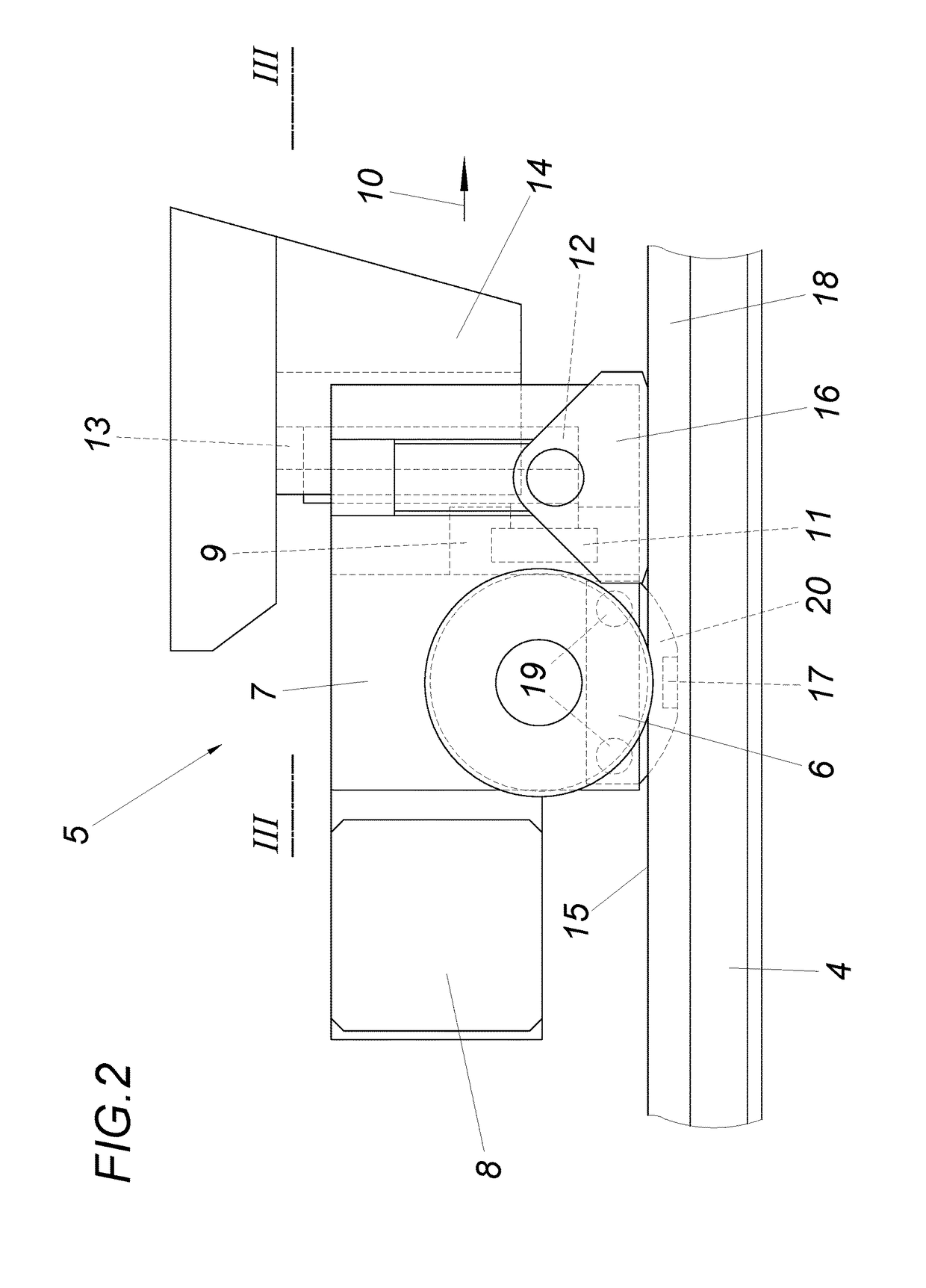

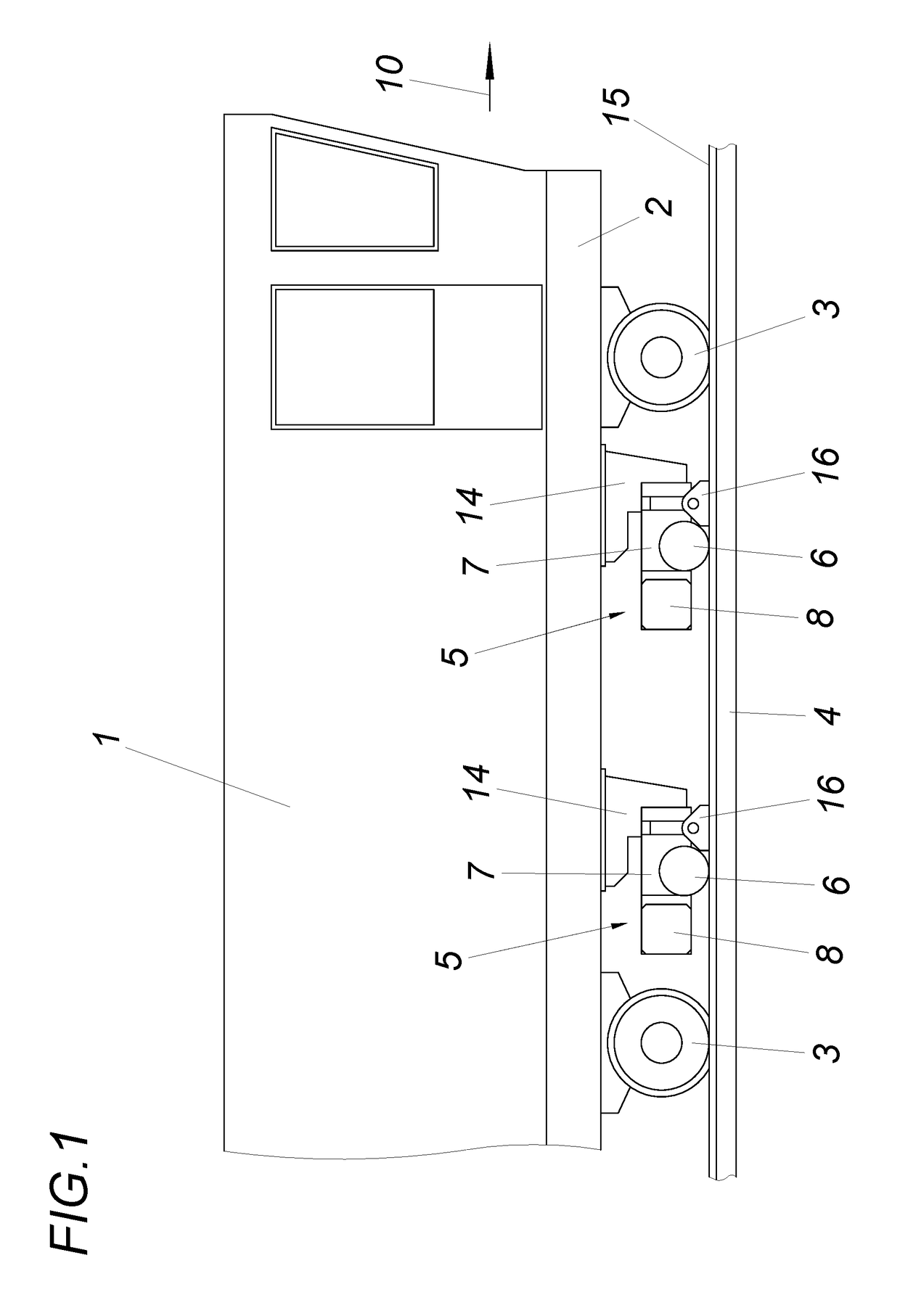

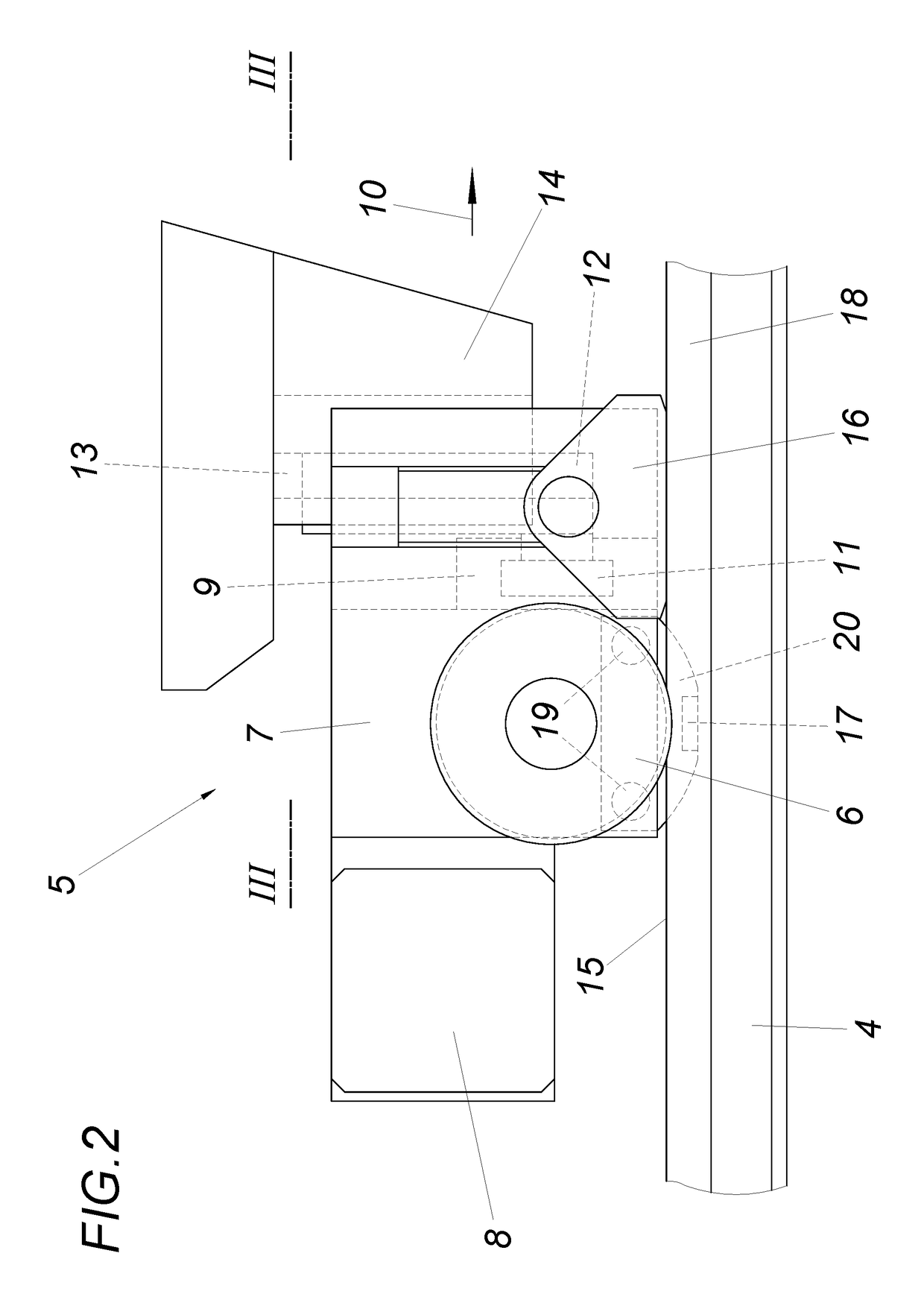

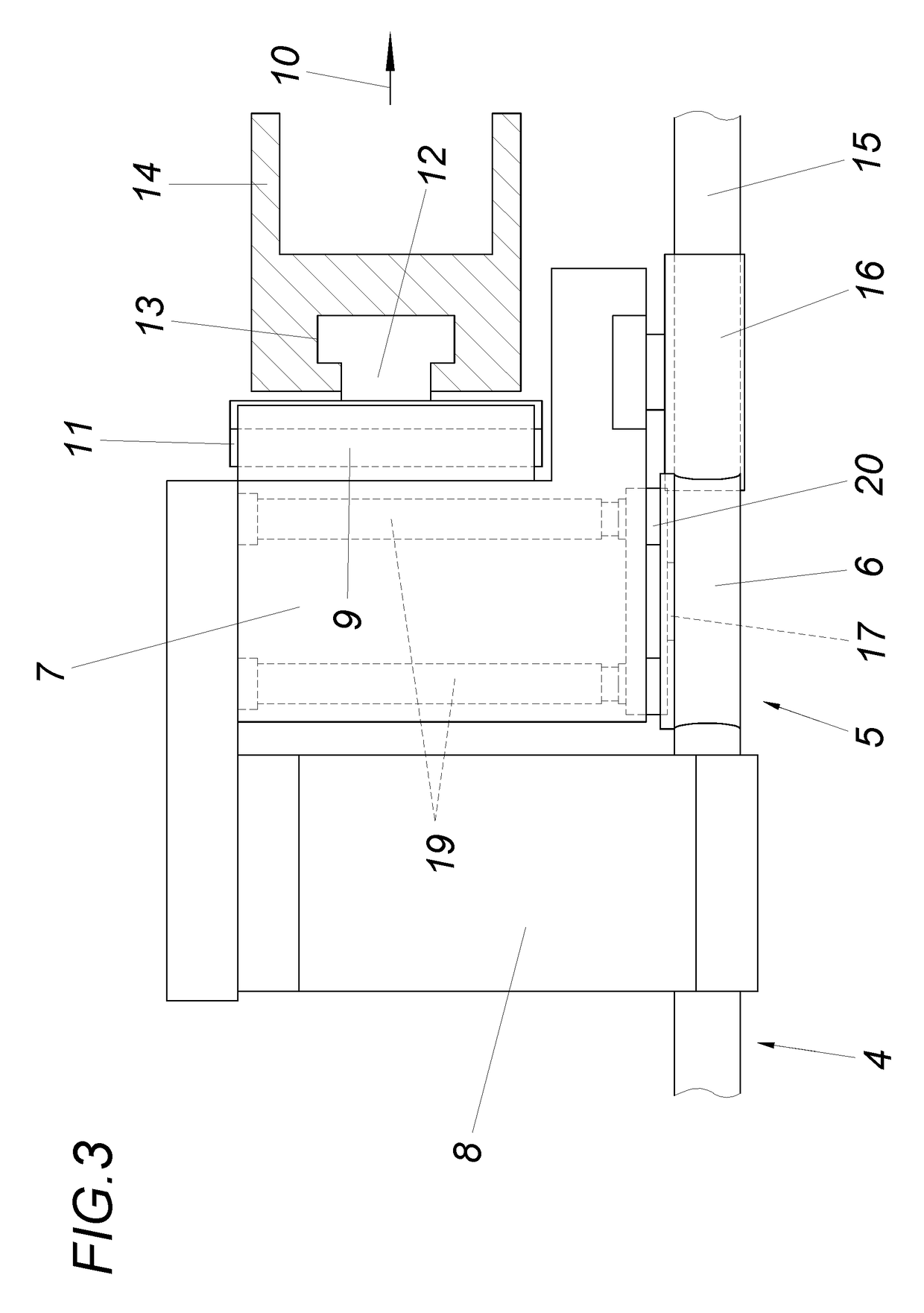

Rail vehicle having a device for finishing the running surface of track rails

A rail vehicle includes a milling device for finishing the running surface of track rails during the travel of the rail vehicle along the track rails. The rail vehicle has a chassis frame having wheel sets. The milling device is provided with a milling head, and includes a framework arranged on the chassis frame having a milling head receptacle, which is displaceable vertically and transversely in relation thereto. The milling head receptacle can be supported for the vertical guiding via a guide shoe on the running surface and for transverse guiding in parallel to the milling head shaft via a guide stop laterally on the railhead. The milling head receptacle forms a transverse carriage, which supports the guide shoe and the guide stop, and the guide path of which, which is vertically displaceable, is provided on the side of the milling head receptacle facing toward the guide shoe.

Owner:LINSINGER MASCHENBAU GES

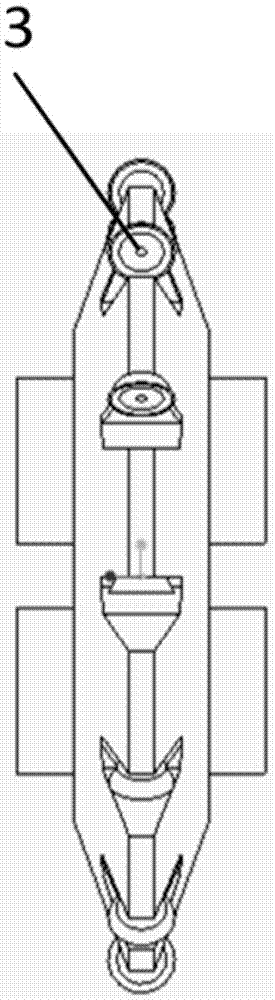

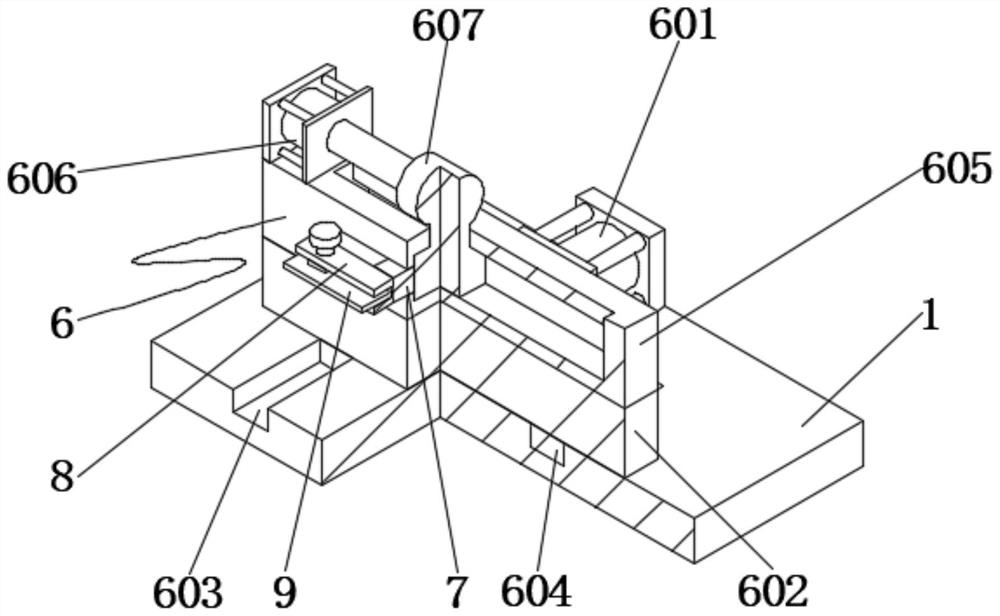

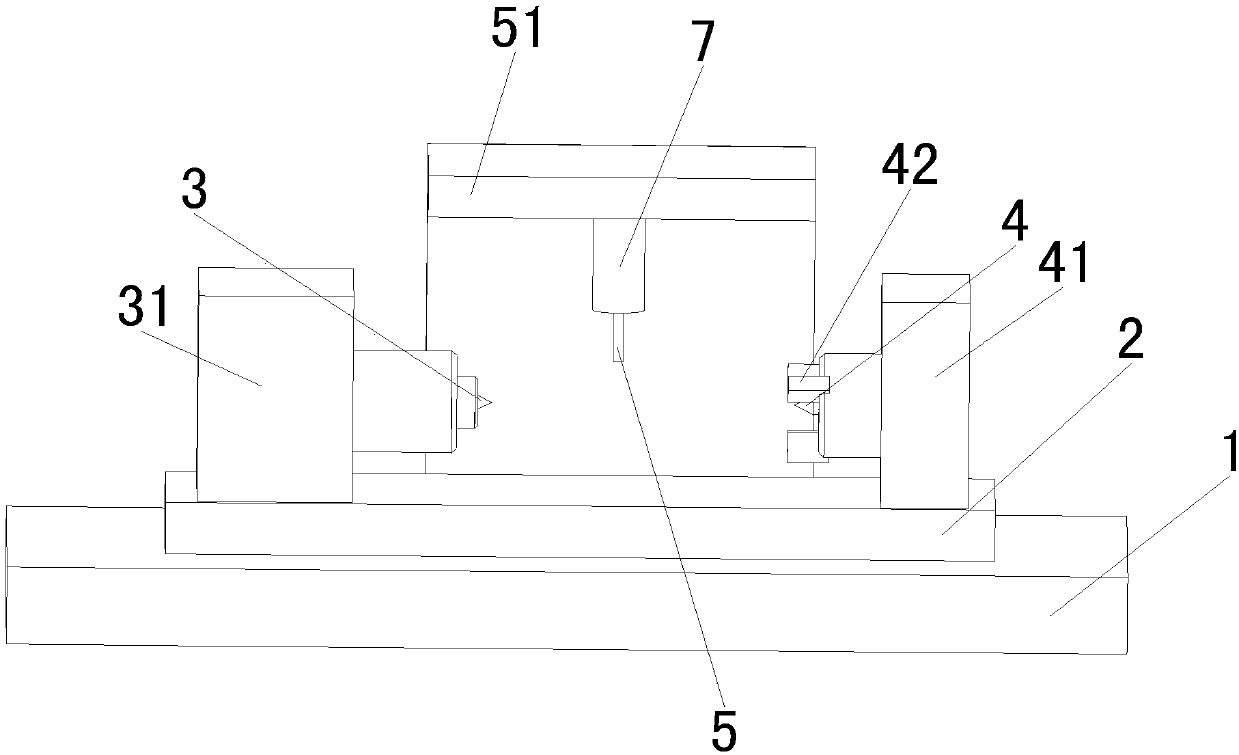

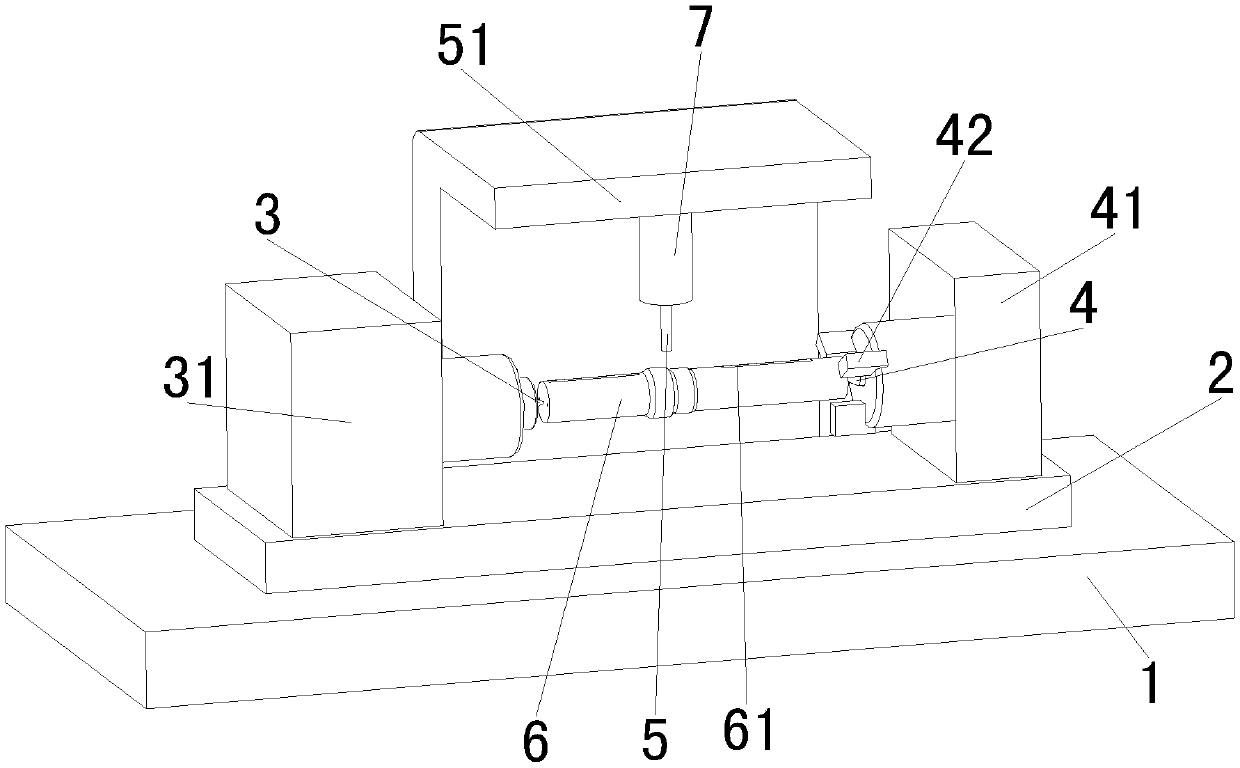

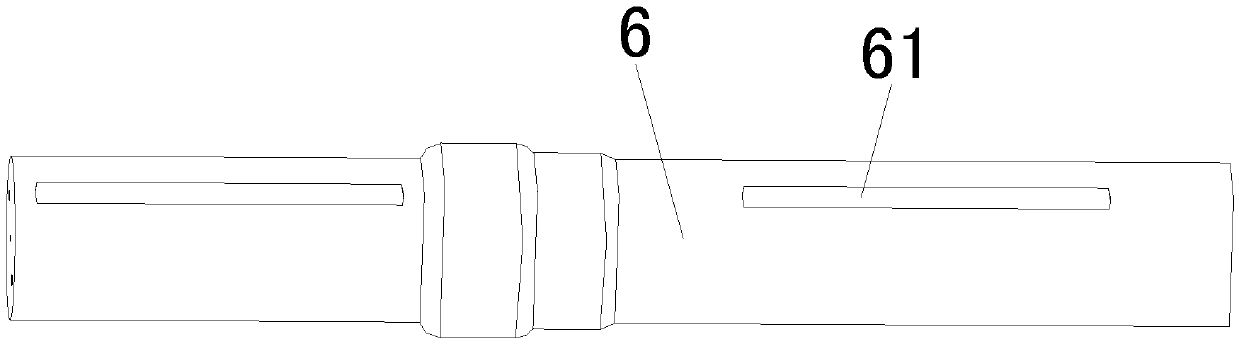

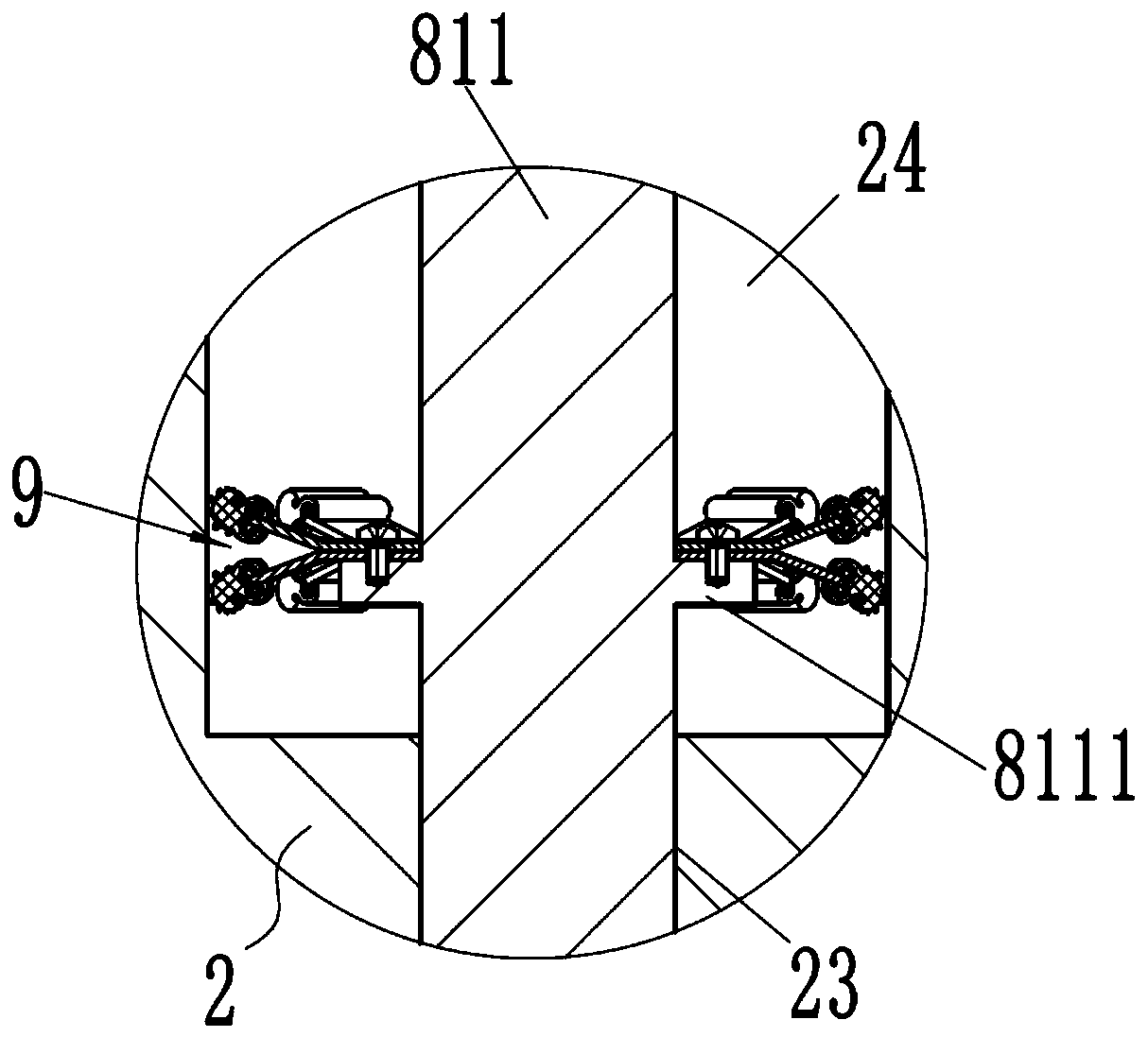

Stepped shaft outer circle surface milling keyway apparatus

PendingCN109249070AAvoiding Difficult to Overlap ProblemsSimple positioning and clampingMilling equipment detailsMilling cutterEngineering

The invention discloses a stepped shaft outer circle surface milling keyway apparatus, which comprises a base, wherein the base is provided with a moving seat capable of horizontally moving left and right, the moving seat is oppositely provided with a left ejection tip support seat and a right ejection tip support seat, the left ejection tip support seat is provided with a left ejection tip, the right ejection tip support seat is provided with a right ejection tip, the center axis of the left ejection tip coincides with the center axis of the right ejection tip, a stepped shaft is arranged between the left ejection tip and the right ejection tip, hydraulic moving claws are uniformly distributed on the right ejection tip support seat along the radial direction of the right ejection tip, thehydraulic moving claw at least has two out surfaces capable of simultaneously grasping the end portion of the stepped shaft, the base is provided with a cutter support seat, the cutter support seat is provided with a cutter installing seat, the cutter installing seat can vertically move up and down, and is vertically provided with a milling cutter, and the milling cutter rotatablely move down, and is matched with the moving seat to mill to form a keyway. According to the present invention, the positioning clamping mode of the stepped shaft outer circle surface milling keyway apparatus is simple, and the keyway milling precision is high.

Owner:曾我部(苏州)减速机制造有限公司

Rail vehicle having a device for finishing the running surface of track rails

Owner:LINSINGER MASCHENBAU GES

Milling machine head for machining heat-insulation bridge-cutoff aluminum doors and windows

PendingCN112846324AImprove milling accuracyMilling speedMilling equipment detailsMetal working apparatusMachineSupport plane

The invention provides a milling machine head for machining heat-insulation bridge-cutoff aluminum doors and windows. The milling machine head can improve the operation efficiency. The milling machine head for machining the heat-insulation bridge-cutoff aluminum doors and windows comprises a supporting frame, two milling assemblies, two front-back moving assemblies and two up-down moving assemblies. The two milling assemblies are the same in structure and are symmetrically arranged on the left side and the right side of the supporting frame. The two front-back moving assemblies are the same in structure, are symmetrically arranged on the left side and the right side of the upper portion of the supporting frame and are used for driving the milling assemblies to move front and back. The two up-down moving assemblies are the same in structure, are arranged in a left-right symmetry manner and are used for driving the milling assemblies to move up and down.

Owner:山东乾正数控机械有限公司

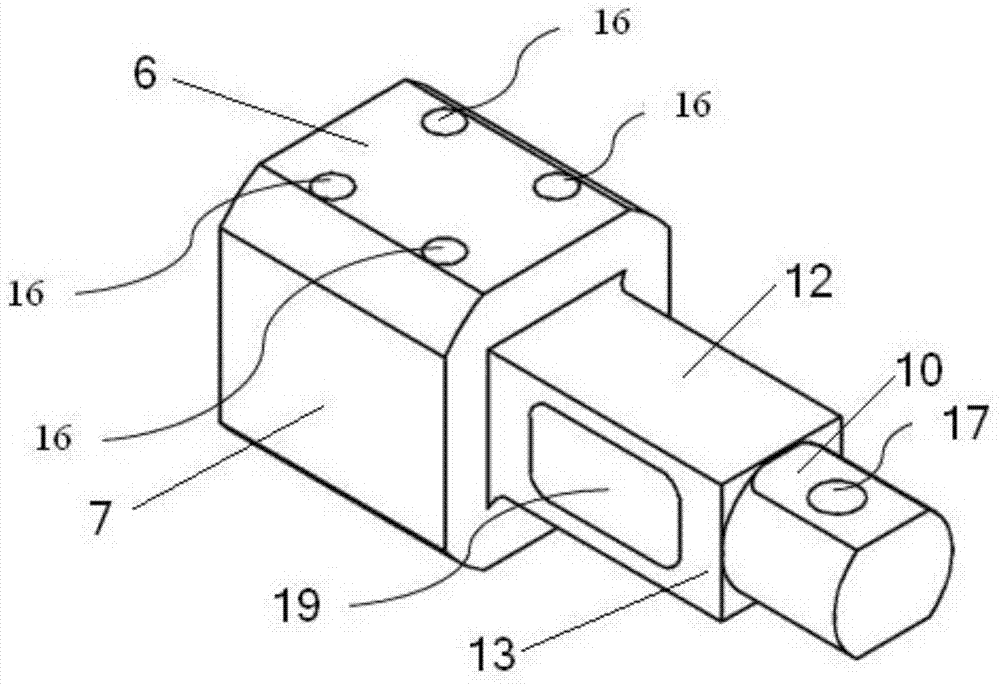

Fixing device for workpiece edge-milling and specially-shaped workpiece edge-milling process

ActiveCN108356568AEasy flipRealize lateral compression fixationWork clamping meansMilling equipment detailsPressure transmissionEngineering

The invention discloses a fixing device for workpiece edge-milling and a specially-shaped workpiece edge-milling process, and belongs to the technical field of edge-milling device processes. The fixing device comprises a fixing table and a pressing device, wherein a limiting block is fixedly arranged on the fixing table; the pressing device comprises a pressing block, a pressure transmission device and a pressure supply device; the pressure transmission device is horizontally fixed on the upper end surface of the fixing table; the pressing block is connected onto the output shaft of the pressure transmission device and is matched with the limiting block in the horizontal direction; the pressure supply device is connected with the pressure transmission device through a pipeline; and a supporting roller and a magnet are further arranged on the upper end surface of the fixing table. According to the fixing device disclosed by the invention, the pressing block, the limiting block and the magnet act with one another for fixing a workpiece onto the fixing table; the workpiece is transmitted to a rack or a next process through the supporting roller after edge-milling is completed, and anyposition on the material can be milled and processed. The fixing device is simple in structure, is convenient to operate, is high in processing efficiency, and is safe and reliable in processing process.

Owner:MAANSHAN XINHUA HETEROTYPE STEEL DEV LIABILITY

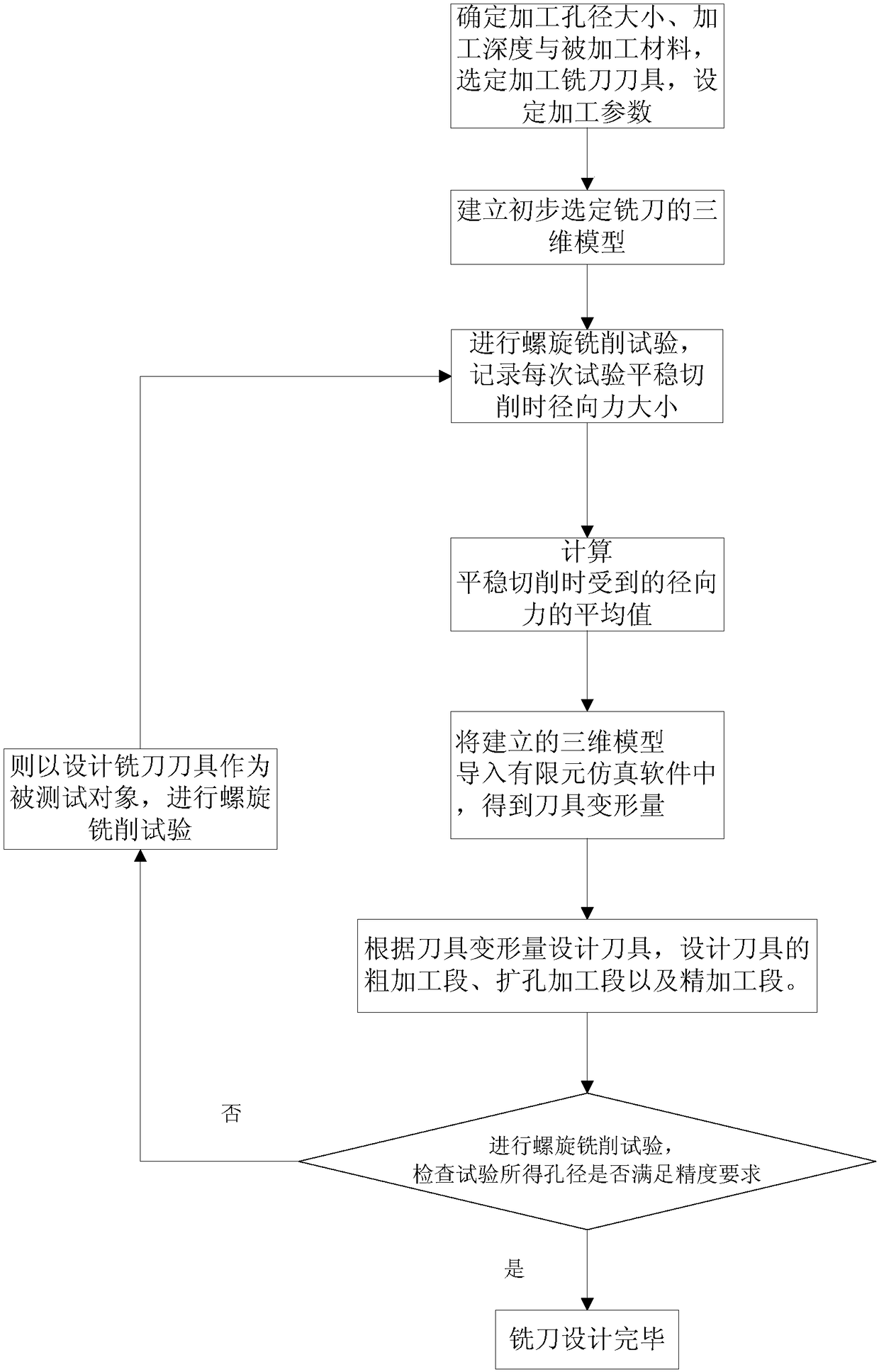

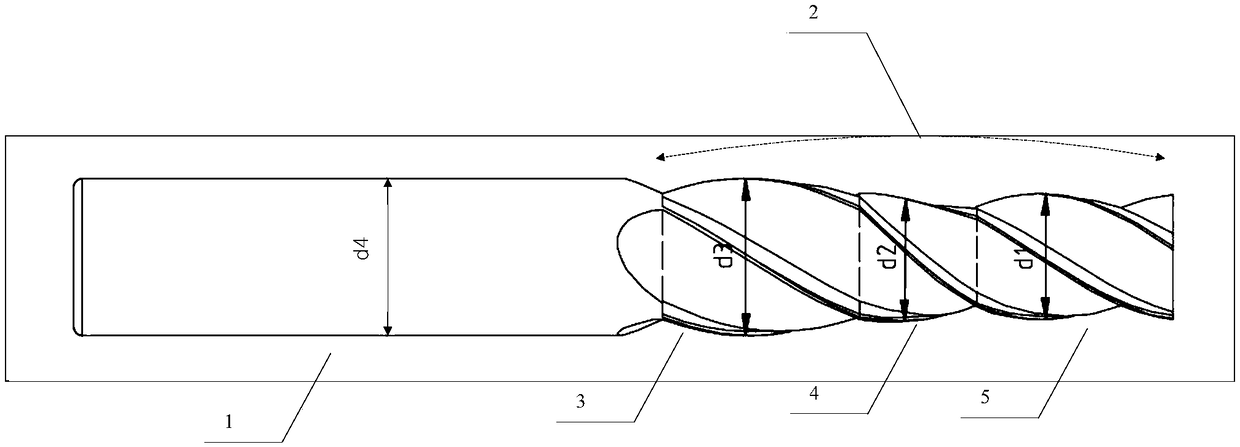

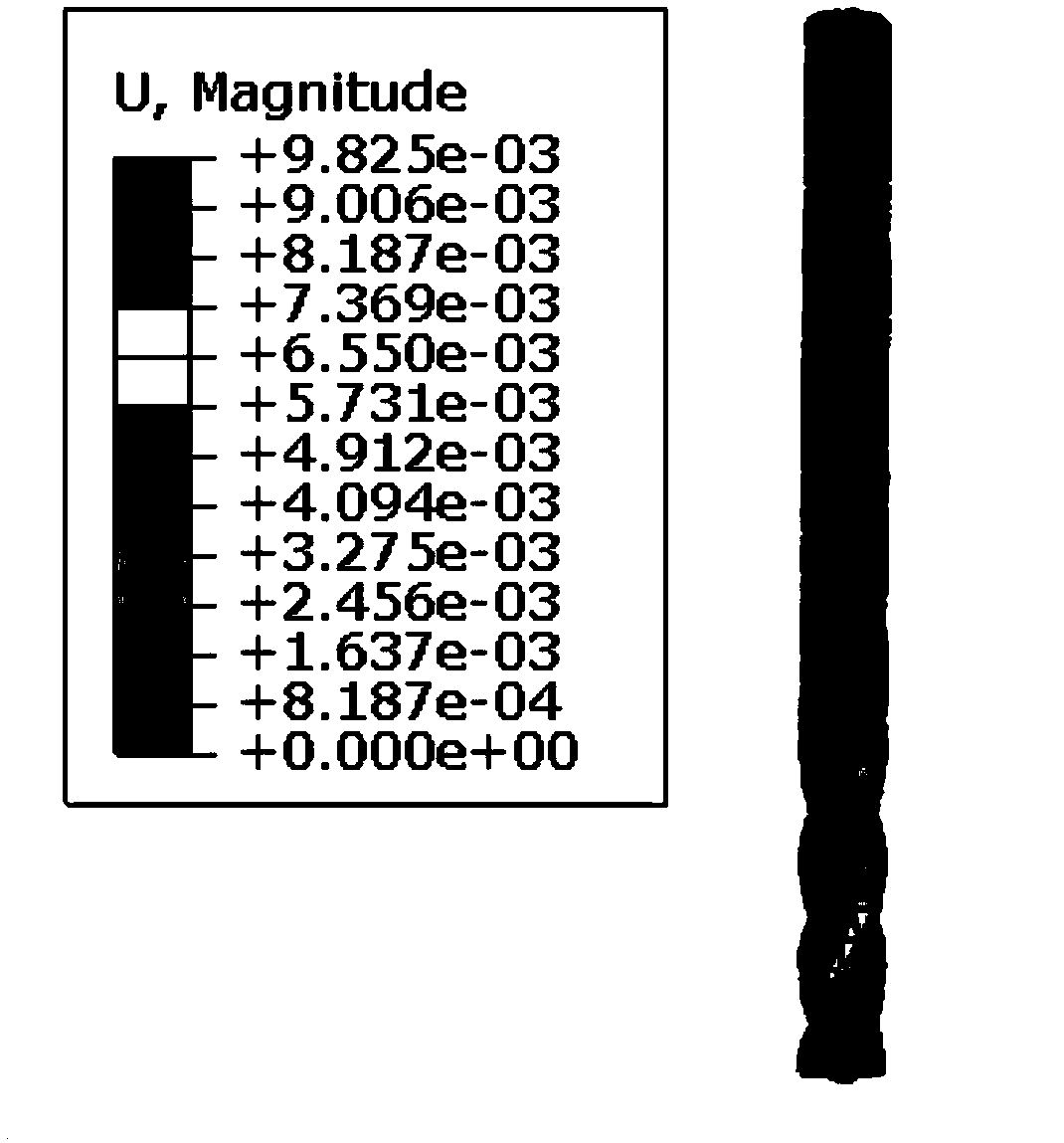

Milling cutter capable of improving spiral milling machining precision, and design method

PendingCN108723454AImprove milling accuracyImprove processing efficiencyProgramme controlComputer controlMachine partsMilling cutter

The invention provides a milling cutter capable of improving spiral milling machining precision, and a design method, and belongs to the field of machining. The milling cutter comprises a cutter handle and a machining part, wherein the machining part comprises a finish machining section, a chambering machining section and a rough machining section; a preliminary selection machining milling cutteris used for carrying out a spiral milling experiment, tested radial force is recorded and the average value of radial force is calculated; through finite element simulation software, a cutter deformation amount is obtained; according to the cutter deformation amount, a new milling cutter is designed; a newly designed milling cutter is used for carrying out the spiral milling experiment, whether anaperture obtained by the experiment meets an accuracy requirement or not is checked; if the requirement is not met, the milling cutter is designed again. According to the milling cutter and the design method, an aperture error caused by deformation since the cutter is affected by radial force in the spiral milling process is eliminated, finally, the measured aperture meets the accuracy requirement, the milling cutter can finish two-time milling of rough machining and finish the finish machining through one-time milling, and milling accuracy and machining efficiency are improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

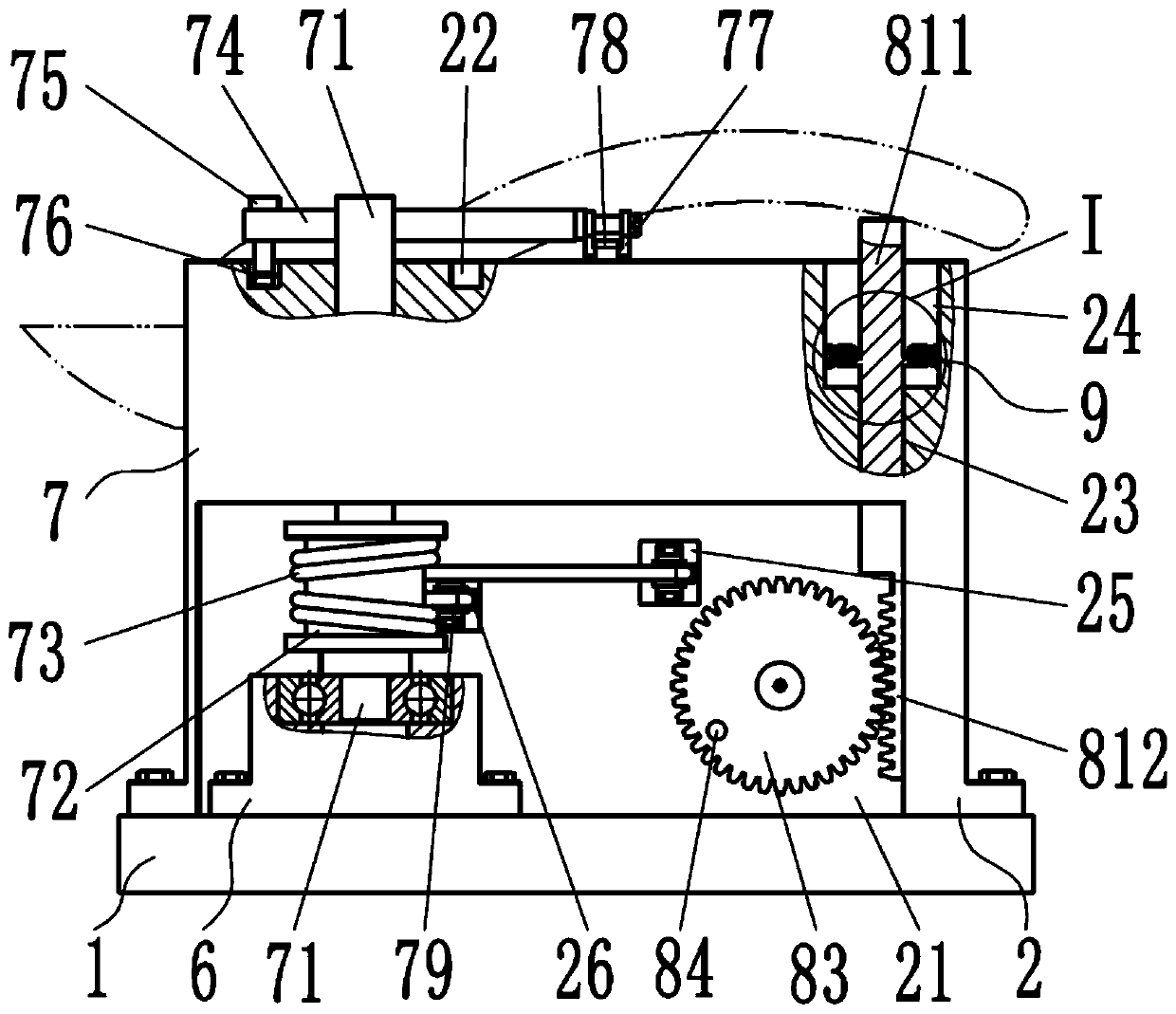

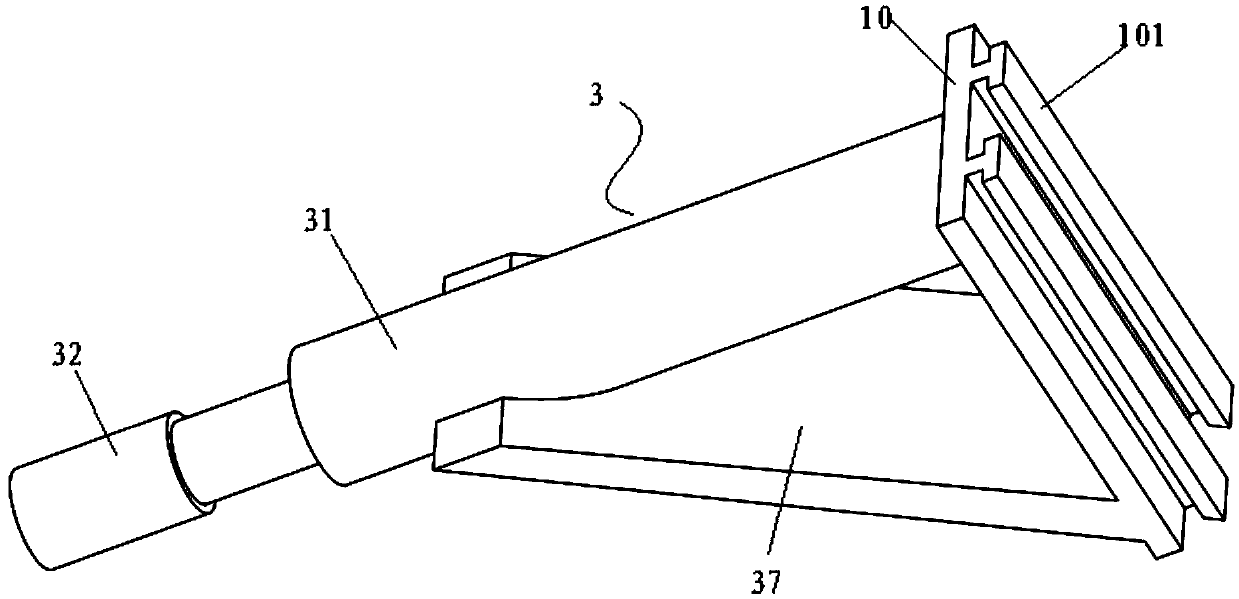

Spindle milling head extending device

InactiveCN109848446AHigh workpiece machining accuracyHigh precisionMilling equipment detailsDriving apparatusProcessing accuracyMachine tool

The invention relates to a machine tool processing device, in particular to a spindle milling head extending device which belongs to the technical field of machine tool processing. The machine tool processing device comprises a tank, wherein a spindle is arranged in the tank; the top part of the spindle is connected with an input shaft; the spindle is fixed to the bottom part of the tank through abearing gland and a spindle dustproof cover; a rotating deice is arranged at the top end of the input shaft; a planetary gear train is arranged in the input shaft; the rotating device is fixedly connected with the planetary gear train; the planetary gear train rotates to drive the input shaft to rotate; the input shaft drives the spindle to rotate through a spline connection manner; a lifting device is arranged at the connecting part of the spindle and the input shaft; and a broaching tool device is arranged in the spindle. The spindle milling head extending device provided by the invention has the beneficial effects that a workpiece is full-automatically processed, so that the workpiece processing accuracy is high, the processing requirement on different processing workpieces can be met,meanwhile, other parts of a machine tool have no need to be replaced, and only a broaching tool needs to be automatically loosened along with the function of an external force of a worm so as to be easily replaced.

Owner:威海鲁海精密机械有限公司

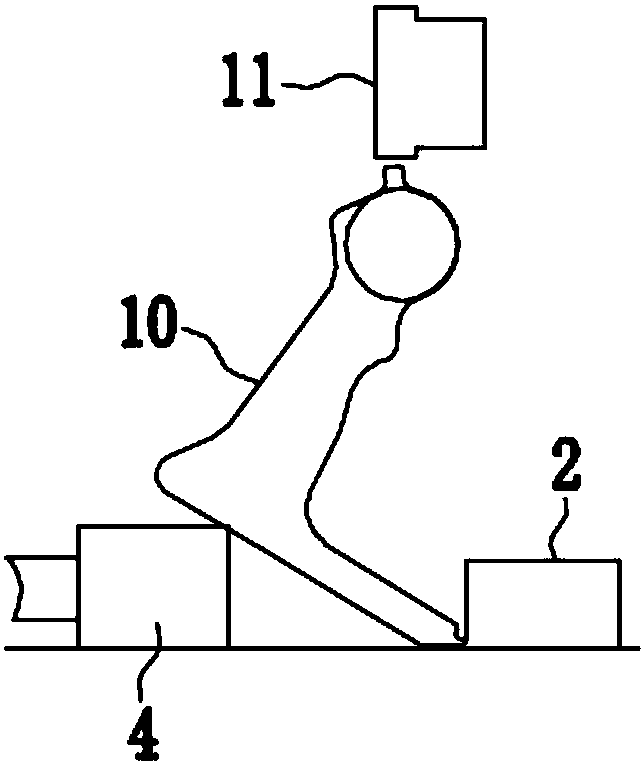

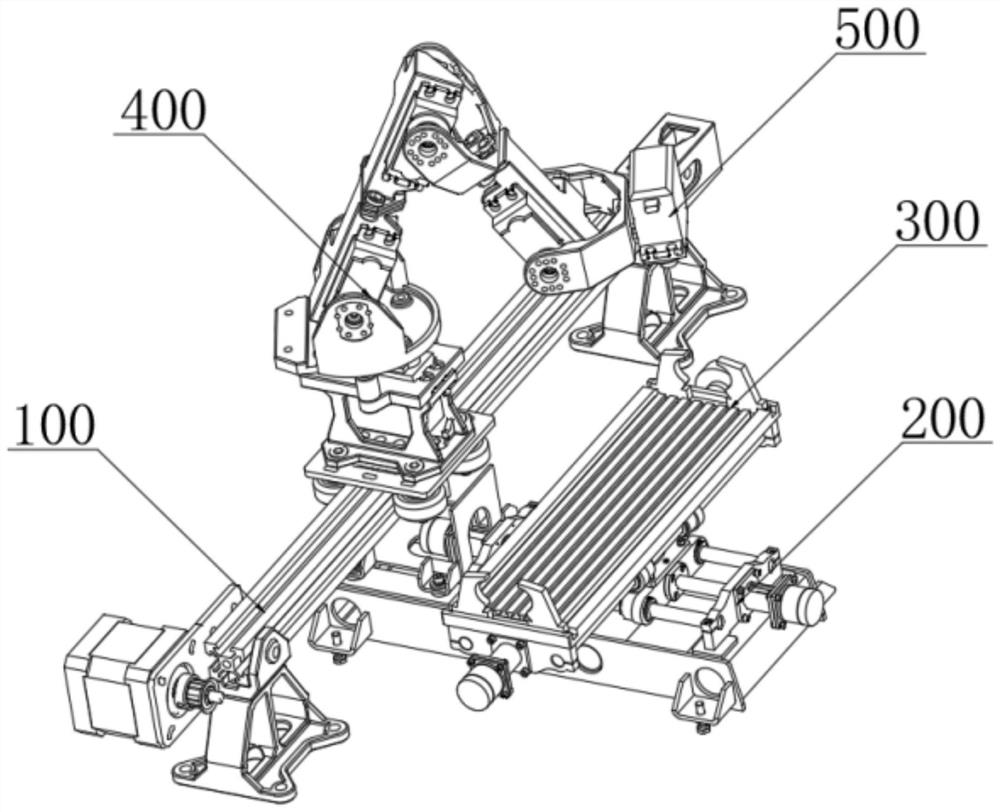

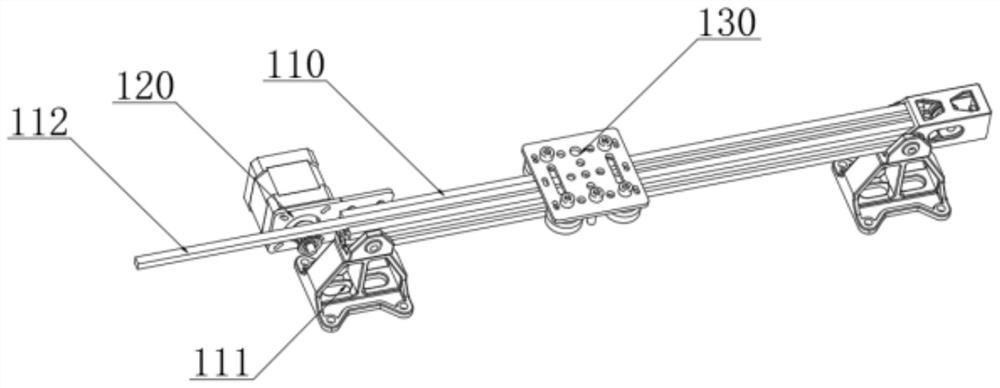

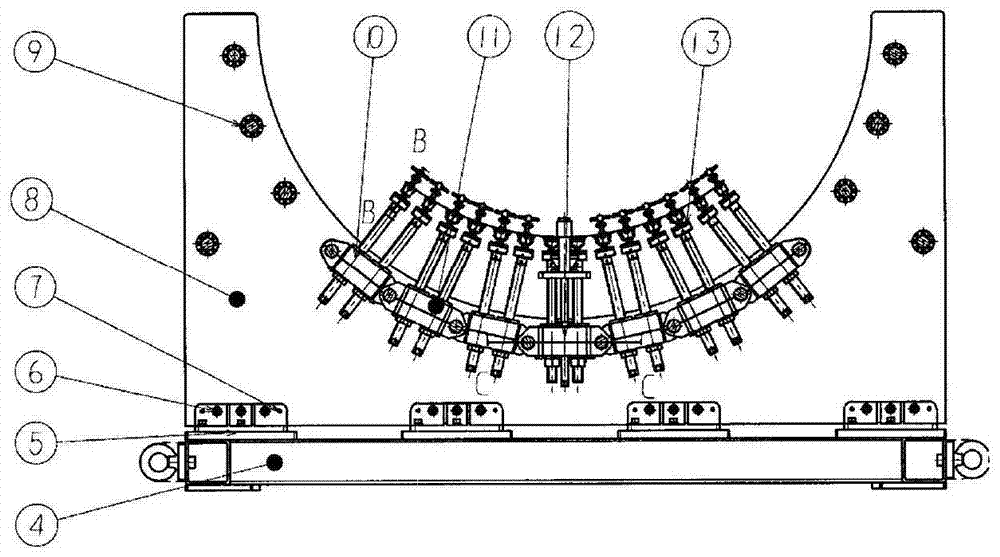

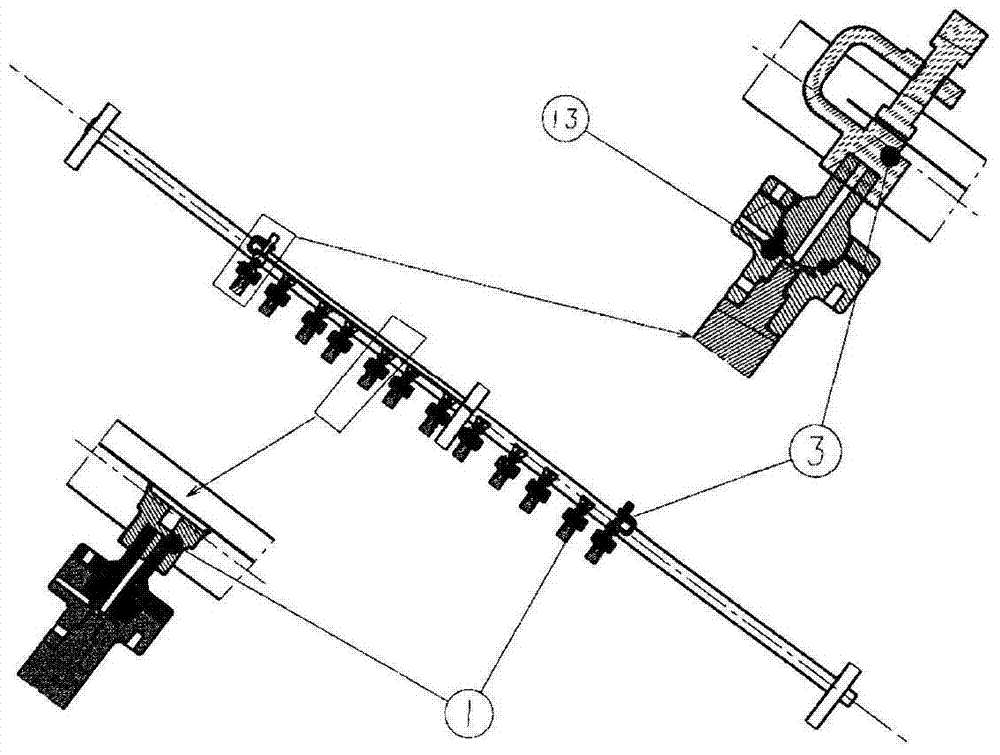

Full-automatic glass fiber reinforced plastic pipeline intersecting line milling device based on robot

PendingCN113787221AImprove unityImprove practicalityMilling equipment detailsGlass fiberPipe fitting

The invention discloses a full-automatic glass fiber reinforced plastic pipeline intersecting line milling device based on a robot. The device comprises a multi-axis movement mechanism, a milling machine head for milling and cutting, a transverse-axis movement mechanism, a pipe fitting movement mechanism and a pipe fitting rotating mechanism, the multi-axis movement mechanism is fixedly mounted on the surface of the transverse-axis movement mechanism, and the bottom surface of the pipe fitting rotating mechanism is fixedly connected with the output end of the pipe fitting movement mechanism. According to the device, a multi-axis connecting arm type milling machine head structure and a pipe fitting movement structure are arranged to carry out linkage type programming control; and the multi-axis movement mechanism and the pipe fitting movement mechanism are used for adjusting the milling dip angle of the milling machine head to conduct arc movement milling of an intersecting line milling face, the pipe fitting movement mechanism and the pipe fitting rotating mechanism are used for conducting movement deflection correction of the pipe fitting to adjust a milling contact face, and unification of the pipe fitting and the machine head is achieved. The milling precision is effectively improved, intersecting faces of different angles are milled, and the practicability of the milling robot is improved.

Owner:JIANGSU UNIV OF TECH

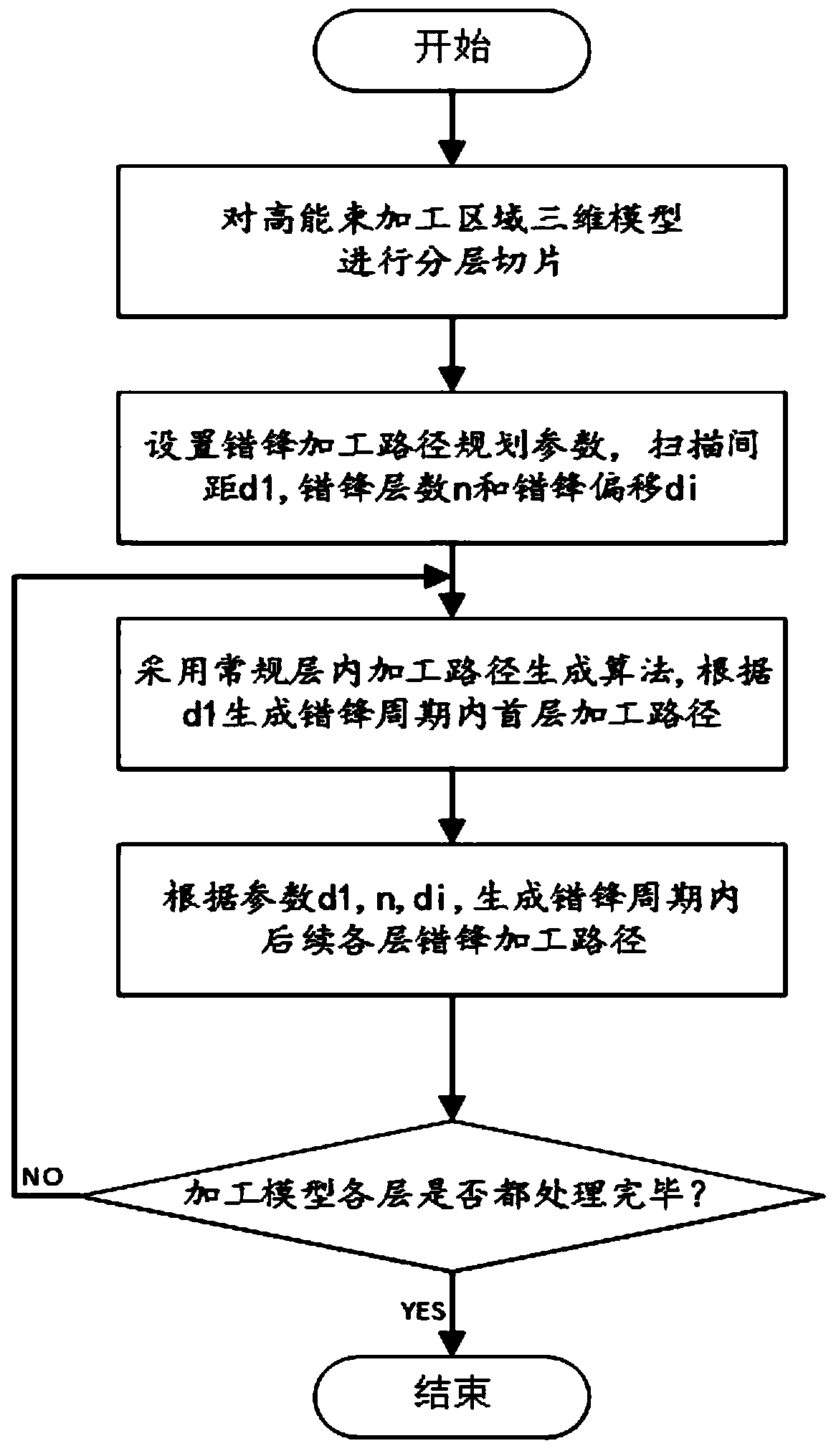

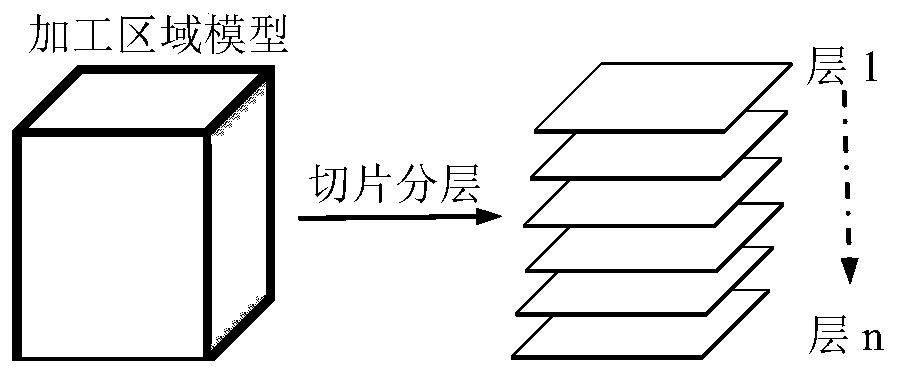

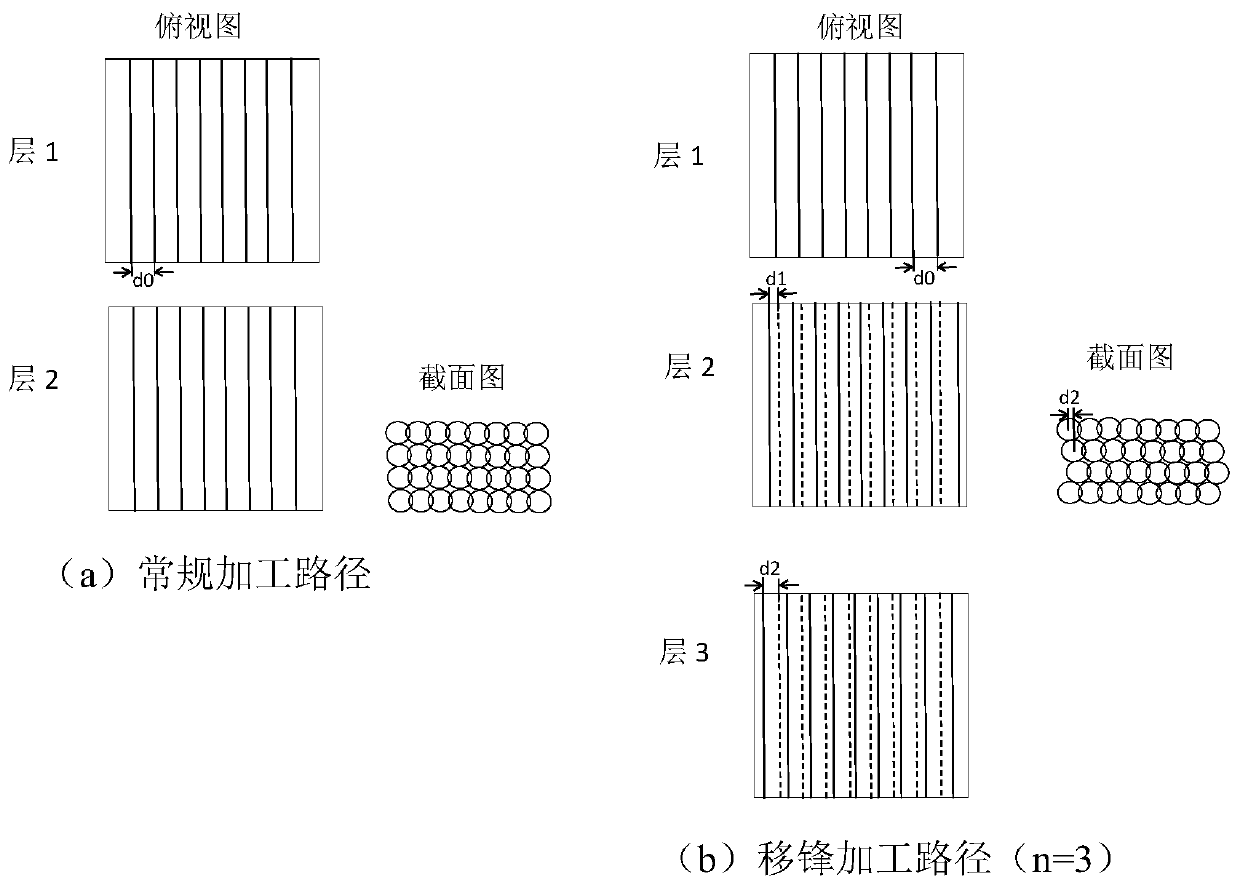

A Path Planning Method for High Energy Beam Moving Front Machining

ActiveCN108705224BImprove distribution uniformityImprove Organizational Performance ConsistencyWelding/cutting auxillary devicesAuxillary welding devicesHigh energyMachining process

The invention discloses a high-energy beam peak moving processing path planning method and belongs to the technical field of high-energy beam manufacturing. According to the high-energy beam peak moving processing path planning method, when filling scanning paths of various to-be-processed layers are generated, between the adjacent various layers, positions, highest in power, in the high-energy beam scanning paths mutually deviate by set amounts, and therefore energy distribution in the processing process is improved, and then the processing quality and precision in the additive manufacturingor subtractive manufacturing process are improved; the method includes the following steps that firstly, a processing model is subjected to layering; secondly, peak moving processing path planning parameters are set; thirdly, a processing path of a first layer in the peak moving period is generated; fourthly, processing paths of subsequent various layers in the peak moving period are generated; and fifthly, the step (3) and the step (4) are repeated till the processing paths of all the layers are generated. According to the method, by adjusting the center position deviation of the high-energybeam scanning paths of the adjacent processing layers, that is, a pointed peak is moved away, peak moving for short, energy density homogenization of processing of the plurality of layers is achieved,and the processing quality and precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Milling machine with disc brake base

InactiveCN101372049ARapid positioningQuick clampingMilling equipment detailsPositioning apparatusMilling cutterEngineering

The invention relates to a disk brake seat milling flat-bed machine which carries out planeness processing on a disk brake seat that is provided with a disk brake piece on a frame of a bicycle. The machine comprises a stander, a nose which is provided with a milling cutter, a worktable which is arranged below the nose; the worktable is movably arranged on the stander and is fixedly provided with an alcula permanent seat for fixing a disk brake seat and a projection for supporting the frame. The invention can fast locate and clamp the frame by fixing the disk brake seat and an across fork, which avoids the play of the frame when the disk brake seat is milled, and provides the milling cutter with abundant movement room, thus increasing the processing precision and the processing efficiency of the milling.

Owner:庄添财

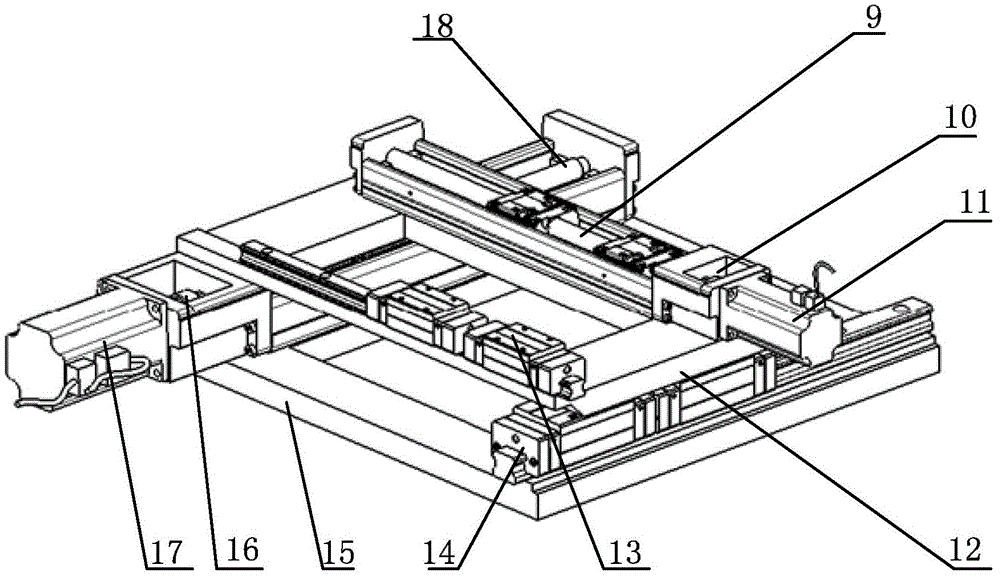

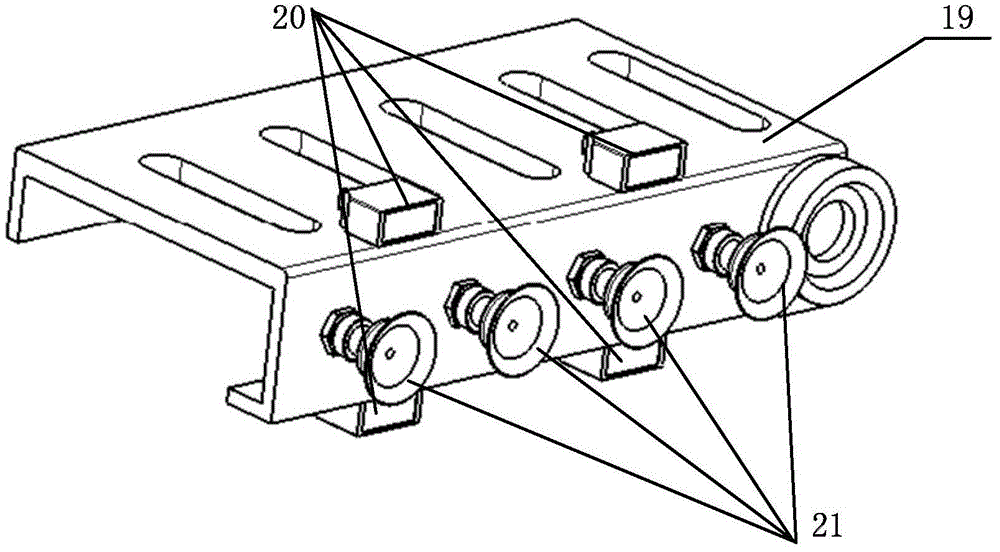

Aircraft skin automatic high-precision edge milling device and edge milling method

ActiveCN104999122BNo incision skewSmall amount of deformationAutomatic control devicesWorkpiecesNumerical controlAutomatic control

The invention relates to an automatic high-precision edge milling device and method for an aircraft skin. Point position alignment, normal leveling, flexible clamping, trajectory planning of a milling cutter, numerical control code generation and other functions on a region to be milled are achieved in an automatic control mode, and accordingly the size precision, normal precision and notch roughness of the skin are guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

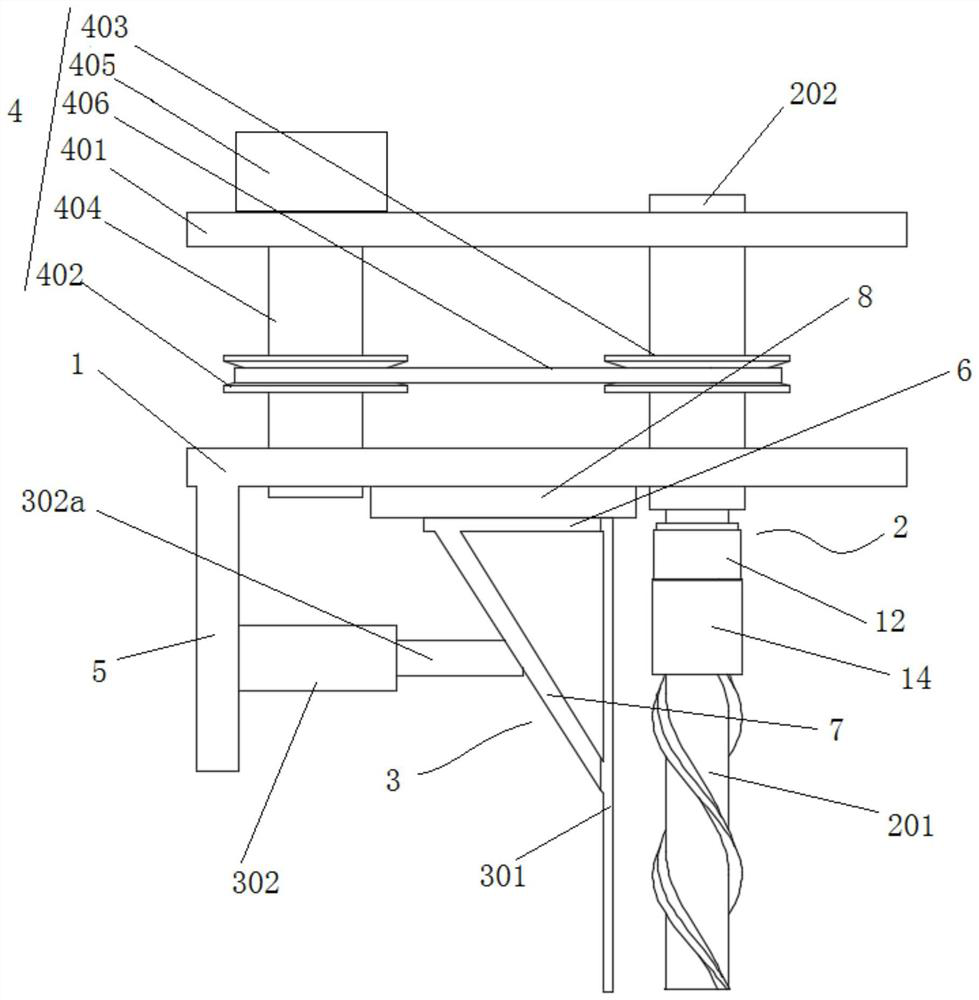

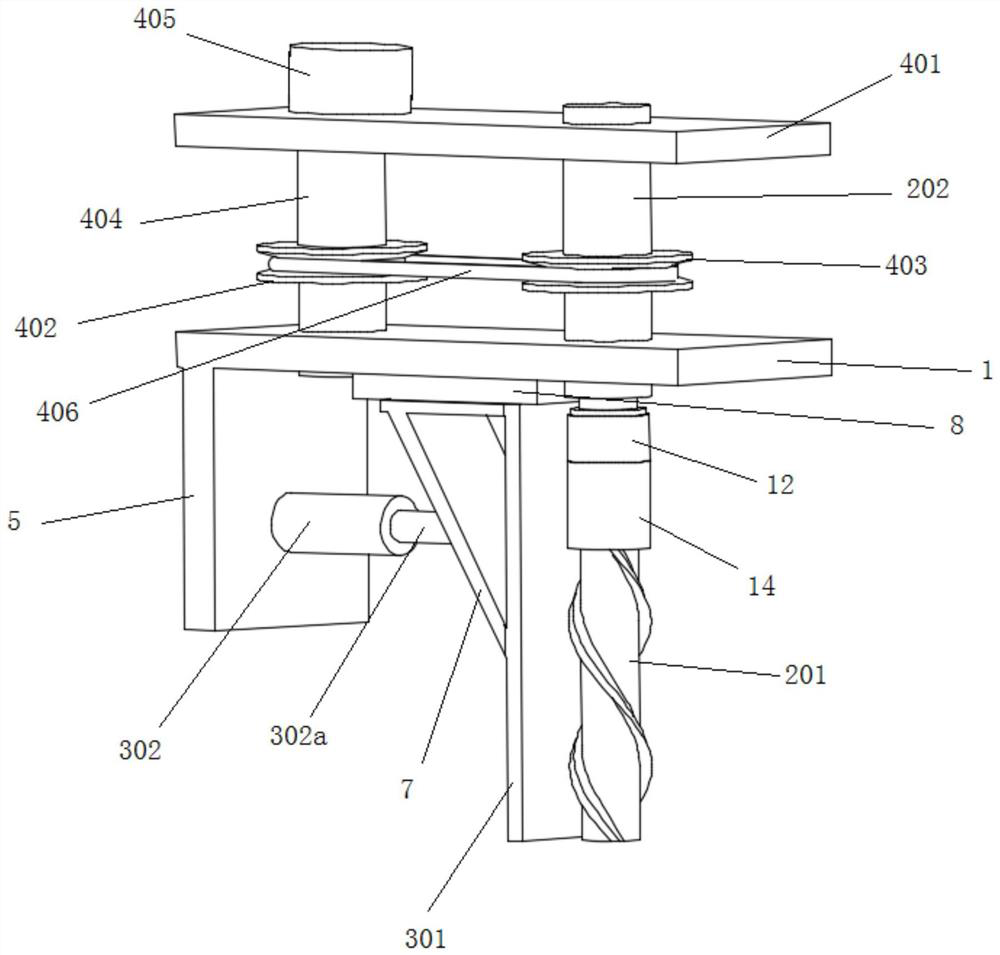

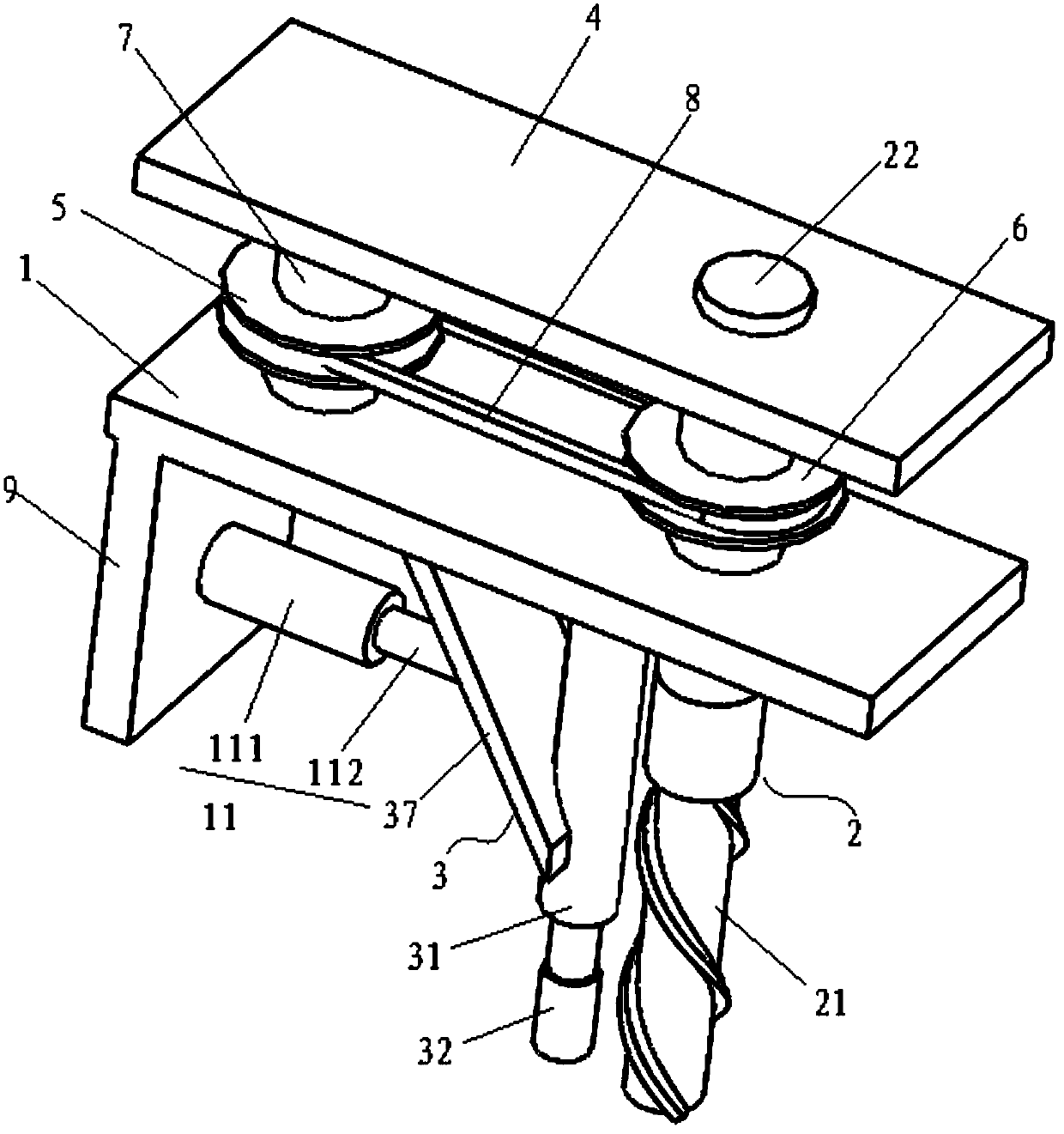

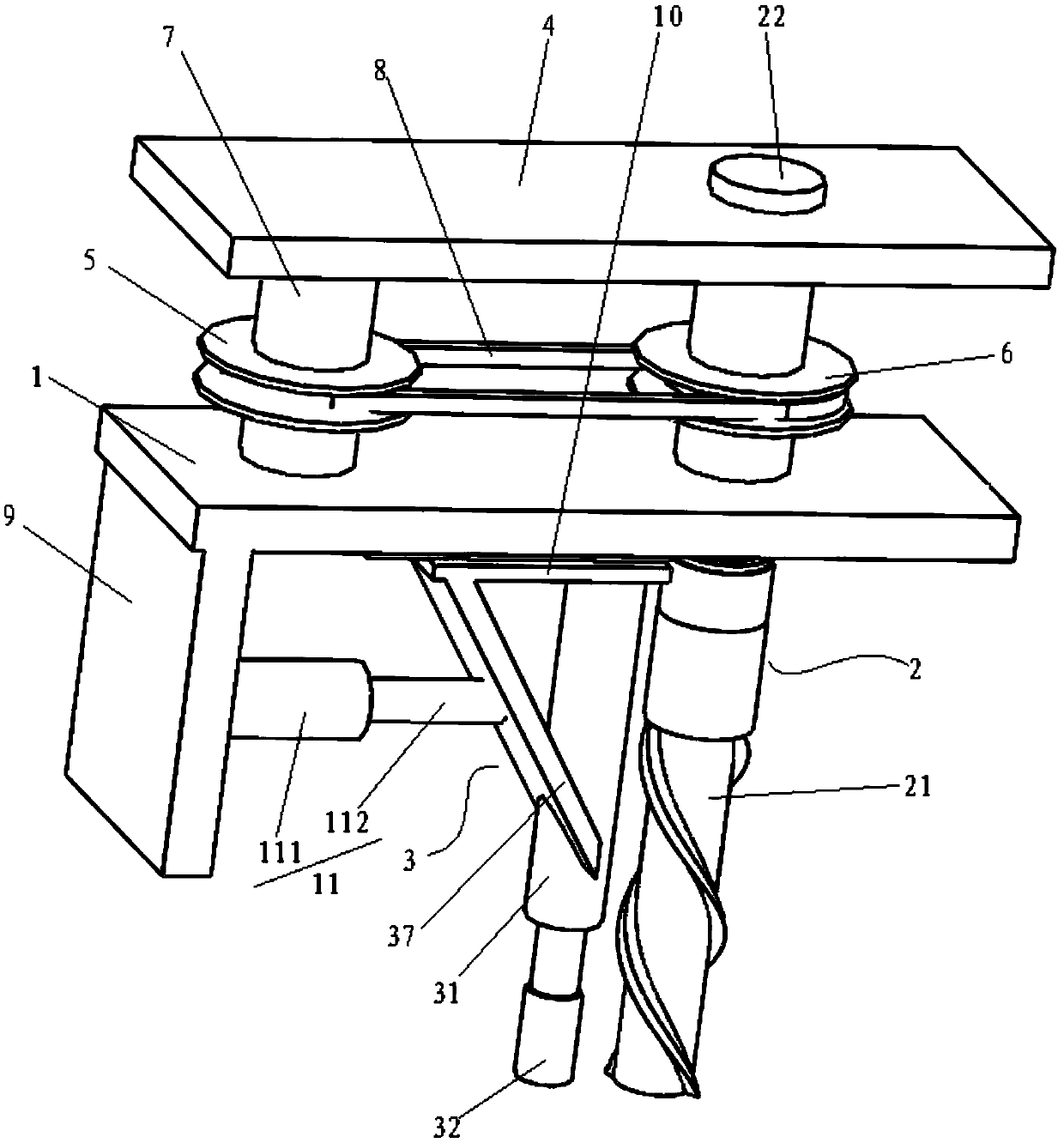

A milling device with anti-deformation function of tiny thin wall

ActiveCN109759629BAvoid deformationImprove milling accuracyMilling equipment detailsMilling cutterThin walled

The invention discloses a milling device with a micro thin-wall anti-deformation function, which relates to the technical field of precision machining. The invention comprises a first mounting plate, a milling mechanism and an anti-deformation component; the first mounting plate is slidably arranged; the milling mechanism includes a milling cutter and a rotating shaft; Installed on one end of the rotating shaft, and the central axis of the milling cutter is on the same line as the central line of the rotating shaft; the anti-deformation component includes a baffle and a cylinder; the upper end of the baffle is slidingly connected with the lower surface of the first mounting plate; the baffle is located on the rotating shaft One side of the baffle; the surface where the baffle is located is parallel to the centerline of the rotating shaft. In the present invention, an anti-deformation assembly is arranged on the first mounting plate. During milling, the anti-deformation assembly is placed against the side of the tiny thin-walled member away from the milling mechanism; Lateral force can prevent deformation during milling, thereby improving milling accuracy.

Owner:SHANDONG JIANZHU UNIV

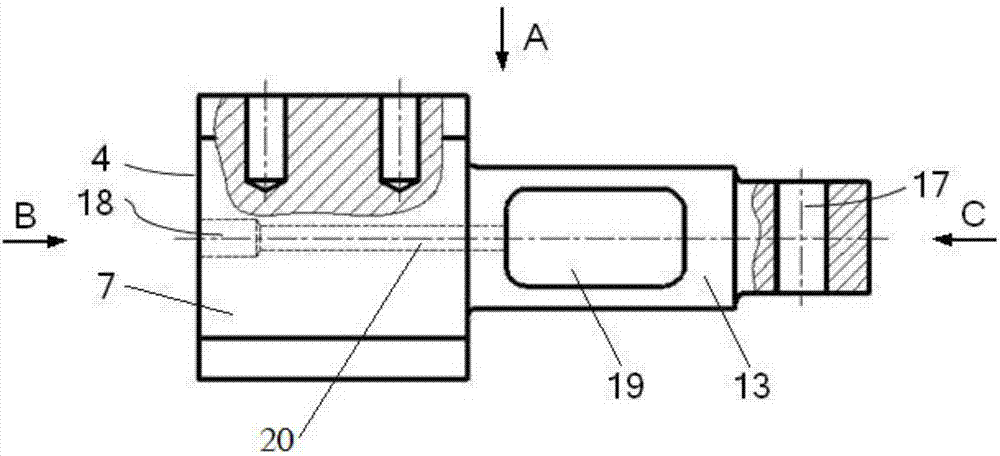

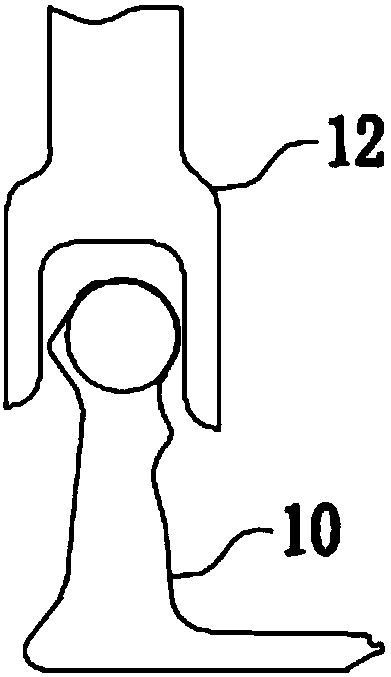

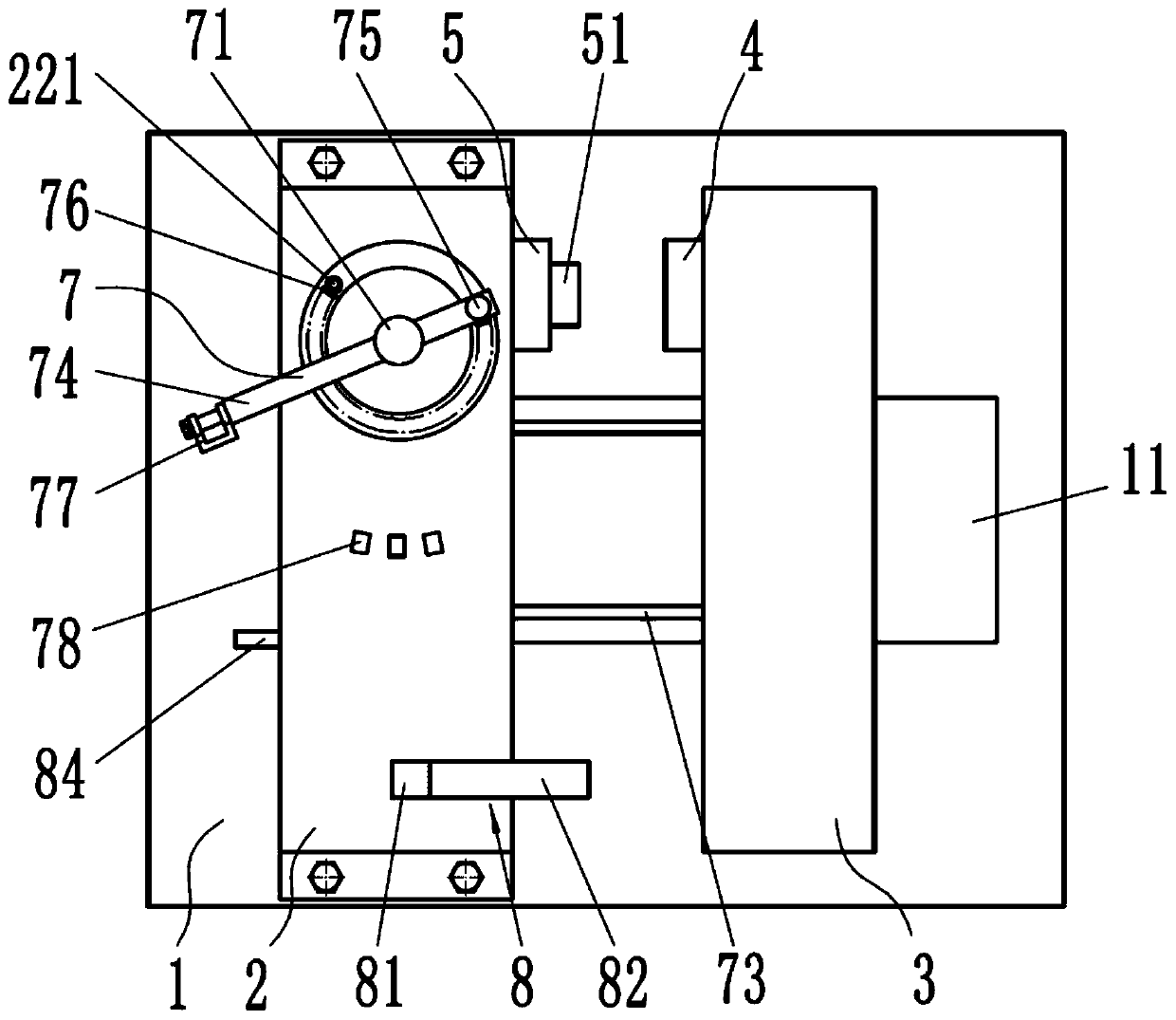

A milling equipment for inner and outer cutting edges of diagonal pliers

ActiveCN109226843BImprove milling accuracyWill not affect processingLarge fixed membersMilling equipment detailsLocking mechanismEngineering

The invention discloses a device for milling inner and outer cutting edges of diagonal cutting pliers. The device comprises a machine body and an operation table, wherein a clamp assembly used for clamping plier bodies of the diagonal cutting pliers is arranged on the operation table; the clamp assembly comprises a bottom plate, a fixed clamping block, a movable clamping block, a driving mechanismand an adjusting mechanism; the bottom plate is arranged on the operation table; the fixed clamping block is arranged on the bottom plate; a fixed clamping head is arranged on the fixed clamping block; the movable clamping block is in sliding connection with the bottom plate; a movable clamping head is arranged on the movable clamping block; the driving mechanism is arranged on the fixed clampingblock and comprises two ropes, a winding mechanism and a locking mechanism; one end of each rope is wound on the winding mechanism, and the other end of each rope is fixedly connected with the movable clamping block. Through adoption of the structure, the device is capable of effectively clamping the plier bodies of the diagonal cutting pliers and accurately positioning plier handles of the diagonal cutting pliers, so that the milling accuracy of the inner and outer cutting edges of the diagonal cutting pliers is improved.

Owner:WENZHOU POLYTECHNIC

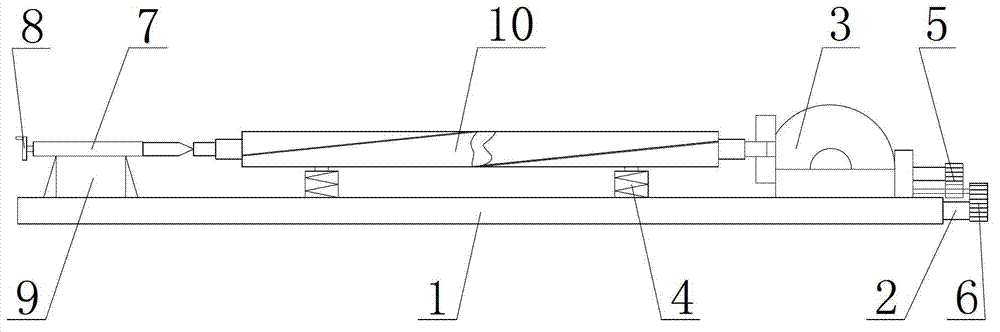

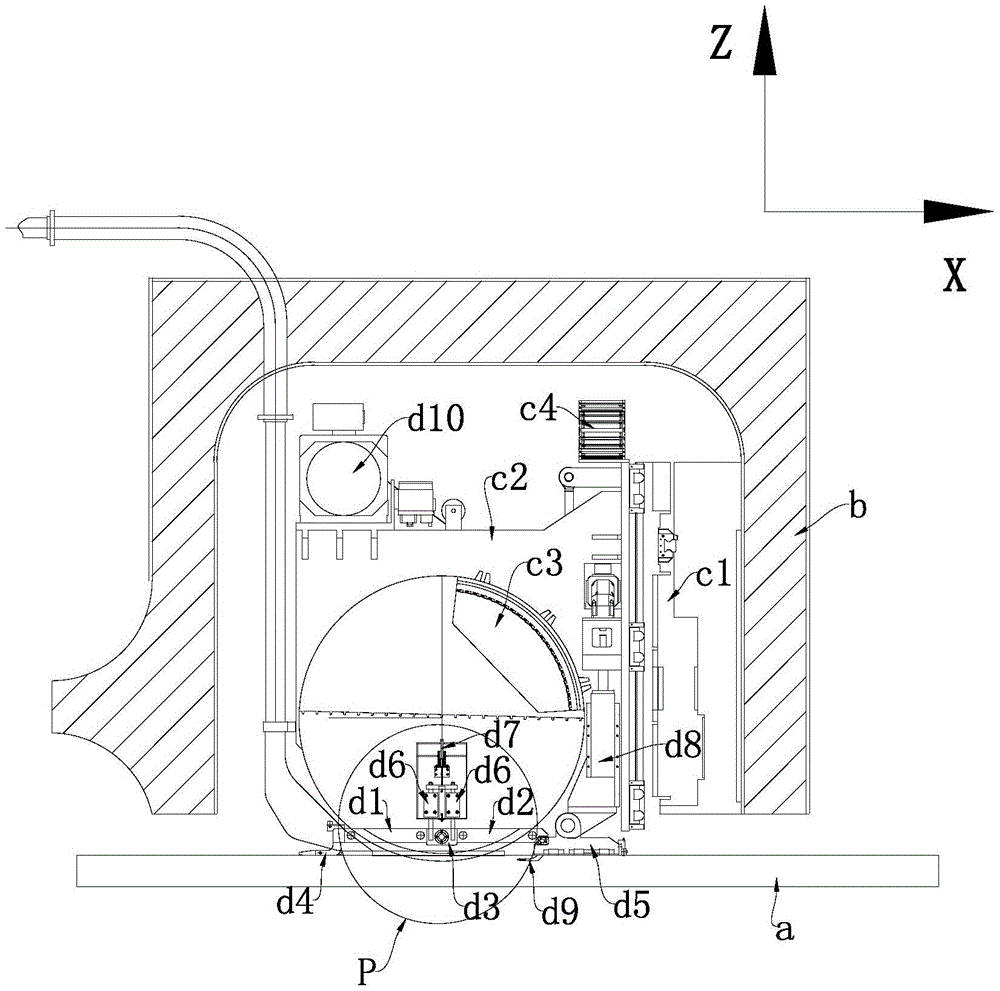

Control method of rail milling operation

ActiveCN105598513BImprove milling accuracyReduce generationFeeding apparatusMilling equipment detailsExecution unitEngineering

The invention provides a control method of a steel rail milling work and relates to a method for repairing a steel rail, aiming at providing the control method of the steel rail milling work, which has high milling precision and high milling efficiency, little pollution and low energy consumption. The control method comprises the following steps: S1: acquiring steel rail outline parameters; S2: carrying out tool setting; S3: initializing an auxiliary positioning device; and S4: carrying out the milling work, and starting a main shaft motor and a vehicle body. Under the driving of the vehicle body, a steel rail milling system moves at a constant speed along the direction of the steel rail, a right contact piece and a left contact piece are controlled to be in contact with the upper surface of the steel rail, and a lateral contact piece is controlled to be in contact with the lateral surface of the steel rail; a Z-directional sensor is used for measuring the height of a cutter disc in the Z direction in real time; a Y-directional sensor is used for measuring the distance between a finger tip of the lateral contact piece and the cutter disc in the Y direction in real time, so that a road condition is judged in real time; and furthermore, the cutter disc is continuously adjusted by a milling executing unit according to the road condition, and thus milling repairing of the steel rail is realized.

Owner:BEIJING TUOBOER TRACK MAINTENANCE TECH CO LTD

A flexible tooling for milling and cutting aircraft skin without margin and its use method

ActiveCN105290841BSimple structureLow costWorkpiecesMilling equipment detailsExtensibilityLocking mechanism

The invention discloses an aircraft skin no-allowance milling flexible tool. Multiple double-rod support units, multiple four-rod support units and multiple reference support units are arranged on a tool frame; bulb locking mechanisms are mounted on the double-rod support units and the four-rod support units; suckers or edge clampers are mounted on the bulb locking mechanisms; machining zero adaptors and assembly hole adaptors are arranged on the reference support units; the tool frame has a base; a connecting bracket is arranged on the base; a random support plate is arranged on the connecting bracket; multiple mounting holes are formed in the random support plate; expansion sleeves are mounted in the mounting holes; connecting rods are inserted in the coaxial mounting holes, and are locked through the expansion sleeves, so that the connecting rods and the random support plate are fastened; and the double-rod support units, the four-rod support units or the reference support units are mounted on the connecting rods. The aircraft skin no-allowance milling flexible tool has the advantages of simple structure, low cost, extensibility of modular structure, high clamping rigidity of thin-wall skin and convenience for application and promotion.

Owner:SHENYANG AIRCRAFT CORP

Milling device for tiny curved impellers under mesoscopic scale

ActiveCN109570585AAvoid deformationImprove milling accuracyMilling equipment detailsImpellerMilling cutter

The invention discloses a milling device for tiny curved impellers under the mesoscopic scale. The device comprises a first mounting board, a milling assembly and an anti-deforming assembly; the firstmounting board is arranged in a sliding mode; the milling assembly comprises a milling cutter and a rotary shaft; the rotary shaft is rotationally installed on the first mounting board; the rotary shaft and a drive device are in transmission connection; the milling cutter is installed at one end of the rotary shaft; the middle axis of the milling cutter and the center line of the rotary shaft arelocated on the same straight line; the anti-deforming assembly comprises a push rod and a top barrel; one end of the push rod is connected with the first mounting board; the top barrel is rotationally arranged at the other end of the push rod in a sleeving mode; the middle axis of the push rod and the middle axis of the milling cutter are parallel; and when the top barrel is used for forming tinythin-walled parts, the top barrel and the milling cutter abut against the tiny thin-walled parts from the two sides. The milling device can prevent the tiny thin-walled parts from deforming in the milling process.

Owner:SHANDONG JIANZHU UNIV

Machining Method of Hardened Tooth Surface of Medium Precision Large Modulus Cylindrical Gear

ActiveCN105436623BGood fixationImprove cutting rigidityGear teeth manufacturing toolsGear teethDynamic stiffnessHelical line

A method for processing a hard tooth surface of a medium-precision large-modulus cylindrical gear is characterized in that a double-parameter non-instantaneous-pole enveloping method is carried out to perform tooth surface generating enveloping and hard milling, namely, a cutter is used for performing weft enveloping along the circumference contour direction of the gear and then performing warp enveloping along a helical line direction of the tooth surface of the gear. According to the method, a large-diameter disc milling cutter, which is provided with a large-space chip storing groove and is high in cutting stiffness and convenient and reliable in blade fixing manner, is utilized, so that a cutter disc is outstanding in comprehensive high-speed hard milling performance; a coated carbide blade is used for achieving high-speed hard milling of hardened steel; the form of the geometric structure of the blade can effectively improve the dynamic stiffness and thermal stiffness and can also reduce the influence of force and heat on a workpiece and the blade, and as a result, the durability of the blade can be improved.

Owner:NANJING GONGDA CNC TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com