Anti-fatigue efficient milling parameter optimization control method for titanium alloy thin-wall component

A thin-walled component, optimized control technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of poor surface integrity characteristics, low material removal rate, etc., to achieve good residual stress and improve material removal , to meet the effect of high reliability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

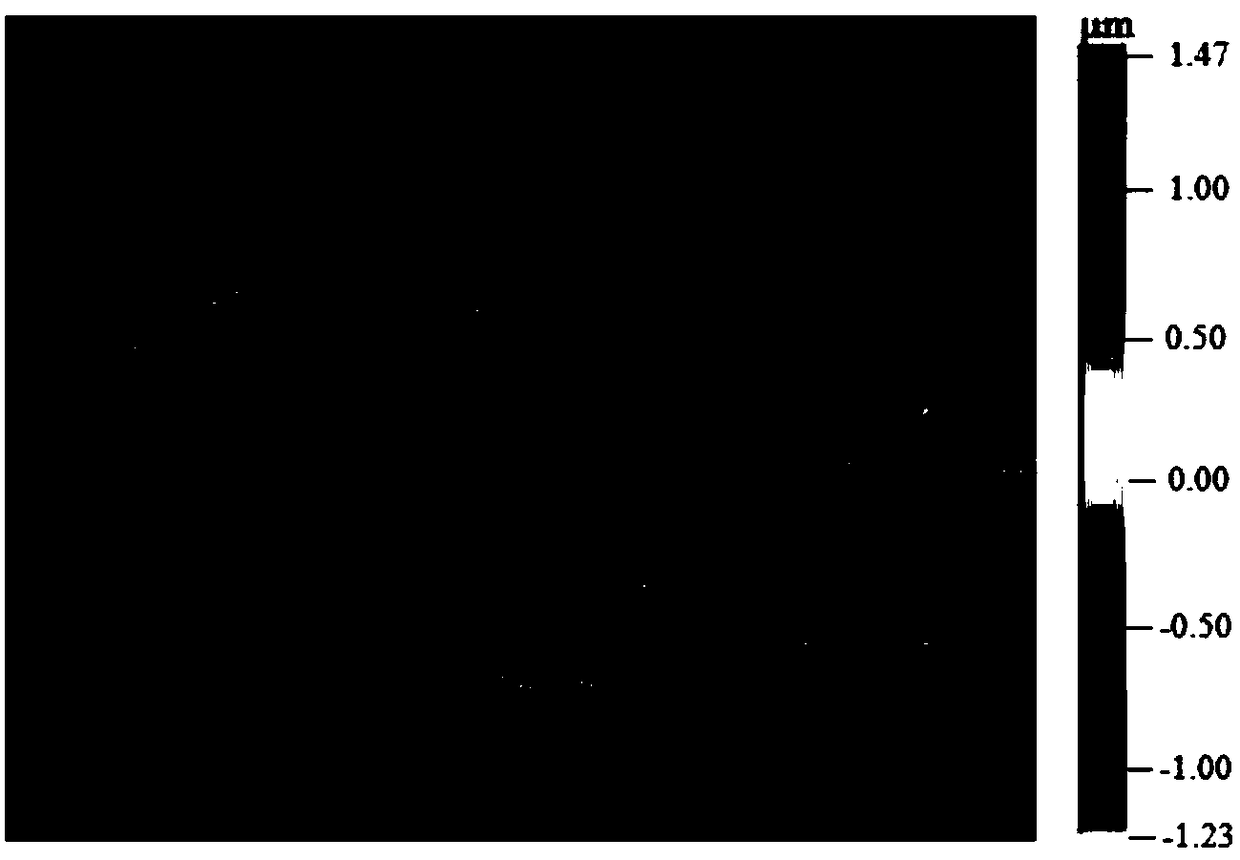

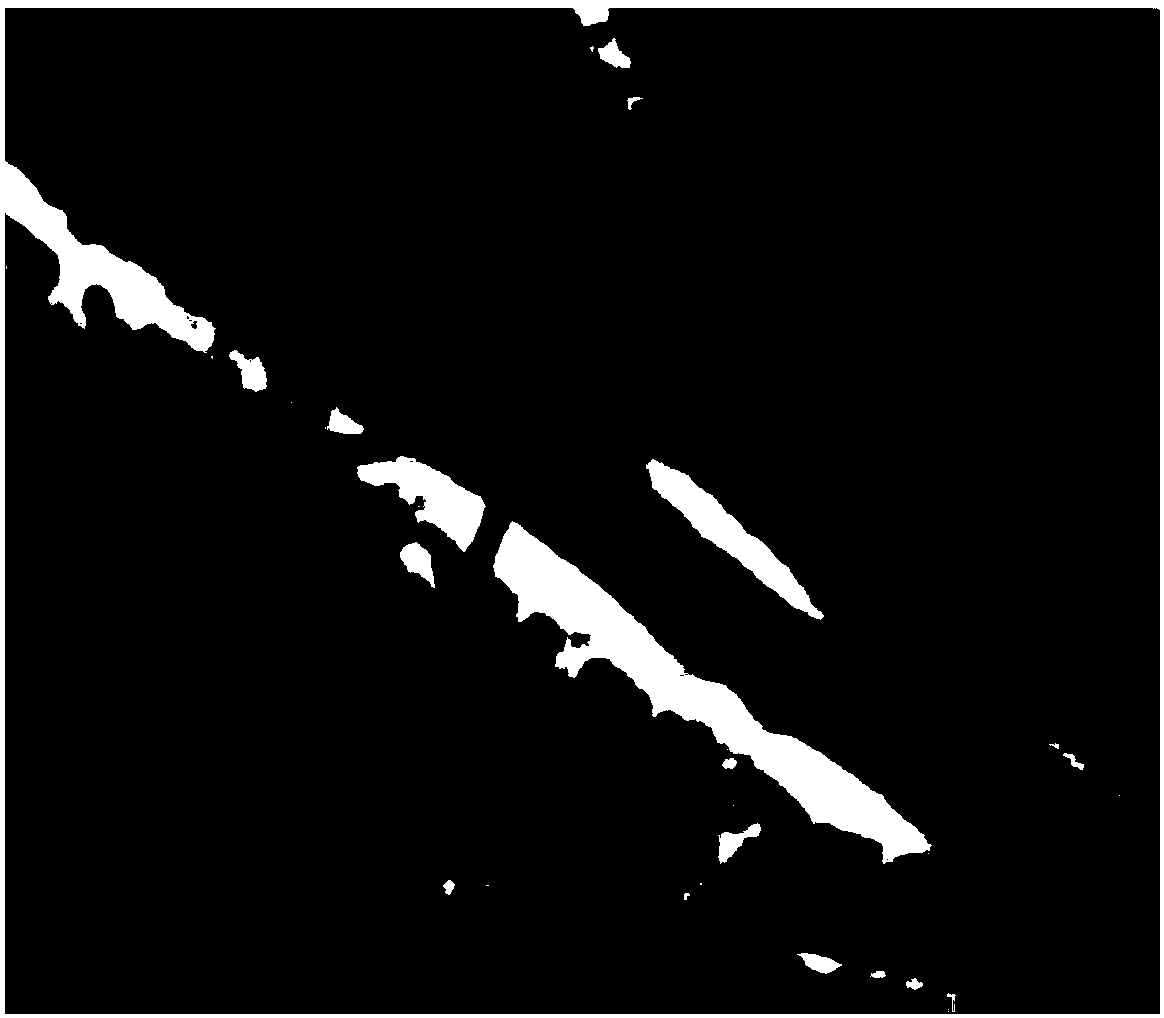

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The invention discloses a fatigue-resistant high-efficiency milling parameter optimization control method for titanium alloy thin-walled components, which specifically includes the following steps:

[0046] Step 1. Establish the primary selection milling process parameter domain of titanium alloy thin-walled components, and conduct an orthogonal test to measure the surface integrity parameters of the test components, and establish the relationship between the milling process parameters and surface integrity characteristics of titanium alloy thin-walled components, specifically Methods as below:

[0047] Step 1.1. Determine the primary milling process parameter domain for titanium alloy thin-walled components.

[0048] In this embodiment, Ti1023 titanium alloy is selected, and the surface integrity milling process parameter domain C is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com