Fixing device for workpiece edge-milling and specially-shaped workpiece edge-milling process

A technology for fixing devices and special-shaped workpieces, applied in positioning devices, clamping devices, metal processing machinery parts, etc., can solve the problems of inconvenient unloading and low processing efficiency, and achieve convenient operation, improved work efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

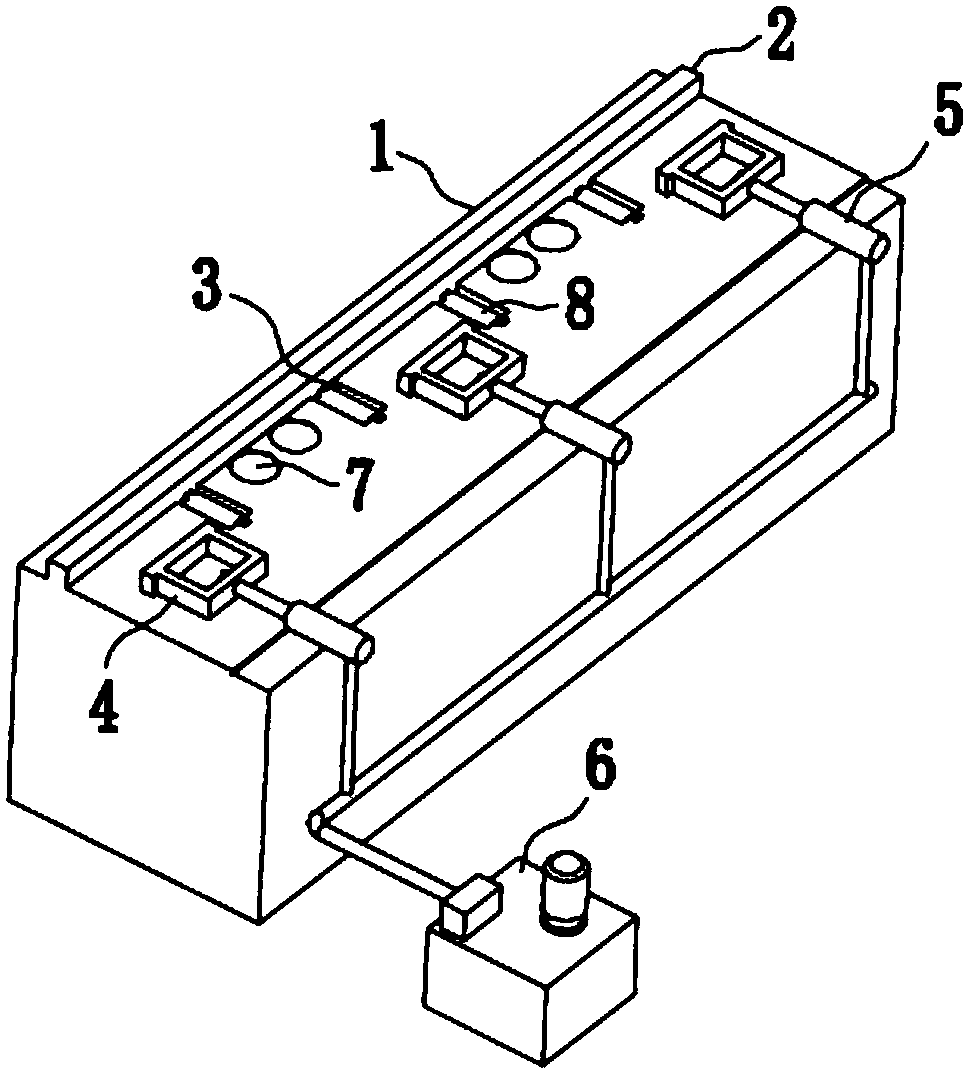

[0053] A fixture for workpiece edge milling, such as figure 1 As shown, it includes a fixed table 1 and a pressing device. The upper end surface of the fixed table 1 is horizontally fixed with a limit block 2. The bit blocks 2 are co-located front and back along the horizontal direction. The pressing device may be a pneumatic pressing device, a hydraulic pressing device, or a screw pressing device or the like. When the pressing device is a pneumatic pressing device or a hydraulic pressing device, the high pressure drives its movement output end to cooperate with the limiting block 2 to fix the workpiece. When the pressing device is a screw pressing device, the fixing of the workpiece can be realized by changing the screw-in length of the screw and cooperating with the limiting block 2 .

[0054] In a specific application, the workpiece to be processed is placed between the limit block 2 and the pressing device on the upper end surface of the fixed table 1, and the pressing d...

Embodiment 2

[0056] A fixture for workpiece edge milling in this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are as follows: figure 1 As shown, the compression device includes a compression block 4, a pressure transmission device 5 and a pressure supply device 6, and the pressure transmission device 5 is a pneumatic cylinder or a hydraulic cylinder, etc.; the pressure transmission device 5 is horizontally fixed on the fixed On the upper end surface of the table 1, the pressing block 4 is detachably connected to the output shaft of the pressure transmission device 5, and is set in cooperation with the limit block 2 in the horizontal direction. The pressing block 4 in this embodiment The connection mode between the block 4 and the pressure transmission device 5 is screw connection; the pressure supply device 6 is connected to the pressure transmission device 5 through a pipeline, and the pressure supply device 6 provides working pressure f...

Embodiment 3

[0061] A fixture for workpiece edge milling in this embodiment, the basic structure is the same as that of Embodiment 2, the differences and improvements are as follows: figure 1 As shown, the compression device includes a plurality of pressure transmission devices 5, and the output shaft of the pressure transmission device 5 can be detachably connected with the compression block 4. In this embodiment, the pressure transmission device 5 The connection between the output shaft and the pressing block 4 is screw connection; the pressure transmission devices 5 are evenly distributed along the length direction of the limiting block 2, and are all connected to the pressure supply device 6 through pipelines. A plurality of said pressing blocks 4 cooperate with said limiting blocks 2, and are fixed at multiple points along the length direction of the workpiece to be processed, and the distribution is uniform, the fixing effect is good, and the milling processing precision is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com