Movable double-robot automatic milling type intelligent flexible production line and running method thereof

A flexible production line and automatic milling technology, applied in the field of mechanical processing, can solve problems such as extended manufacturing cycle, low operating efficiency, and benchmark deviation, and achieve the effects of reducing production cycle and cost, increasing flexibility, and improving milling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

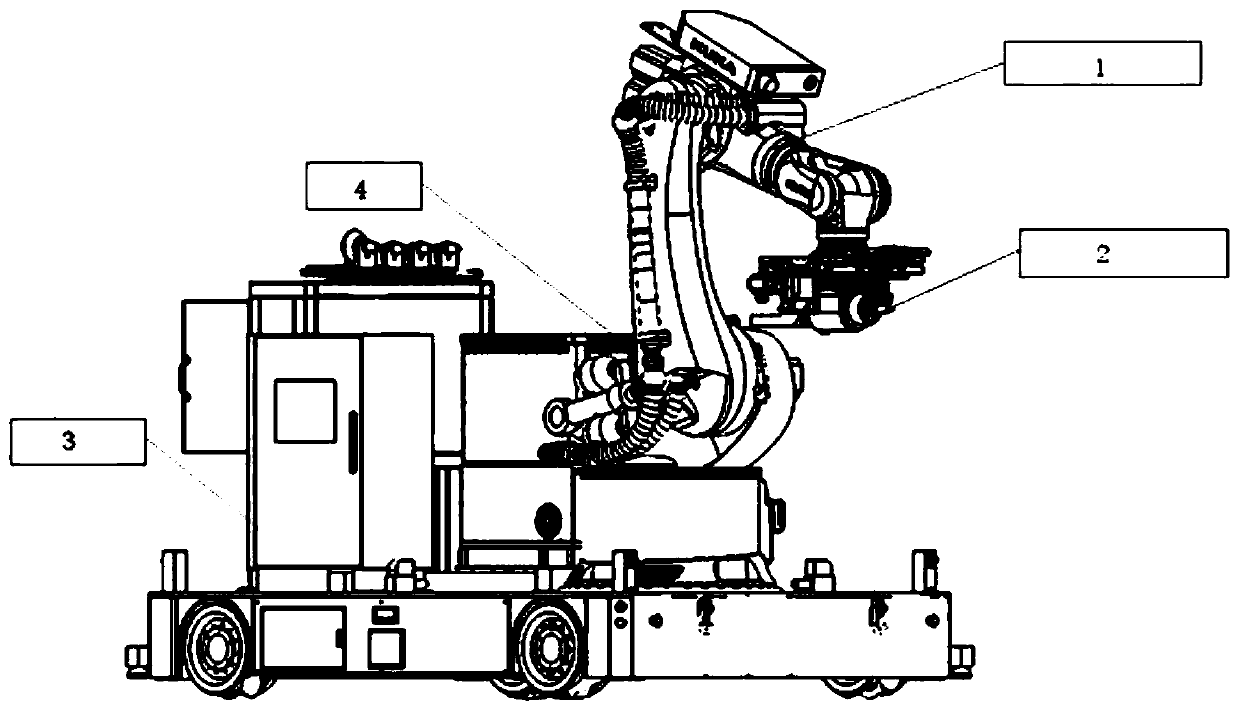

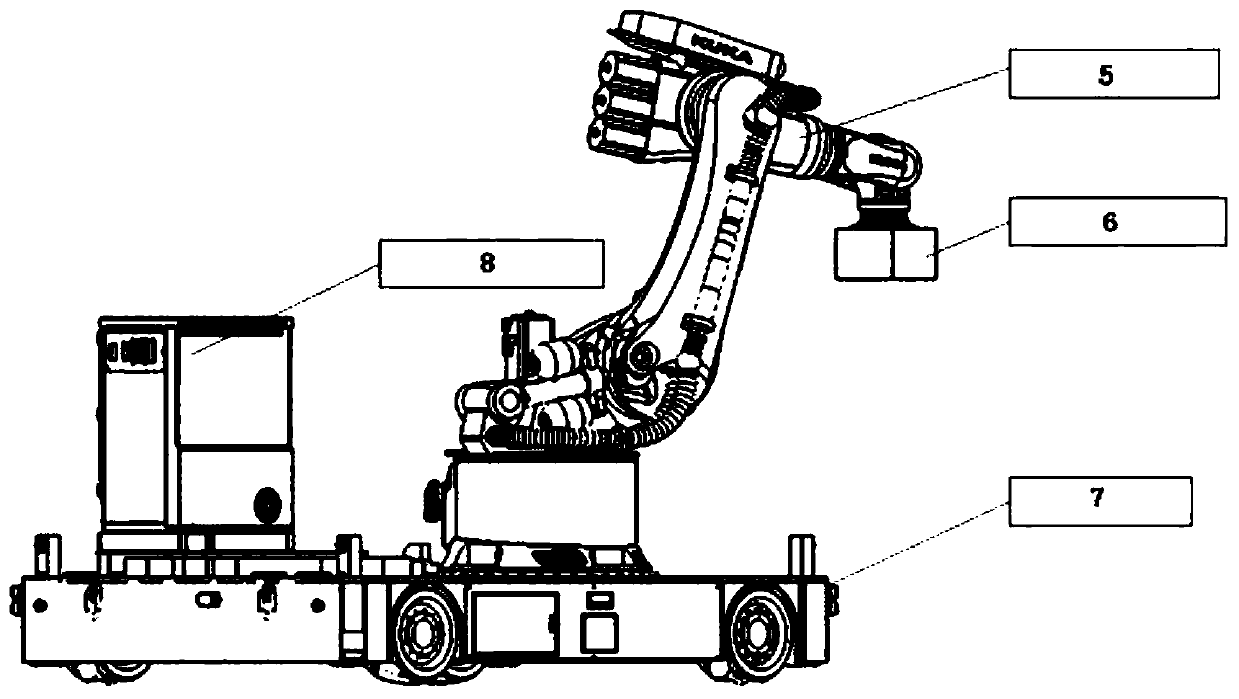

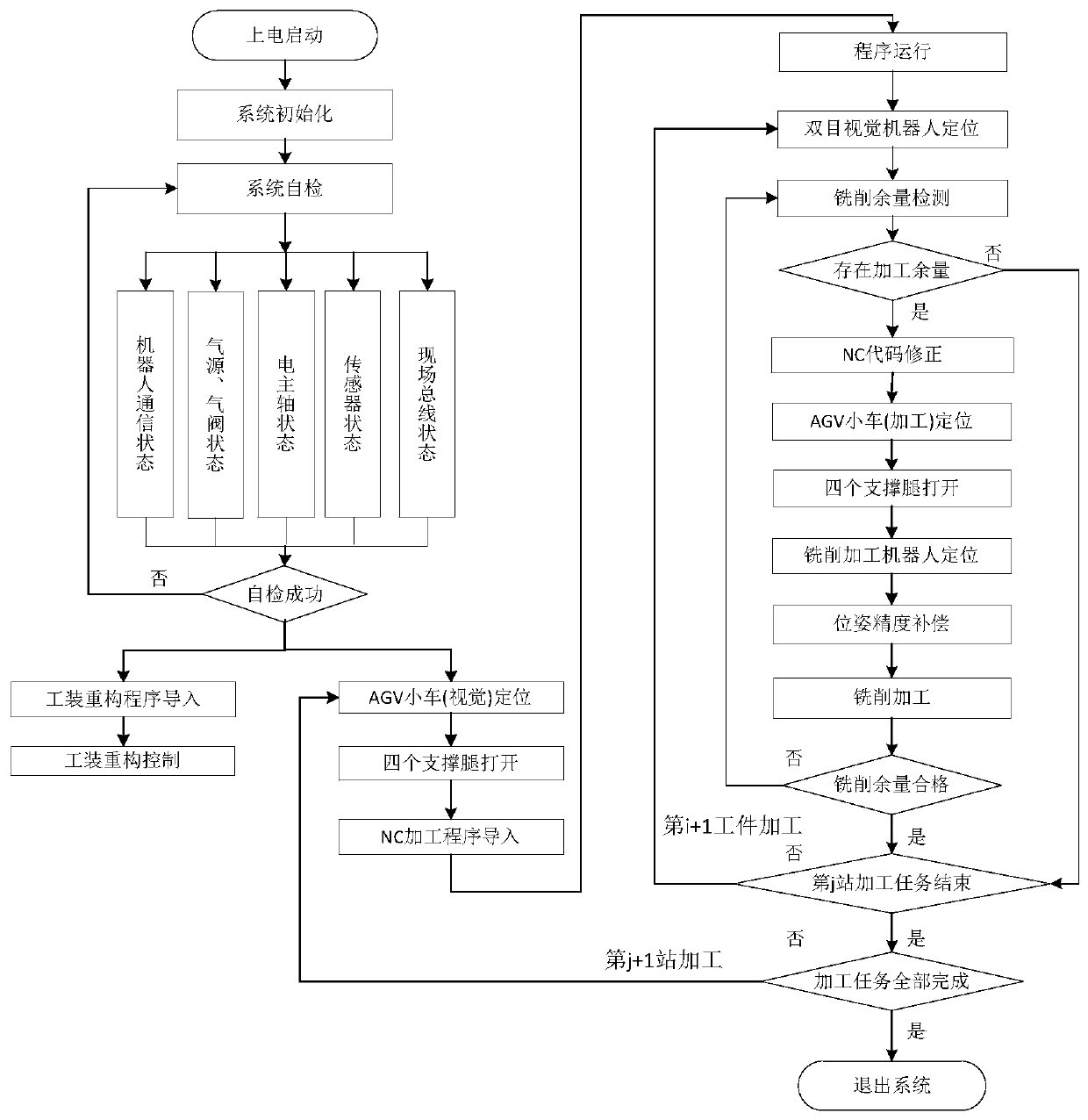

[0048] The present invention provides an intelligent flexible production line for automatic milling with movable double robots and its operation method. The components and processing flow of the production line are as follows: Figure 1 to Figure 3 As shown, the system can complete the spare parts detection and milling tasks. A binocular vision robot mounted on a free-moving platform can realize multi-station online detection tasks, and a milling robot can also be mounted on a free-moving platform to realize multi-station milling processing tasks. The two robots cooperate to complete the milling work, effectively improving the robot's work The flexibility of the robot expands the processing range of the robot, improves the efficiency of product processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com