Control method of rail milling operation

A control method and milling technology, applied in milling machine equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of high energy consumption, large environmental pollution, and high construction cost, and achieve the effect of protecting the environment, reducing dust effects, and improving milling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

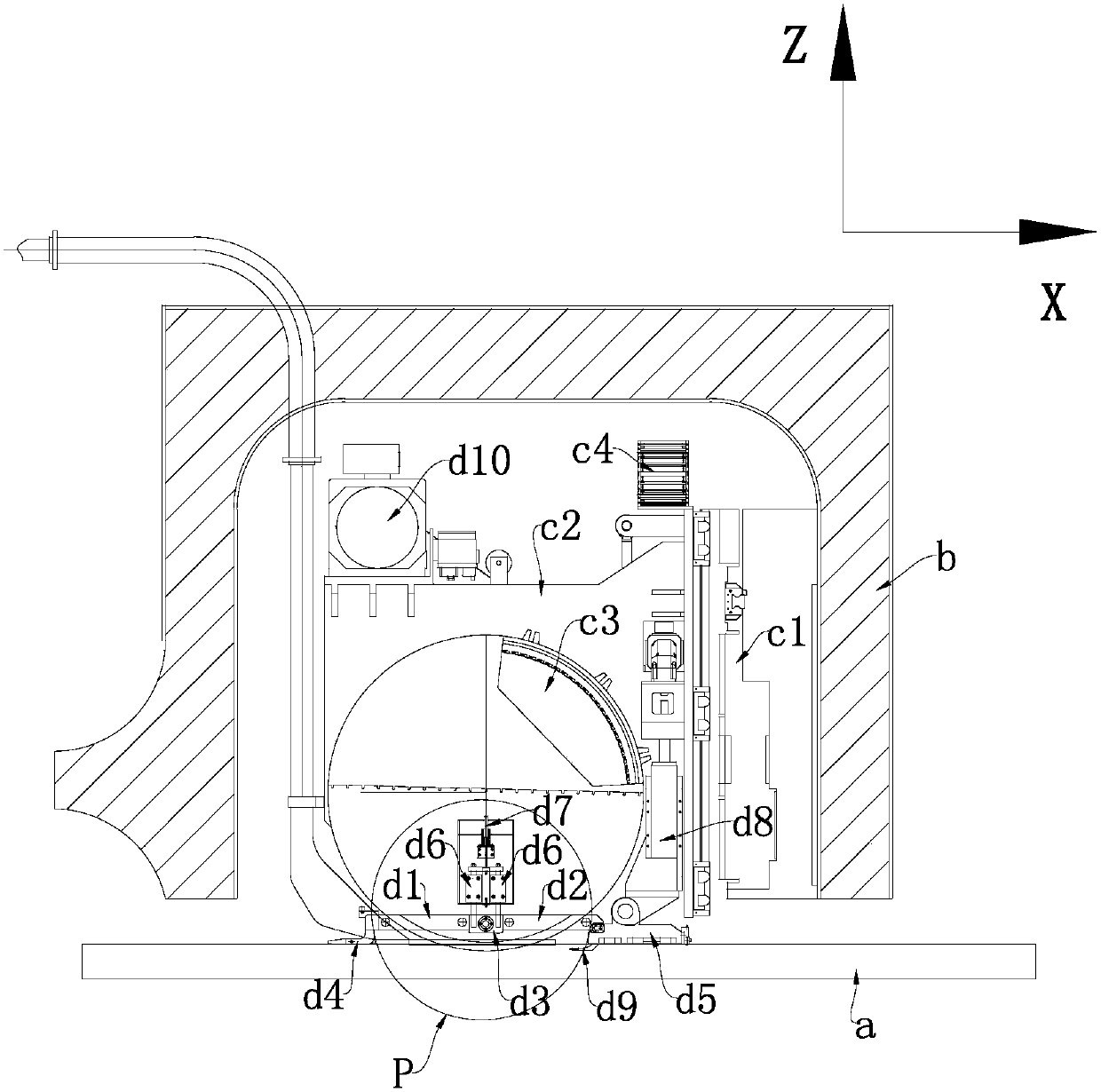

[0042] In order to illustrate the present invention more clearly, the following definitions are made: the direction along the length of the rail is defined as the X direction, the direction perpendicular to the side surface of the rail is defined as the Y direction, and the direction perpendicular to the upper surface of the rail is defined as the Z direction.

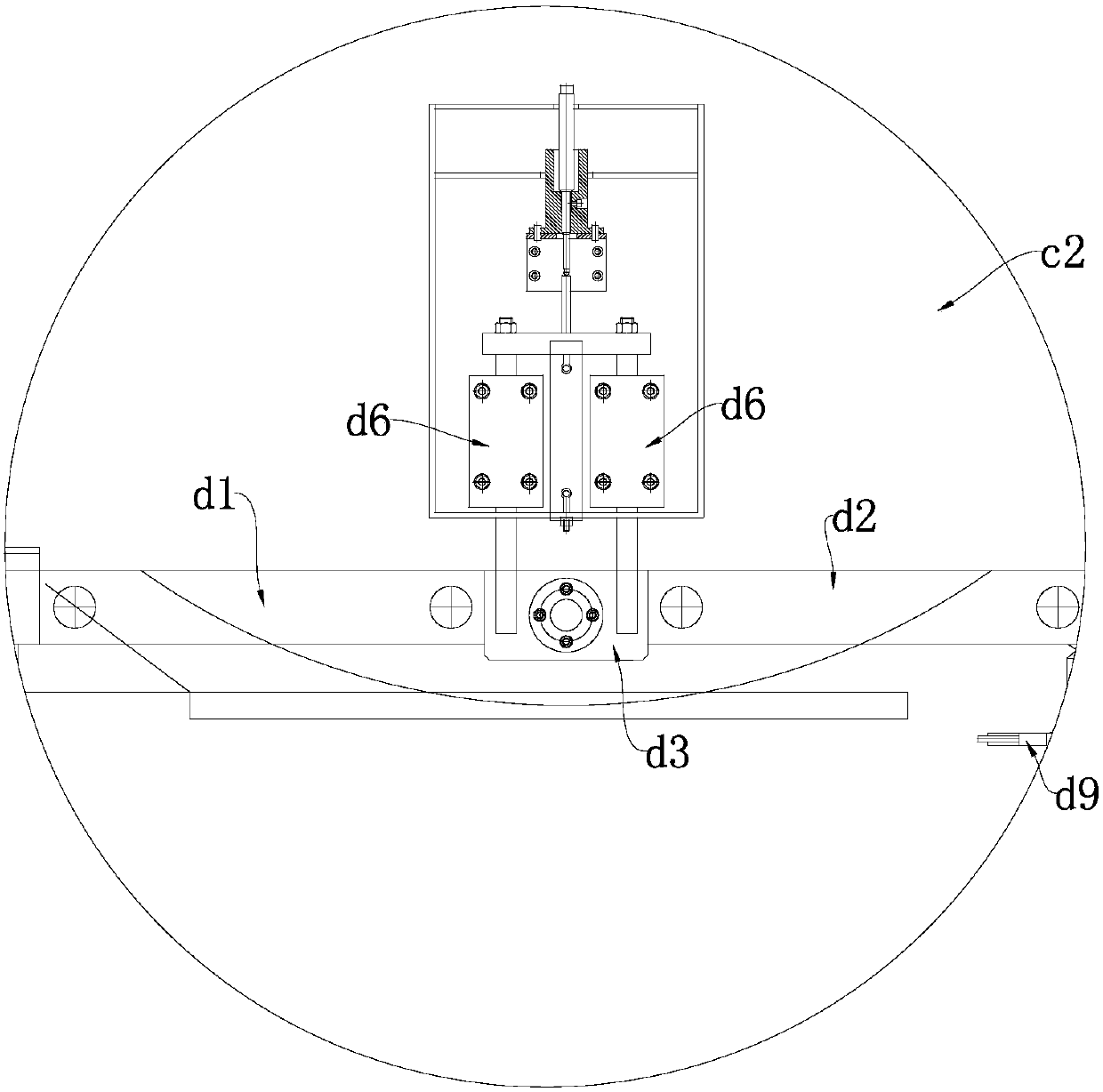

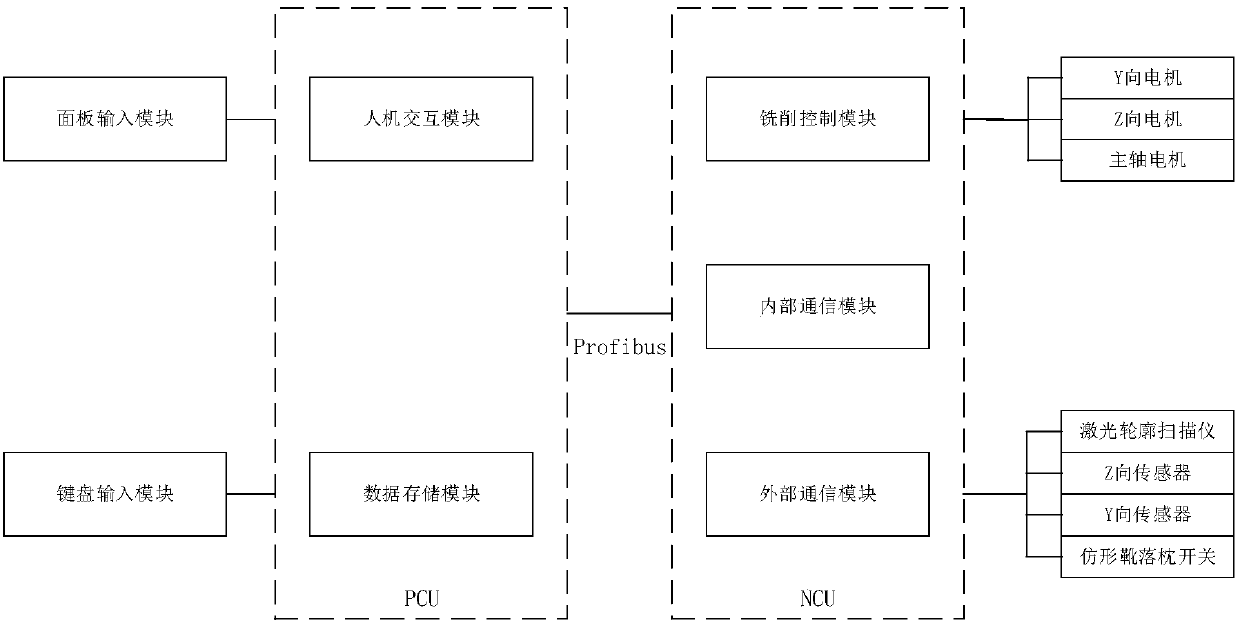

[0043] For the implementation of the present invention, a design such as Figure 1-2 The rail milling operation system shown; specifically, the rail milling operation system includes: a car body b, a milling execution unit and an auxiliary positioning unit.

[0044] The milling execution unit includes: a cross slide c1, a cutter head frame c2, a cutter head c3, a Y-direction motor (not shown in the figure), a Z-direction motor c4 and a spindle motor (not shown in the figure);

[0045] The fixed end of the cross slide c1 is fixedly arranged on the car body b, and the movable end is fixedly connected with the cutter head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com