Automatic high-precision edge milling device and method for aircraft skin

A technology of aircraft skin and edge milling device, which is applied to automatic control device, positioning device, milling machine equipment and other directions, can solve the problem of edge milling that does not solve different curvatures, cannot guarantee edge milling accuracy, etc. The effect of small deformation and improved edge milling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will now be further described in conjunction with the embodiments and drawings:

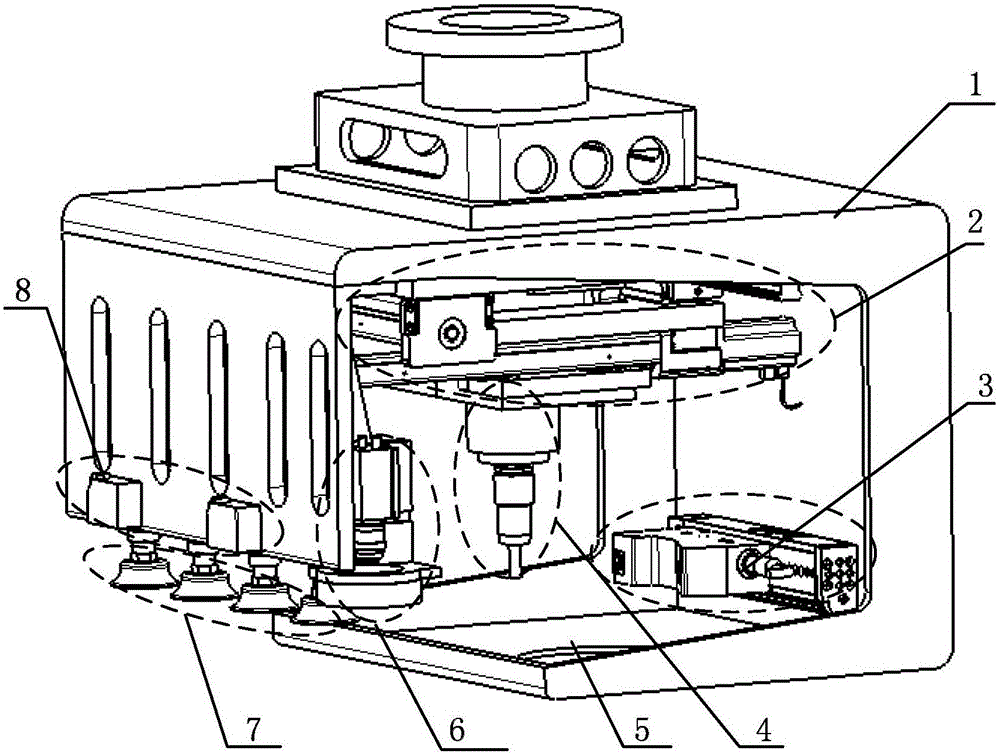

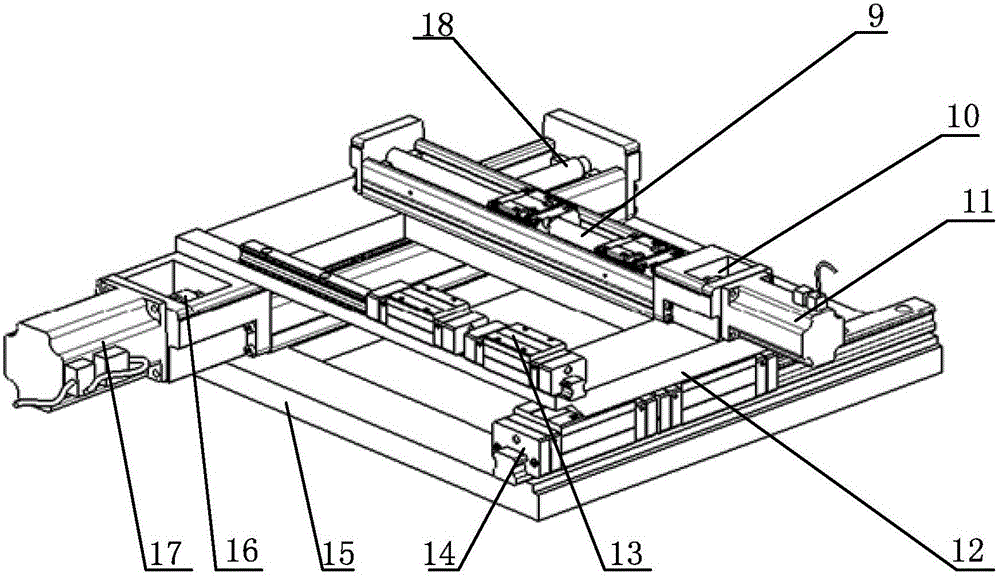

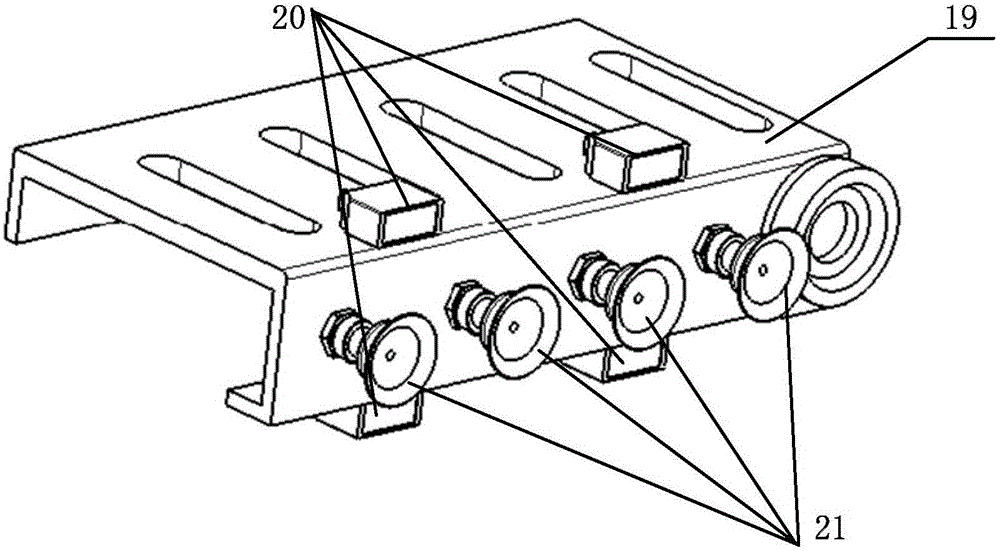

[0035] The device of the present invention includes an equipment base 1, an XY moving unit 2, an edge sweeping unit 3, an electric spindle unit 4, a base connecting plate 19, a visual alignment unit 6, a flexible clamping unit 7 and a normal leveling unit 8.

[0036] Such as figure 1 As shown, the equipment base 1 is provided with an opening and the middle is empty, the outer upper side of the equipment base 1 is equipped with a flange (used to connect with a robot or a coordinate machine tool), and the XY moving unit 2 is installed on the equipment base 1. The side sweeping unit 3 is installed on one side of the inside of the equipment base 1, the other side of the equipment base 1 is connected with the base connecting plate 19 by bolts, and the inside of the equipment base 1 is provided with dust removal Entrance of chip suction unit 5. The visual alignment unit 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com