Method for processing hard tooth surface of medium-precision large-modulus cylindrical gear

A cylindrical gear and large modulus technology, which is applied in the field of precision large modulus cylindrical gear hardened tooth surface finishing, can solve the problems of high price, high grinding process cost, and poor overall economic efficiency, and achieve good economy and good quality. Comprehensive performance, effect of large space chip flute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and through the embodiments. The following embodiments explain the present invention, but the present invention is not limited to the following embodiments.

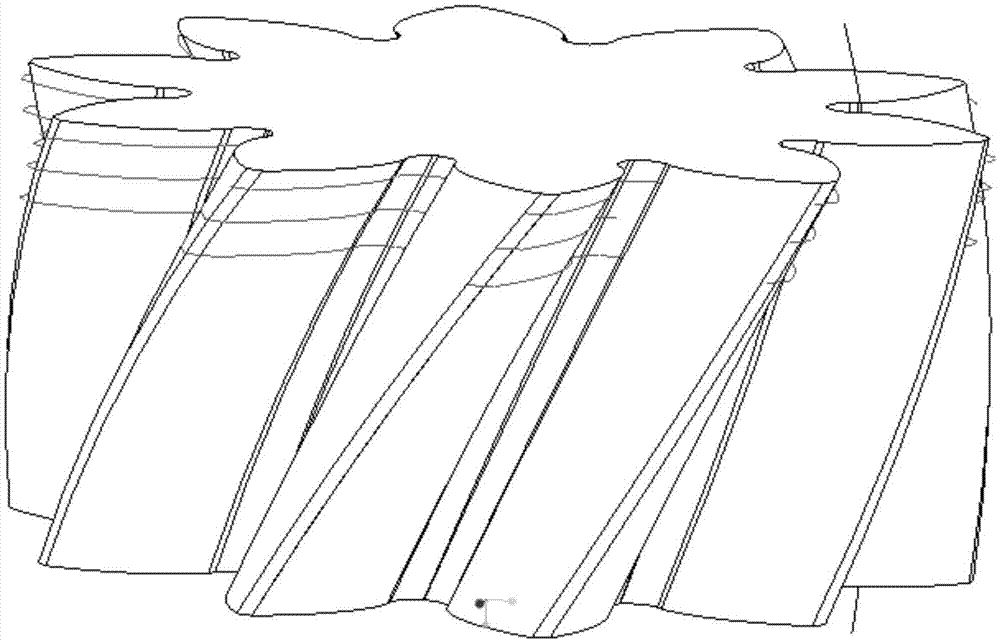

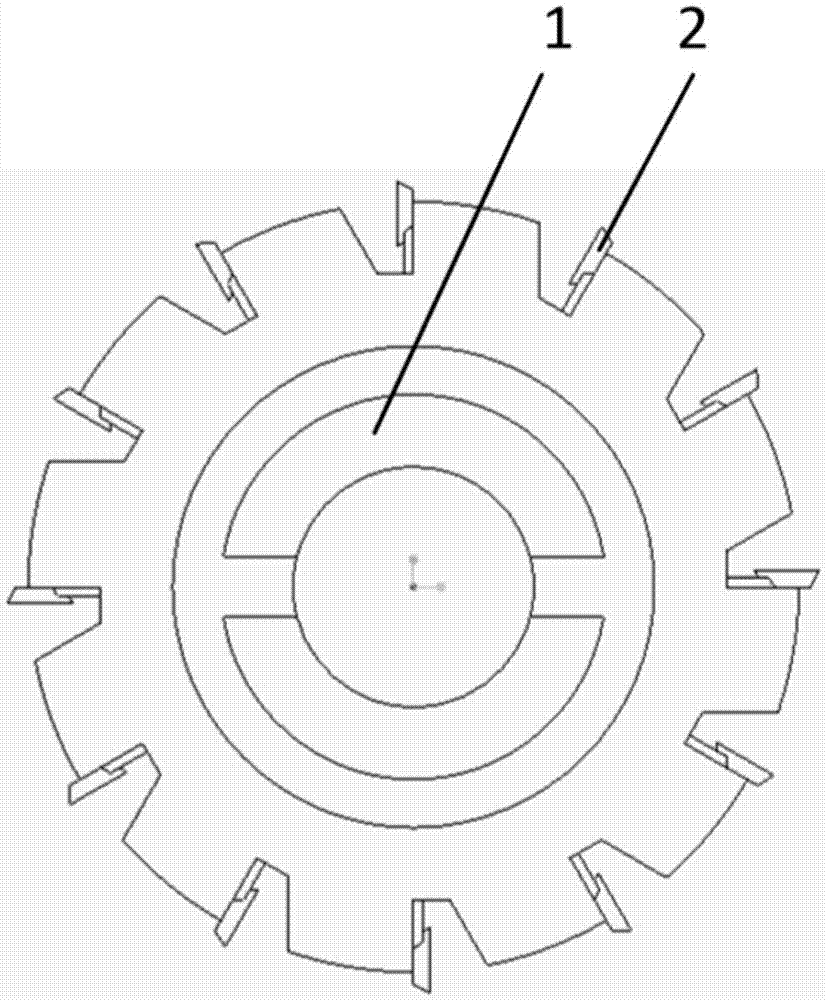

[0031] A method for finishing hardened tooth surfaces of medium-precision large-module cylindrical gears. The double-parameter non-instantaneous center envelope method is used to perform enveloping hard milling on the tooth surface, that is, the tool performs latitudinal enveloping along the circumferential profile direction of the gear. Carry out warp enveloping along the helical direction of the gear tooth surface;

[0032] The envelope processing steps are as follows:

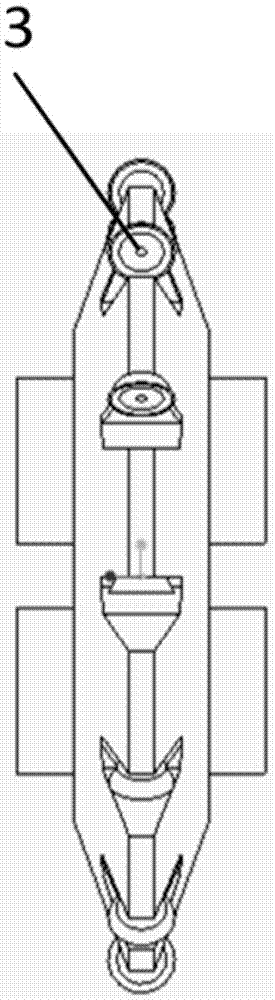

[0033] The first step is to adjust the attitude of the disc milling cutter so that the axis of the disc milling cutter and the axis of the gear are placed at a staggered angle, and the staggered angle is the complementary angle of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com