Waste vitriol re-use technics and apparatus for accumulator plate product

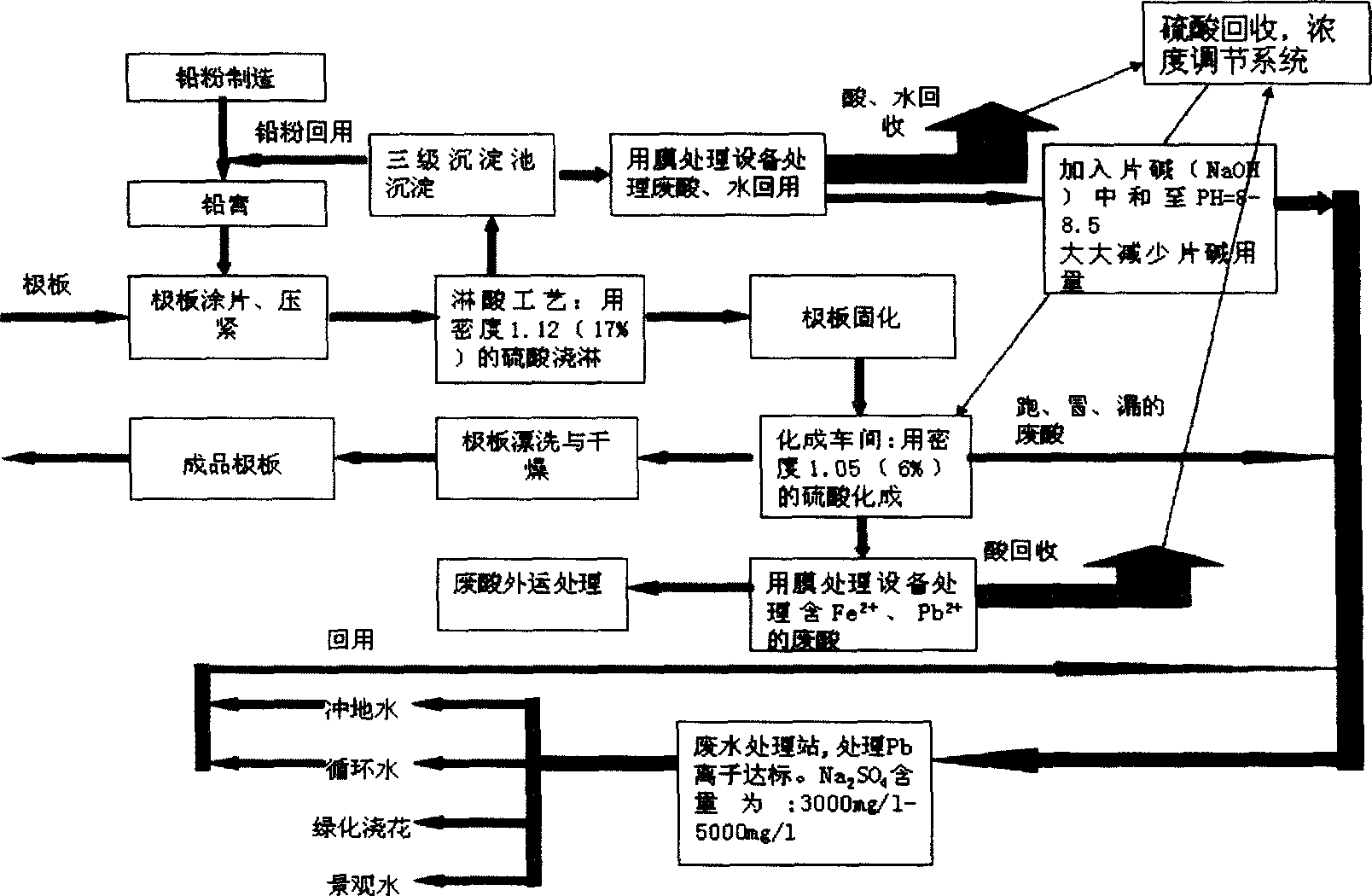

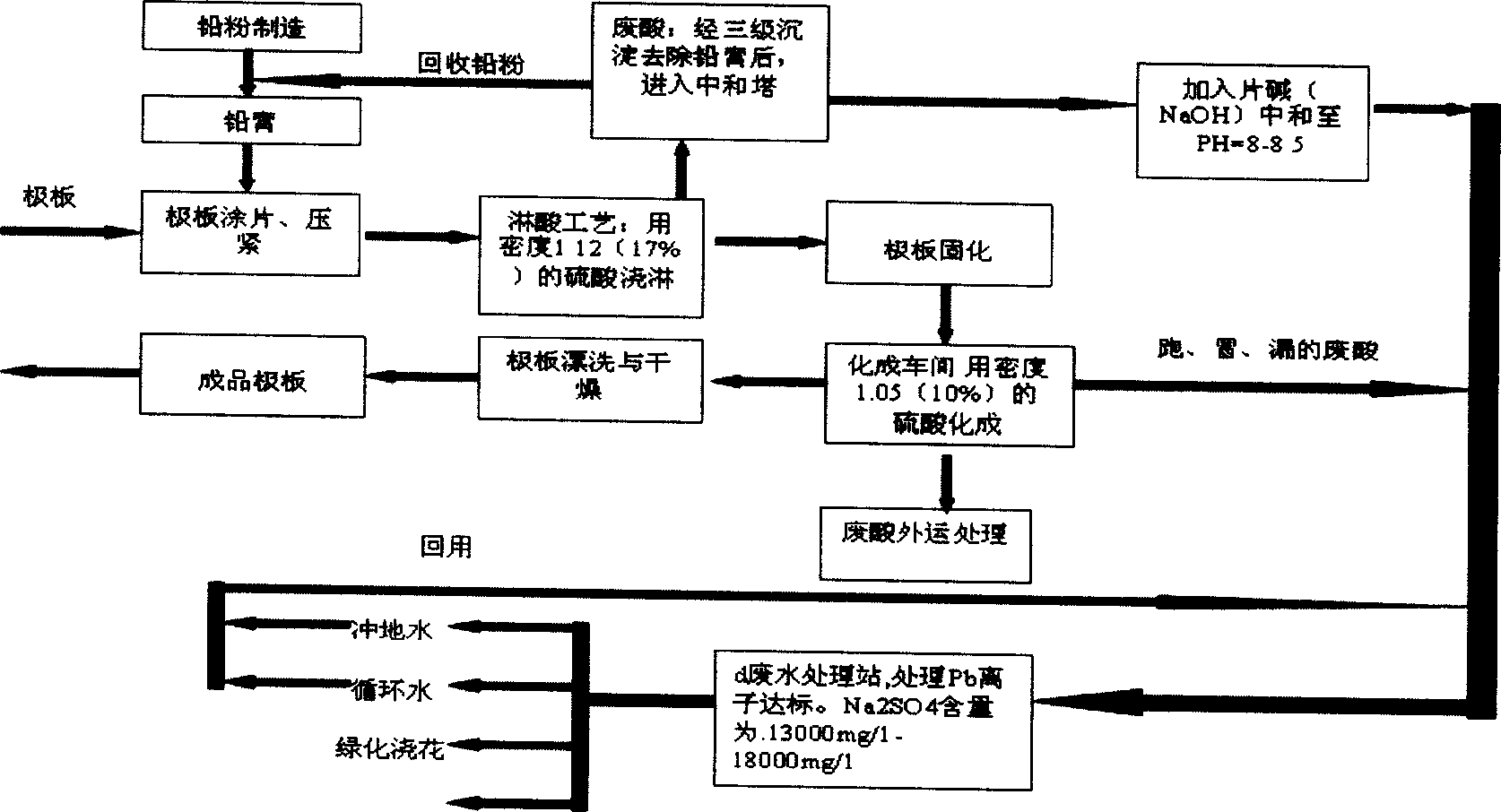

A waste sulfuric acid and storage battery technology, which is applied in the direction of lead-acid battery electrodes, battery recycling, recycling technology, etc., can solve the problems that battery plates cannot meet the requirements of environmental protection and production water reuse, high cost of environmental protection treatment, and affect the beauty of the site. , to achieve the effect of improving the comprehensive utilization rate, improving the level of environmental protection and economic benefits, and reducing the purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

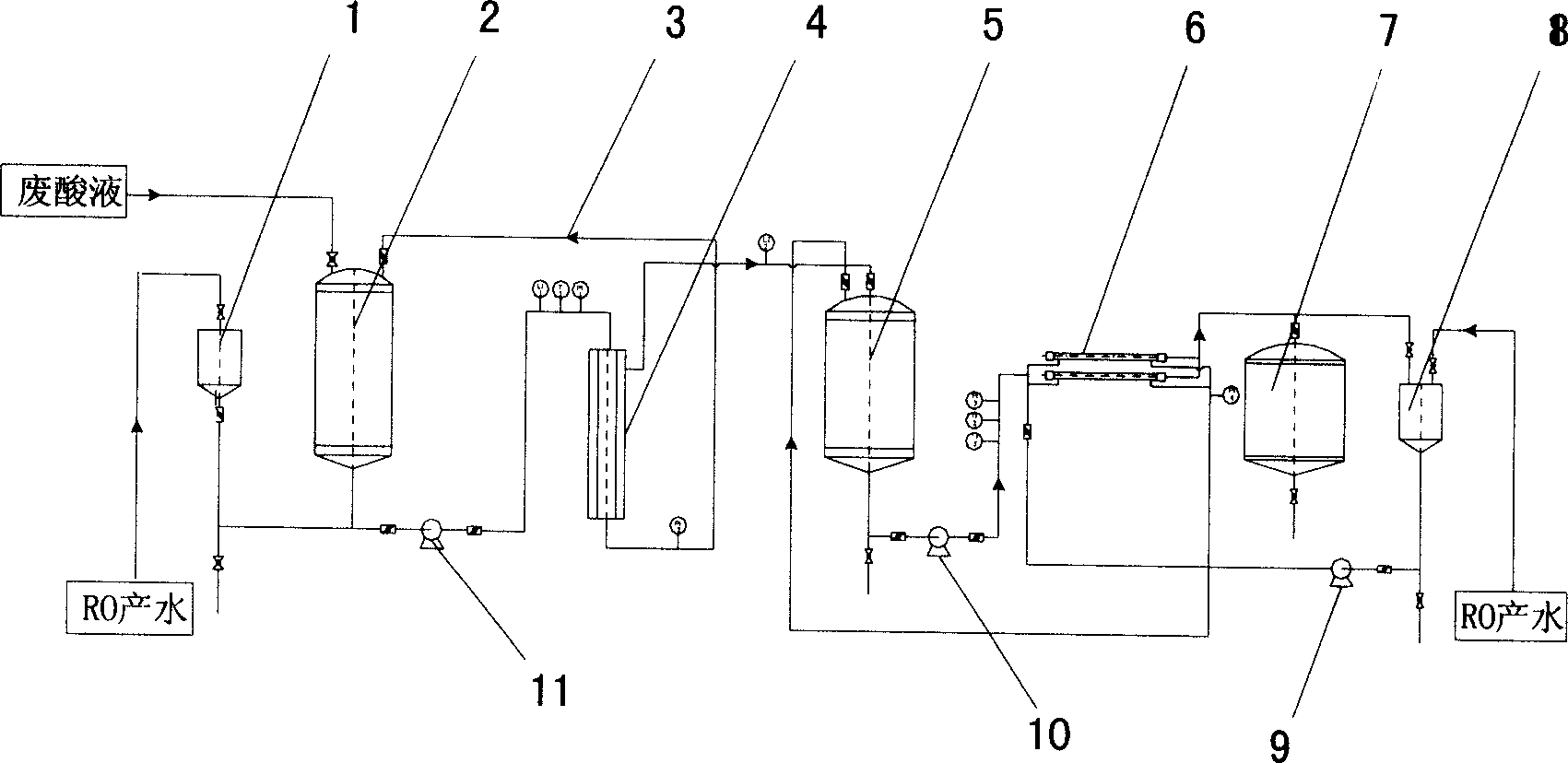

[0033] 1) In the acid leaching process, after the waste acid solution is precipitated in a three-stage sedimentation tank, microfiltration or ultrafiltration membranes are used to treat the acid leaching process in the plate production (some battery plate manufacturers have no leaching acid process section) Waste acid liquid, the waste acid liquid is pumped into the microfiltration or ultrafiltration membrane circulation treatment unit, the concentrated liquid is discharged into the sewage treatment station of the factory for treatment or exported, and the filtrate is pumped into the circulation tank for storage; the waste acid liquid The concentration of iron ions in the medium is unstable. The microfiltration or ultrafiltration membrane treatment unit is mainly used as the pretreatment unit of the nanofiltration membrane treatment unit equipment to remove solids and suspended substances such as lead powder, lead oxide and lead sulfate in the waste sulfuric acid of leaching ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com