Stainless steel thermal insulating jacket and its manufacturing method

A production method, stainless steel technology, applied in heat preservation, pipeline protection, pipeline protection through heat insulation, etc., can solve problems affecting performance, collision sag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

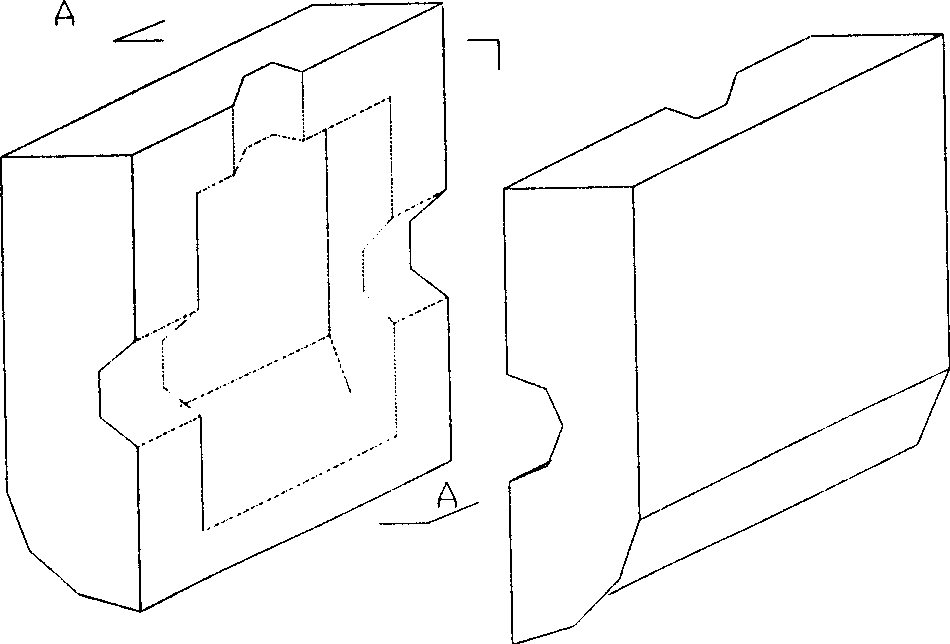

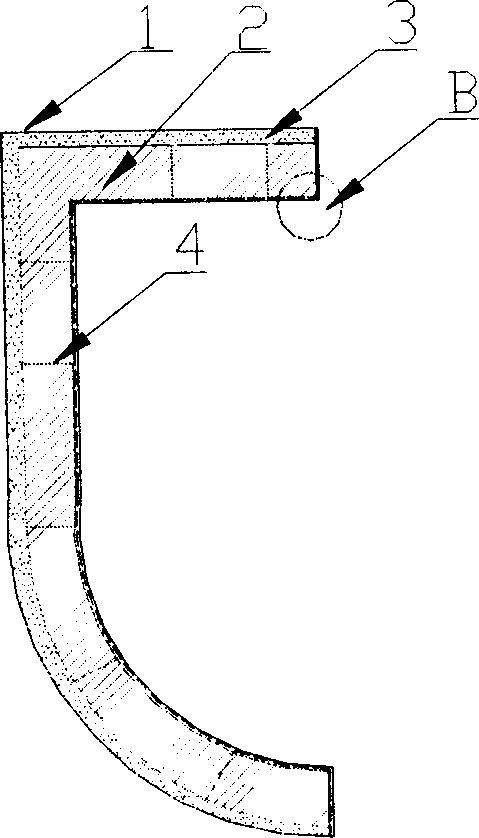

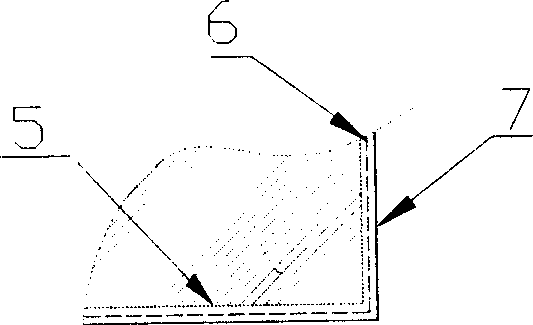

[0012] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-Figure 2 As shown, the present invention mainly includes a stainless steel shell 1 and an insulating layer 2 provided therein. At least one deck of glass fiber reinforced plastic skeleton layer 3 is compounded on the inner wall of described stainless steel shell 1, and is provided with at least one layer of insulation layer 2 made of thermal insulation material above the glass fiber reinforced plastic skeleton layer 3; Described insulation layer 2 can be made of glass fiber wool or Made of aluminum silicate wool or rock wool and other thermal insulation materials, it is fixed on the glass fiber reinforced plastic frame 3 with hook nails 4 . One deck of glass fiber cloth 5 and stainless steel wire mesh 6 are also arranged on the insulation layer 2, and one deck of sealing layer 7 is finally arranged. The sealing layer 7 can be made of materials such as aluminum fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com