Burning explosion prevention method and system for oxygen compressor

An oxygen compressor and anti-explosion technology, which is used in mechanical equipment, machines/engines, liquid variable-capacity machinery, etc. The effect of preventing explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

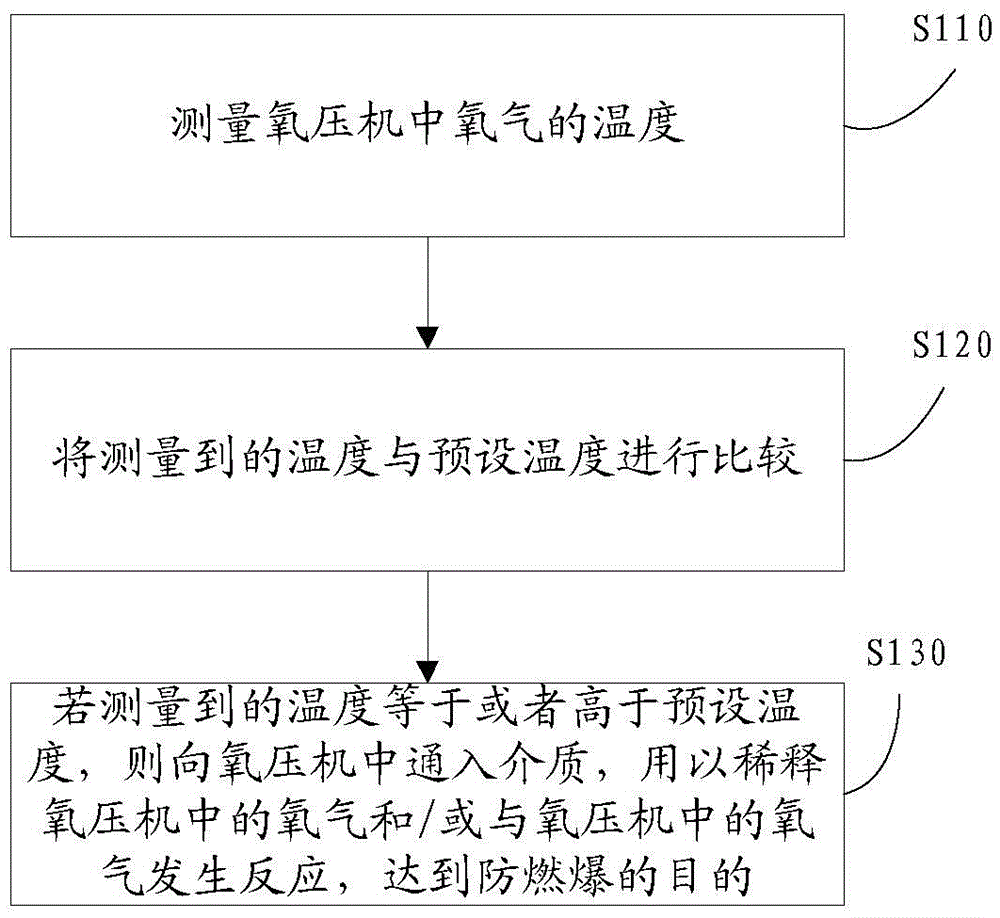

[0034] see figure 1 , the fire and explosion prevention method for the oxygen compressor provided by the embodiment of the present invention includes:

[0035] Step S110: measuring the temperature of oxygen in the oxygen compressor;

[0036] In order to comprehensively measure the oxygen temperature in the oxygen compressor, so as to further prevent the explosion of the oxygen compressor, step S110 specifically includes:

[0037] Measure the temperature of high-temperature and high-pressure oxygen in all stages of compressed oxygen compressor.

[0038] Step S120: comparing the measured temperature with the preset temperature;

[0039] In this embodiment, the preset temperature is between 170°C and 180°C.

[0040] Step S130: If the measured temperature is equal to or higher than the preset temperature, it means that the oxygen compressor has a risk of explosion, and the medium is passed into the oxygen compressor to dilute the oxygen in the oxygen compressor and / or with the ...

Embodiment 2

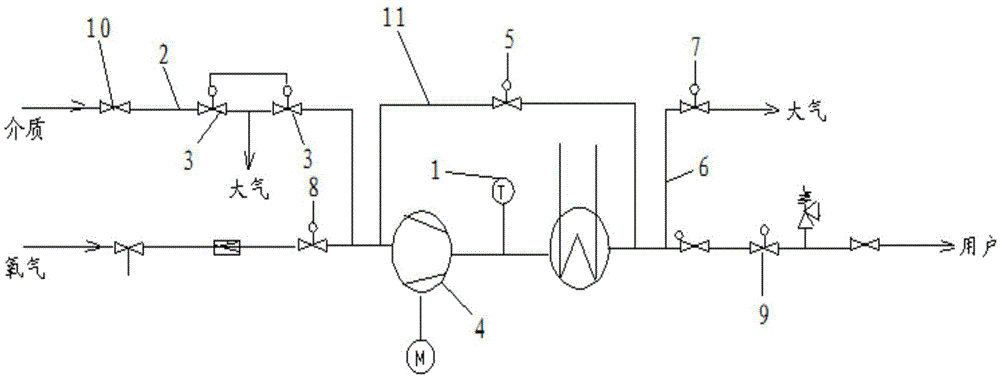

[0043] see figure 2 , the anti-flammation system for the oxygen compressor provided by the embodiment of the present invention includes: a temperature measuring component 1, a medium delivery pipeline 2 and a connecting rod valve 3; the temperature measuring component 1 is arranged after each compression stage in the oxygen compressor 4 On the outlet pipeline; the medium output end of the medium delivery pipeline 2 leads to the oxygen compressor 4; the connecting rod valve 3 is arranged on the medium delivery pipeline 2.

[0044] When the connecting rod valve 3 leaks, in order to prevent the medium from entering the oxygen compressor 4 and affecting the product quality of downstream users, there is a through hole at the connecting rod valve 3 of the medium delivery pipeline 2 .

[0045] To illustrate the structure of the embodiment of the present invention, the ratio of the diameter of the through hole to the inner diameter of the medium delivery pipeline 2 is between 1 / 10-1 / ...

Embodiment 3

[0053]The operating principle of the system provided by the embodiment of the present invention is (the medium in this embodiment is nitrogen):

[0054] 1. The temperature of the high-temperature and high-pressure oxygen at each stage compressed by the oxygen compressor 4 is measured through the temperature measuring component 1 . When the measured oxygen temperature reaches 175°C, the main motor of the oxygen compressor 4 is powered off and stops running, and the auxiliary oil pump is powered off;

[0055] 2. The anti-surge valve 5 is fully opened, thereby unloading the operating load of the oxygen compressor 4 . Close the inlet control valve 8 and the outlet control valve 9 at the same time, so as to achieve the purpose of cutting off oxygen (combustible material);

[0056] 3. The discharge valve 7 is fully opened, and the gas in the oxygen compressor 4 is discharged to the atmosphere;

[0057] 4. The connecting rod valve 3 is fully opened, and the nitrogen in the medium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com