Engine overspeed protection and control method

An engine overspeed and protection control technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as the action of the engine overspeed protection device, affecting the normal use of the engine, and the failure of the protection device, so as to improve reliability and save electricity. , the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

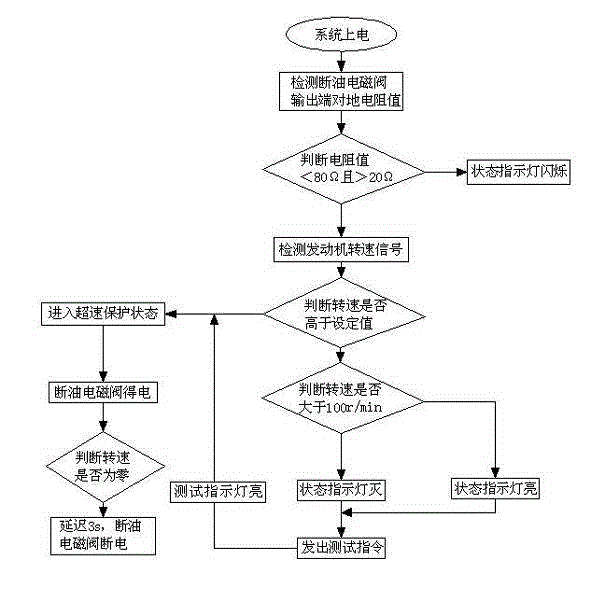

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

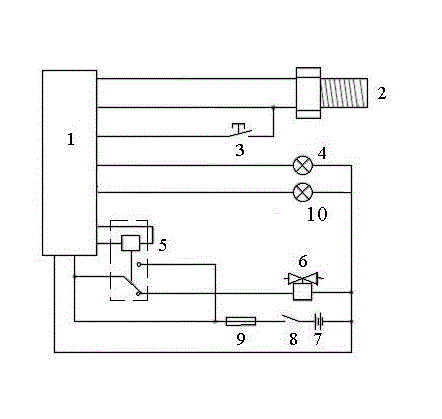

[0023] An engine overspeed protection control system includes a controller 1 , a rotational speed sensor 2 , a test button 3 , a storage battery 7 , an over relay 5 , a fuel cutoff solenoid valve 6 , a state indicator light 4 and a test indicator light 10 .

[0024] The rotational speed sensor is used to detect the rotational speed of the engine in real time, and transmit the detected rotational speed of the engine to the controller in real time. The fuel cut-off solenoid valve is connected to the output end of the controller, and the relay is set between the fuel cut-off solenoid valve and the controller. The relay is used to control the power on and off of the fuel cut-off solenoid valve under the instructions issued by the controller, and further makes the fuel cut-off solenoid valve act , cut off the engine fuel. The test button is used to start the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com