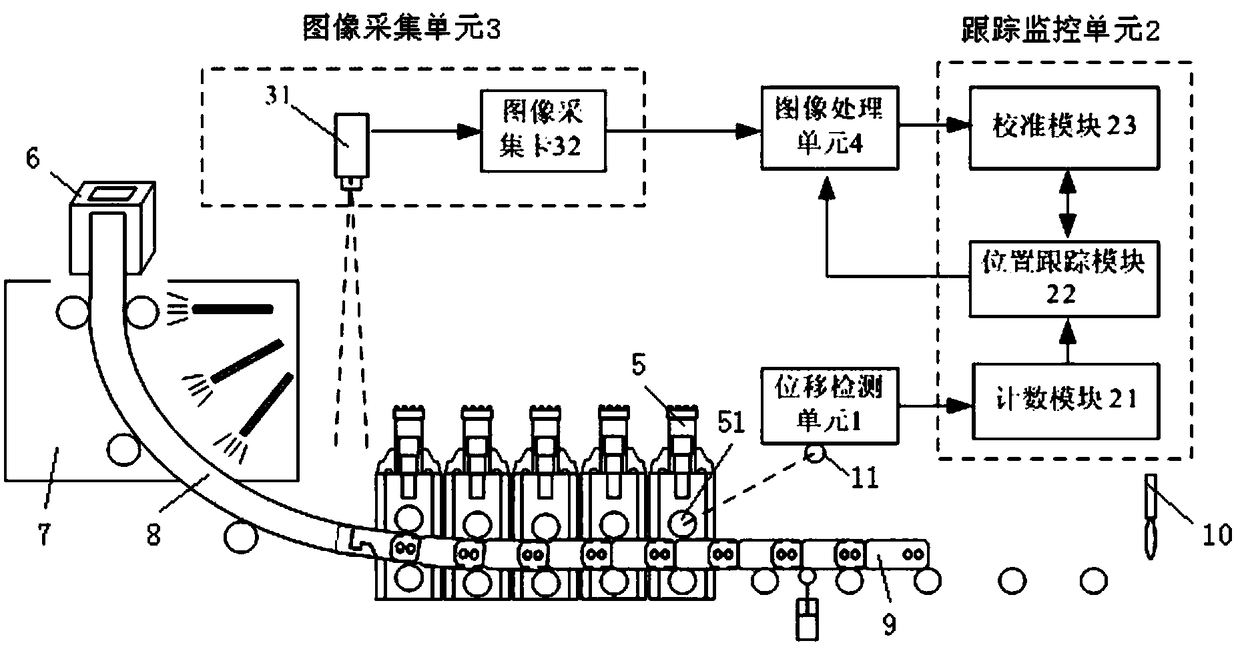

Tracking and detecting system and method for head and tail billet positions of continuous casting

A technology of tracking detection and continuous casting slabs, which is applied in the field of continuous casting head and tail slab position tracking detection systems, can solve the problems of unreliable solutions and large cumulative errors, so as to eliminate cumulative errors, avoid normal operation, and ensure control accuracy and quality The effect of control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

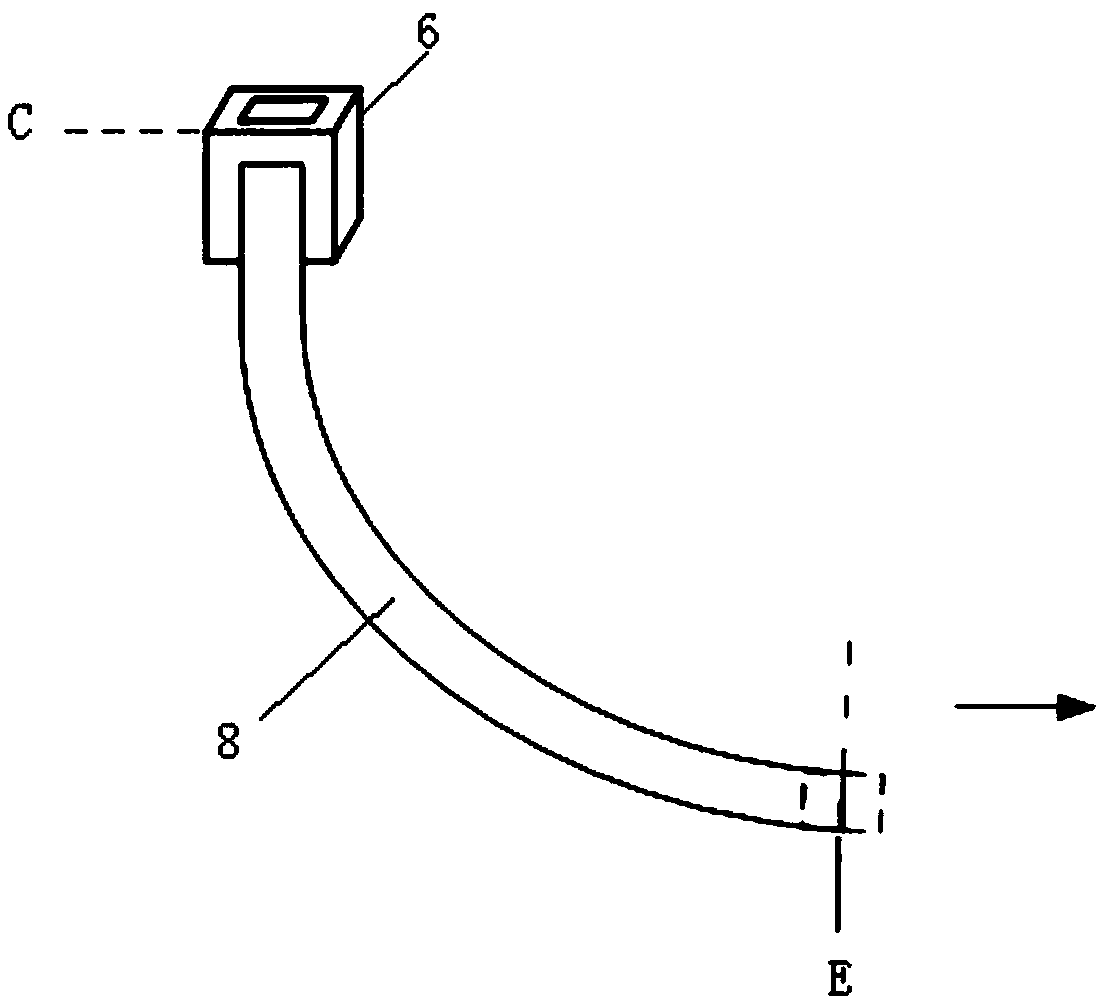

[0097] In some embodiments, determining the casting length of the head stock or the tail stock in real time comprises the steps of:

[0098] (1) A pulse generator is used to convert the casting length change of the continuous casting slab into a corresponding number of pulses in real time.

[0099] (2) Use the counting module to count the edge of the pulse to generate the pulse count value.

[0100] (3) Determine the billet head or billet tail tracking mode according to the casting state, and based on the billet head or billet tail tracking mode, according to the pulse count value, calculate the casting length of the head billet or tail billet in real time by incremental accumulation method.

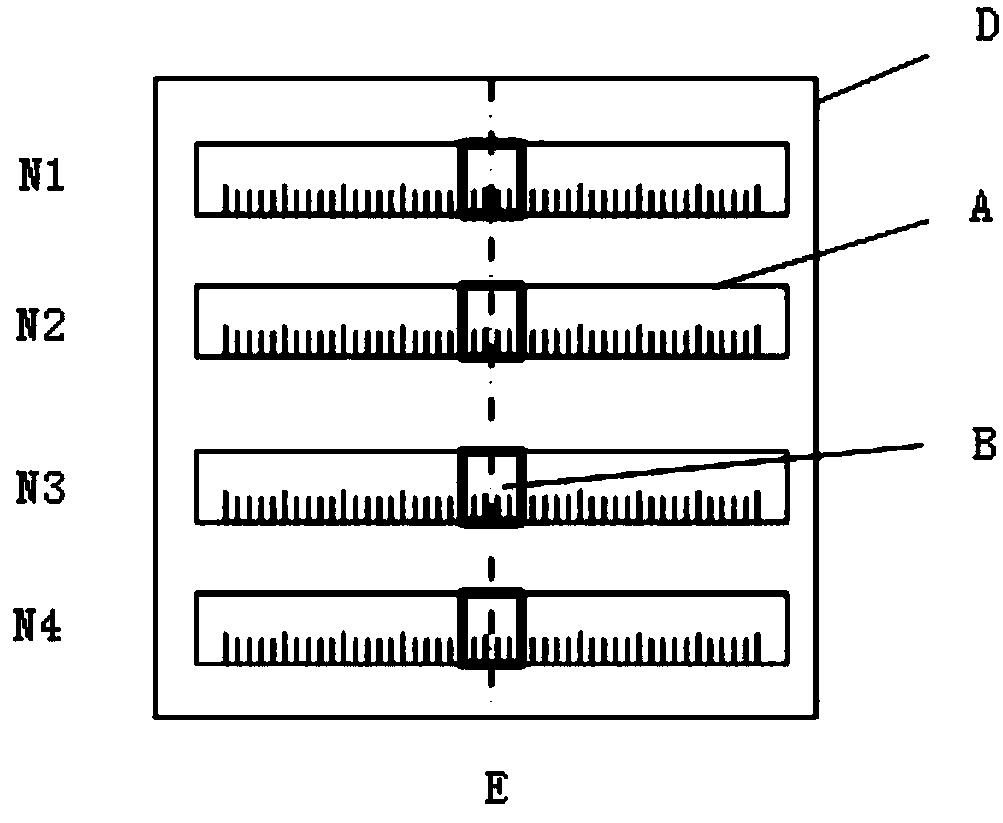

[0101] In some embodiments, the image information of multi-strand continuous casting slabs is collected in real time, and the image information of each strand of continuous casting slabs within the detection window is identified.

[0102] In some embodiments, identifying the image infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com