Process for producing sodium selenite

A technology for preparing sodium selenite, which is applied in the direction of sodium/potassium compounds, selenium/tellurium compounds, alkali metal compounds, etc., can solve the problems of high sodium carbonate price, increased production cost and danger of sodium selenite, and achieve The production process is simple, the operation is simple and convenient, and the investment in production equipment is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

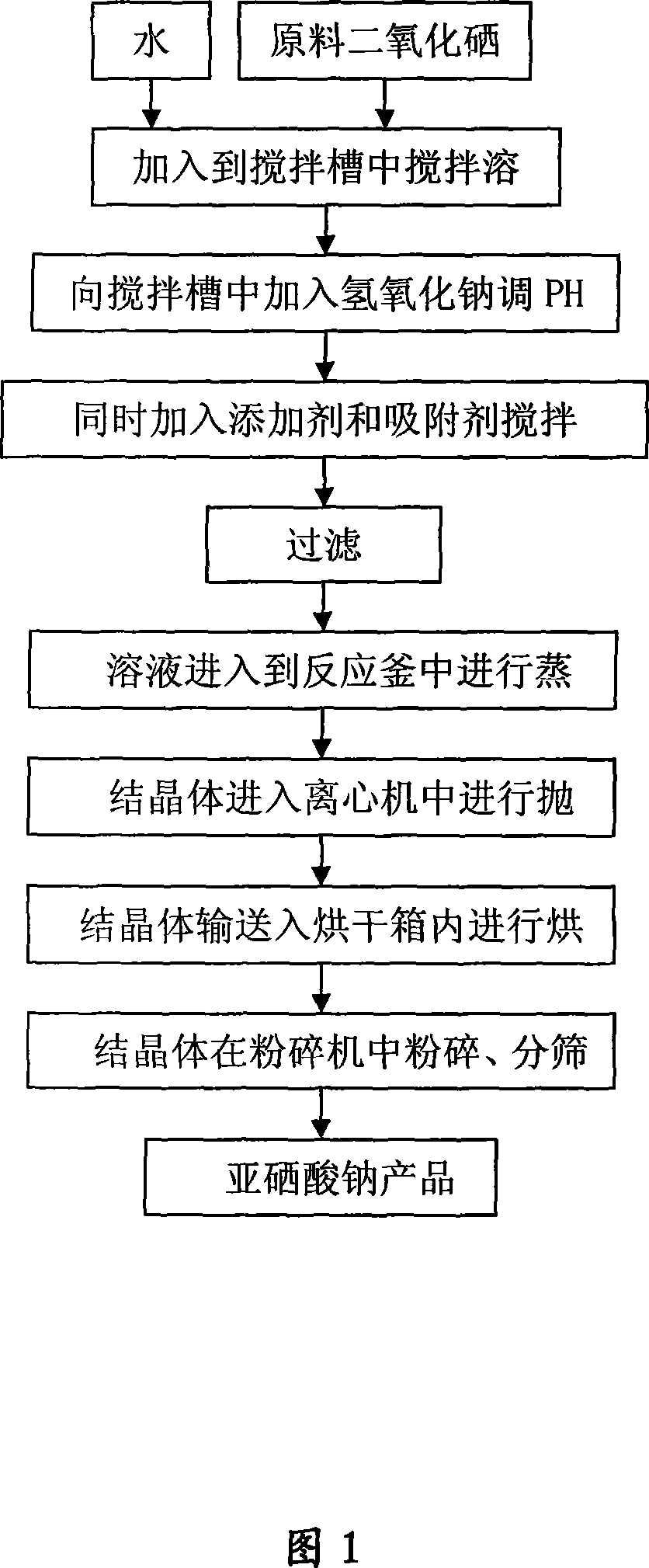

[0030] A preparation technique for sodium selenite, comprising the following technical steps:

[0031] 1. Add 1000L of water to the stirring tank, and put in 500kg of selenium dioxide, and start stirring to dissolve;

[0032] 2. After the selenium dioxide is completely dissolved, in the stirring tank, slowly add 360 kg of sodium hydroxide (99% mass concentration) to adjust the pH value, and synthesize sodium selenite.

[0033] 3. Then weigh 0.4kg of the additive, dissolve the additive in water, add it to the stirring tank, and stir evenly; then add 0.5kg of the adsorbent, and stir for 1 hour;

[0034] 4. Subsequently, the sodium selenite solution is filtered, and the clear solution is transported into the reaction kettle, heated and evaporated, so that the solution forms a supersaturated state, and sodium selenite crystallizes out from the solution;

[0035] 5. Transport the sodium selenite crystals with crystal water into the centrifuge, and turn on the centrifuge for centri...

Embodiment 2

[0038] A preparation technique for sodium selenite, comprising the following technical steps:

[0039] 1. Add 2000L of water to the stirring tank, and put in 1000kg of selenium dioxide, and start stirring to dissolve;

[0040] 2. After selenium dioxide dissolves completely, in stirring tank, slowly add sodium hydroxide (99% mass concentration) 720kg to adjust pH value, synthetic sodium selenite.

[0041] 3. Then, weigh 800g of the additive, dissolve the additive in water, add it to the stirring tank, and stir evenly; then add 1kg of the adsorbent, and stir for 2 hours;

[0042] 4. Subsequently, the sodium selenite solution is filtered, and the clear solution is transported into the reaction kettle, heated and evaporated, so that the solution forms a supersaturated state, and sodium selenite crystallizes out from the solution;

[0043] 5. Transport the sodium selenite crystals with crystal water into the centrifuge, and turn on the centrifuge for centrifugal dehydration. The ...

Embodiment 3

[0046] A preparation technique for sodium selenite, comprising the following technical steps:

[0047] 1. Add 3000L of water into the stirring tank, and put in 1500kg of selenium dioxide, and start stirring to dissolve.

[0048] 2. After selenium dioxide is completely dissolved, in the stirring tank, slowly add sodium hydroxide (99% mass concentration) 1080kg to adjust the pH value, and synthesize sodium selenite.

[0049] 3. Then, weigh 1.2 kg of the additive. Dissolve the additive in water, add it into the stirring tank, and stir evenly; then add 1.5 kg of adsorbent and stir for 5 hours.

[0050] 4. Subsequently, the sodium selenite solution is filtered, and the clear solution is transported into the reaction kettle, heated and evaporated to make the solution form a supersaturated state, and the sodium selenite crystallizes out from the solution.

[0051] 5. Transport the sodium selenite crystals with crystal water into the centrifuge, and turn on the centrifuge for centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com