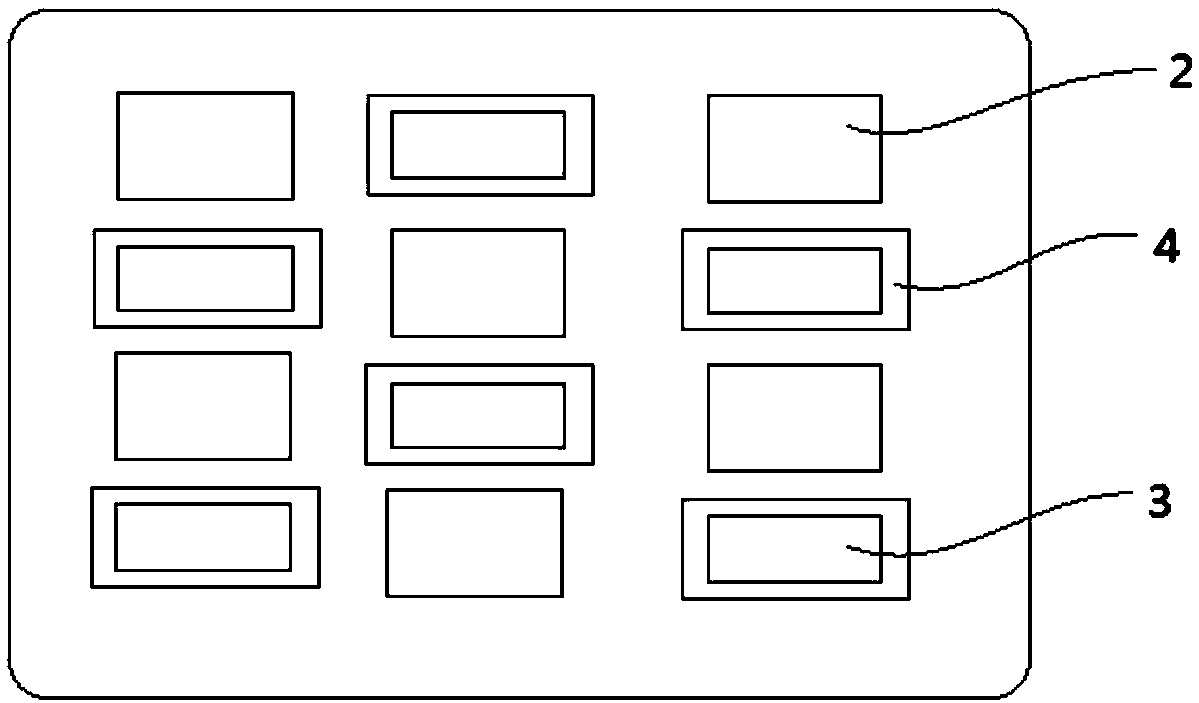

Display panel and display device having the same

A display panel and end face technology, which is applied in the field of display screens, can solve the problems of support column damage, colorful spots, bright spots, etc., and achieve the effect of enhancing impact and shock resistance and avoiding support column damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

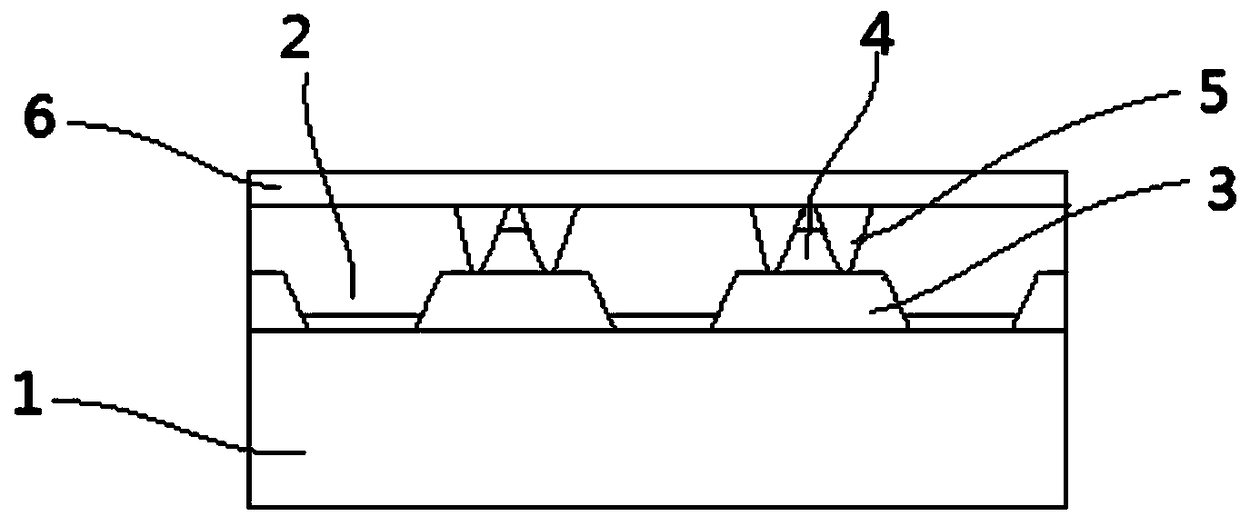

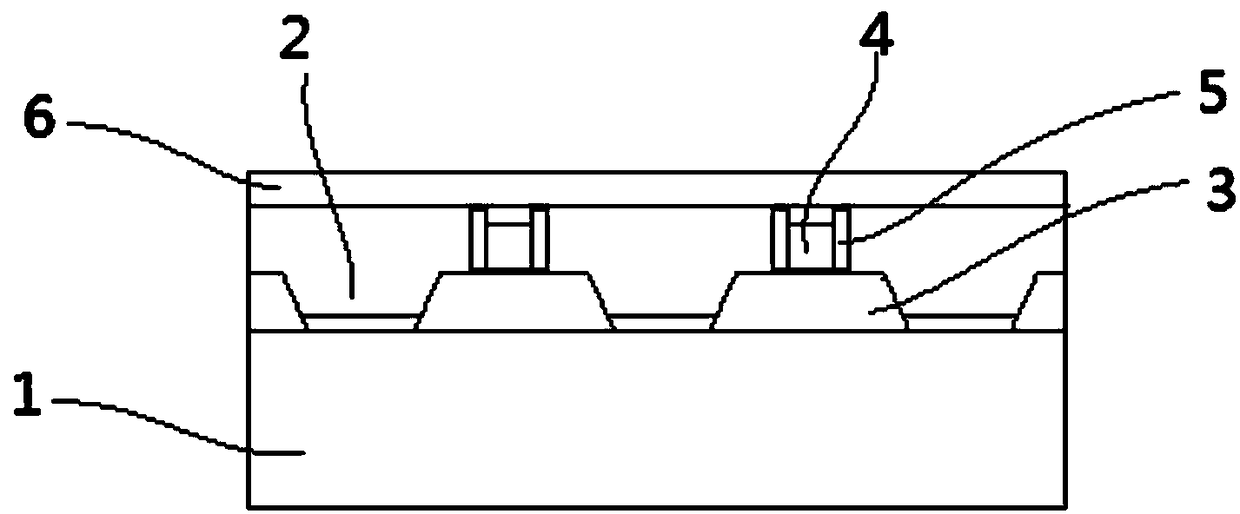

[0023] The display screen in the traditional technology is prone to display failure problems, such as black spots, bright spots, and colorful spots in the display area of the display screen. The research of the inventors found that the root cause of this problem is that the display screen The shock absorption and cushioning effect of the display screen is not good. When a heavy object hits the display screen, the stress on the display screen is difficult to release, which may cause the display screen to break or the components inside the display screen to be damaged. The display panel is the main functional area of the display screen. Improving the shock and shock resistance of the display panel can effectively improve the display failure problem of the display screen.

[0024] In order to solve the above problems, the inventors add a buffer layer between the pixel defining layer and the encapsulation structure. Specifically, a buffer layer close to the supporting pillars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com