High temperature resistant defoamer for delaying coking reaction tower

A technology of delayed coking and defoamer, which is applied in the field of high-temperature resistant defoamer and defoamer, which can solve the problems of hydrofining device influence, high silicon content of products, etc., and achieve the effect of inhibiting and eliminating foam generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

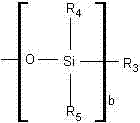

Method used

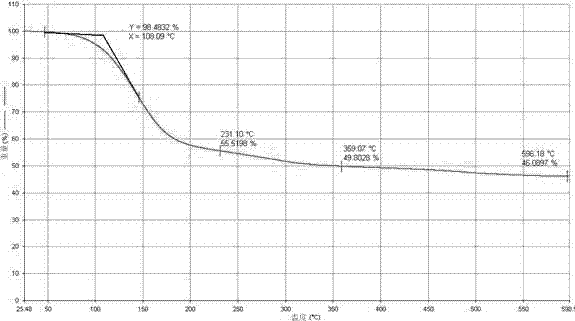

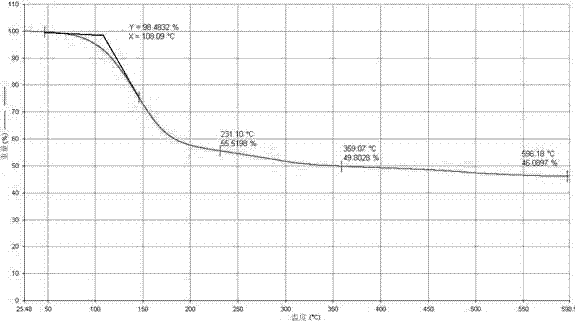

Image

Examples

Embodiment 1

[0030] Take 50 grams of modified polysiloxane compound A, 10 grams of phenyl silicone oil, and 40 grams of heavy aromatic solvent oil into a 250mL round bottom flask, heat at 60°C, and stir with magnetic force for 1 hour to obtain the product.

Embodiment 2

[0032] Take 20 grams of modified polysiloxane compound A, 20 grams of phenyl silicone oil, and 60 grams of heavy aromatic solvent oil into a 250mL round bottom flask, heat at 60°C, and stir with magnetic force for 1 hour to obtain the product.

Embodiment 3

[0034] Take 30 grams of modified polysiloxane compound A, 30 grams of phenyl silicone oil, and 40 grams of heavy aromatic solvent oil into a 250mL round bottom flask, heat at 60°C, and stir with magnetic force for 1 hour to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com