Continuous production device and method for silane modified sealing material

A technology for silane modification and sealing materials, which is applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc. To achieve the effect of realizing continuous production, increasing the temperature of dehydration, and facilitating continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

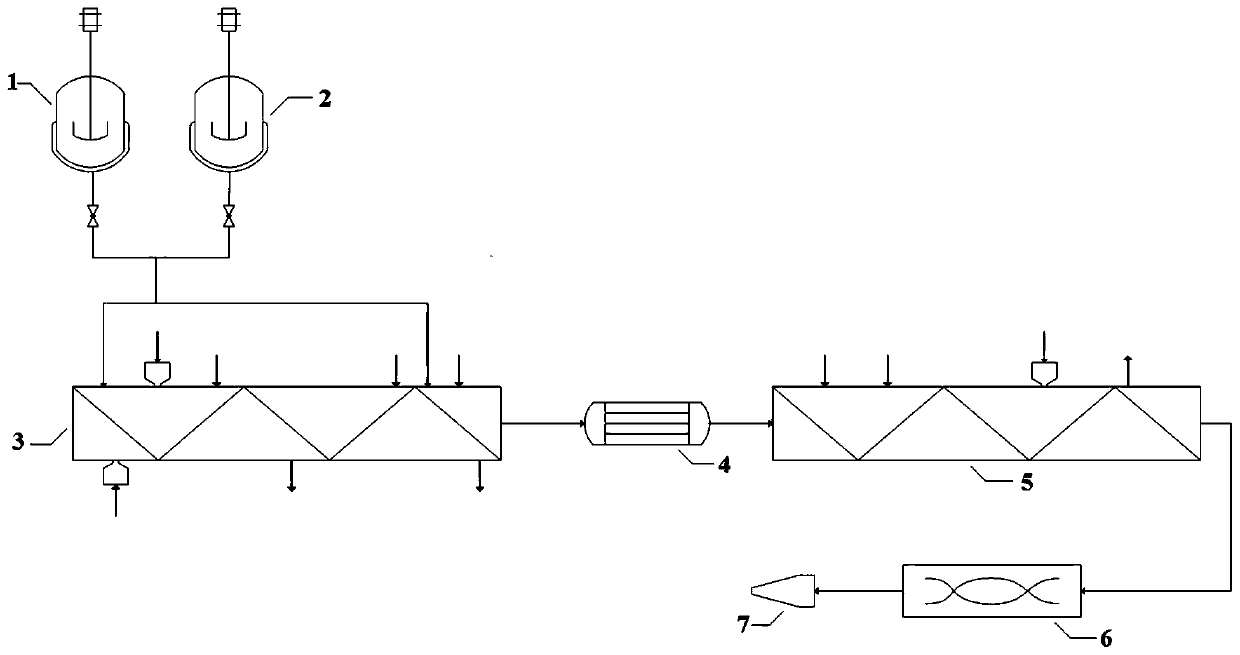

[0082] This embodiment provides a continuous production device for silane-modified sealing materials, and the structural schematic diagram of the continuous production device is as follows figure 1 As shown, it includes a twin-screw extruder unit, a cooling unit 4 and a static mixing unit 6;

[0083] The twin-screw extruder unit includes two twin-screw extruders in series, the cooling unit 4 is arranged between the first-stage twin-screw extruder 3 and the second-stage twin-screw extruder 5, and the second-stage twin-screw extruder 5 The outlet of the screw extruder 5 is connected to a static mixing unit 6 .

[0084] The device also includes a premixing unit, the outlet of the premixing unit is connected to the inlet of the first-stage twin-screw extruder 3, and the premixing unit includes two premixing tanks arranged in parallel, respectively the first premixing Still 1 and the second premixing still 2, all are equipped with stirring device in the said premixing still, descr...

Embodiment 2

[0088] This embodiment provides a continuous production device for silane modified sealing material, the continuous production device includes a twin-screw extruder unit, a cooling unit 4 and a static mixing unit 6;

[0089] The twin-screw extruder unit includes three twin-screw extruders connected in series, and the cooling unit 4 is arranged between the second-stage twin-screw extruder and the third-stage twin-screw extruder, and the third-stage twin-screw extruder The outlet of the machine is connected with the static mixing unit 6.

[0090] The device also includes a premixing unit, the outlet of the premixing unit is connected to the inlet of the first-stage twin-screw extruder 3, and the premixing unit includes two premixing tanks arranged in parallel, respectively the first premixing Still 1 and the second premixing still 2, all are equipped with stirring device in the said premixing still, described the first premixing still 1 and the second premixing still 2 and on th...

Embodiment 3

[0095] This embodiment provides a continuous production method for silane-modified sealing materials, wherein the components and parts by weight of silane-modified sealing materials are: 50 parts of MS polymer S203H, 50 parts of S303H; 2 parts of heat stabilizer IRGANOX 245; 60 parts of plasticizer PPG3000; 100 parts of filler nano-calcium carbonate, 50 parts of heavy calcium carbonate; 2 parts of polyamide wax as thixotropic agent; 1 part of UV-326; 2 parts of coupling agent N-aminoethyl-γ-aminopropyltrimethoxysilane; 2 parts of catalyst dibutyltin diacetylacetonate;

[0096] The method is carried out using the device in Example 1, comprising the following steps:

[0097] (1) 50 parts of MS polymer S203H, 50 parts of S303H and 2 parts of IRGANOX 245 are mixed in the premixing tank and then added to the first-stage twin-screw extruder 3, and the mixed raw materials are fed from the first-stage twin-screw extruder 3 An entry of the join;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com