Mixing station and grout preparation method thereof

A mixing station and mixing device technology, which is applied in mixing plants, cement mixing devices, chemical instruments and methods, etc., can solve the problems that are easy to affect the slurry, and achieve the effect of avoiding uneven dryness and wetness, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

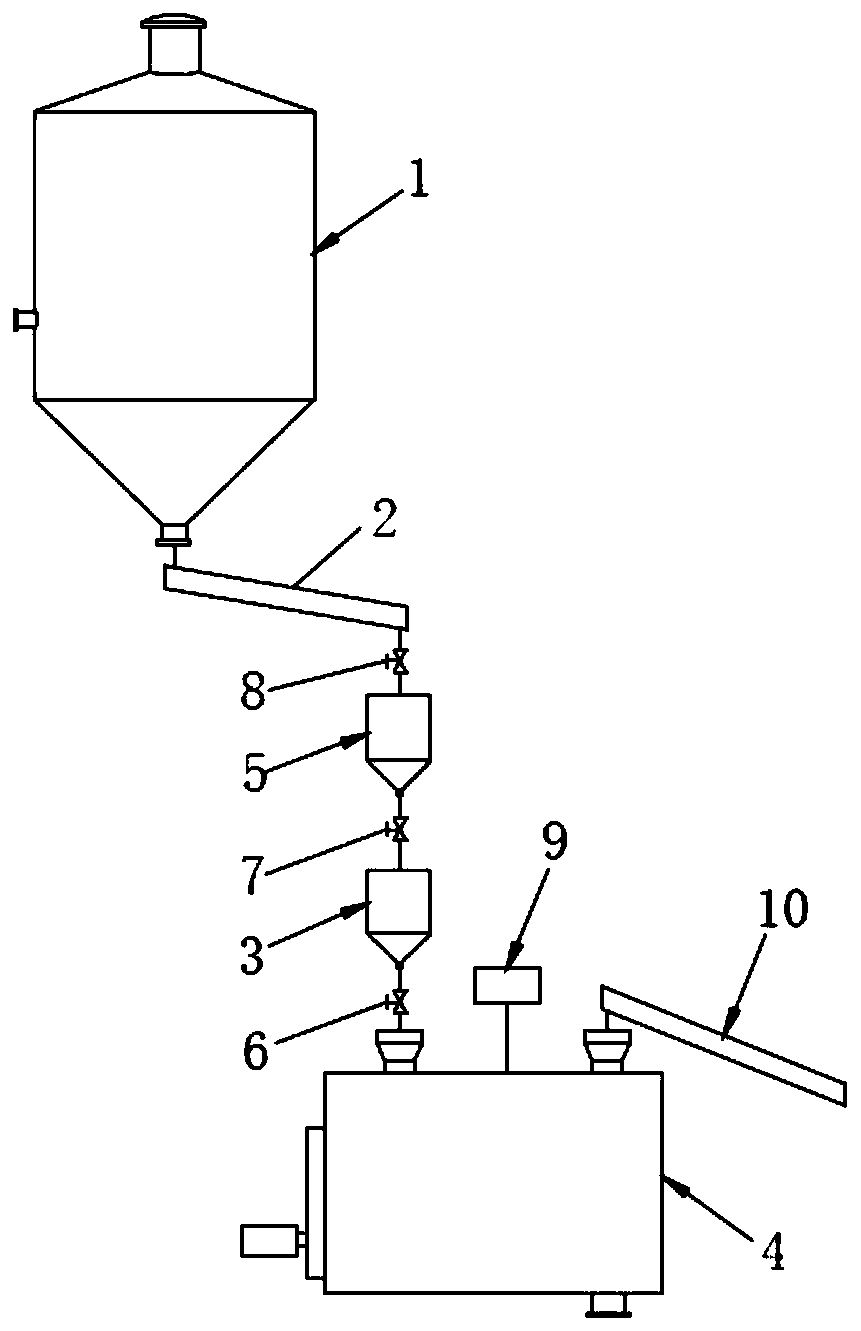

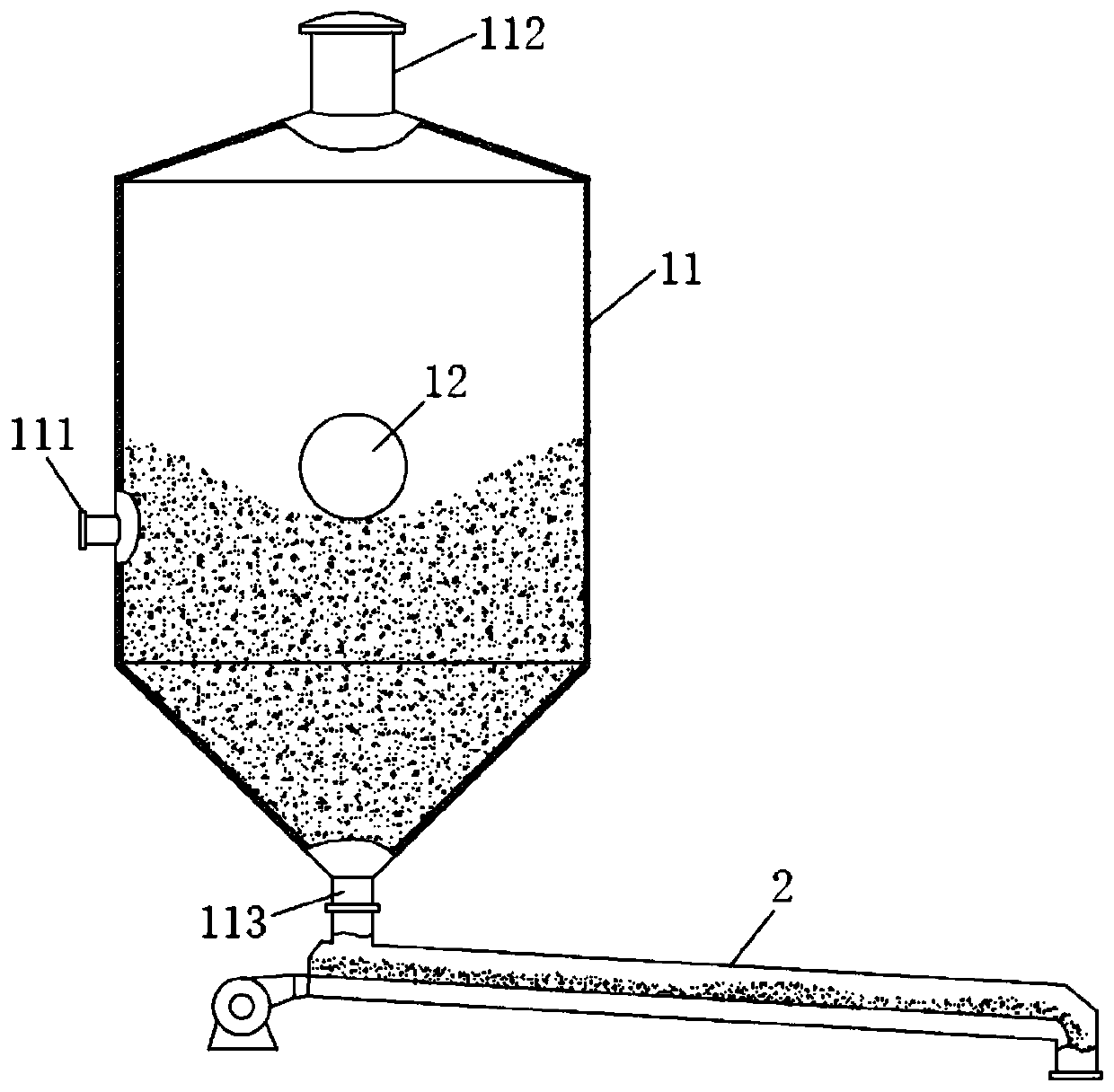

[0049] Such as figure 1 As shown in , a mixing station in this embodiment includes a mixing device 4 for mixing and preparing concrete slurry; and an aggregate supply system 10, which quantitatively supplies aggregates to the mixing device 4; and powder A supply system, which quantitatively supplies powder into the stirring device 4; and a water supply system 9, which quantitatively supplies water to the stirring device 4; the stirring device 4 is provided with a humidity sensor 44 for detecting the humidity of the aggregate, It is used to detect the humidity of the aggregate put into the stirring device 4.

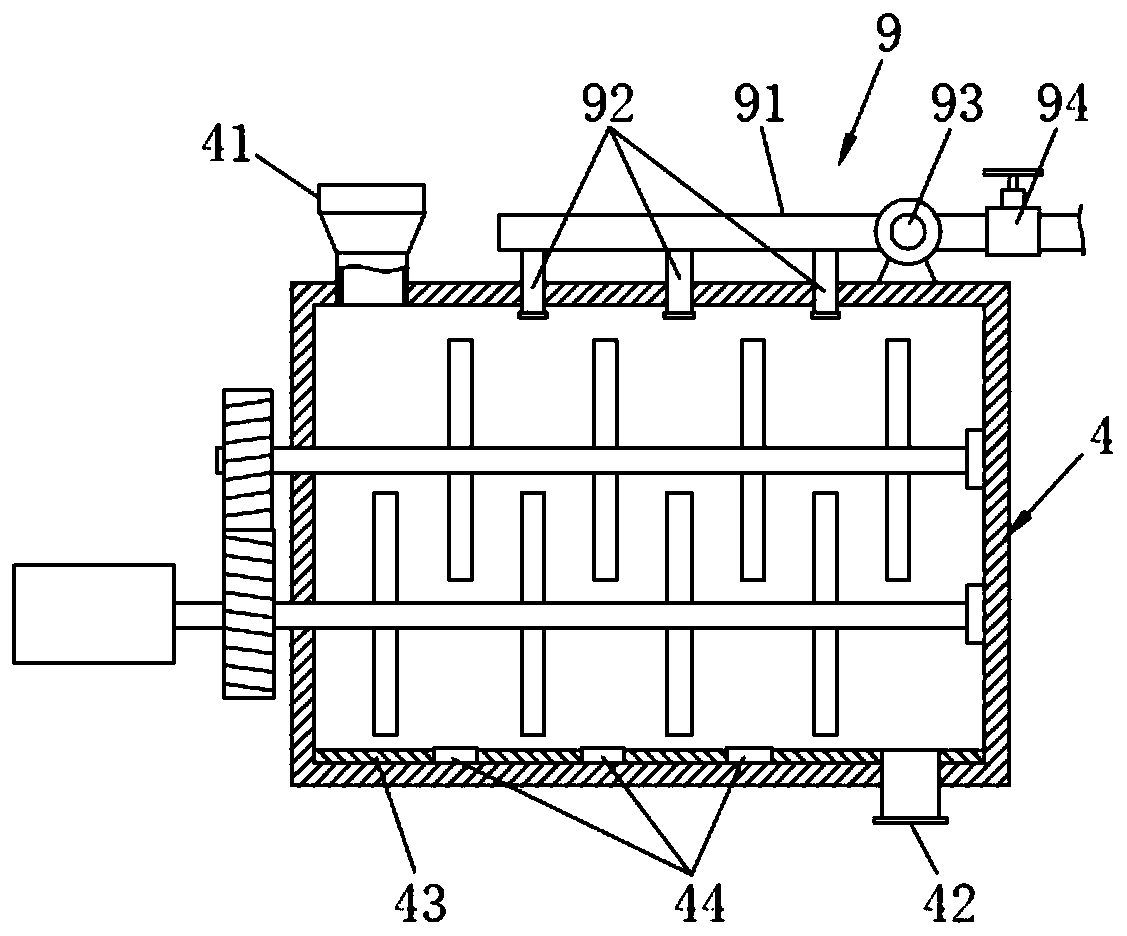

[0050] Such as figure 2 As shown in , the stirring device 4 in this embodiment includes a feeding port 41 and a slurry outlet 42, and the feeding port 41 is provided with a plurality of them, which are respectively used to put aggregate and powder into the stirring device 4; The feeding port 41 for feeding aggregates is set in cooperation with the aggregate supply syst...

Embodiment 2

[0055] The stirring station in the present embodiment, basic structure is the same as in embodiment 1, difference and improvement are, as figure 1 As shown in , the powder supply system includes a powder tank 1, an air conveying chute 2, a metering bin 3 and a stirring device 4 connected in sequence, and the metering bin 3 is arranged on the stirring device 4 for feeding On the feeding port 41 of the powder, a buffer tank 5 is also arranged between the air conveying chute 2 and the metering bin 3 to store the powder conveyed by the air conveying chute 2 to avoid air conveying slant The tank 2 conveys more powder to the metering bin 3, so as to realize the precise and quantitative conveying of the powder. A butterfly valve I6 is arranged between the metering bin 3 and the stirring device 4, which is used to block the powder passage between the metering bin 3 and the stirring device 4 during the process of metering the amount of powder, so as to prevent the powder from directly ...

Embodiment 3

[0067] The mixing station in the present embodiment, basic structure simultaneously embodiment 2, difference and improvement are, as Figure 5 As shown in , the buffer tank 5 includes a buffer tank body 51 and a level gauge 52 , and the level gauge 52 is vertically inserted into the buffer tank body 51 .

[0068] After each quantitative delivery of powder, excess powder will enter the buffer tank 5. After long-term use, the amount of powder in the buffer tank 5 will accumulate until the buffer tank 5 is filled. If the staff cannot find out in time, it will affect the normal operation of the system.

[0069] Therefore, in this embodiment, the amount of powder inside is monitored by setting a level gauge 52 in the buffer tank 5. The remaining amount of powder exceeds 60% of the capacity of the level gauge 52. When conveying the powder, the butterfly valve II7 is opened after closing the closed butterfly valve I6, so that the powder in the buffer tank 5 is discharged into the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com