Antibacterial warm down jacket fabric and production method thereof

A technology for down jacket fabrics and production methods, applied in the field of down jacket fabrics, can solve the problems of difficulty in removing creases, influence on product quality, influence on lifespan, etc., and achieve the effects of improving cleaning effect, improving thermal stability, and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

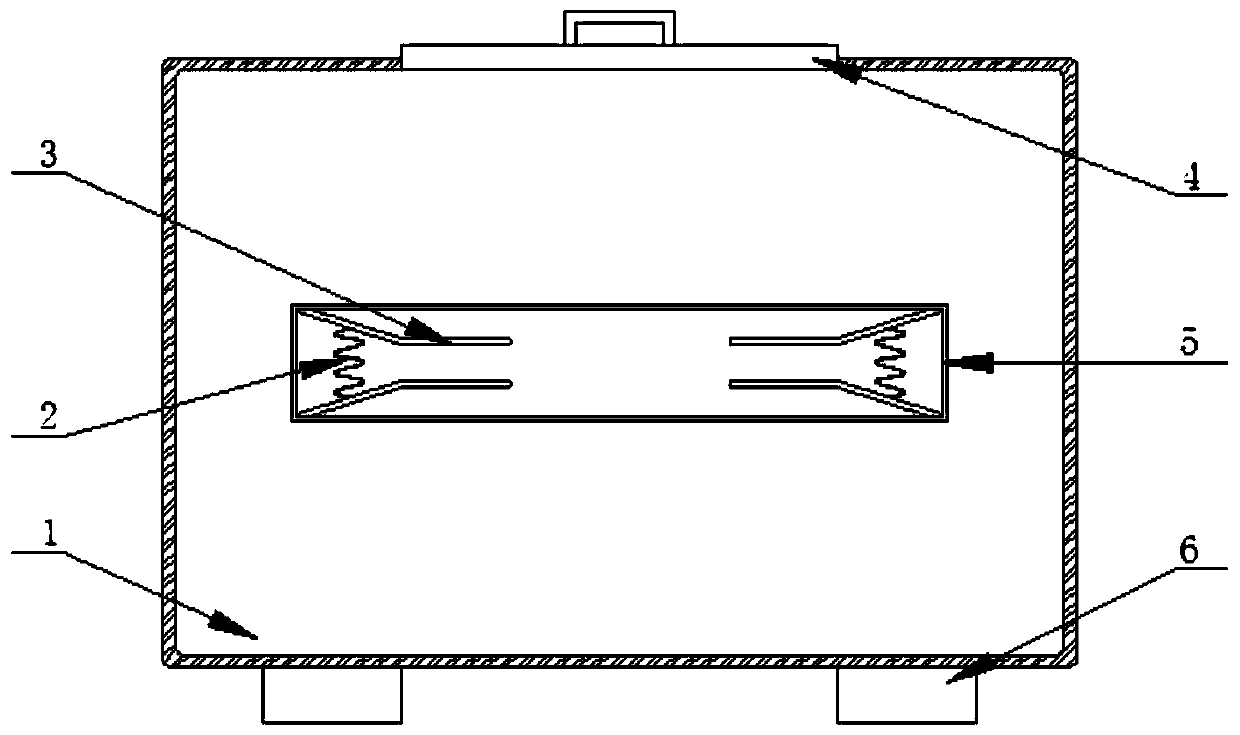

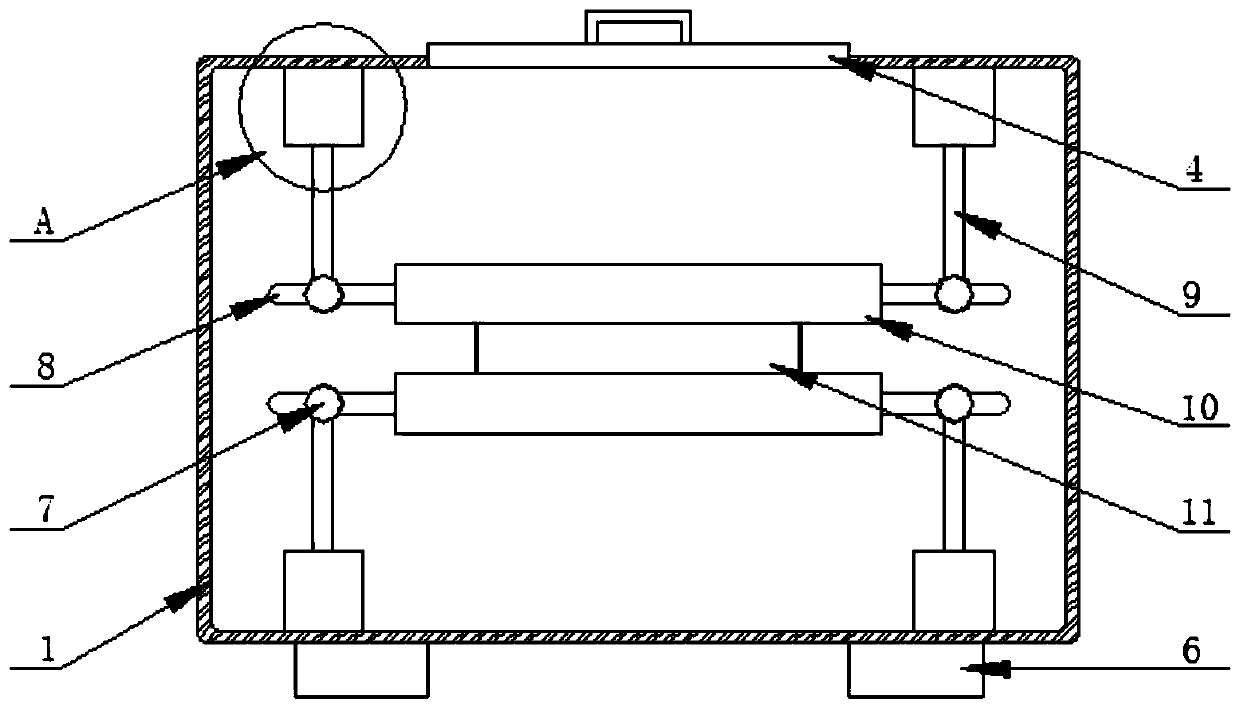

[0038] The antibacterial warm down jacket fabric comprises an outer layer fabric, a middle layer fabric and an inner layer fabric, one side of the middle layer fabric is covered with an outer layer fabric, and the other side of the middle layer fabric is covered with an inner layer fabric;

[0039] The raw materials and preparation methods of the outer fabric and the inner fabric are the same, and the raw materials are respectively 50% cotton fiber, 25% polyester fiber, 15% cupro ammonia fiber and 10% copper ammonia fiber by weight percentage. Polyurethane fiber;

[0040] The middle layer fabric is composed of vinylon and polyurethane sponge, and both sides of vinylon are provided with polyurethane sponge, and the thickness of polyurethane sponge is 0.5mm;

[0041] The preparation method of the middle layer fabric is as follows: first attach the polyurethane sponge to the two sides of the vinylon, and then use the melted acrylic pressure-sensitive adhesive to press them togeth...

Embodiment 2

[0052] Antibacterial warm down jacket fabric, with embodiment 1.

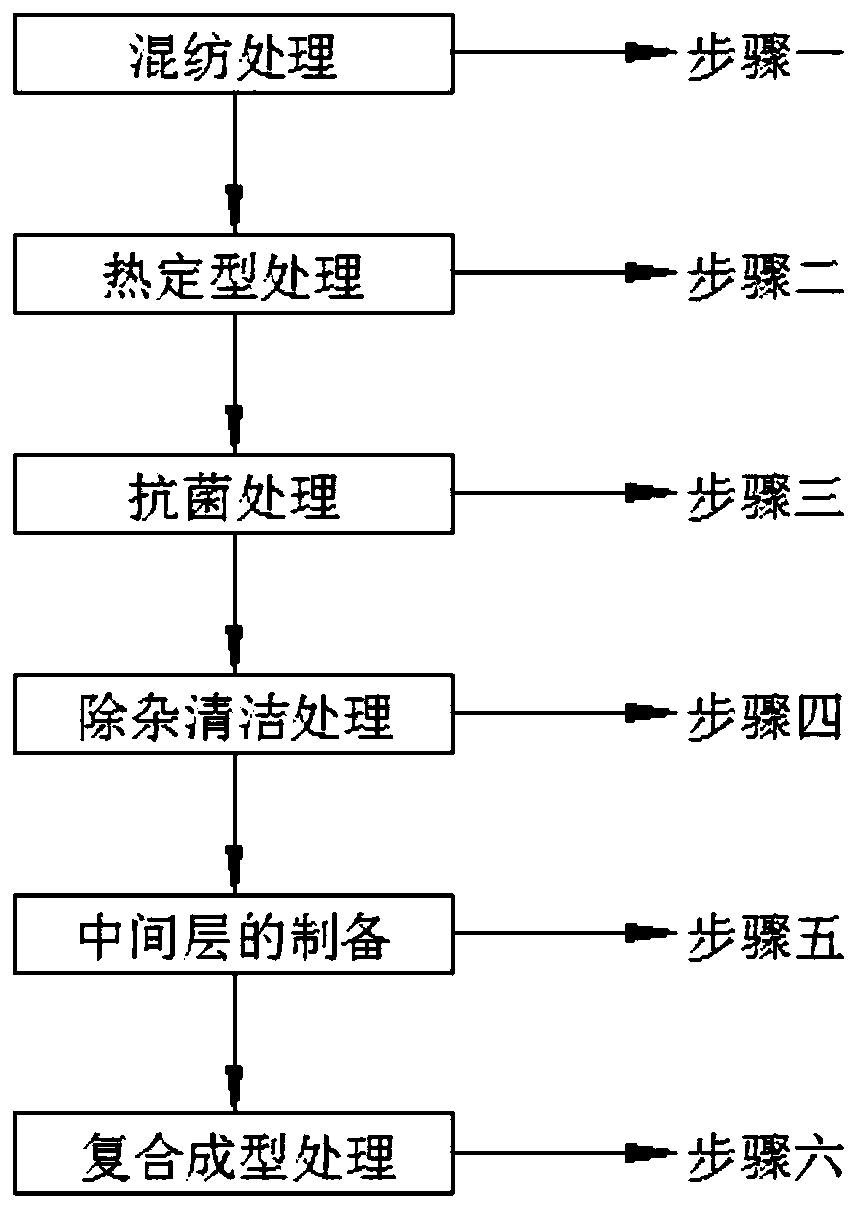

[0053] The production method of antibacterial warm down jacket fabric, comprises the steps:

[0054] 1) Blending treatment: Firstly, cotton fiber, polyester fiber, cupro fiber and polyurethane fiber are mixed and drawn, and then roving and spun to obtain fine yarn, and then the fine yarn is introduced into the shuttle loom for weaving , to get gray cloth;

[0055] 2) heat setting treatment: the gray cloth obtained in step 1) is placed in a tenter setting machine for heat setting operation, and the heating temperature of the heat setting operation is controlled at 100 degrees, and the heating duration is controlled at 300 seconds, and then reduced to Normal temperature, and the surface tension of the gray cloth by the stenter setting machine is controlled at 120N, so as to obtain the primary fabric;

[0056] 3) Antibacterial treatment: first immerse the primary fabric obtained in step 2) into a storage tank eq...

Embodiment 3

[0063] Antibacterial warm down jacket fabric, with embodiment 1.

[0064] The production method of antibacterial warm down jacket fabric comprises the steps: same as embodiment 1.

[0065] Wherein, in the modified antibacterial auxiliary agent in step 3), each constituent raw material is 55% n-octane chloride, 30% didodecylmethyl tertiary amine and 15% methyl chloride by weight percentage.

[0066] Wherein, the preparation method of the modified antibacterial auxiliary agent is as follows: first introduce chloro-n-octane into a stirred tank, and the solvent in the stirred tank is a mixed solution of isopropanol and sodium carbonate, and then add didodecylmethyl tertiary Add the amine into the stirring tank and mix and stir for 150 minutes, and the stirring temperature is controlled at 90 degrees, the stirring rate is controlled at 300 rpm, and then after mixing and stirring, feed methyl chloride into it, and after the temperature is raised to 120 degrees, the same Continue to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com