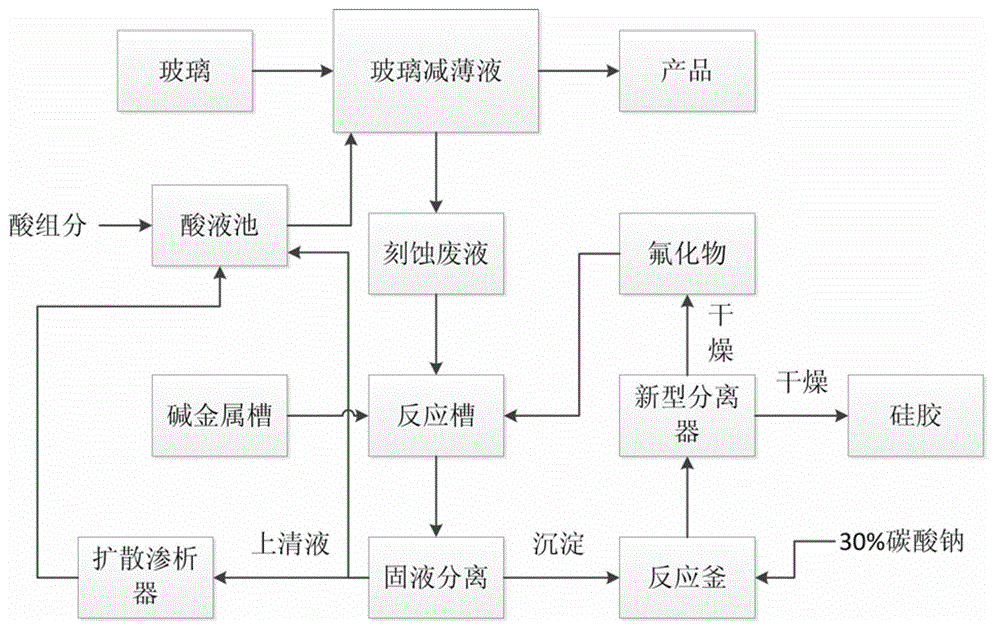

Method for treating and recycling glass thinning and etching waste liquor

A glass thinning and etching waste liquid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high pollution, high waste, high consumption, etc. Achieve the effects of avoiding environmental pollution, high removal efficiency, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 20ml simulated glass thinning etching waste solution to 50ml centrifuge tubes 1, 2, 3, and 4 respectively, the composition of which is 10% H 2 SiF 6 , 10% HF, 5% HCl and 2% H 2 SO 4 Add NaCl saturated solution (solubility 36g) 4.5ml, 5.6ml, 6.7ml, 7.8ml in each tube, make NaCl and H 2 SiF 6 The molar stoichiometric ratio is 1.6, 2.0, 2.4, 2.8; shake the centrifuge tube so that NaCl and H 2 SiF 6 Fully contact with the reaction, then let stand for 30min, filter, measure H 2 SiF 6 The removal rates were 72.39%, 93%, 98.62%, and 99.33%, respectively.

[0035] In NaCl and H 2 SiF 6 Under the condition that the molar stoichiometric ratio is 2, the simulated glass thinning etching waste liquid after treatment passes through the anion diffusion dialyzer at a flow rate of 10ml / min, the flow rate of clear water is controlled at 11ml / min, and the recovery rate of the acid solution after treatment is 60-70%. , The removal rate of metal ions is 60-80%.

[0036] 100g ...

Embodiment 2

[0038] Add 20ml simulated glass thinning waste liquid to 50ml centrifuge tubes 1, 2, 3, and 4 respectively, the composition of which is 10% H 2 SiF 6 , 10% HF, 5% HCl and 2% H 2 SO 4 ; Add KCl saturated solution (solubility 34g) 5.3ml, 6.6ml, 7.9ml, 10.5.ml in each tube, so that KCl and H 2 SiF 6 The molar stoichiometric ratio is 1.4, 1.7, 2.1, 2.8; shake the centrifuge tube so that KCl and H 2 SiF 6 Fully contact with the reaction, then let it stand for 30min, filter, and calculate H 2 SiF 6 The removal rates were 66.20%, 83.76%, 98.08%, and 99.50%, respectively.

[0039] In NaCl and H 2 SiF 6 The simulated glass thinning etching waste liquid treated under the condition of molar stoichiometric ratio of 2 passes through the anion diffusion dialyzer at a flow rate of 10ml / min, the flow rate of clear water is controlled at 11ml / min, and the recovery rate of the acid solution after treatment is 60-70%. The removal rate of metal ions is 60-80%.

Embodiment 3

[0041] Prepare 4 kinds of glass thinning waste liquids, numbered A~D respectively, and the H in each simulated waste liquid 2 SiF 6 The content is 2.03%, 4.20%, 5.77%, 7.74%, and the other components are the same, respectively 10% HF, 5% HCl, 2% H 2 SO 4 and 5% NH 4 HF 2 , take 20ml of waste liquid from A~D respectively, and add them to 50ml centrifuge tubes 1, 2, 3, and 4 in turn; add 1.15ml, 2.42ml, 3.36ml, 4.39.ml of NaCl saturated solution (solubility 36g) to each tube , so that NaCl and H 2 SiF 6 The molar stoichiometric ratio is 2; shake the centrifuge tube so that NaCl and H 2 SiF 6 Fully contact with the reaction, then let it stand for 30min, filter, and measure the H in the solution 2 SiF 6 content, calculate H 2 SiF 6 The removal rates were 46.62%, 78.99%, 81.92% and 86.82%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com