Separation and recovery method of sodium phosphate and sodium fluoride in mixed rare earth concentrate alkaline smelting process

A mixed rare earth, separation and recovery technology, applied in the field of separation and recovery of sodium phosphate and sodium fluoride in the rare earth smelting process, can solve the problems of high radioactivity, serious problems, increased costs, etc., and achieve the effect of high process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Roast the mixed rare earth concentrate with REO grade of 65.42%, the roasting temperature is 500°C, and the roasting time is 60 minutes.

[0020] (2) The roasted ore is leached with hydrochloric acid, the concentration of hydrochloric acid is 7mol / L, the consumption of hydrochloric acid: the quality of mixed rare earth concentrate: the quality of concentrated hydrochloric acid=1: 2.0, the leaching temperature is 95 ° C, and the time is 1.5 hours to obtain acid leaching residue and acid Dip. In the leaching process, thiourea is used as a reducing agent, and the added mass of thiourea is 0.055 times the mass of the mixed rare earth concentrate.

[0021] (3) Add sodium hydroxide solution to the acid leaching residue after hydrochloric acid leaching for alkali decomposition, the mass concentration of sodium hydroxide solution is 50%, the alkali decomposition temperature is 150° C., and the time is 1.5 hours.

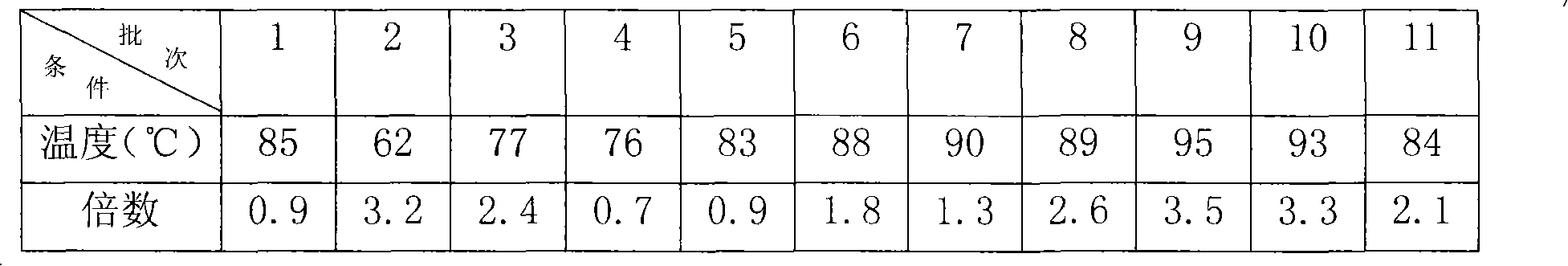

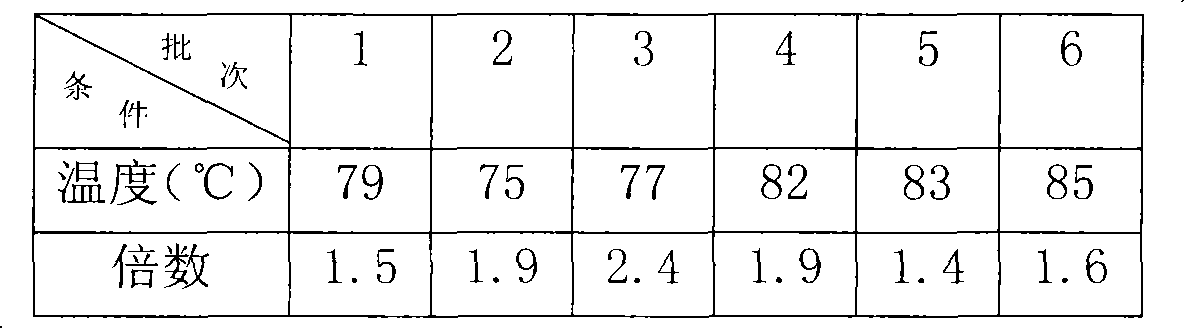

[0022] (4) Continuously repeat the above steps to make 7 ba...

Embodiment 2

[0029] (1) Roast the mixed rare earth concentrate with REO of 55.20%, the roasting temperature is 540°C, and the roasting time is 30 minutes.

[0030] (2) The roasted ore is leached with hydrochloric acid, the concentration of hydrochloric acid is 7mol / L, the amount of hydrochloric acid: the mass of mixed rare earth concentrate: the mass of concentrated hydrochloric acid=1:2.8, the leaching temperature is 75 ° C, and the time is 1 hour. In the leaching process, thiourea is used as a reducing agent, and the added mass of thiourea is 0.075 times the mass of the original ore.

[0031] (3) Add sodium hydroxide solution to the acid leaching residue after hydrochloric acid leaching for alkali decomposition, the mass concentration of sodium hydroxide solution is 75%, the alkali decomposition temperature is 200° C., and the time is 1.2 hours.

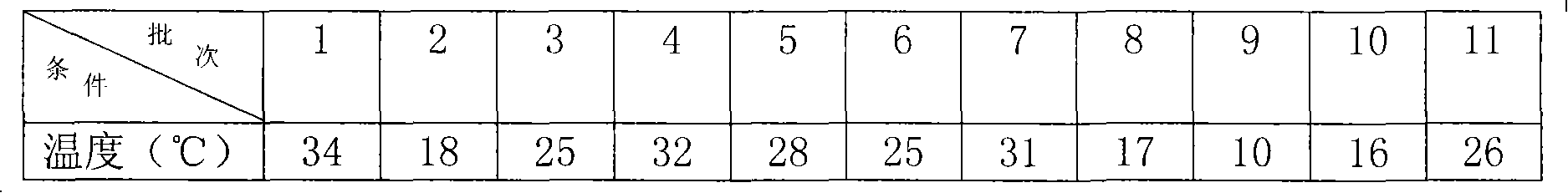

[0032] (4) Continuously repeating the above steps to make 9 batches of mixed rare earth concentrates to obtain 9 batches of alkali-decomposed ...

Embodiment 3

[0034] (1) Roast the mixed rare earth concentrate with REO of 67.75%, the roasting temperature is 480°C, and the roasting time is 90 minutes.

[0035] (2) The roasted ore is leached with hydrochloric acid, the concentration of hydrochloric acid is 10mol / L, the amount of hydrochloric acid: the mass of mixed rare earth concentrate: the mass of concentrated hydrochloric acid=1:2.2, the leaching temperature is 80°C, and the time is 2.5 hours. In the leaching process, thiourea is used as a reducing agent, and the added mass of thiourea is 0.095 times the mass of the original ore.

[0036] (3) Add sodium hydroxide solution to the acid leaching residue after hydrochloric acid leaching for alkali decomposition, the mass concentration of sodium hydroxide solution is 50%, the alkali decomposition temperature is 230° C., and the time is 0.5 hours.

[0037] (4) 11 batches of mixed rare earth concentrates were continuously repeated according to the above steps to obtain 11 batches of alkal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com