Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

A technology of fluorine compounds and silicon compounds, which is applied in the direction of alkali metal fluorides, silicates, aluminum fluoride, etc., can solve the problems of cumbersome process, waste liquid and waste residue recovery and treatment, and achieve high resource recovery rate and improve recovery The effect of high efficiency and advanced production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

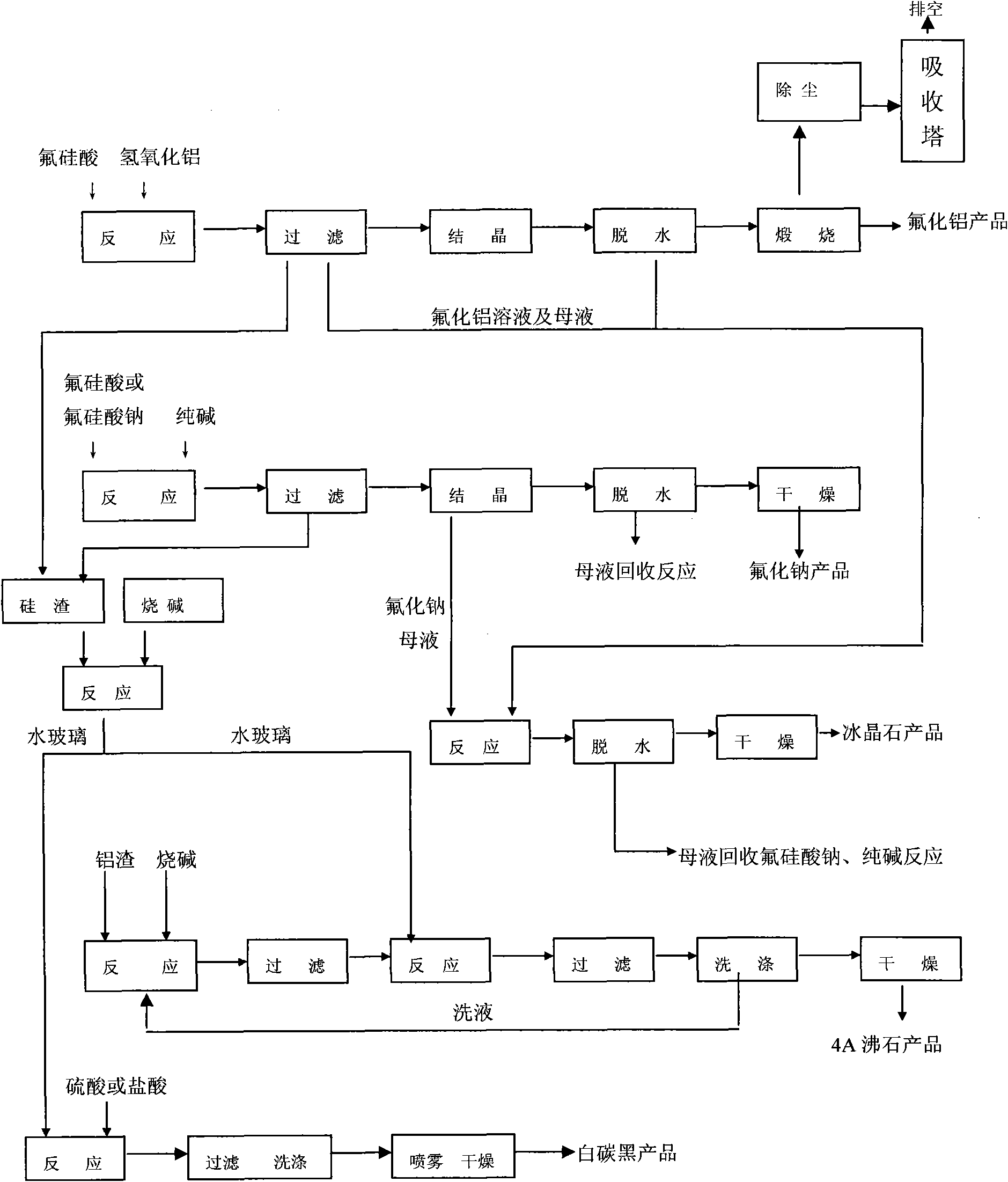

[0032] see figure 1 Shown, the concrete steps of processing method of the present invention are as follows:

[0033] (1) Preheat the fluosilicic acid (mass fraction: 18%) sent from the phosphate fertilizer plant to 55°C, then react with aluminum hydroxide for 20-30min, filter and remove the silicon slag after the reaction, and filter the filtrate Heating to 90°C, crystallization and centrifugal dehydration to obtain aluminum fluoride trihydrate, which is subjected to two-stage calcination, cyclone dust removal and bag dust removal to obtain anhydrous aluminum fluoride product, in which the waste gas is washed and emptied by water, and the waste liquid in the calcination section Recycle together with the mother liquor obtained by crystallization and filtration;

[0034] (2) React fluosilicic acid with the prepared soda ash solution, filter to remove silicon slag, divide the filtrate into two parts, one part is crystallized and centrifugally dehydrated, and the obtained sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com