Circular treatment apparatus for treating mercury-containing sludge

A technology for recycling and sludge treatment, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

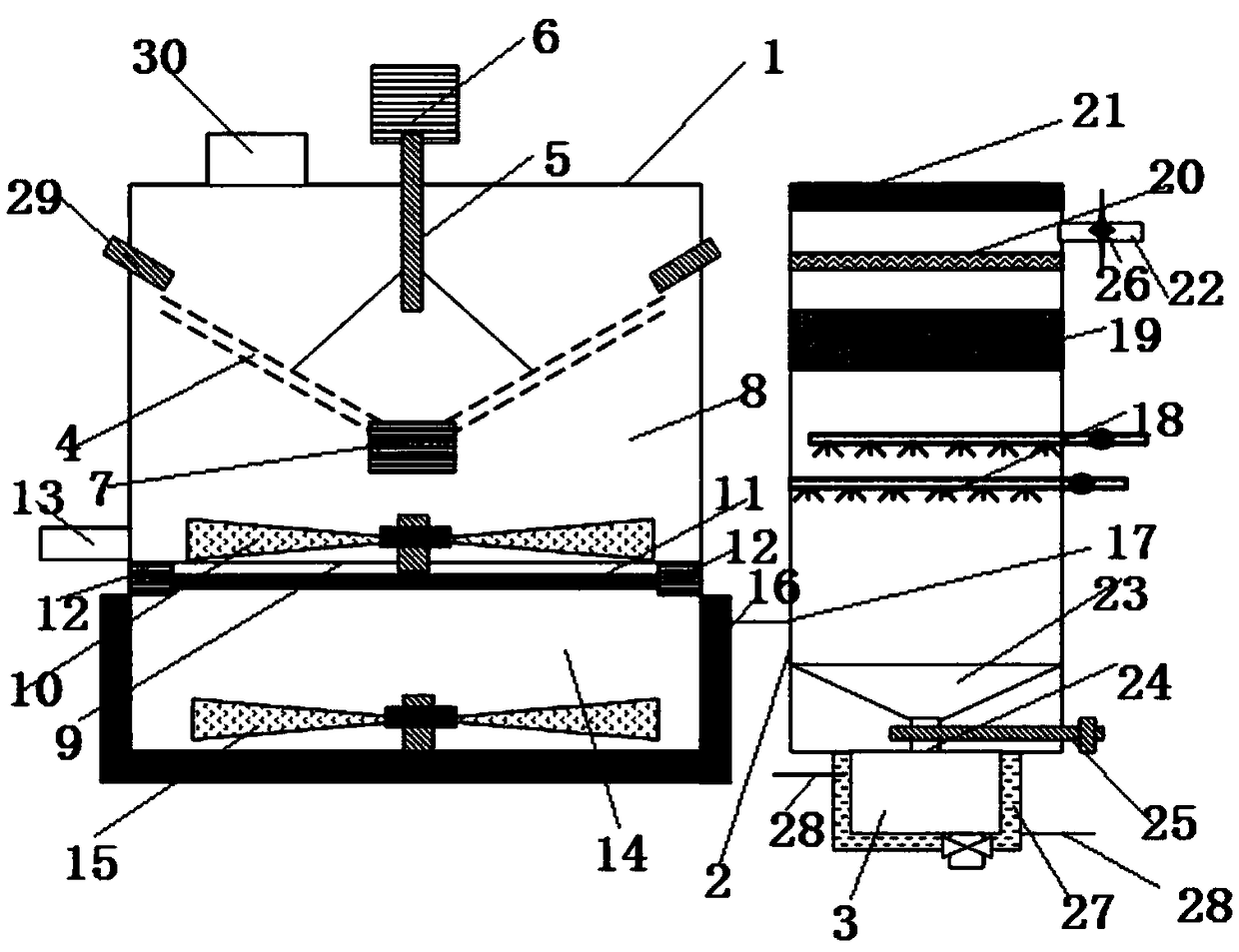

[0018] see figure 1 , a circulating treatment device for treating mercury-containing sludge, comprising a heat treatment room 1, a mercury recovery room 2 and a mercury storage room 3;

[0019] Described heat treatment chamber 1 comprises chamber body, and bowl-shaped strainer 4 is arranged in described chamber, and described bowl-shaped strainer 4 upper surface is fixed on the rotating shaft 5, and described rotating shaft 5 is connected with rotating motor 6, and described bowl Bowl-shaped filter screen bottom is provided with opening 7 with valve; Described bowl-shaped filter screen 4 below is transition area 8, and the bottom of described transition area 8 is provided with dividing plate 9, and the first stirring device 10 is fixed on described dividing plate 9, so A heating element 11 is provided at the bottom of the partition 9, and an outlet 12 with a valve is provided on the edge of the partition 9; a waste water outlet 13 is provided on the chamber side wall of the tr...

Embodiment 2

[0022] see figure 1 , as an improvement of the present invention, a gas detection device 26 is provided on the gas outlet 22 . It is used to detect whether there are harmful substances such as mercury in the exhaust gas.

Embodiment 3

[0024] see figure 1 , as an improvement of the present invention, the outer wall of the mercury storage chamber 3 is provided with an interlayer 27, the interlayer 27 is filled with a cooling medium, and the interlayer 27 communicates with a circulating water pipe 28. Avoid liquid mercury volatilization into gaseous state, resulting in leakage and pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com