Remanufacturing method for waste oil tubes

A remanufacturing and tubing technology, which is applied in the remanufacturing field of reproducing waste tubing, can solve problems such as tubing strength and pipe wall eccentric wear that have not been repaired, and achieve energy saving, resource recovery, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

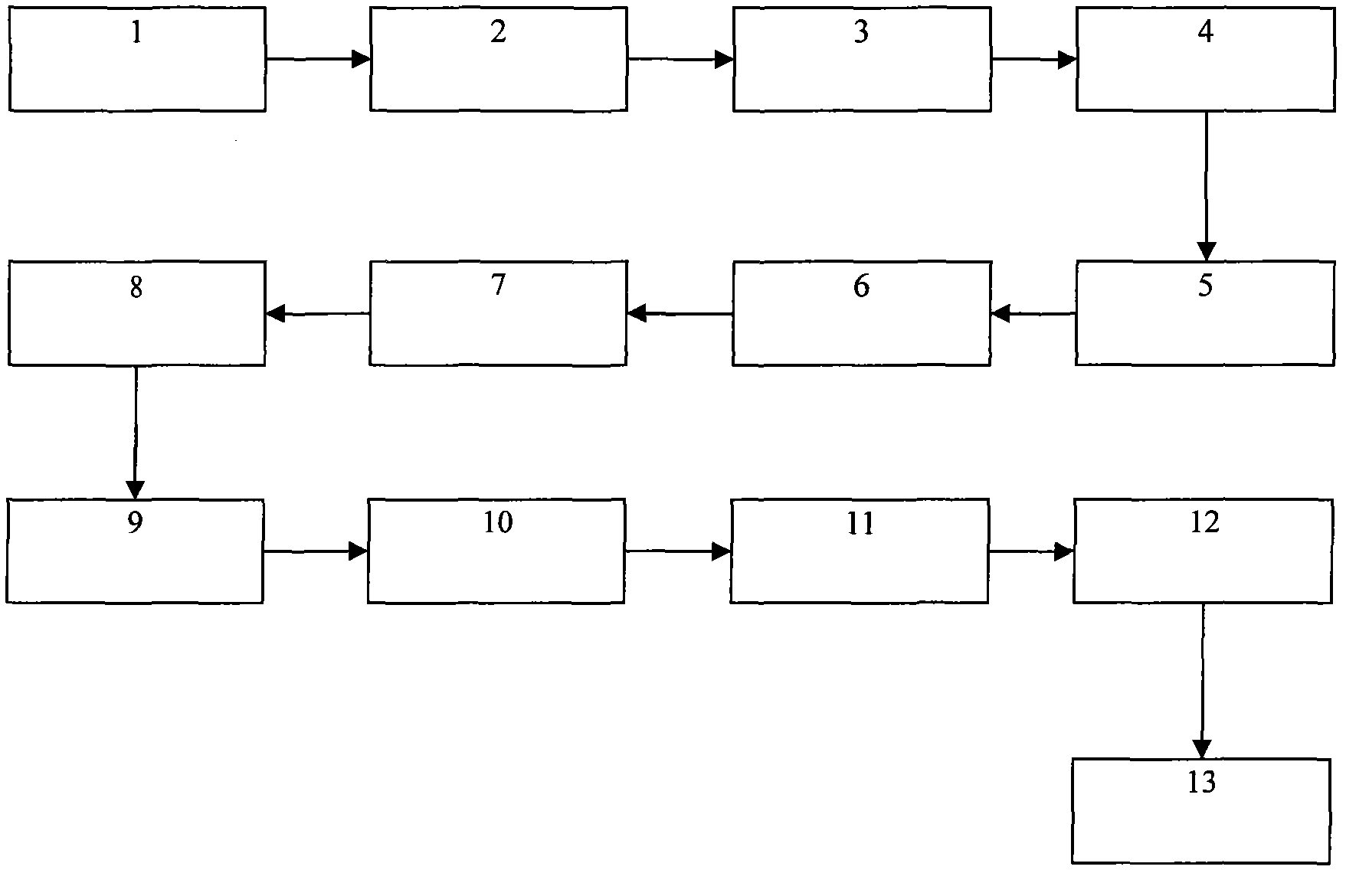

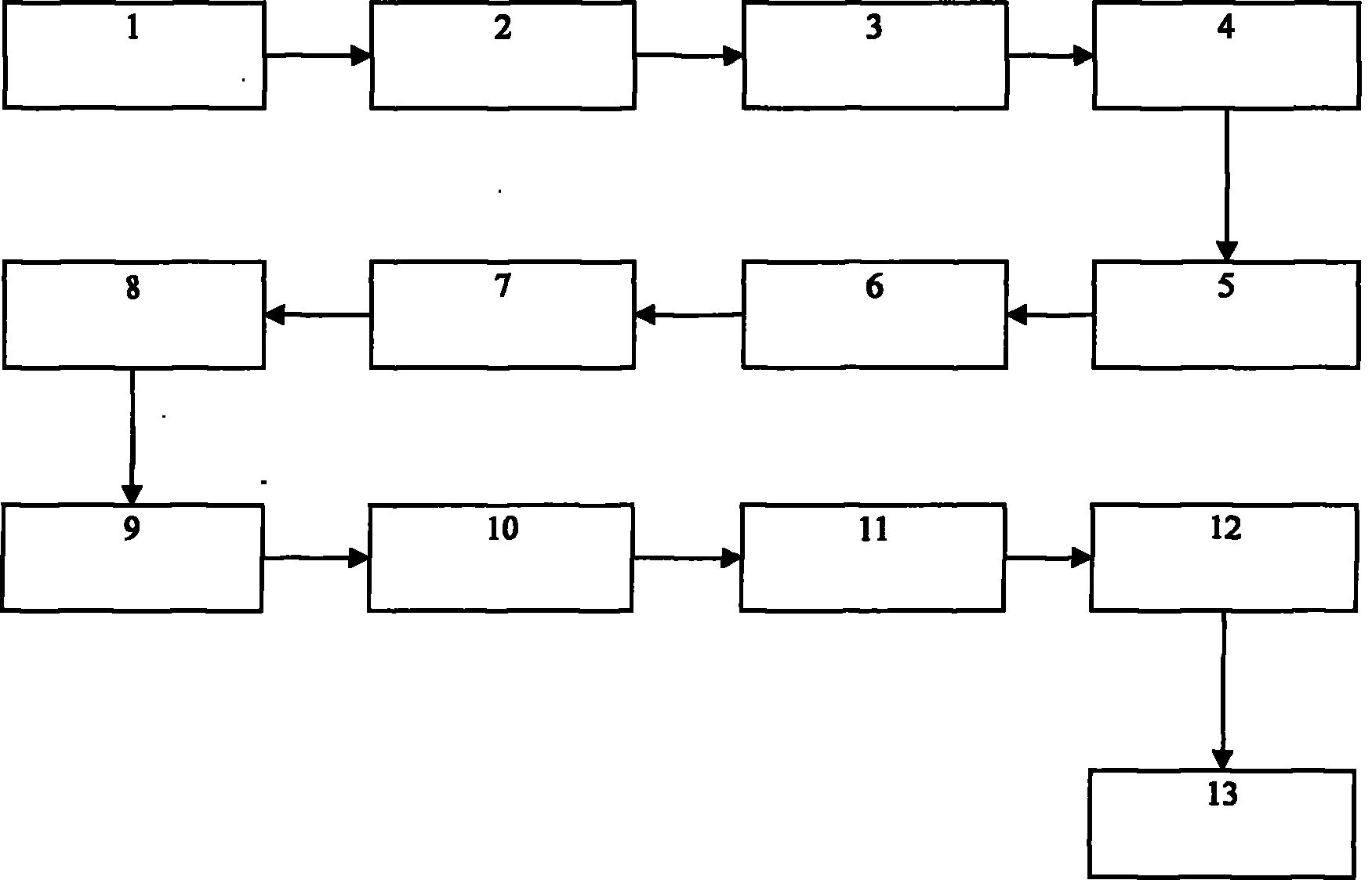

[0012] figure 1 Shown is the block diagram of the remanufacturing method flow of the waste oil pipe of the present invention.

[0013] According to an embodiment of the present invention, the remanufacturing method of waste oil pipe is:

[0014] (1) Cut off the upsetting parts at both ends of the scrap oil pipes that have lost their service ability, leaving only the middle part;

[0015] (2) Heating the tubing to remove the dirt, squeezing the heated tubing to repair pits on the surface of the tubing, and removing stress from the fatigued tubing to prepare for the next step of processing;

[0016] (3) Straighten the oil pipe to make it meet the standard requirements. The function of straightening is to prevent the oil pipe from being unable to be hot-rolled and restored in the subsequent process;

[0017] (4) Carry out hot rolling reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com