Flue gas treatment and resource recovery system

A technology for resource recovery and flue gas recovery, applied in the system field of flue gas treatment and resource recovery, can solve the problems of microbial cell toxicity, limit the efficiency of flue gas treatment and energy recovery, and fail to grow, so as to avoid toxic effects, Ensure efficient growth and avoid high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

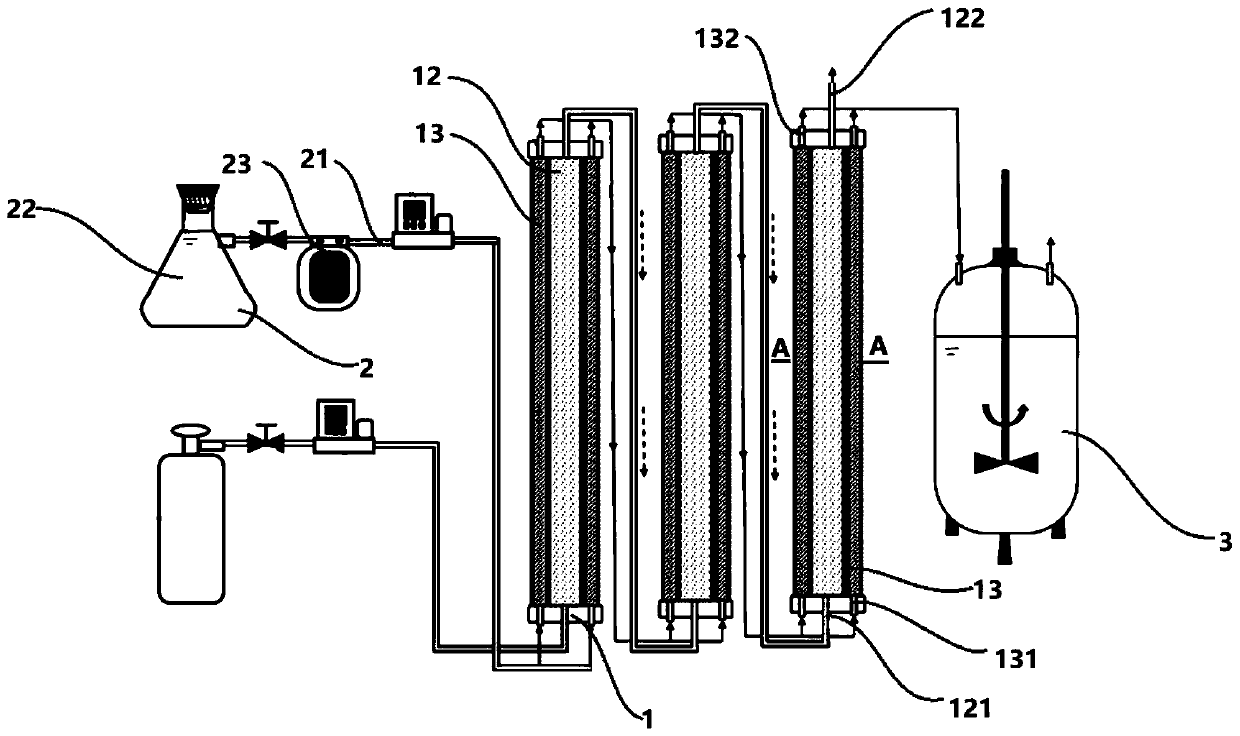

[0024] Example 1 The flue gas treatment and resource recovery system of the present invention treats industrial flue gas

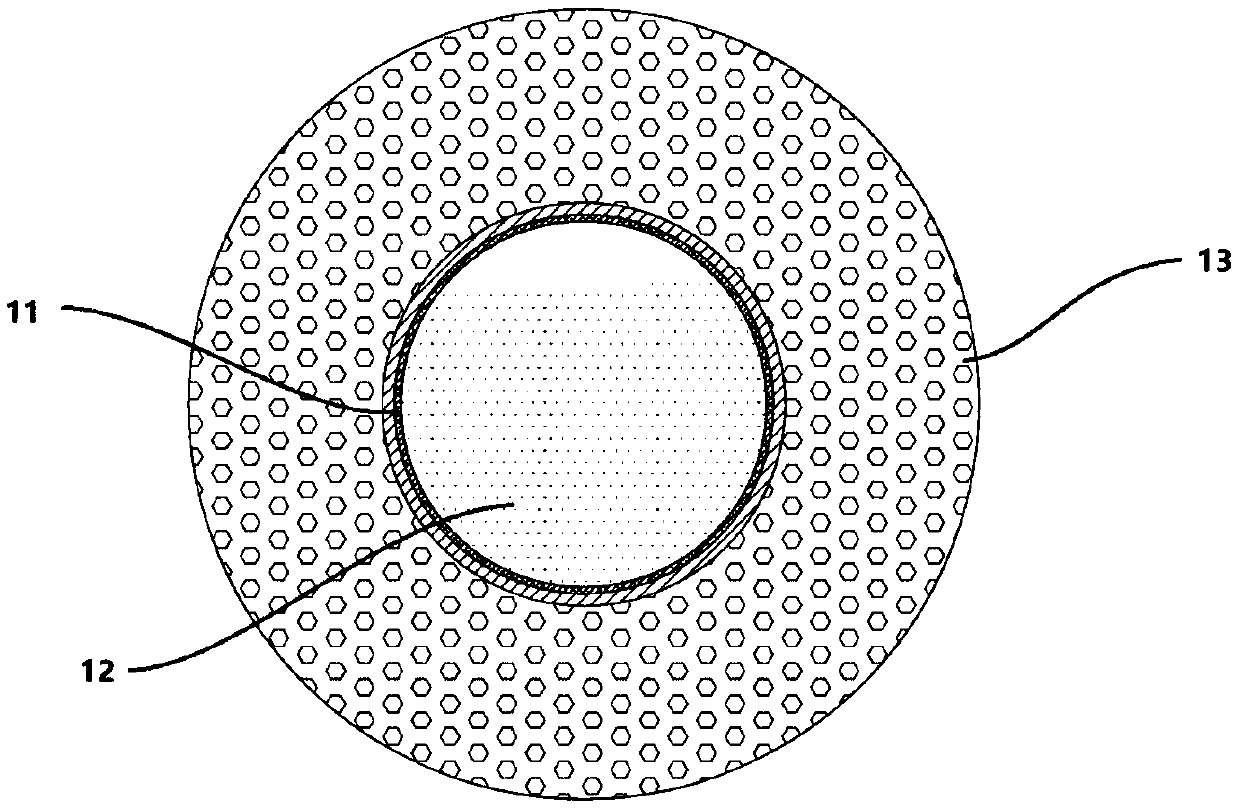

[0025] The first step: construction of a new system, which includes: microbial supply unit 2, 3 flue gas recovery units 1 and production unit 3 in series, see figure 2, the flue gas recovery unit 1 is a hollow tube with both ends sealed, the hollow tube is made of transparent material, an inner tube with the same length is arranged inside the hollow tube, the surface of the inner tube is hollowed out, and an anion exchange membrane 11 is adhered, The inner pipe is an alkaline absorption chamber, and what the inner pipe and the outer pipe form a chamber is a microbial absorption chamber 12; the bottom of the alkaline absorption chamber 12 is provided with a flue gas inlet 121, and the alkaline absorption chamber 12 The top of the microbial absorption chamber is provided with a flue gas outlet 122; the bottom 13 of the microorganism absorption chamber is pr...

Embodiment 2

[0029] Example 2 The flue gas treatment and resource recovery system of the present invention treats automobile exhaust

[0030] The first step: construction of a new system, which includes: microbial supply unit 2, 3 flue gas recovery units 1 and production unit 3 in series, see figure 2 , the flue gas recovery unit 1 is a hollow tube with both ends sealed, the hollow tube is made of transparent material, an inner tube with the same length is arranged inside the hollow tube, the surface of the inner tube is hollowed out, and an anion exchange membrane 11 is adhered, The inner pipe is an alkaline absorption chamber, and what the inner pipe and the outer pipe form a chamber is a microbial absorption chamber 12; the bottom of the alkaline absorption chamber 12 is provided with a flue gas inlet 121, and the alkaline absorption chamber 12 The top of the microbial absorption chamber is provided with a flue gas outlet 122; the bottom 13 of the microorganism absorption chamber is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com